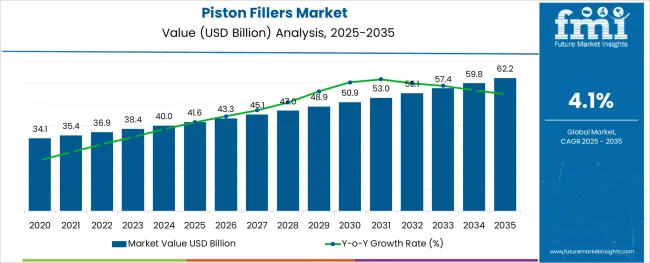

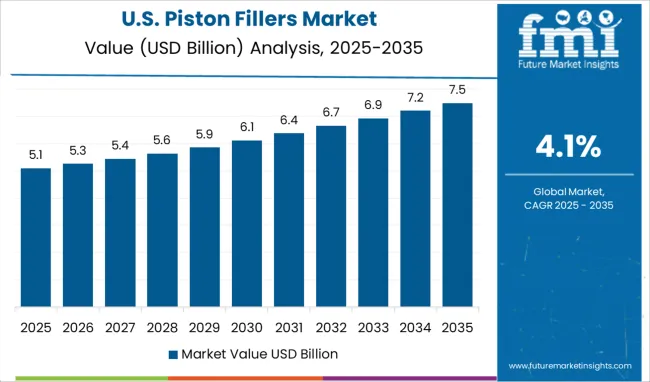

The Piston Fillers Market is estimated to be valued at USD 41.6 billion in 2025 and is projected to reach USD 62.2 billion by 2035, registering a compound annual growth rate (CAGR) of 4.1% over the forecast period.

The piston fillers market is witnessing gradual expansion driven by the rising demand for precise filling solutions across the food, beverage, personal care, and chemical industries. Growing production volumes in these sectors have led to increased investments in filling machinery that delivers accuracy and minimizes product waste. Technological innovations in piston filling machines have improved operational speed and reduced downtime contributing to greater production efficiency.

Manufacturers have shifted toward equipment that supports a wide range of viscosities and filling requirements enhancing the versatility of piston fillers. Additionally, as packaging formats diversify companies are seeking flexible filling solutions that can handle liquids creams and pastes with equal ease.

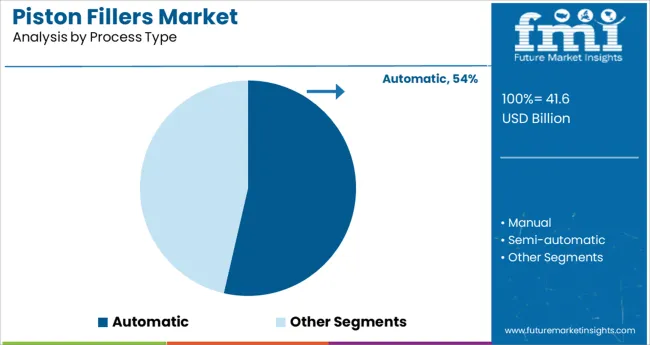

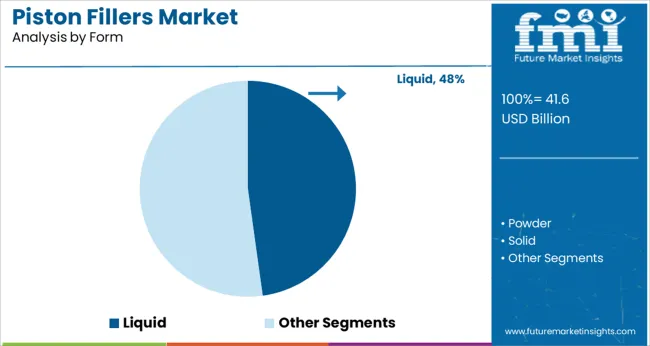

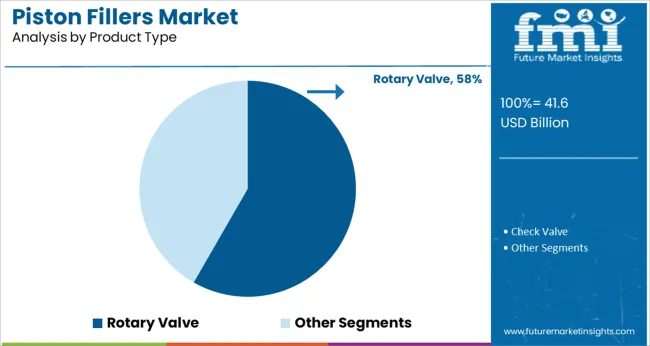

The market outlook remains optimistic as industries continue to automate their filling operations to meet rising consumer demand and regulatory requirements. Segmental growth is projected to be driven by Automatic process types for their efficiency Liquid forms due to their high-volume applications and Rotary Valve products for their ability to handle a broad range of product consistencies.

The market is segmented by Process Type, Form, Product Type, Design, and Application and region. By Process Type, the market is divided into Automatic, Manual, and Semi-automatic. In terms of Form, the market is classified into Liquid, Powder, Solid, and Semi-solid. Based on Product Type, the market is segmented into Rotary Valve and Check Valve.

By Design, the market is divided into Multi Head and Single Head. By Application, the market is segmented into Food and Beverages, Cosmetics, and Pharmaceutical. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Automatic segment is forecasted to account for 53.6% of the piston fillers market revenue in 2025 securing its place as the leading process type. Growth in this segment has been fueled by the industry’s shift toward high-speed production lines where automation plays a critical role in minimizing human error and ensuring consistency. Automatic piston fillers are preferred for their ability to deliver uniform fill levels across large production batches making them essential in operations that require both speed and precision.

Additionally production facilities have increasingly adopted automatic fillers to reduce labor dependency and improve hygiene standards during the filling process. The push for cost optimization and production scalability has further strengthened the position of automatic systems in both small and large manufacturing environments.

As industries continue to expand their automated processes the Automatic segment is expected to maintain its leadership within the piston fillers market.

The Liquid segment is projected to contribute 47.8% of the piston fillers market revenue in 2025 maintaining its dominance among form categories. Liquids represent one of the most common product types filled by piston fillers due to their extensive use in food beverages pharmaceuticals and personal care products. Manufacturers have relied on piston fillers for their ability to handle liquids with varying viscosities providing smooth and spill-free filling.

The segment has gained traction as consumer-packaged goods companies introduce new liquid-based product formats requiring precision filling at scale. Additionally growing demand for ready-to-drink beverages sauces and liquid detergents has expanded the application base for liquid piston fillers.

Production lines have favored these fillers for their ease of cleaning quick changeover capabilities and ability to maintain product integrity. With liquid products remaining a key category in manufacturing the Liquid segment is expected to retain its strong market presence.

The Rotary Valve segment is estimated to hold 58.3% of the piston fillers market revenue in 2025 establishing itself as the leading product type. This segment’s growth has been driven by the versatility of rotary valve systems which enable precise filling of products with varying viscosities from thin liquids to thick pastes. Rotary valve piston fillers have been widely used in industries that require consistent fill volumes and reduced product shear making them suitable for delicate and high-viscosity products.

Equipment designers have enhanced rotary valve technology to provide faster filling cycles and improved cleaning processes supporting hygiene compliance in food and pharmaceutical applications. Additionally the adaptability of rotary valves to both manual and automatic configurations has broadened their appeal across diverse production setups.

As manufacturers continue to seek reliable and adaptable filling solutions the Rotary Valve segment is expected to sustain its leading market position.

As piston fillers are solely based on conventional technology, these are easy to operate and relatively low cost for the majority of the end-use industries. High demand for cost-effective and rapid filling technologies for faster production is a crucial factor that is expected to foster the global piston fillers market growth in the evaluation period.

Besides, surging need for customized filling and packaging equipment to attain operational excellence is likely to bode well for the global market. High demand for pharmaceutical and cosmetics products across the globe owing to rising disposable income and changing lifestyles is another major factor that is predicted to fuel growth in the market.

Piston fillers are difficult to clean after usage and thus require high maintenance cost. Chances of leakage is also high with the usage of piston fillers. Latest variants are expensive and would incur high installation cost. Often, debris block the pipeline and the nozzle of the filling drips the liquid. Spurred by the aforementioned disadvantages, sales of piston fillers may decline in the upcoming years.

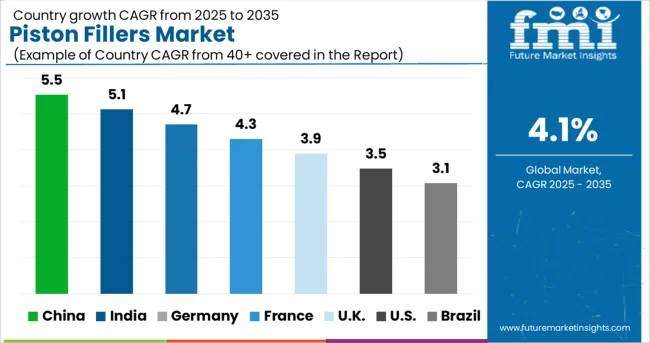

North America is estimated to remain at the forefront by generating the largest piston fillers market share in the forthcoming years. Wider acceptance of innovative technologies in the USA and Canada is expected to bolster the regional market. In addition to that, increasing demand for packaged food items across North America is set to aid growth.

The presence of a large number of renowned cosmetics manufacturers in North America is another significant factor that would spur growth. New product launches, high demand for organic cosmetics, and surging consciousness about external beauty are some of the factors responsible for pushing the demand for cosmetics and personal care products in North America.

Ongoing expansion of the food and beverage industry in India, China, South Korea, and Japan is expected to expand the Asia Pacific piston fillers market size in future. Increasing demand for cost-effective and automated solutions in emerging economies is another factor that is set to propel the regional market.

Further, extensive consumption of ready-to-eat meals among college students and working professionals is likely to bolster growth. Growing pressure on brands to provide new products that are better for the environment is resulting in the shift of companies towards the development of vegan or plant-based ingredients. Increasing number of supermarkets, grocery stores, and hypermarkets across Asia Pacific is also expected to drive growth.

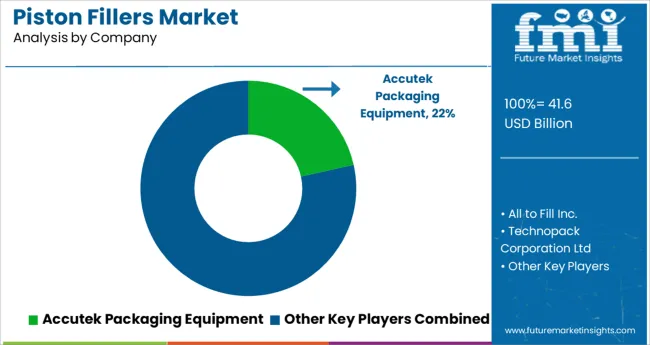

Some of the prominent companies operating in the global piston fillers market include Biner-Ellison Packaging Systems, All-Fill Inc., Busch Machinery, Cleveland Equipment & Machinery, Accutek Packaging Equipment Companies, Inc., Raque Food Systems, E-PAK Machinery, Technopack Corporation Ltd, Unifiller Systems Inc., Apacks, Filling Equipment Co. Inc., Simplex Filler Company, and JBT among others.

The global market is highly competitive in nature with the presence of various large- and small-scale companies. They are mainly focusing on mergers and acquisitions with local companies to expand their presence in the global market.

Some of the other key players are investing huge sums in research and development activities to come up with novel, yet cost-effective piston fillers to help food manufacturers keep up with strict government norms.

| Report Attribute | Details |

|---|---|

| Growth Rate | CAGR of 4.1% from 2025 to 2035 |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in million and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments Covered |

Process Type, Form, Product Type, Design, Application, Region |

| Regions Covered |

North America; Latin America; Western Europe; Eastern Europe; APEJ; Japan; Middle East and Africa |

| Key Countries Profiled | USA, Canada, Brazil, Argentina, Germany, UK, France, Spain, Italy, Nordics, BENELUX, Australia & New Zealand, China, India, ASEAN, GCC, South Africa |

| Key Companies Profiled |

Biner-Ellison Packaging Systems; All-Fill Inc.; Busch Machinery; Cleveland Equipment & Machinery; Accutek Packaging Equipment Companies, Inc.; Raque Food Systems; E-PAK Machinery; Technopack Corporation Ltd; Unifiller Systems Inc.; Apacks; Filling Equipment Co. Inc.; Simplex Filler Company; JBT |

| Customization | Available Upon Request |

The global piston fillers market is estimated to be valued at USD 41.6 billion in 2025.

It is projected to reach USD 62.2 billion by 2035.

The market is expected to grow at a 4.1% CAGR between 2025 and 2035.

The key product types are automatic, manual and semi-automatic.

liquid segment is expected to dominate with a 47.8% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Piston Grouting Pump Market Size and Share Forecast Outlook 2025 to 2035

Piston Seals Market Size, Growth, and Forecast 2025 to 2035

Axial Piston Motor Market- Analysis and Forecast by Product Type, End-User and Region 2025 to 2035

Axial Piston Pumps Market

Engine Piston Ring Set Market Size and Share Forecast Outlook 2025 to 2035

Radial Piston Motor Market Size, Share, and Forecast 2025 to 2035

Radial Piston Pumps Market

Automotive Piston System Market Growth - Trends & Forecast 2025 to 2035

Lightweight Aluminium Pistons Market Growth - Trends & Forecast 2025 to 2035

Fillers & Extenders Market Size and Share Forecast Outlook 2025 to 2035

Sack Fillers Market Size and Share Forecast Outlook 2025 to 2035

Dermal Fillers Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Dermal Fillers and Botulinum Toxin Market Outlook - Size, Trends & Forecast 2025 to 2035

Breast Fillers Market Analysis - Trends & Forecast 2025 to 2035

Competitive Overview of Dermal Fillers Market Share

Plastic Fillers Market Size and Share Forecast Outlook 2025 to 2035

Polymer Fillers Market Analysis - Size, Share, and Forecast 2025 to 2035

Aseptic Fillers Market Growth - Trends & Forecast 2025 to 2035

Europe Dermal Fillers Market Size and Share Forecast Outlook 2025 to 2035

Volumetric Cup Fillers Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA