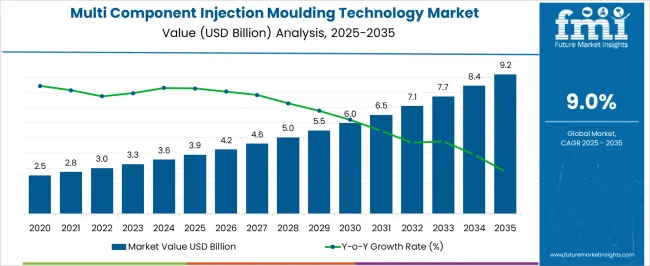

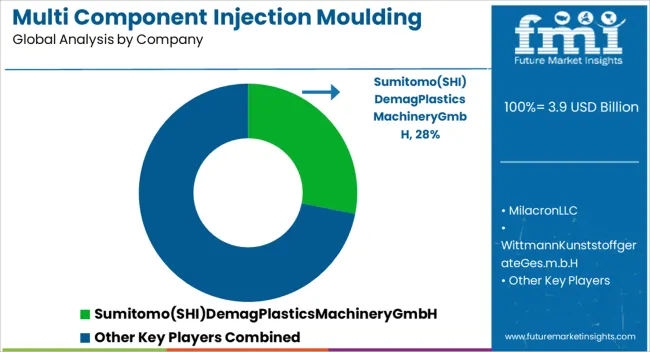

The Multi Component Injection Moulding Technology Market is estimated to be valued at USD 3.9 billion in 2025 and is projected to reach USD 9.2 billion by 2035, registering a compound annual growth rate (CAGR) of 9.0% over the forecast period.

| Metric | Value |

|---|---|

| Multi Component Injection Moulding Technology Market Estimated Value in (2025 E) | USD 3.9 billion |

| Multi Component Injection Moulding Technology Market Forecast Value in (2035 F) | USD 9.2 billion |

| Forecast CAGR (2025 to 2035) | 9.0% |

The Multi Component Injection Moulding Technology market is gaining traction as industries continue to prioritize efficiency, durability, and design integration in manufacturing processes. With growing demand for compact, lightweight, and multifunctional components, the market is being propelled by innovations in tooling and materials that allow the combination of different polymers or elastomers in a single moulding cycle.

This technology significantly reduces production steps, minimizes assembly costs, and enhances bonding strength between different materials, making it increasingly relevant across high-precision sectors. The automotive, consumer electronics, and medical device industries are particularly investing in this technology to meet strict design tolerances and improve ergonomics.

Regulatory focus on sustainability and product lifecycle management is further promoting the shift towards multi component moulding due to its ability to lower material waste and energy consumption The integration of digital mould flow simulations, automation, and robotic part handling is expected to improve production scalability and support the global expansion of this market across both developed and emerging economies.

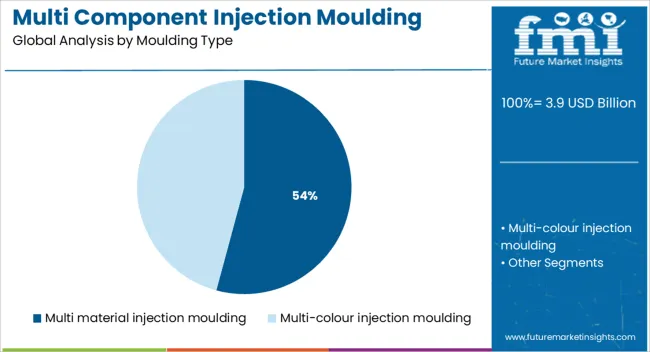

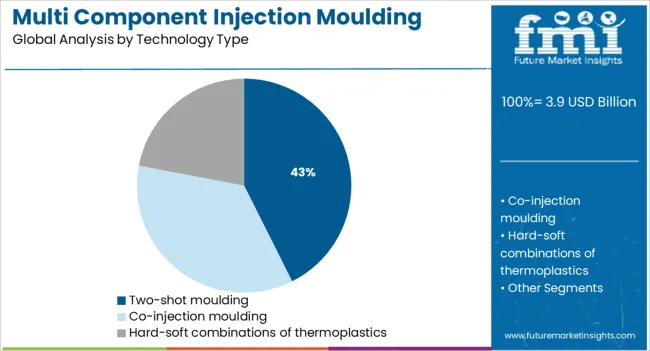

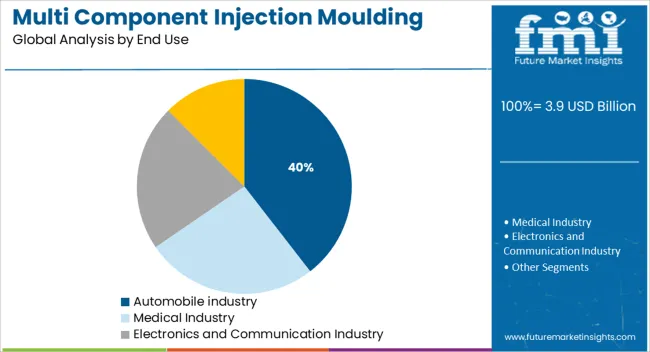

The market is segmented by Moulding Type, Technology Type, and End Use and region. By Moulding Type, the market is divided into Multi material injection moulding and Multi-colour injection moulding. In terms of Technology Type, the market is classified into Two-shot moulding, Co-injection moulding, and Hard-soft combinations of thermoplastics. Based on End Use, the market is segmented into Automobile industry, Medical Industry, Electronics and Communication Industry, and Sports Industry. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Multi material injection moulding is projected to account for 54.2% of the overall revenue share in the Multi Component Injection Moulding Technology market in 2025, making it the dominant moulding type. The segment’s leadership is being driven by the capability to combine materials with distinct physical or chemical properties into a single component, enhancing both product functionality and structural integrity. The process eliminates the need for secondary assembly or bonding operations, which contributes to faster production cycles and lower labour costs.

Adoption has been particularly high in applications where tactile finishes, color contrasts, and multi-functionality are required. The compatibility of multi material moulding with thermoplastics, elastomers, and bio-based resins has further expanded its application in precision-engineered parts.

Advances in simulation tools and hot runner systems have enabled manufacturers to precisely control flow characteristics and material transitions during the moulding process, ensuring high repeatability This segment continues to gain prominence due to its contribution to reduced waste, improved product lifecycle, and aesthetic product enhancement.

Two shot moulding is expected to contribute 42.6% of the total market revenue in the Multi Component Injection Moulding Technology market in 2025, emerging as a key technology type due to its ability to integrate multiple materials or colours in a single moulding cycle. The process involves the sequential injection of two materials into the same mould, resulting in strong inter-material bonding and design complexity not achievable through conventional techniques.

Its adoption has been driven by the need to produce ergonomic and durable parts with enhanced grip, insulation, and aesthetic value. Two shot moulding has found significant uptake in industries requiring precision engineering, particularly in automotive interiors, consumer electronics, and healthcare devices.

The ability to reduce production time, improve part accuracy, and streamline quality control processes has solidified its relevance across mass production environments Improvements in automated mould handling, servo-driven rotary platens, and advanced material compatibility have reinforced its role in accelerating product innovation and manufacturing efficiency.

The automobile industry is forecast to hold 39.5% of the total revenue share in the Multi Component Injection Moulding Technology market in 2025, reflecting its position as the leading end use sector. This dominance is being influenced by the automotive sector’s need to reduce part counts, optimize structural strength, and enhance interior and exterior aesthetics.

Multi component moulding allows for the integration of soft and hard materials in a single automotive part, such as dashboards, sealing components, knobs, and light assemblies, leading to lower assembly costs and increased design flexibility. The shift towards electric vehicles and lightweighting initiatives has further intensified the demand for materials and processes that deliver both strength and weight reduction.

The integration of noise dampening, thermal resistance, and tactile features into single-part solutions has made multi component technology a critical enabler for innovation in vehicle design Additionally, the emphasis on sustainability and circular economy in the automotive sector is driving investment in recyclable and bio-based multi material systems, securing the segment’s long-term growth trajectory.

Multi component injection moulding technology involves combination of different materials to produce high quality of plastic components. Multi component injection moulding technology covers all the processes involving the stages, which more than one plastic components undergo, during their treatment to achieve a particular functionality.

With the help of this technology, one can improve design and functionality of products, in a cost effective manner. It is the technique of manufacturing custom plastic parts with two or more plastic resins. Multi material moulding processes can be classified in multi component injection moulding technology, multi shot moulding and over moulding.

This technology or technique is used for manufacturing of multi-colour and soft touch over moulding products for different markets such as packaging, automotive, consumer and others. In addition, the global multi component injection moulding technology is expected to enjoy high preference over the forecast period, which can be attributed to process reliability and increased applications in various fields.

Multi component injection moulding technology is now applied extensively in the electronics, packaging, and sports industries, in addition to integration with automotive, medical and communication technologies.

Multi component injection moulding technology is used for manufacturing articles made with different materials. Multi component injection moulding technology has witnessed rapid development in recent years and so growth rate of traditional moulding came to a pause. These rapid developments include new variants of processes, plastics and material combinations which have been added for new applications in various fields.

The technology is evolving in new directions and its technical developments include machines with four to six barrels, thermoplastic/thermosets combinations, combinations of materials with gas or water assists and many more. Since many multi shots or co injections presses are customized, moving to multi component can be expensive.

However, the versatility it provides compensates the high cost. Multi component injection moulding technology is used to produce a finished portion in the mould without using a downstream equipment which is expensive to use, buy and maintain.

Applications of multi component injection moulding technology are barrier products, shielding against electromagnetic interference, recycling of thermoplastic materials and many more. Numerous applications in some of the most lucrative industries in the market are expected to drive the global multi component injection moulding technology market, owing to its cost effective nature, reliability, and quality.

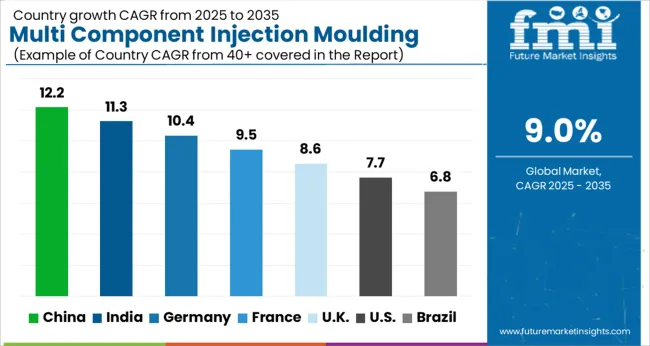

Geographically, the global Multi Component Injection Molding Technology market can be segmented as:

The North America and Western Europe region are expected to witness increase in applications of multi component injection moulding technology, over the forecast period, owing to a large and mature industry and high quality standards.

Multi component injection moulding technology machinery demand in North America accounts for a small portion of net sales However, the region is expected to witness rise in market share. Western Europe is expected to outdo North America in terms of multi component injection moulding technology demand.

For instance, over 20% of Ferromatik Milacron's sales in Germany is multi-component presses. The APAC region is also expected to witness healthy growth in the multi component injection molding technology market, over the forecast period.

Few of the key players operating in the global multi component injection moulding technology market are:

Sumitomo (SHI) Demag Plastics Machinery GmbH, Milacron LLC, Wittmann Kunststoffgerate Ges.m.b.H, Haitian International Holdings Ltd., and Mold Hotrunner Solutions Inc., among others.

The global multi component injection moulding technology market is estimated to be valued at USD 3.9 billion in 2025.

The market size for the multi component injection moulding technology market is projected to reach USD 9.2 billion by 2035.

The multi component injection moulding technology market is expected to grow at a 9.0% CAGR between 2025 and 2035.

The key product types in multi component injection moulding technology market are multi material injection moulding and multi-colour injection moulding.

In terms of technology type, two-shot moulding segment to command 42.6% share in the multi component injection moulding technology market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Multifunctional Loader Market Size and Share Forecast Outlook 2025 to 2035

Multipurpose Goods Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Multichannel Electrochemical Workstation Market Size and Share Forecast Outlook 2025 to 2035

Multi Colored LED Beads Market Size and Share Forecast Outlook 2025 to 2035

Multi-Drug/Combination Injectable Market Forecast and Outlook 2025 to 2035

Multiplex Sepsis Biomarker Panels Market Size and Share Forecast Outlook 2025 to 2035

Multiplex Protein Profiling Market Size and Share Forecast Outlook 2025 to 2035

Multihead Weighers Market Size and Share Forecast Outlook 2025 to 2035

Multi-Cloud Networking Market Forecast Outlook 2025 to 2035

Multispectral Camera Market Size and Share Forecast Outlook 2025 to 2035

Multi-functional Packaging Market Size and Share Forecast Outlook 2025 to 2035

Multiplex Biomarker Imaging Market Forecast and Outlook 2025 to 2035

Multichannel Order Management Market Forecast and Outlook 2025 to 2035

Multiexperience Development Platform Market Forecast and Outlook 2025 to 2035

Multi Depth Corrugated Box Market Size and Share Forecast Outlook 2025 to 2035

Multilayer Flexible Packaging Market Size and Share Forecast Outlook 2025 to 2035

Multi Attachment Loaders Market Size and Share Forecast Outlook 2025 to 2035

Multi Pocket Holders Market Size and Share Forecast Outlook 2025 to 2035

Multi-Screen Super Glass Market Size and Share Forecast Outlook 2025 to 2035

Multichannel Reagent Reservoir Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA