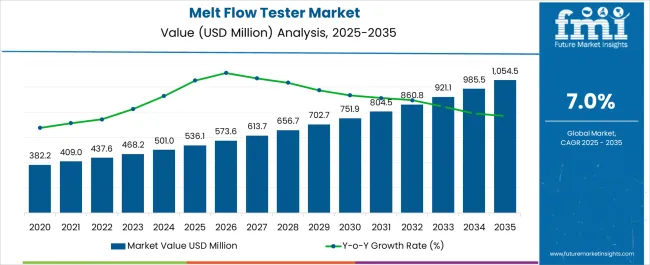

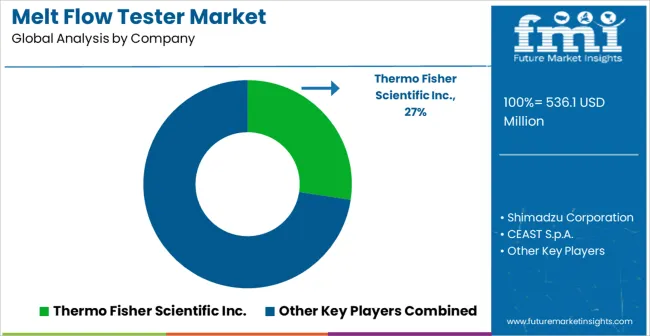

The Melt Flow Tester Market is estimated to be valued at USD 536.1 million in 2025 and is projected to reach USD 1054.5 million by 2035, registering a compound annual growth rate (CAGR) of 7.0% over the forecast period.

| Metric | Value |

|---|---|

| Melt Flow Tester Market Estimated Value in (2025 E) | USD 536.1 million |

| Melt Flow Tester Market Forecast Value in (2035 F) | USD 1054.5 million |

| Forecast CAGR (2025 to 2035) | 7.0% |

The Melt Flow Tester market is experiencing robust growth driven by the increasing demand for quality control and performance assessment in polymer manufacturing. The current market scenario is characterized by a strong focus on precision testing of polymer flow properties, which is critical for consistent material performance in downstream applications. The market growth is being supported by the rising production of thermoplastics and engineering polymers in both developed and emerging economies.

Investments in advanced manufacturing technologies, automation, and stringent quality standards are accelerating the adoption of melt flow testers. Manufacturers are increasingly leveraging these devices to optimize extrusion and molding processes, ensuring efficient production with minimal material waste.

Additionally, the integration of digital interfaces and automated data analysis capabilities in modern melt flow testers is enhancing operational efficiency, enabling manufacturers to monitor and adjust polymer properties in real time With ongoing emphasis on polymer research, lightweight materials, and high-performance plastics, the melt flow tester market is expected to maintain steady growth, providing critical support for both industrial applications and regulatory compliance across the polymer industry.

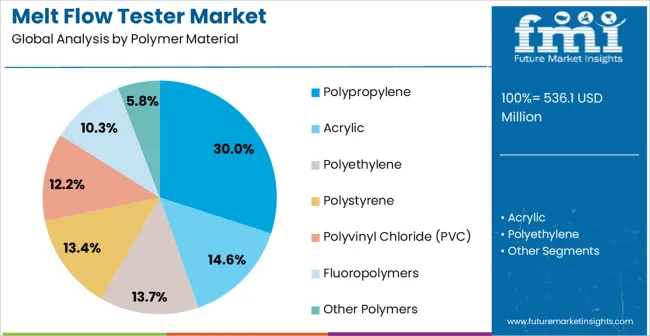

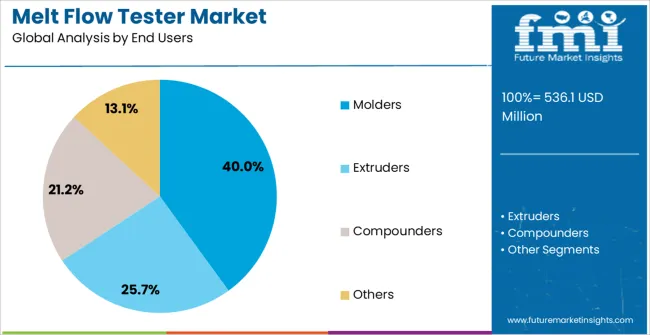

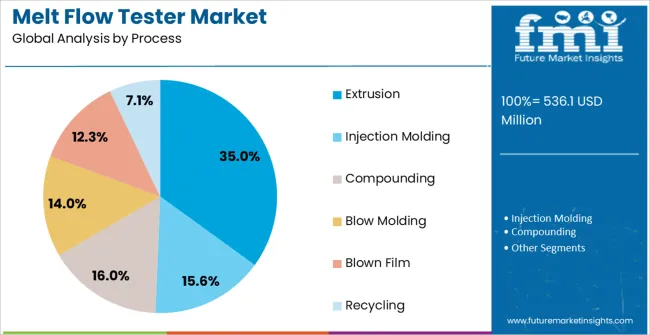

The melt flow tester market is segmented by polymer material, end users, process, mode of operation, and geographic regions. By polymer material, melt flow tester market is divided into Polypropylene, Acrylic, Polyethylene, Polystyrene, Polyvinyl Chloride (PVC), Fluoropolymers, and Other Polymers. In terms of end users, melt flow tester market is classified into Molders, Extruders, Compounders, and Others. Based on process, melt flow tester market is segmented into Extrusion, Injection Molding, Compounding, Blow Molding, Blown Film, and Recycling. By mode of operation, melt flow tester market is segmented into Automatic, Manual, and Semiautomatic. Regionally, the melt flow tester industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Polypropylene polymer material segment is projected to hold 30.00% of the Melt Flow Tester market revenue in 2025, establishing it as the leading material type. This dominance is being driven by the widespread use of polypropylene across multiple industries, including packaging, automotive, and consumer goods, where consistent flow properties are critical for product performance. The growth of this segment is supported by the material’s versatility, cost-effectiveness, and compatibility with various extrusion and molding processes.

The increasing demand for lightweight, durable, and recyclable polymers has further strengthened the adoption of polypropylene testing. Melt flow testers provide manufacturers with essential insights into viscosity, flow rate, and material consistency, which ensures that polypropylene products meet stringent quality standards.

The segment’s growth is also being influenced by the rising production volumes of polypropylene globally and the increasing focus on process optimization in polymer manufacturing facilities Continuous improvements in testing technology and automated reporting have enhanced reliability and efficiency, reinforcing polypropylene as the leading polymer material segment in the market.

The Molders end-use segment is expected to account for 40.00% of the total Melt Flow Tester market revenue in 2025, making it the largest contributor among end users. This segment’s growth has been driven by the critical need for precise control over polymer processing conditions to produce high-quality molded components.

Molders rely on melt flow testing to ensure consistency in part dimensions, surface finish, and mechanical properties, which directly affects product performance and customer satisfaction. The expansion of industries such as automotive, consumer goods, and packaging, where molded polymer components are extensively used, has further fueled demand for reliable melt flow testing.

Increased emphasis on process standardization, reduction of material waste, and adherence to regulatory quality standards has reinforced the adoption of melt flow testers by molders As manufacturers continue to focus on operational efficiency and material optimization, the use of melt flow testing for real-time quality control and process validation is expected to remain a key driver for the segment’s continued leadership in the market.

The Extrusion process segment is projected to hold 35.00% of the Melt Flow Tester market revenue in 2025, establishing it as the leading process type. The growth of this segment is being attributed to the essential role of extrusion in the manufacturing of films, sheets, pipes, and profiles, where precise control of polymer flow is crucial for consistent product quality.

Melt flow testers are extensively used to monitor and adjust processing parameters, ensuring uniformity, minimizing defects, and optimizing material performance. The segment’s expansion has been reinforced by the increasing adoption of automated and high-speed extrusion lines in packaging, construction, and industrial applications.

Continuous advancements in testing technology have improved accuracy, repeatability, and data analysis, which has further boosted reliance on melt flow testers in extrusion processes Additionally, the growing emphasis on regulatory compliance, product standardization, and sustainable material usage has contributed to the segment’s leadership, as manufacturers seek to reduce waste, enhance production efficiency, and deliver high-quality extruded polymer products.

Melt flow index is the measure of the viscosity of the polymer melt at a given temperature. Melt flow tester simply tests the melt flow index, which is also called as volume flow rate of the polymer melt or melt mass flow rate. One can test the melting properties of the polymers with the help of melt flow tester.

Melt flow tester is necessary for understanding the behavior of the polymer for various processing techniques. Melt flow tester generally made up of a cylinder surrounded by a coil used for heating the material for testing. The coil is provided with the insulation, to control heat loss.

The material is deposited by a piston provided with a standard weight. Melt flow tester tests the mass of the material flow through the die in the specified time, and calculates the melt flow index of the material. ASTM D1238 and ISO 1133 standards are the common for using the melt flow tester.

These standards are used for defining the specifications and test methods for equipment. Prices of melt flow tester varies with the various options in the equipment. Automations in the melt flow tester increases its prices accordingly.

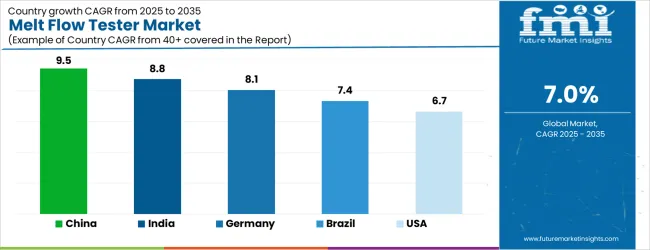

| Country | CAGR |

|---|---|

| China | 9.5% |

| India | 8.8% |

| Germany | 8.1% |

| Brazil | 7.4% |

| USA | 6.7% |

| UK | 6.0% |

| Japan | 5.3% |

The Melt Flow Tester Market is expected to register a CAGR of 7.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.5%, followed by India at 8.8%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.3%, yet still underscores a broadly positive trajectory for the global Melt Flow Tester Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 8.1%. The USA Melt Flow Tester Market is estimated to be valued at USD 201.3 million in 2025 and is anticipated to reach a valuation of USD 201.3 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 29.3 million and USD 16.3 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 536.1 Million |

| Polymer Material | Polypropylene, Acrylic, Polyethylene, Polystyrene, Polyvinyl Chloride (PVC), Fluoropolymers, and Other Polymers |

| End Users | Molders, Extruders, Compounders, and Others |

| Process | Extrusion, Injection Molding, Compounding, Blow Molding, Blown Film, and Recycling |

| Mode Of Operation | Automatic, Manual, and Semiautomatic |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Thermo Fisher Scientific Inc., Shimadzu Corporation, CEAST S.p.A., ZwickRoell GmbH & Co. KG, Dynisco LLC, Tinius Olsen Holdings, LLC, Matest S.p.A., and Toyo Seiki Seisaku-Sho, Ltd. |

The global melt flow tester market is estimated to be valued at USD 536.1 million in 2025.

The market size for the melt flow tester market is projected to reach USD 1,054.5 million by 2035.

The melt flow tester market is expected to grow at a 7.0% CAGR between 2025 and 2035.

The key product types in melt flow tester market are polypropylene, acrylic, polyethylene, polystyrene, polyvinyl chloride (pvc), fluoropolymers and other polymers.

In terms of end users, molders segment to command 40.0% share in the melt flow tester market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Melt Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Flower Box Market Size and Share Forecast Outlook 2025 to 2035

Flow Pack Films Market Size and Share Forecast Outlook 2025 to 2035

Flow Pack Machine Market Size and Share Forecast Outlook 2025 to 2035

Flow Indicator Market Size and Share Forecast Outlook 2025 to 2035

Flow Chemistry Market Size and Share Forecast Outlook 2025 to 2035

Flow Wrappers Market Size and Share Forecast Outlook 2025 to 2035

Flow Computer Market Size and Share Forecast Outlook 2025 to 2035

Melt-Blown Polypropylene Filters Market Size and Share Forecast Outlook 2025 to 2035

Melting Point Apparatus Market Size and Share Forecast Outlook 2025 to 2035

Flow Meter Devices Market Size, Share, and Forecast 2025 to 2035

Flow Cytometry Market - Trends & Growth Forecast 2025 to 2035

Flow Wrap Machines Market by Horizontal & Vertical Systems Through 2025 to 2035

Flow Wrap Packaging Market Growth from 2025 to 2035

Flower Extract Market Analysis by Type, Application and Form Through 2035

Flow Meters Market Growth - Trends & Forecast 2025 to 2035

Flow Wrap Machines Market Analysis – Size, Share & Industry Trends 2025-2035

Flow Diverter Market Analysis – Size, Trends & Forecast 2024-2034

Flow Wrap Market from 2024 to 2034

Flowback Tank Market Growth – Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA