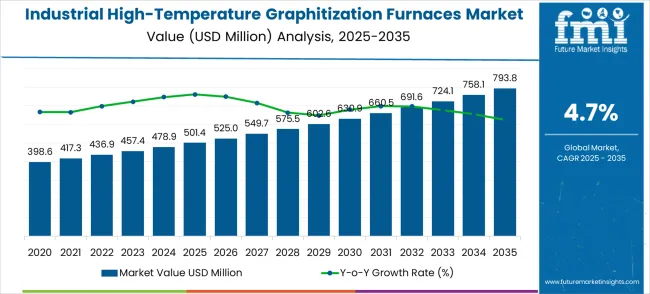

The industrial high-temperature graphitization furnaces market is projected to grow from USD 501.4 million in 2025 to USD 793.8 million by 2035, registering a 4.7% CAGR driven by rising adoption of high-performance graphite materials across batteries, aerospace, and advanced industrial processing. Growth is supported by increasing demand for ultra-high-temperature treatment systems capable of exceeding 2800°C, enabling the transformation of carbon precursor materials into high-purity graphite with superior electrical and thermal conductivity. As electric vehicle battery production accelerates and carbon fiber usage expands in lightweight automotive and aerospace components, demand for precision-controlled, energy-efficient graphitization furnaces continues to intensify.

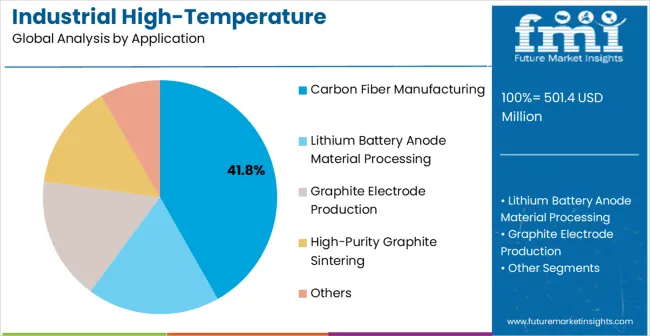

Continuous graphitization furnaces, commanding 58.6% of total demand, remain the dominant configuration due to their efficiency in high-volume manufacturing environments and ability to deliver consistent material quality with reduced cycle time. In application terms, carbon fiber manufacturing leads with 41.8% share, reflecting its dependence on stable high-temperature processing for fiber strength, structural reliability, and aerospace-grade performance standards. Lithium-ion battery anode manufacturing also forms a major growth pillar, where the purity and crystallinity achieved through graphitization directly influence charge capacity and cycle life.

The market faces challenges related to the high capital investment associated with graphitization furnace systems. These furnaces require advanced insulation materials, precision temperature controls, and significant energy consumption, which can constrain adoption among smaller manufacturers. Additionally, the requirement for skilled operators and strict compliance with safety protocols may add to operational complexity. However, the long operating life, low maintenance needs, and high throughput capabilities of modern furnaces offer strong returns on investment, driving adoption despite initial cost barriers.

Opportunities remain robust as manufacturers increasingly pursue energy-efficient and automation-enabled furnace technologies. Advancements such as intelligent temperature control systems, renewable-energy-powered furnace designs, and improved refractory materials are reducing energy consumption and operational costs. Growing demand for green graphite, recycling of graphite materials, and expansion of synthetic graphite production also present new avenues for furnace manufacturers.

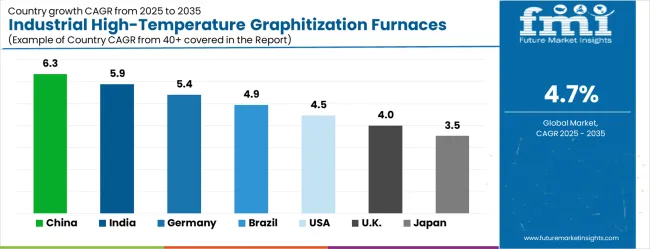

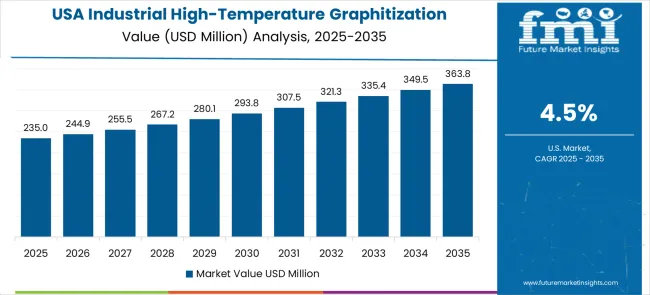

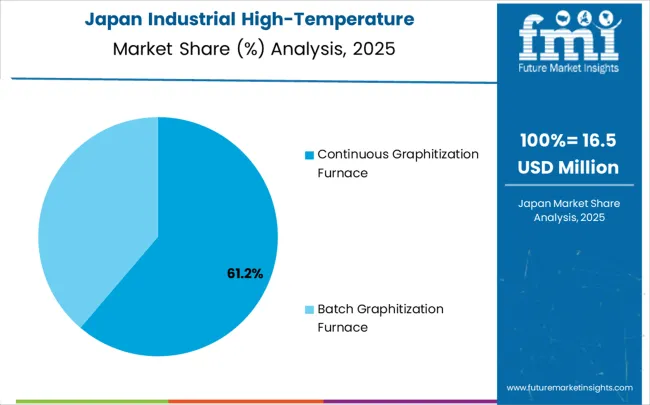

Regionally, China (6.3% CAGR) and India (5.9% CAGR) drive market expansion through rapid EV supply-chain scaling and significant investments in advanced materials infrastructure. Germany (5.4%) and Brazil (4.9%) follow with activity tied to industrial modernization and aerospace-automotive innovation. The United States (4.5%), the United Kingdom (4.0%), and Japan (3.5%) contribute steady replacement-cycle and technology-upgrade demand rather than new greenfield capacity. Competitive positioning is defined by high-temperature expertise, energy-management innovation, and integrated process-control capabilities, with Thermconcept, Carbolite Gero, HTM Reetz GmbH, ECM Technologies, and Nabertherm retaining advantage through engineering depth and established relationships with carbon materials processors.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 501.4 million |

| Market Forecast Value (2035) | USD 793.8 million |

| Forecast CAGR (2025 to 2035) | 4.7% |

Between 2025 and 2030, the Industrial High-Temperature Graphitization Furnaces Market is projected to expand from USD 501.4 million to USD 630.9 million, resulting in a value increase of USD 129.5 million, which represents 44.3% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for electric vehicle battery components, product innovation in energy-efficient furnace technologies and advanced temperature control systems, as well as expanding integration with automated manufacturing processes and quality control systems. Companies are establishing competitive positions through investment in advanced heating element technologies, energy recovery solutions, and strategic market expansion across carbon fiber, battery materials, and aerospace applications.

From 2030 to 2035, the market is forecast to grow from USD 630.9 million to USD 793.8 million, adding another USD 162.9 million, which constitutes 55.7% of the overall ten-year expansion. This period is expected to be characterized by the expansion of specialized furnace systems, including atmosphere-controlled processing solutions and integrated monitoring platforms tailored for specific graphitization applications, strategic collaborations between equipment providers and materials processing manufacturers, and an enhanced focus on energy efficiency and environmental sustainability in high-temperature processing.

The Industrial High-Temperature Graphitization Furnaces Market grows by enabling materials processing manufacturers to achieve precise graphitization temperatures and enhanced product quality in high-performance carbon material production. Manufacturing companies face mounting pressure to produce high-purity graphite materials with superior electrical and thermal conductivity properties, with graphitization furnaces typically achieving temperatures above 2800°C to transform carbon structures into high-quality graphite, making advanced furnace systems essential for competitive materials production.

The materials industry's need for consistent quality and process repeatability creates demand for advanced furnace solutions that can maintain precise temperature uniformity, control atmospheric conditions, and ensure reliable processing cycles without material contamination. Electric vehicle battery production requirements and aerospace industry growth drive adoption in lithium battery anode manufacturing, carbon fiber processing, and specialized graphite applications, where reliable high-temperature processing has a direct impact on material performance and end-product quality.

Government initiatives promoting electric mobility and advanced manufacturing drive adoption across battery materials, aerospace components, and industrial applications. However, high energy costs for continuous high-temperature operations and the complexity of maintaining furnace systems at extreme temperatures may limit adoption rates among smaller manufacturers and developing regions with limited industrial infrastructure investment capabilities.

The market is segmented by Furnace Type, Application, and region. By Furnace Type, the market is divided into Continuous Graphitization Furnace, Batch Graphitization Furnace, and Others. Based on the Application, the market is categorized into Carbon Fiber Manufacturing, Lithium Battery Anode Material Processing, Graphite Electrode Production, High-Purity Graphite Sintering, and Others. Regionally, the market is divided into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa.

Continuous Graphitization Furnace is projected to account for 58.6% share of the Industrial High-Temperature Graphitization Furnaces Market in 2025. This dominant position is supported by the technology's widespread application in high-volume production environments, battery material processing facilities, and industrial graphite manufacturing, where continuous processing capabilities provide cost-effective and efficient high-temperature treatment solutions. The segment enables stakeholders to benefit from continuous operation workflows, reduced batch changeover times, and enhanced production efficiency that supports high-volume manufacturing requirements.

The widespread adoption of continuous systems in battery materials processing and carbon fiber manufacturing across major industrial facilities worldwide drives consistent demand for these solutions, as manufacturers prioritize proven technologies that maximize throughput while providing reliable performance and consistent material quality.

Batch Graphitization Furnace systems represent 34.7% of the market share, primarily serving specialized processing applications and research facilities that require precise control over individual processing cycles. These systems are essential for high-purity graphite applications, experimental materials processing, and facilities where batch tracking and quality control for specific material lots are priorities. The segment benefits from applications requiring flexible processing parameters and customized atmospheric conditions for different material grades.

The Others category, accounting for 6.7% market share, includes specialized furnace solutions designed for specific applications such as vacuum graphitization systems and experimental high-temperature processing technologies.

Key advantages include:

Carbon Fiber Manufacturing applications are expected to represent 41.8% share of Industrial High-Temperature Graphitization Furnaces applications in 2025. This leading position reflects the critical role of graphitization furnaces in carbon fiber production processes, aerospace materials manufacturing, and automotive lightweight components, where high-temperature processing is essential for achieving superior mechanical properties and structural performance. The segment provides critical support for carbon fiber processing in high-performance applications where consistent material properties directly impact end-product reliability and performance specifications.

Growth drivers include aerospace industry expansion, increasing demand for lightweight automotive components, renewable energy infrastructure development requiring advanced composite materials, and the need for high-strength carbon fiber solutions that support performance and weight reduction goals.

Lithium Battery Anode Material Processing applications account for 28.4% of the market share, serving electric vehicle battery manufacturing, energy storage systems, and portable electronics applications that require high-performance graphite anodes with specific electrical conductivity and structural properties. Graphite Electrode Production applications represent 16.2% market share, primarily focused on steel production, electric arc furnace applications, and industrial processes requiring high-conductivity graphite electrodes.

High-Purity Graphite Sintering applications contribute 9.3% market share, supporting semiconductor manufacturing, nuclear applications, and specialized industrial processes requiring ultra-high purity graphite materials. The Others category, representing 4.3% market share, includes specialized applications such as research and development materials processing and experimental high-temperature applications.

Key market dynamics include:

The market is driven by three concrete demand factors tied to advanced materials manufacturing outcomes. First, electric vehicle market expansion creates increasing demand for high-quality battery anode materials, with lithium battery production growing by 25-30% annually in major manufacturing regions worldwide, requiring comprehensive graphitization furnace infrastructure. Second, aerospace and defense industry growth drives mandatory adoption of high-performance carbon fiber materials, with many aerospace manufacturers setting targets for 40-50% weight reduction through advanced composite material integration by 2030.

Third, technological advancements in furnace design and energy management enable more efficient and reliable processing solutions that reduce operational costs while improving material quality standards and production consistency. The growing emphasis on sustainable manufacturing creates additional demand for energy-efficient furnace systems that integrate with renewable energy sources and provide optimized energy consumption for high-temperature processing applications.

Market restraints include high capital investment requirements that can deter smaller materials processing companies from acquiring advanced furnace systems, particularly in developing regions where funding for high-temperature processing equipment remains limited. Energy consumption costs pose another significant challenge, as maintaining temperatures above 2800°C requires substantial electrical power, potentially causing operational cost increases and limiting profitability for energy-intensive processing operations.

Technical complexity requirements across different materials applications create additional challenges for operators, demanding specialized expertise and training programs for safe high-temperature operation and maintenance procedures. The complexity of integrating advanced furnace systems with existing production workflows presents operational challenges that may result in extended commissioning periods and higher integration costs than initially projected.

Key trends indicate accelerated adoption in Asia-Pacific markets, particularly China and India, where rapid electric vehicle manufacturing growth and industrial materials processing expansion drive comprehensive furnace system deployment. Design shifts toward energy-efficient furnace solutions with heat recovery systems, advanced insulation technologies, and integrated process monitoring enable reduced operational costs and environmental impact while maintaining processing quality standards.

The increasing focus on automation and artificial intelligence integration drives demand for advanced furnace solutions that can optimize processing parameters automatically and provide predictive maintenance capabilities across manufacturing networks. However, the market thesis could face disruption if alternative materials processing technologies or significant changes in carbon materials manufacturing standards minimize reliance on traditional high-temperature graphitization processes.

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.3% |

| India | 5.9% |

| Germany | 5.4% |

| Brazil | 4.9% |

| USA | 4.5% |

| UK | 4.0% |

| Japan | 3.5% |

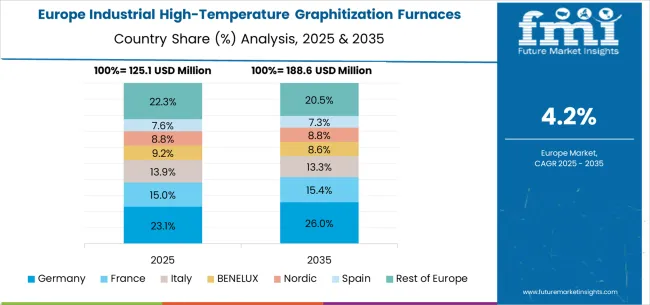

The industrial high-temperature graphitization furnaces market is accelerating worldwide, with China leading at a CAGR of 6.3%, driven by massive electric vehicle manufacturing expansion and government-backed advanced materials development investments. Close behind, India, growing at 5.9% CAGR, is propelled by industrial modernization and electric vehicle manufacturing initiatives, positioning it as a strategic Asia-Pacific manufacturing hub. Germany advances steadily with a 5.4% CAGR, supported by integration of advanced materials processing technologies within Europe's automotive and aerospace infrastructure.

Brazil, expanding at 4.9% CAGR, emphasizes industrial modernization and materials processing development. The U.S. records 4.5% CAGR, reflecting strong adoption of advanced manufacturing technologies, while the U.K. (4.0% CAGR) and Japan (3.5% CAGR) sustain consistent industrial technology modernization. Together, China and India anchor global growth momentum, while others contribute stability and technological innovation leadership.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

China demonstrates the strongest growth potential in the industrial high-temperature graphitization furnaces market with a CAGR of 6.3% through 2035. The country's leadership position stems from massive electric vehicle manufacturing expansion, government-backed advanced materials development programs, and comprehensive battery supply chain development driving the adoption of high-temperature processing systems.

Growth is concentrated in major industrial regions, including Guangdong, Jiangsu, Zhejiang, and Shandong provinces, where battery manufacturers and carbon materials processors are implementing advanced furnace solutions for enhanced production efficiency and material quality. Distribution channels through state-approved industrial equipment suppliers and manufacturing technology programs expand deployment across lithium battery manufacturing facilities and carbon materials processing plants.

The country's "Made in China 2025" strategy provides policy support for advanced manufacturing initiatives, including high-temperature processing technology adoption and materials processing capabilities development.

Key market factors:

In Mumbai, Chennai, Bangalore, and Pune, adoption of industrial high-temperature graphitization furnace systems is accelerating across materials processing facilities and battery manufacturing plants, driven by rapid industrial modernization and government electric vehicle manufacturing initiatives. The market demonstrates strong growth momentum with a CAGR of 5.9% through 2035, linked to comprehensive manufacturing infrastructure development and increasing focus on advanced materials processing capabilities.

Indian manufacturers are implementing advanced furnace systems and process control platforms to enhance production efficiency while meeting growing demand for high-quality graphite materials in expanding electric vehicle and industrial applications. The country's National Electric Mobility Mission creates sustained demand for battery materials processing solutions, while increasing emphasis on manufacturing self-reliance drives adoption of advanced processing equipment.

Advanced manufacturing sector in Germany demonstrates sophisticated implementation of industrial high-temperature graphitization furnace systems, with documented case studies showing significant improvements in materials processing efficiency and product quality through precision temperature control platforms. The country's industrial infrastructure in major regions, including North Rhine-Westphalia, Bavaria, and Baden-Württemberg, showcases integration of advanced furnace technologies with existing materials processing systems, leveraging expertise in precision engineering and automation technologies.

German manufacturers emphasize engineering excellence and quality standards, creating demand for high-performance furnace solutions that support continuous improvement initiatives and advanced materials development requirements. The market maintains steady growth through focus on Industry 4.0 integration and sustainability compliance, with a CAGR of 5.4% through 2035.

Key development areas:

Market in Brazil expansion is driven by diverse industrial manufacturing demand, including materials processing facilities in São Paulo and Rio de Janeiro, automotive component manufacturing in major industrial centers, and comprehensive manufacturing modernization across multiple states. The country demonstrates promising growth potential with a CAGR of 4.9% through 2035, supported by federal government industrial development programs and state-level manufacturing infrastructure investment initiatives.

Brazilian manufacturers face implementation challenges related to capital investment constraints and technical expertise availability, requiring phased deployment approaches and financing support from international development institutions. However, growing automotive industry requirements and industrial modernization demands create compelling business cases for furnace adoption, particularly in metropolitan industrial areas where manufacturing efficiency has a direct impact on competitiveness.

Market characteristics:

The U.S. market leads in advanced furnace system innovation based on integration with automated manufacturing systems and artificial intelligence technologies for enhanced process optimization. The country shows strong potential with a CAGR of 4.5% through 2035, driven by the modernization of existing materials processing infrastructure and the expansion of electric vehicle battery manufacturing in major industrial regions.

American manufacturers are adopting intelligent furnace systems for operational efficiency improvement and quality consistency, particularly in regions with established aerospace and automotive industries requiring advanced materials processing capabilities. Technology deployment channels through established industrial equipment distributors and direct manufacturer relationships expand coverage across materials processing facilities and manufacturing operations.

Leading market segments:

In Birmingham, Manchester, Sheffield, and Glasgow, materials processing facilities are implementing industrial high-temperature graphitization furnace solutions to modernize aging processing infrastructure and improve operational efficiency, with documented case studies showing significant improvements in materials quality and production consistency. The market shows moderate growth potential with a CAGR of 4.0% through 2035, linked to the ongoing modernization of aerospace manufacturing facilities and automotive component production networks.

British manufacturers are adopting advanced furnace and monitoring platforms to enhance system reliability while maintaining quality standards demanded by aerospace and automotive industry requirements. The country's established materials processing infrastructure creates sustained demand for replacement and upgrade solutions that integrate with existing manufacturing systems.

Market development factors:

Industrial High-Temperature Graphitization Furnaces Market in Japan demonstrates sophisticated implementation focused on precision engineering and operational excellence optimization, with documented integration of advanced processing systems achieving significant improvements in materials quality and production efficiency across manufacturing and materials processing networks.

The country maintains steady growth momentum with a CAGR of 3.5% through 2035, driven by manufacturing facilities' emphasis on quality standards and continuous improvement methodologies that align with lean manufacturing principles applied to materials processing operations. Major industrial regions, including Kanto, Kansai, and Chubu areas, showcase advanced deployment of intelligent furnace platforms where processing systems integrate seamlessly with existing automation systems and comprehensive quality management programs.

Key market characteristics:

The industrial high-temperature graphitization furnaces market consists of 14–18 specialized manufacturers, with the top five companies controlling 55–60% of global market share. Growth is driven by rising demand for synthetic graphite, Li-ion battery anode materials, carbon–carbon composites, nuclear-grade graphite, semiconductor components, and high-purity industrial carbon. Competition centers on maximum temperature capability (2500–3000°C+), atmosphere control, thermal uniformity, graphite insulation quality, energy efficiency, and long-duration operational stability, rather than price. Thermconcept leads the market with an 17.5% share, supported by its strong engineering expertise in custom graphitization systems designed for continuous and batch operations in advanced materials manufacturing.

Other major players such as Carbolite Gero, HTM Reetz GmbH, ECM Technologies, and Nabertherm GmbH maintain strong competitive positions through high-precision vacuum and inert-gas furnace technologies, robust graphite-element heating systems, and integration with automation, thermal-profiling software, and contamination-control modules. Their equipment is widely used in battery precursor graphitization, aerospace carbon composites, and semiconductor-grade purification processes.

Challengers including Plansee SE, SCHMETZ Vacuum Furnaces, Shimadzu Corporation, and Materials Research Furnaces specialize in ultra-high-temperature systems for research labs, nuclear materials, and aerospace applications where extreme purity and temperature repeatability are essential.

Additional players such as T-M Vacuum Products Inc., Graphite Furnace Systems Inc., Thermcraft Inc., ALD Vacuum Technologies, Tectra GmbH, and Linn High Therm GmbH strengthen global competition by offering modular, customizable, and cost-competitive graphitization platforms with strong regional support—particularly across Asia and Europe, where lithium-ion battery and advanced carbon materials production is expanding rapidly.

The industrial high-temperature graphitization furnaces market is central to advanced materials manufacturing, electric vehicle battery production, and aerospace component development systems. With energy efficiency concerns, manufacturing cost pressures, and rising demand for high-performance materials, the sector faces pressure to balance processing efficiency, energy consumption, and environmental impact. Coordinated action from governments, industry associations, equipment manufacturers, suppliers, and investors is essential to transition toward energy-efficient, environmentally sustainable, and technologically advanced graphitization furnace systems.

| Item | Value |

|---|---|

| Market Value (2025) | USD 501.4 million |

| Furnace Type | Continuous Graphitization Furnace, Batch Graphitization Furnace, Others |

| Application | Carbon Fiber Manufacturing, Lithium Battery Anode Material Processing, Graphite Electrode Production, High-Purity Graphite Sintering, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, U.S., U.K., Japan, and 25+ additional countries |

| Key Companies Profiled | Thermconcept, Carbolite Gero, HTM Reetz GmbH, ECM Technologies, Nabertherm GmbH, Plansee SE, SCHMETZ Vacuum Furnaces, Shimadzu Corporation, Materials Research Furnaces, T-M Vacuum Products Inc., Graphite Furnace Systems Inc., Thermcraft Inc., ALD Vacuum Technologies, Tectra GmbH, and Linn High Therm GmbH |

| Additional Attributes | Market share analysis by furnace type and application segments, country-wise CAGR projections across Asia Pacific, Europe, and North America, competitive landscape with industrial equipment manufacturers and materials processing technology providers, technology adoption patterns for battery materials and carbon fiber manufacturing, integration with automated production systems and process control platforms, innovations in energy efficiency and predictive maintenance systems, and development of specialized solutions with enhanced temperature control and environmental compliance capabilities. |

The global industrial high-temperature graphitization furnaces market is estimated to be valued at USD 501.4 million in 2025.

The market size for the industrial high-temperature graphitization furnaces market is projected to reach USD 793.8 million by 2035.

The industrial high-temperature graphitization furnaces market is expected to grow at a 4.7% CAGR between 2025 and 2035.

The key product types in industrial high-temperature graphitization furnaces market are continuous graphitization furnace and batch graphitization furnace.

In terms of application, carbon fiber manufacturing segment to command 41.8% share in the industrial high-temperature graphitization furnaces market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Grade Electrochemical CO Sensor Market Size and Share Forecast Outlook 2025 to 2035

Industrial Bench Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Low Profile Floor Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Industrial Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA