Hot melt equipment, as the name suggests, is used for the application of hot melt adhesives on the operational surface. Hot melt adhesives (HMA) are thermoplastic adhesives, also known as hot glue. These adhesives are generally applied through hot melt glue guns or hot melt equipment.

To heat and melt the thermoplastic glue, the equipment uses a continuous heating option and when it is pushed with the mechanical trigger arrangement/gun or by pressure from hand, the glue is squeezed out of the heated nozzle, which is hot enough to burn skin. It is sticky when hot, and solidifies over a few seconds (up to one minute). Hot melt thermoplastic glue can also be applied by spraying or dipping.

In various industries, hot melt adhesives are preferred over solvent-based adhesives as they offer several advantages such as low or no organic content and the fact that drying or curing is not needed. Hot melt adhesives have an extended work life and can easily be disposed of without special precautions. However, using thermoplastic adhesives at higher temperatures can lead to the complete melting of the adhesives and therefore, the thermal load of the substrate is a limitation.

But this can be minimized to a greater extent by using a reactive adhesive that, after solidification, goes through further curing by moisture to form reactive urethanes and silicone, or which can also be cured by UV radiation. Some hot melt adhesives are not resistant to weathering and chemical attacks and they don't lose thickness during solidification, while solvent-based adhesives lose up to 60 – 70% thickness of the layer at the time of drying.

Hot Melt Equipment are extensively used in the packaging industry. They are an effective solution for high volume packaging applications in various industry such as food and beverage and paint and coating. Growth of the global packaging industry (especially in Asia Pacific) is anticipated to be a key factor driving the demand for hot melt equipment during the forecast period.

Rising development in pharmaceutical packaging, coupled with various regulations across the globe, is another factor adding to the growth of the hot melt equipment market. Furthermore, increasing adoption of electric hot melt equipment in growing industries such as electronic packaging is expected to fuel the demand for hot melt equipment and create significant growth opportunities for manufacturers in the mentioned market.

Hot melt adhesive technology is preferred by high-volume fiberboard packagers and high-speed paperboards. This can be attributed to the fact that it is comparatively quicker and more flexible than other adhesive technologies.

The cost of hot melt adhesives is calculated per pound, whereas the cost of tape is calculated on a per foot basis. Tape dispensers are generally mechanical devices, such as rollers, tension bars and cutting blades, whereas hot melt dispensers are electronic devices that consist of a valve, which is wired to a sensor and conveyer.

The global hot melt equipment market is segmented into the following regions – North America, Latin America, Europe, South East Asia-Pacific, China, Japan, India and the Middle East and Africa. China, India and Southeast Asia are dominant in the global hot melt equipment market and is one of the major hubs of manufacturing and an exporter.

The growth of the packaging industry I basically dependent on the growth of other industry. The growing demand for packaging from various industry from China, India, and ASEAN etc. will lead to the growth of global hot melt equipment market.

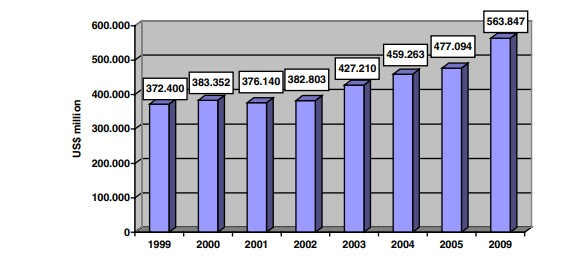

Global Packaging Market

Source – World packaging org

Some of the key players identified in the global hot melt equipment market are Nordson Corporation, Glenmar Technology, Ellsworth Adhesives India PTY Limited, SURE TACK SYSTEMS, Banseok Precision Industry Co., Ltd, Musashi Engineering, Inc., Shenzhen Tengsheng Industrial Equipment Co., Ltd., and Twin Engineers Private Limited.

Increasing opportunities in the packaging industry due to growth of end use industries such as food and beverage and electronics are expected to create demand for hot melt equipment manufacturers in the coming years. With the market being less concentrated, opportunities for market entrants are projected to be on the optimistic side with focus on regional/local markets by market participants.

The value chain is also anticipated to expand due to an influx of product suppliers and retailers catering to high sales volume demand from consumers earning attractive trade margins.

FMI will follow a modeling-based approach and triangulation methodology to estimate data covered in this report. A detailed market understanding and assessment of the nature, product type and end uses of the product segments covered in the study are followed by a demand-side analysis to estimate the sales of target product segments, which is then cross-referenced with a supply-side assessment of value generated over a pre-defined period. The statistics and data are collected at a regional level and consolidated and synthesized at a global level to estimate the overall market sizes.

Some of the key data points covered in our report include:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global hot melt equipment market can be segmented on the basis of mode of operation, end use and regions.

On the basis of portability, the global hot melt equipment market can be segmented as follows:

On the basis of application, the global hot melt equipment market can be segmented as follows:

On the basis of end use industry, the global hot melt equipment market can be segmented as follows:

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Hot Melt Intermediate Joint Market Size and Share Forecast Outlook 2025 to 2035

Hot Melt Adhesive Tapes Market Size and Share Forecast Outlook 2025 to 2035

Hot Melt Adhesives Market Growth - Trends & Forecast 2025 to 2035

Phototherapy Equipment Market Size and Share Forecast Outlook 2025 to 2035

Photorejuvenation Equipment Market Size and Share Forecast Outlook 2025 to 2035

Reactive Hot Melt Adhesive Market Forecast Outlook 2025 to 2035

Polyester Hot Melt Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Hot Air Sterilization Dust Mite Controller Market Size and Share Forecast Outlook 2025 to 2035

Hot and Cold System Market Forecast and Outlook 2025 to 2035

Hot Fill Packaging Market Size and Share Forecast Outlook 2025 to 2035

Melt Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Hot Stamping Foil Market Size and Share Forecast Outlook 2025 to 2035

Melt Flow Tester Market Size and Share Forecast Outlook 2025 to 2035

Hot And Cold Therapy Packs Market Size and Share Forecast Outlook 2025 to 2035

Hotplate Stirrers Market Size and Share Forecast Outlook 2025 to 2035

Hot Runner Temperature Controller Market Size and Share Forecast Outlook 2025 to 2035

Hot Fill Food Packaging Market Size and Share Forecast Outlook 2025 to 2035

Hot Rolled Or Cold Finished Alloy Steel Bars Market Size and Share Forecast Outlook 2025 to 2035

Melt-Blown Polypropylene Filters Market Size and Share Forecast Outlook 2025 to 2035

Equipment Management Software Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA