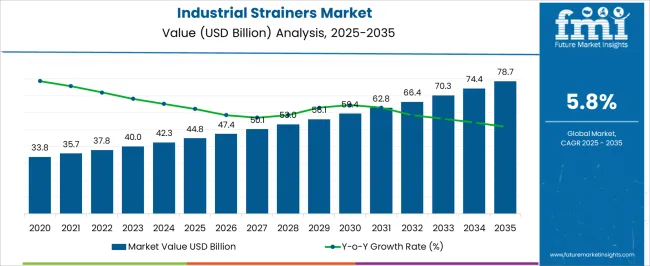

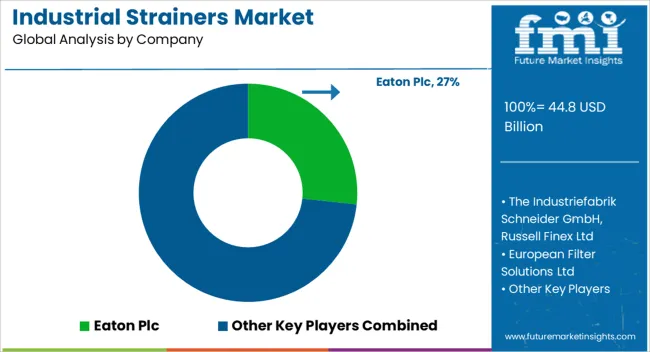

The Industrial Strainers Market is estimated to be valued at USD 44.8 billion in 2025 and is projected to reach USD 78.7 billion by 2035, registering a compound annual growth rate (CAGR) of 5.8% over the forecast period.

| Metric | Value |

|---|---|

| Industrial Strainers Market Estimated Value in (2025 E) | USD 44.8 billion |

| Industrial Strainers Market Forecast Value in (2035 F) | USD 78.7 billion |

| Forecast CAGR (2025 to 2035) | 5.8% |

The industrial strainers market is witnessing robust growth as industries prioritize operational efficiency, equipment protection, and compliance with stringent environmental standards. Increasing demand for filtration solutions in process industries such as chemicals, petrochemicals, water treatment, and power generation is driving adoption.

The need to prevent pipeline blockages, reduce downtime, and maintain consistent product quality has positioned strainers as an essential component in industrial operations. Advancements in material durability, corrosion resistance, and customized design options are further enhancing product reliability and lifespan.

Regulatory emphasis on wastewater discharge standards and clean energy initiatives is accelerating investments in efficient strainer solutions. The outlook for the market remains positive as end users increasingly adopt advanced strainer technologies to ensure uninterrupted operations, optimize maintenance cycles, and meet sustainability goals.

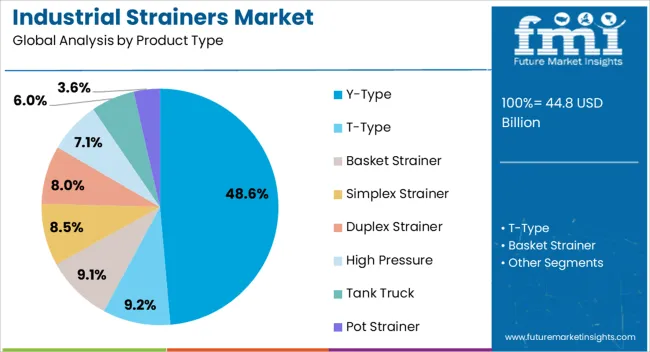

The Y type product segment is projected to account for 48.60% of market revenue by 2025, making it the leading product type. This dominance is attributed to its compact design, cost efficiency, and ability to handle high pressure applications across industries.

The ease of installation and maintenance, along with effective particle filtration, has reinforced its adoption in pipelines requiring continuous flow. Its versatility in both horizontal and vertical installations provides flexibility for various industrial systems.

As industries seek efficient straining solutions that balance performance and affordability, the Y type segment continues to hold the largest share.

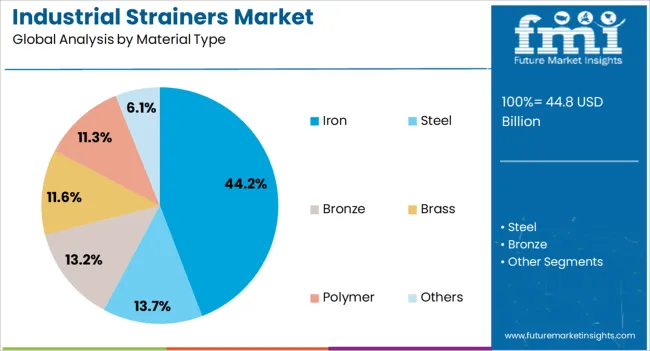

The iron material type segment is expected to capture 44.20% of the market by 2025, positioning it as the dominant material choice. The preference for iron strainers is driven by their strength, durability, and cost effectiveness, making them suitable for heavy duty applications.

Iron strainers offer reliable resistance to mechanical stress and are widely used in water treatment, oil and gas, and general industrial processes. Their compatibility with large scale pipeline systems and ability to withstand varying pressure conditions make them a preferred material type.

Continued reliance on durable and affordable strainer solutions has solidified the iron segment’s leadership.

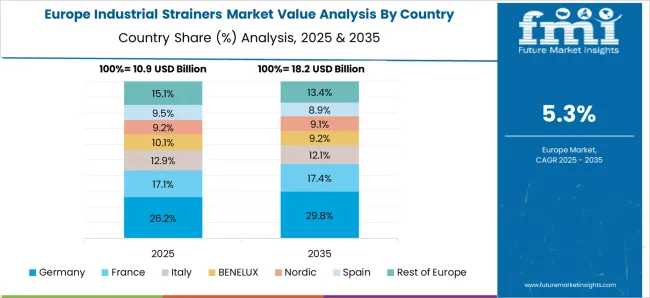

According to research, the Industrial Strainers market is projected to grow steadily across regions, expanding at approximately 5.1 % CAGR over the 2024-2035 forecast period.

The increasing usage of industrial strainers in a variety of applications has LED to manufacturers' inclination toward developing cost-optimized products.

Strainers are commonly used in industrial facilities such as manufacturing/processing plants, mills/forges, and refineries where cooling towers are installed which remove heat from machinery, hot process material/fluids, buildings, and other sources by exchanging heat with a coolant such as water or chemical solutions.

When cooling towers are not closed circuit, air and waterborne particles can build, fouling or clogging key downstream gear and processing equipment like chillers, heat exchangers, spray nozzles, and small-bore pipework in cooling circuits. If not addressed properly, this can have a substantial impact on the industrial facility's process efficiency and uptime.

Traditional cooling tower filtration systems exist, but they have substantial downsides in terms of reliability, labor-intensive cleaning/change out, and downtime.

As a result, the industry has developed industrial strainers specific to such requirements of manufacturing industries which are substantially more reliable and efficient. Multi-element, self-cleaning strainers can now aid to improve cooling and process efficiency while reducing maintenance and downtime.

Basket strainers are critical in the wastewater treatment process. Depending on the mesh or perforation employed, they can remove particles and dirt to varied degrees. This permits trash to be filtered out in phases so that one filter does not become clogged. Strainers are employed in a variety of industries.

Basket strainers are an important part of the production process for a range of food and beverage companies. For sensitive applications like this, Eaton has a number of FDA-approved alternatives.

The petroleum business relies on high-cost machinery to process oil and gasoline. Basket strainers are extremely useful in refineries and processing plants because they can remove dirt while also protecting equipment from damage.

The type of industrial strainer utilized in automotive applications is determined on the product and the stage of production. An industrial oil strainer is a necessary aspect of the process when dealing with slippery, viscous liquids. Different strainer types may be used for other vehicle fluids, such as antifreeze.

Manufacturers have introduced automatic self-cleaning strainers to the market to address the time-consuming maintenance process. In addition, new trends in strainers are driving market growth in the region. Electric motor-driven strainers and revolving screen strainers are some of these introductions.

They're backed by tubular backwashing and mechanical cleaning technologies that require less maintenance and let the fluid process run more efficiently.

Manufacturers in United Kingdom, are developing strainers made of various materials and joint types which are also differentiated based on the type of application.

However, a surging trend in the adoption of polymer-based strainers is preferred by end-users in Europe. A greater number of market participants from Europe are eyeing Eastern markets.

The demand from end-use industries across Asia-Pacific region is expected to play an important role in overall market development. Several end-use industries in India and ASEAN countries like chemical processing industry, food & beverage industry and general manufacturing industries are rapidly evolving to cater to new demand trends.

In India, the developments in filtration systems market will also be influential to shape the overall regional dynamics. Manufacturers in China are deploying low cost strainers to end-users.

Some of the leading manufacturers and suppliers include

The rising demands from various industries has put forth challenges for strainer manufacturers to respond earliest to the changing demands. The manufacturers need to perform in an extremely competitive environment and they are focusing to retain their existing customers. The market leaders are striving to operate in cyclical industries such as oil and gas, construction, transportation and mining.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global industrial strainers market is estimated to be valued at USD 44.8 billion in 2025.

The market size for the industrial strainers market is projected to reach USD 78.7 billion by 2035.

The industrial strainers market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types in industrial strainers market are y-type, t-type, basket strainer, simplex strainer, duplex strainer, high pressure, tank truck and pot strainer.

In terms of material type, iron segment to command 44.2% share in the industrial strainers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Bench Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Low Profile Floor Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Industrial Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Industrial Furnace Industry Analysis in Europe Forecast and Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA