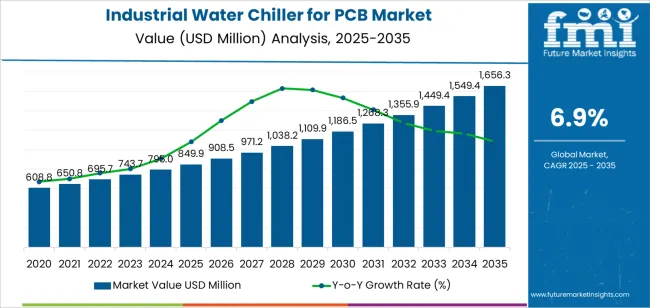

The global industrial water chiller for PCB market is projected to reach USD 1,656.2 million by 2035, recording an absolute increase of USD 806.4 million over the forecast period. The market is valued at USD 849.9 million in 2025 and is set to rise at a CAGR of 6.9% during the assessment period. The overall market size is expected to grow by nearly 1.9 times during the same period, supported by increasing demand for precision temperature control in PCB manufacturing processes, driving demand for advanced cooling solutions and increasing investments in semiconductor manufacturing infrastructure and electronic component production facilities globally. However, high energy consumption costs and maintenance complexity may pose challenges to market expansion.

The expansion trajectory reflects fundamental shifts in electronics manufacturing requirements, where thermal management has emerged as a critical factor determining production yield and component reliability in PCB fabrication operations. Manufacturing facilities face mounting pressure to implement precise temperature control systems that maintain optimal processing conditions across multiple production stages including etching, plating, drilling, and testing operations. Advanced industrial chillers deliver temperature stability within plus or minus 0.5 degrees Celsius, enabling manufacturers to achieve consistent quality standards while preventing thermal stress that damages sensitive electronic components and compromises circuit integrity during high-speed production cycles.

Regional market dynamics show pronounced variation, with developed markets emphasizing energy-efficient systems and automation integration while emerging economies prioritize manufacturing capacity expansion and production infrastructure development. PCB manufacturers and electronics assembly facilities represent the primary demand centers, where air-cooled and water-cooled chiller systems integrate with existing production equipment to standardize thermal management and process control protocols. The technology landscape encompasses various cooling configurations and capacity ranges, creating diverse product offerings tailored to specific production scales and thermal load requirements across semiconductor testing, metal processing, and laser plating applications.

Investment patterns indicate sustained commitment from electronics manufacturers and industrial facilities toward cooling equipment that supports quality assurance and operational efficiency objectives. Production managers pursue systems that minimize temperature fluctuations while optimizing energy consumption, driving adoption of sophisticated chiller platforms despite higher capital costs. The convergence of miniaturization trends, production speed requirements, and quality control standards establishes favorable conditions for market expansion through 2035, though implementation challenges related to installation costs and system complexity will require ongoing attention from manufacturers and facility operators to ensure reliable thermal management across diverse PCB production environments and manufacturing configurations.

Between 2025 and 2030, the industrial water chiller for PCB market is projected to expand from USD 849.9 million to USD 1,186.4 million, resulting in a value increase of USD 336.5 million, which represents 41.7% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for precision cooling systems in semiconductor facilities and PCB manufacturing plants, product innovation in energy-efficient compressor technologies and intelligent temperature control systems, as well as expanding integration with production automation platforms and real-time monitoring capabilities. Companies are establishing competitive positions through investment in advanced refrigeration technologies, IoT-enabled control systems, and strategic market expansion across metal processing, laser plating, semiconductor testing, and other electronics manufacturing applications.

From 2030 to 2035, the market is forecast to grow from USD 1,186.4 million to USD 1,656.2 million, adding another USD 469.8 million, which constitutes 58.3% of the overall ten-year expansion. This period is expected to be characterized by the expansion of specialized cooling systems, including advanced modular chiller configurations and integrated thermal management solutions tailored for specific PCB production requirements, strategic collaborations between chiller manufacturers and electronics equipment suppliers, and an enhanced focus on energy efficiency and environmental sustainability. The growing emphasis on production quality optimization and Industry 4.0 integration will drive demand for advanced, high-performance industrial water chiller solutions across diverse PCB manufacturing applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 849.9 million |

| Market Forecast Value (2035) | USD 1,656.2 million |

| Forecast CAGR (2025-2035) | 6.9% |

The industrial water chiller for PCB market grows by enabling electronics manufacturers to achieve precise temperature control and consistent production quality while preventing thermal damage to sensitive components. PCB fabrication facilities face mounting pressure to implement reliable cooling infrastructure that maintains optimal processing temperatures, with industrial chillers typically providing temperature stability within 0.5 degrees Celsius compared to 2-3 degrees variation in conventional systems, making precision cooling essential for high-density circuit production and advanced packaging operations. The miniaturization trend in electronics creates demand for sophisticated thermal management solutions that can handle increasing heat loads from multi-layer boards and high-power components across drilling, etching, and testing processes.

Government initiatives promoting electronics manufacturing development and sustainable production practices drive adoption in metal processing, laser plating, semiconductor testing, and other applications, where thermal control has a direct impact on yield rates and product reliability. The global expansion of consumer electronics and automotive electronics markets accelerates chiller demand as manufacturers seek equipment capable of supporting increased production volumes while maintaining stringent quality specifications. However, high initial capital costs and energy consumption requirements may limit adoption rates among smaller manufacturers and regions with elevated electricity prices.

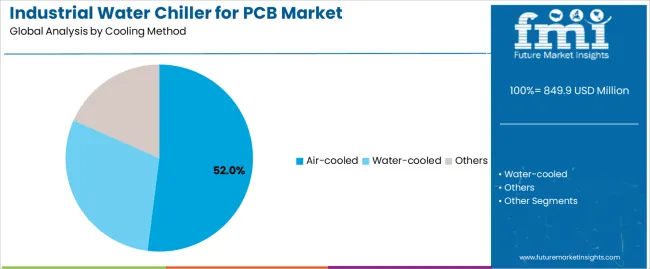

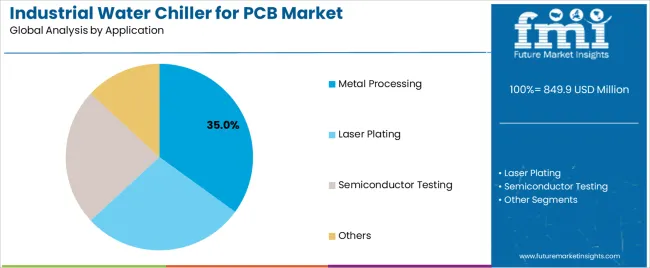

The market is segmented by cooling method, application, and region. By cooling method, the market is divided into air-cooled, water-cooled, and others. Based on application, the market is categorized into metal processing, laser plating, semiconductor testing, and others. Regionally, the market is divided into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa.

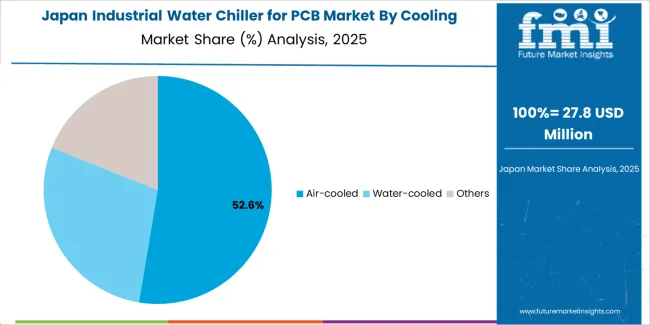

The air-cooled segment represents the dominant force in the industrial water chiller for PCB market, capturing approximately 52.0% of total market share in 2025. This category delivers comprehensive cooling capabilities with simplified installation requirements and reduced infrastructure dependencies. The air-cooled segment's market leadership stems from its widespread adoption in small to medium-scale manufacturing facilities, elimination of cooling tower requirements, and lower maintenance complexity compared to water-cooled alternatives.

The water-cooled segment maintains a substantial 38.0% market share, serving large-scale production facilities that require higher cooling capacities and superior energy efficiency through centralized heat rejection systems. The others segment accounts for 10.0% market share, featuring evaporative and hybrid cooling configurations suited for specialized environmental conditions.

Key advantages driving the air-cooled segment include:

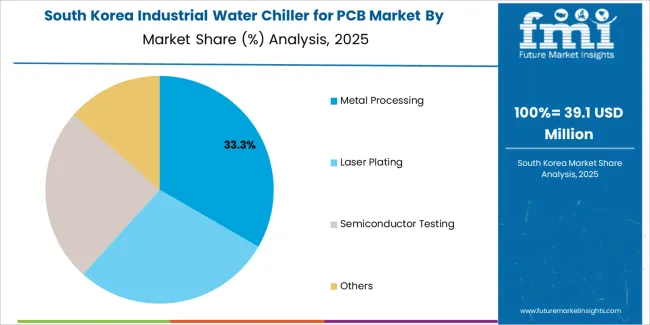

Metal processing applications dominate the industrial water chiller for PCB market with approximately 35.0% market share in 2025, reflecting the critical need for temperature control in electroplating, surface treatment, and metal deposition processes where thermal stability directly impacts coating uniformity and adhesion quality. The metal processing segment's market leadership is reinforced by widespread adoption across PCB electroplating lines, through-hole plating operations, and surface finishing systems, which require consistent temperature maintenance for chemical bath stability and plating thickness control.

The laser plating segment represents 28.0% market share through specialized laser direct structuring and additive manufacturing processes that demand precise thermal management during material deposition operations. The semiconductor testing segment accounts for 22.0% market share, featuring cooling requirements for automated test equipment and burn-in systems. The others segment holds 15.0% market share, encompassing drilling operations, lamination processes, and general manufacturing cooling applications.

Key market dynamics supporting application preferences include:

The market is driven by three concrete demand factors tied to manufacturing quality and production efficiency. First, electronics miniaturization trends create increasing requirements for precision thermal management, with advanced smartphones containing PCBs with component densities exceeding 300 parts per square centimeter according to industry data, requiring stable cooling systems to prevent thermal stress during fabrication processes that could compromise circuit functionality. Second, production speed intensification drives facilities toward automated cooling solutions, with modern PCB lines operating at speeds 40-60% faster than systems deployed five years ago while maintaining tighter temperature tolerances that demand responsive chiller systems with rapid load adjustment capabilities. Third, energy cost pressures incentivize adoption of efficient cooling technologies, with chillers consuming 15-25% of total facility energy in typical PCB manufacturing plants, creating strong economic motivation for high-efficiency equipment that reduces operational expenses through optimized refrigeration cycles and variable-speed compressor control.

Market restraints include substantial capital equipment investments affecting purchasing decisions and replacement cycles, particularly for large-capacity water-cooled systems where installations can exceed USD 100,000 per unit including auxiliary equipment, posing financial barriers for smaller manufacturers and contract assemblers operating on constrained capital budgets. Technical complexity regarding system sizing, refrigerant selection, and integration with existing production equipment creates additional challenges, as proper chiller specification requires detailed thermal load analysis and process understanding to prevent oversizing that wastes energy or undersizing that compromises temperature control during peak production periods.

Key trends indicate accelerated adoption in Asia-Pacific markets, particularly China and India, where electronics manufacturing expansion and semiconductor fab construction drive demand for industrial cooling equipment through government incentive programs and foreign direct investment in production capacity. Technology advancement trends toward inverter-driven compressors with continuous capacity modulation, intelligent control systems utilizing machine learning algorithms for predictive maintenance, and environmentally-friendly refrigerants meeting global phase-down schedules are enabling next-generation product development. The market could face disruption if alternative thermal management approaches, such as liquid immersion cooling or thermoelectric systems with comparable capacity and efficiency, achieve cost-competitiveness while offering simplified installation or superior temperature stability compared to current vapor-compression chiller platforms.

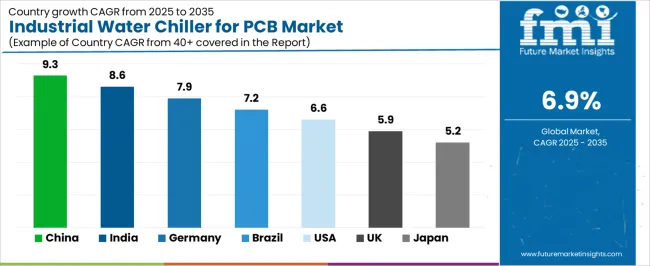

| Country | CAGR (2025-2035) |

|---|---|

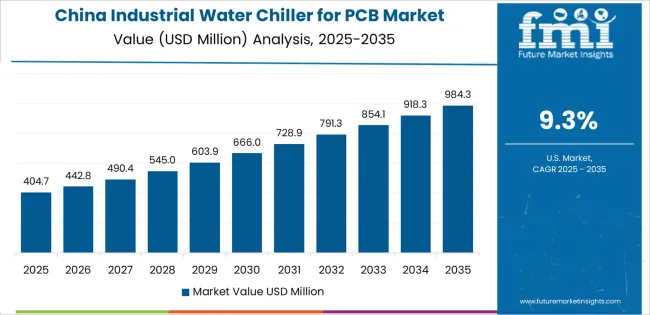

| China | 9.3% |

| India | 8.6% |

| Germany | 7.9% |

| Brazil | 7.2% |

| United States | 6.6% |

| United Kingdom | 5.9% |

| Japan | 5.2% |

The industrial water chiller for PCB market is gaining momentum worldwide, with China taking the lead thanks to aggressive electronics manufacturing expansion and semiconductor industry development programs. Close behind, India benefits from electronics production incentive schemes and growing PCB fabrication capacity, positioning itself as a strategic growth hub in the Asia-Pacific region. Germany shows strong advancement, where automotive electronics demand and Industry 4.0 initiatives strengthen its role in European manufacturing ecosystems.

Brazil demonstrates robust growth through consumer electronics assembly expansion and industrial equipment investments, signaling continued development in Latin American electronics markets. Meanwhile, the United States maintains steady progress through advanced semiconductor manufacturing and defense electronics requirements, while the United Kingdom and Japan continue to record consistent advancement driven by specialized electronics production and technology innovation programs. Together, China and India anchor the global expansion story, while established markets build stability and technological advancement into the market's growth path.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

China demonstrates the strongest growth potential in the Industrial Water Chiller for PCB Market with a CAGR of 9.3% through 2035. The country's leadership position stems from comprehensive electronics manufacturing infrastructure, intensive semiconductor fab construction programs, and aggressive PCB production capacity expansion driving adoption of advanced cooling systems. Growth is concentrated in major electronics manufacturing clusters, including Guangdong, Jiangsu, Zhejiang, and Shanghai, where PCB fabricators, semiconductor facilities, and electronics assembly operations are implementing precision chiller systems for quality control and process optimization.

Distribution channels through industrial equipment distributors, manufacturing equipment suppliers, and direct manufacturer relationships expand deployment across consumer electronics, automotive electronics, and telecommunications equipment production facilities. The country's Made in China 2025 strategy provides policy support for electronics manufacturing advancement, including investment in production automation and thermal management technologies.

Key market factors:

In major electronics manufacturing regions, emerging industrial zones, and government-designated manufacturing clusters, the adoption of industrial water chiller systems is accelerating across PCB fabrication facilities, electronics assembly plants, and semiconductor testing operations, driven by production localization initiatives and government manufacturing development programs. The market demonstrates strong growth momentum with a CAGR of 8.6% through 2035, linked to comprehensive electronics sector expansion and increasing focus on production infrastructure enhancement solutions.

Indian manufacturers are implementing precision cooling equipment and automated temperature control systems to improve production yields while meeting international quality standards for export markets including North America and Europe. The country's Production Linked Incentive scheme for electronics manufacturing creates sustained demand for industrial cooling infrastructure, while increasing emphasis on technological self-reliance drives adoption of advanced manufacturing support systems that enhance competitiveness.

Germany's advanced electronics manufacturing sector demonstrates sophisticated implementation of industrial water chiller systems, with documented integration showing 80-90% precision temperature control achievement in automotive electronics and industrial equipment production facilities through comprehensive thermal management platforms. The country's manufacturing infrastructure in major industrial centers, including Bavaria, Baden-Württemberg, North Rhine-Westphalia, and Hesse, showcases integration of high-efficiency cooling technologies with existing production systems, leveraging expertise in automotive electronics and industrial automation equipment manufacturing. German manufacturers emphasize energy efficiency and process reliability, creating demand for advanced chiller systems that support sustainability commitments and quality assurance protocols. The market maintains strong growth through focus on manufacturing excellence and environmental compliance, with a CAGR of 7.9% through 2035.

Key development areas:

The Brazilian market demonstrates growing implementation of industrial water chiller technologies based on electronics assembly expansion and industrial equipment production development for enhanced manufacturing capabilities. The country shows solid potential with a CAGR of 7.2% through 2035, driven by consumer electronics demand and increasing domestic production requirements across major manufacturing regions, including São Paulo, Santa Catarina, Amazonas, and Rio Grande do Sul. Brazilian manufacturers are adopting reliable cooling equipment for compliance with production quality requirements, particularly in free trade zone electronics assembly operations and in automotive electronics manufacturing facilities implementing advanced production standards. Technology deployment channels through industrial equipment distributors, production machinery suppliers, and integrated solution providers expand coverage across diverse manufacturing sectors.

Leading market segments:

The USA market demonstrates advanced implementation of industrial water chiller technologies based on semiconductor manufacturing reshoring and defense electronics production requirements for enhanced supply chain security. The country shows solid potential with a CAGR of 6.6% through 2035, driven by domestic semiconductor fab construction and increasing electronics manufacturing localization across major technology regions, including California, Texas, Arizona, and Oregon. American manufacturers are adopting high-performance cooling systems for compliance with military specifications, particularly in aerospace electronics production requiring stringent environmental controls and in advanced semiconductor fabs implementing next-generation process technologies. Technology deployment channels through specialized equipment distributors, semiconductor tooling suppliers, and direct manufacturer relationships expand coverage across high-reliability electronics segments.

Leading market segments:

The United Kingdom's industrial water chiller for PCB market demonstrates mature implementation focused on specialized electronics production and aerospace component manufacturing, with documented deployment across 70-80% of high-reliability electronics facilities through established equipment supply channels. The country maintains steady growth momentum with a CAGR of 5.9% through 2035, driven by aerospace electronics requirements and specialized industrial equipment manufacturing aligned with defense and medical electronics sectors. Major manufacturing regions, including Southeast England, West Midlands, Scotland, and Northwest areas, showcase consistent deployment of precision cooling systems that support high-reliability electronics production requiring stringent environmental controls and quality documentation.

Key market characteristics:

Japan's industrial water chiller for PCB market demonstrates sophisticated implementation focused on high-density PCB production and advanced semiconductor packaging applications, with documented integration achieving 85-95% temperature stability performance in precision electronics manufacturing through comprehensive process control systems. The country maintains steady growth momentum with a CAGR of 5.2% through 2035, driven by automotive electronics advancement and consumer electronics innovation aligned with miniaturization trends and quality excellence standards. Major manufacturing regions, including Aichi, Kanagawa, Osaka, and Kumamoto, showcase advanced deployment of precision chiller systems that integrate with existing cleanroom infrastructure and sophisticated environmental management protocols.

Key market characteristics:

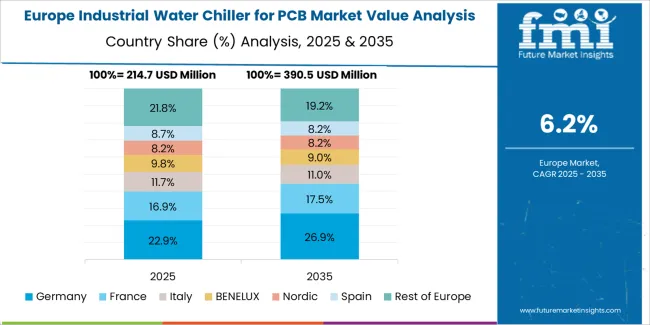

The industrial water chiller for PCB market in Europe is projected to grow from USD 297.0 million in 2025 to USD 544.9 million by 2035, registering a CAGR of 6.3% over the forecast period. Germany is expected to maintain its leadership position with a 29.5% market share in 2025, declining slightly to 28.8% by 2035, supported by its extensive automotive electronics infrastructure and major manufacturing centers, including Bavaria, Baden-Württemberg, and North Rhine-Westphalia production regions.

France follows with a 17.2% share in 2025, projected to reach 17.8% by 2035, driven by comprehensive aerospace electronics production and automotive component manufacturing expansion. The United Kingdom holds a 14.6% share in 2025, expected to decrease to 14.1% by 2035 due to specialized production focus. Italy commands a 12.3% share, while Spain accounts for 10.7% in 2025. The Netherlands maintains 6.4% in 2025, reaching 6.8% by 2035 on semiconductor equipment production. The Rest of Europe region is anticipated to hold 9.3% in 2025, expanding to 9.6% by 2035, attributed to increasing industrial chiller adoption in Nordic countries and emerging Central and Eastern European electronics manufacturing programs.

The Japanese industrial water chiller for PCB market demonstrates a mature and quality-focused landscape, characterized by sophisticated integration of air-cooled chiller systems and precision temperature control platforms with existing electronics manufacturing infrastructure across semiconductor facilities, automotive electronics plants, and specialty PCB fabricators. Japan's emphasis on production excellence and energy efficiency drives demand for reliable cooling equipment that supports miniaturization objectives and quality assurance commitments in high-density electronics manufacturing.

The market benefits from strong partnerships between international chiller manufacturers and domestic industrial equipment distributors, creating comprehensive service ecosystems that prioritize equipment reliability and technical support programs. Manufacturing centers in Aichi, Kanagawa, Osaka, and other major electronics production areas showcase advanced cooling implementations where chiller systems achieve 98% temperature accuracy through comprehensive monitoring management and precision control protocols.

The South Korean industrial water chiller for PCB market is characterized by growing international equipment provider presence, with companies maintaining significant positions through comprehensive installation support and technical services capabilities for semiconductor and electronics manufacturing applications. The market demonstrates increasing emphasis on production efficiency improvement and quality enhancement initiatives, as Korean facilities increasingly demand advanced cooling equipment that integrates with domestic manufacturing execution systems and sophisticated factory automation platforms deployed across major electronics complexes.

Regional equipment distributors are gaining market share through strategic partnerships with international manufacturers, offering specialized services including Korean regulatory compliance support and application engineering programs for electronics manufacturing operations. The competitive landscape shows increasing collaboration between multinational chiller companies and Korean industrial technology specialists, creating integrated service models that combine international engineering expertise with local manufacturing requirements and precision production systems.

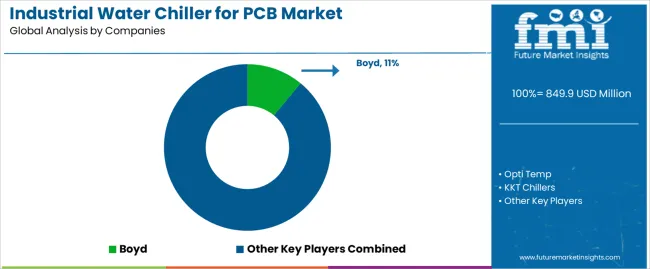

The industrial water chiller for PCB market features approximately 40-50 meaningful players with moderate fragmentation, where the top three companies control roughly 28-33% of global market share through established manufacturing relationships and comprehensive product portfolios. Competition centers on temperature control precision, energy efficiency performance, and after-sales technical support rather than price competition alone. Boyd leads with approximately 11.0% market share through its comprehensive thermal management solutions and electronics cooling portfolio.

Market leaders include Boyd, Opti Temp, and KKT Chillers, which maintain competitive advantages through global service networks, extensive application engineering expertise, and deep knowledge of electronics manufacturing requirements across multiple process stages, creating trust and reliability advantages with PCB fabrication operations. These companies leverage research and development capabilities in refrigeration system optimization and ongoing technical support relationships to defend market positions while expanding into specialized cooling applications and energy management solutions.

Challengers encompass Refrind and TEYU S&A Chiller, which compete through specialized chiller platforms and strong regional presence in key electronics manufacturing markets. Technology specialists, including Shenzhen Shilin Refrigeration Equipment, Changzhou Hongkang Refrigeration Equipment, and Beijing Jiuzhou Tongcheng, focus on specific cooling capacities or application segments, offering differentiated capabilities in custom system design, rapid delivery programs, and localized technical support.

Regional players and emerging cooling equipment manufacturers create competitive pressure through manufacturing cost advantages and rapid response capabilities, particularly in high-growth markets including China and India, where proximity to electronics manufacturing clusters provides advantages in installation timelines and service availability. Market dynamics favor companies that combine system reliability with comprehensive application support offerings that address the complete thermal management cycle from heat load analysis through system commissioning and preventive maintenance programs.

| Item | Value |

|---|---|

| Quantitative Units | USD 849.9 million |

| Cooling Method | Air-cooled, Water-cooled, Others |

| Application | Metal Processing, Laser Plating, Semiconductor Testing, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, USA, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Boyd, Opti Temp, KKT Chillers, Refrind, TEYU S&A Chiller, Shenzhen Shilin Refrigeration Equipment, Changzhou Hongkang Refrigeration Equipment, Beijing Jiuzhou Tongcheng, Shenzhen Kaideli, Suzhou OLT Refrigeration Equipment, Shenzhen Benson Intelligent Equipment, Shenzhen Keli Zhixin Technology, Dongguan Huaxiang Refrigeration Equipment, Suzhou Hemei Refrigeration Equipment, Guangdong Kedisheng Refrigeration Technology |

| Additional Attributes | Dollar sales by cooling method and application categories, regional adoption trends across Asia Pacific, Europe, and North America, competitive landscape with chiller manufacturers and distribution networks, equipment specifications and capacity requirements, integration with PCB manufacturing processes and production automation systems, innovations in refrigeration technology and energy efficiency systems, and development of specialized platforms with enhanced temperature control accuracy and operational reliability capabilities. |

The global industrial water chiller for pcb market is estimated to be valued at USD 849.9 million in 2025.

The market size for the industrial water chiller for pcb market is projected to reach USD 1,656.3 million by 2035.

The industrial water chiller for pcb market is expected to grow at a 6.9% CAGR between 2025 and 2035.

The key product types in industrial water chiller for pcb market are air-cooled, water-cooled and others.

In terms of application, metal processing segment to command 35.0% share in the industrial water chiller for pcb market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Industrial Furnace Industry Analysis in Europe Forecast and Outlook 2025 to 2035

Industrial Denox System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronic Pressure Switch Market Size and Share Forecast Outlook 2025 to 2035

Industrial WiFi Module Market Size and Share Forecast Outlook 2025 to 2035

Industrial Security System Market Forecast Outlook 2025 to 2035

Industrial Film Market Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA