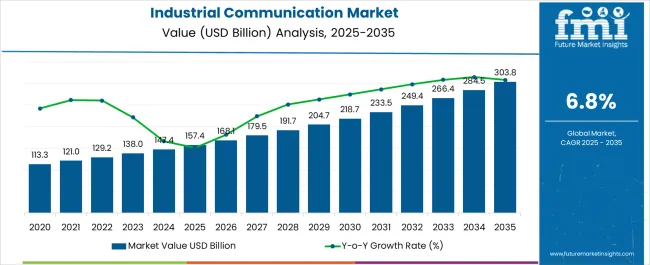

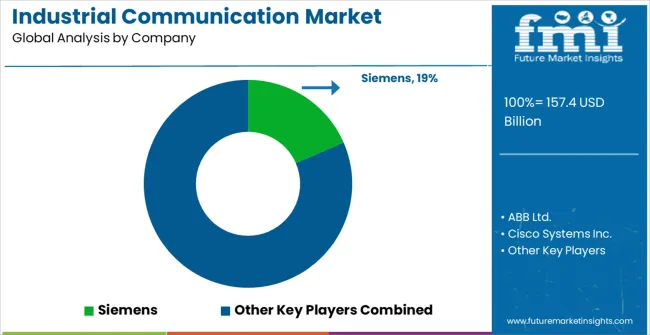

The Industrial Communication Market is estimated to be valued at USD 157.4 billion in 2025 and is projected to reach USD 303.8 billion by 2035, registering a compound annual growth rate (CAGR) of 6.8% over the forecast period.

| Metric | Value |

|---|---|

| Industrial Communication Market Estimated Value in (2025 E) | USD 157.4 billion |

| Industrial Communication Market Forecast Value in (2035 F) | USD 303.8 billion |

| Forecast CAGR (2025 to 2035) | 6.8% |

The Industrial Communication market is expanding steadily, driven by the rising need for seamless connectivity, automation, and real-time data exchange in industrial ecosystems. As industries transition toward smart manufacturing and Industry 4.0, the demand for reliable communication systems is intensifying across factories, energy grids, transportation, and logistics. Industrial communication technologies enable efficient monitoring, control, and optimization of processes, leading to higher productivity and reduced downtime.

The market is also benefiting from advancements in protocols, hardware integration, and software platforms that support interoperability and scalability. Edge computing, cloud integration, and IoT-based industrial frameworks are reinforcing demand for robust communication solutions that can handle high data volumes with minimal latency. Furthermore, cybersecurity considerations and regulatory compliance are pushing companies to invest in secure and standardized systems.

With industrial automation and digital transformation initiatives accelerating worldwide, the adoption of industrial communication solutions is expected to grow consistently Strong focus on predictive maintenance, remote monitoring, and operational efficiency will continue to shape the market landscape, ensuring long-term growth momentum across diverse applications.

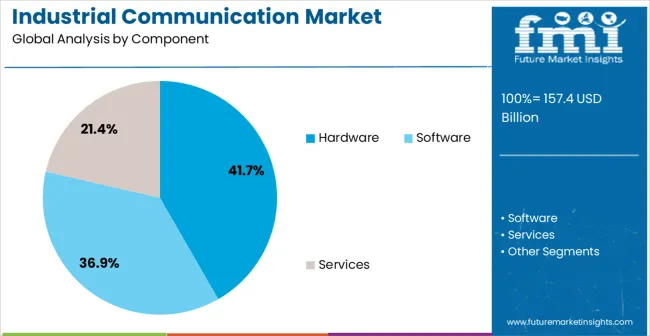

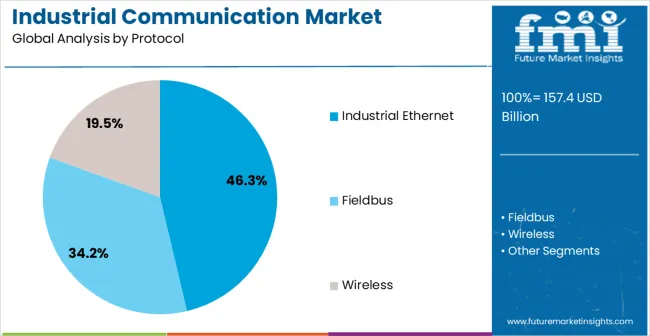

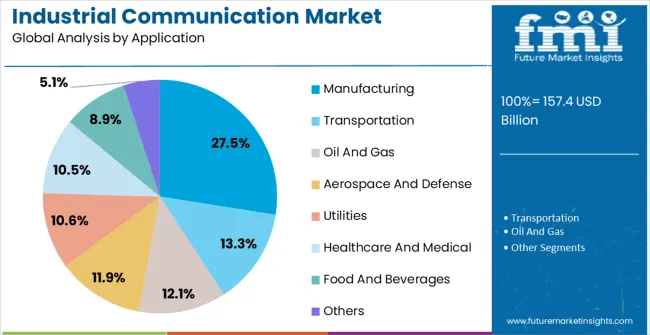

The industrial communication market is segmented by component, protocol, application, and geographic regions. By component, industrial communication market is divided into Hardware, Software, and Services. In terms of protocol, industrial communication market is classified into Industrial Ethernet, Fieldbus, and Wireless. Based on application, industrial communication market is segmented into Manufacturing, Transportation, Oil And Gas, Aerospace And Defense, Utilities, Healthcare And Medical, Food And Beverages, and Others. Regionally, the industrial communication industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The hardware component segment is projected to account for 41.7% of the Industrial Communication market revenue in 2025, making it the leading component type. Growth in this segment is being fueled by the demand for devices such as switches, routers, gateways, and controllers that form the backbone of industrial networks. These hardware systems ensure reliable data transmission and support integration with advanced protocols for seamless communication across industrial environments.

The durability, reliability, and scalability of hardware components are critical factors in industries where operational continuity is essential. Hardware infrastructure is being increasingly designed with modularity and compatibility in mind, allowing for smooth upgrades and integration with emerging technologies. The adoption of IoT and automation technologies is further reinforcing hardware demand, as connected devices require robust physical communication frameworks.

Companies are investing in high-performance hardware that supports both wired and wireless networks while ensuring minimal latency As industries continue to modernize their operations, hardware will remain a cornerstone of communication systems, supporting growth through reliability, adaptability, and technological enhancements.

The industrial ethernet protocol segment is anticipated to hold 46.3% of the Industrial Communication market revenue in 2025, establishing it as the dominant protocol. This leadership is supported by the growing reliance on high-speed, secure, and scalable communication systems in industrial environments. Industrial ethernet provides real-time connectivity, enabling automation systems to function with precision and efficiency.

It supports integration with enterprise IT systems, ensuring data flow across operational and business layers for enhanced decision-making. Compatibility with multiple hardware and software platforms has also driven widespread adoption. Industrial ethernet’s ability to handle complex processes, large data volumes, and time-sensitive applications makes it a preferred choice in manufacturing and energy industries.

Continuous improvements in standards and interoperability are enhancing its deployment in diverse sectors Furthermore, the rising adoption of smart factories, predictive maintenance, and remote monitoring is fueling demand for ethernet-based solutions Its scalability and cost-effectiveness ensure it remains a critical enabler of Industry 4.0, driving future growth and reinforcing its market dominance.

The manufacturing application segment is expected to contribute 27.5% of the Industrial Communication market revenue in 2025, positioning it as the leading application area. The segment’s strength is attributed to the increasing need for advanced communication systems to enable smart manufacturing processes. Industrial communication technologies in manufacturing environments support machine-to-machine communication, real-time monitoring, and process optimization, resulting in enhanced productivity and reduced downtime.

The adoption of automation, robotics, and IoT devices has reinforced the importance of reliable communication frameworks to ensure seamless data flow. Manufacturing companies are increasingly relying on industrial communication to implement predictive maintenance, improve quality control, and enhance operational efficiency. With global industries focusing on digital transformation and competitive productivity, communication technologies are becoming central to strategic growth.

The ability to integrate communication systems with enterprise resource planning and supply chain management is providing additional value to manufacturers As smart factories continue to expand, the manufacturing segment is set to remain a key contributor, reflecting the essential role of communication systems in modern industrial environments.

Various industry verticals have different requirements on connectivity solutions due to harsh environments in which they operate in. This leads companies to adopt different methods of industrial communication. In addition to traditional wired communications between devices, the industry is increasingly relying on wireless connections.

Industrial communication is the key to greater productivity for any company as it helps the enterprise in controlling machines and entire production line, monitor modern traffic systems and control power distribution.

High performance industrial communication technology can transfer large amounts of data in real-time and with minimum delay, operates in an energy efficient manner, utilizes more wireless technology, both within plant and remote connectivity and connects a large number of individual devices in a reliable manner with data security.

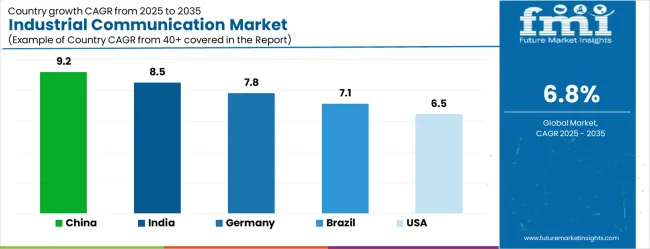

| Country | CAGR |

|---|---|

| China | 9.2% |

| India | 8.5% |

| Germany | 7.8% |

| Brazil | 7.1% |

| USA | 6.5% |

| UK | 5.8% |

| Japan | 5.1% |

The Industrial Communication Market is expected to register a CAGR of 6.8% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.2%, followed by India at 8.5%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.1%, yet still underscores a broadly positive trajectory for the global Industrial Communication Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.8%. The USA Industrial Communication Market is estimated to be valued at USD 59.0 billion in 2025 and is anticipated to reach a valuation of USD 59.0 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 7.5 billion and USD 4.3 billion respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 157.4 Billion |

| Component | Hardware, Software, and Services |

| Protocol | Industrial Ethernet, Fieldbus, and Wireless |

| Application | Manufacturing, Transportation, Oil And Gas, Aerospace And Defense, Utilities, Healthcare And Medical, Food And Beverages, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Siemens, ABB Ltd., Cisco Systems Inc., Rockwell Automation, Schneider Electric, Advantech Co. Ltd., and Omron Corporation |

The global industrial communication market is estimated to be valued at USD 157.4 billion in 2025.

The market size for the industrial communication market is projected to reach USD 303.8 billion by 2035.

The industrial communication market is expected to grow at a 6.8% CAGR between 2025 and 2035.

The key product types in industrial communication market are hardware, software and services.

In terms of protocol, industrial ethernet segment to command 46.3% share in the industrial communication market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Grade Electrochemical CO Sensor Market Size and Share Forecast Outlook 2025 to 2035

Industrial Bench Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Low Profile Floor Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Industrial Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA