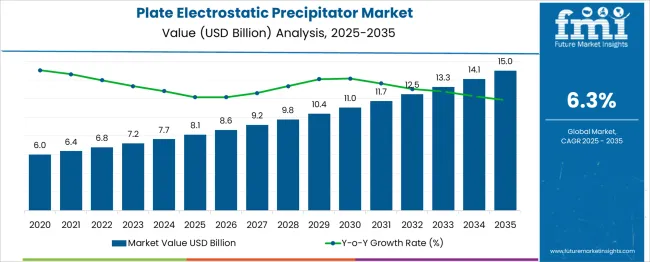

The Plate Electrostatic Precipitator Market is estimated to be valued at USD 8.1 billion in 2025 and is projected to reach USD 15.0 billion by 2035, registering a compound annual growth rate (CAGR) of 6.3% over the forecast period. Focusing on the five-year outlook from 2020 to 2025, the market is expected to increase from USD 6.0 billion to USD 7.7 billion, generating an incremental gain of USD 1.7 billion. This growth phase is driven by rising industrial activities across various sectors, coupled with stricter environmental regulations aimed at reducing particulate emissions and improving air quality globally. Increasing adoption of electrostatic precipitator technology in power generation, cement, steel, and chemical manufacturing plants further supports this upward trend.

Year-on-year values during this period, USD 6.4 billion in 2021, USD 6.8 billion in 2022, USD 7.2 billion in 2023, and USD 7.7 billion in 2024, reflect steady and consistent growth influenced by regulatory compliance requirements and the rising focus on emission control. Between 2026 and 2030, the market is poised to advance from USD 8.1 billion to USD 10.4 billion, propelled by an increasing number of retrofit projects in older industrial facilities and robust expansion in emerging economies. This period is also characterized by technological innovations in plate precipitator design, which enhance collection efficiency and reduce operational and maintenance costs. Manufacturers are investing in advanced materials and automation technologies to improve system reliability and longevity. Overall, the five-year growth outlook confirms a positive trajectory for the Plate Electrostatic Precipitator Market, driven by global efforts to curb air pollution, ongoing industrial modernization, and continuous advancements in filtration and emission control technologies.

| Metric | Value |

|---|---|

| Plate Electrostatic Precipitator Market Estimated Value in (2025 E) | USD 8.1 billion |

| Plate Electrostatic Precipitator Market Forecast Value in (2035 F) | USD 15.0 billion |

| Forecast CAGR (2025 to 2035) | 6.3% |

The plate electrostatic precipitator (ESP) market holds a specialized yet critical role in the industrial emissions control landscape. Within the overall electrostatic precipitator industry, plate ESP systems account for approximately 45–48%, underlining their dominance in handling high-volume gas streams and particulate control in power generation and heavy industries. In the broader air pollution control equipment market, this segment represents nearly 20–22%, supported by regulatory pressure to reduce particulate emissions from coal-fired plants, cement kilns, and steel production units. Within flue gas treatment solutions, plate ESP systems contribute about 28–30%, driven by their capability to manage fine dust particles under high-temperature and high-pressure conditions.

In the industrial air quality management ecosystem, the share of plate ESP is estimated at 15–18%, attributed to their long operational life, scalability for large facilities, and adaptability to various fuel types. Their presence within renewable biomass energy projects remains moderate at around 8–10%, primarily due to the compatibility of ESP technology with combustion-based processes. Growth is fueled by tightening emission norms across Asia-Pacific and Europe, retrofitting initiatives for aging plants, and industry shifts toward high-efficiency gas-cleaning solutions. Manufacturers are investing in digital monitoring systems, high-voltage power optimization, and corrosion-resistant electrode materials to enhance performance. As industries aim to meet zero-particulate discharge targets, plate ESP systems continue to be positioned as a critical enabler for achieving stringent environmental compliance and operational reliability worldwide.

Industries such as power generation, cement, and metals processing are increasingly adopting advanced particulate collection systems to meet environmental compliance standards. Growth in the market is being supported by sustained investments in clean energy infrastructure and the retrofitting of older facilities with high-efficiency electrostatic systems.

The growing awareness regarding the health hazards posed by particulate emissions has encouraged both public and private sectors to prioritize pollution mitigation technologies. Technological advancements in design optimization, automatic voltage control, and energy efficiency are further enhancing the reliability and cost-effectiveness of plate-type electrostatic precipitators.

As industries seek to minimize their environmental footprint and avoid regulatory penalties, the demand for these systems is expected to expand. Emerging markets are also contributing significantly to future opportunities as industrialization and environmental regulations advance simultaneously..

The plate electrostatic precipitator market is segmented by system, emitting industry, and geographic regions. The plate electrostatic precipitator market is divided into Dry and wet systems. In terms of the emitting industry, the plate electrostatic precipitator market is classified into Power generation, Chemicals and petrochemicals, Cement, Metal processing & mining, Manufacturing, Marine, and Others. Regionally, the plate electrostatic precipitator industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

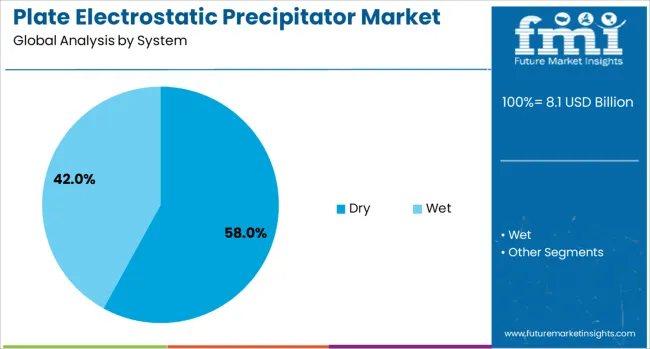

The dry system segment is projected to account for 58% of the Plate Electrostatic Precipitator market revenue share in 2025, positioning it as the leading system type. This segment's dominance has been attributed to its wide applicability across industries where the removal of dry particulate matter from flue gases is essential.

Dry electrostatic precipitators have been preferred due to their robust performance in high-temperature environments and their ability to efficiently handle large gas volumes with low pressure drop. Their relatively low maintenance requirements and extended operational life have made them a practical choice for power plants and other heavy industries.

The use of dry systems has been further reinforced by their compatibility with modern control systems and advanced material coatings that enhance corrosion resistance. As environmental compliance becomes more stringent and operational efficiency remains a key industrial priority, dry systems continue to gain preference as a reliable and cost-effective emission control solution..

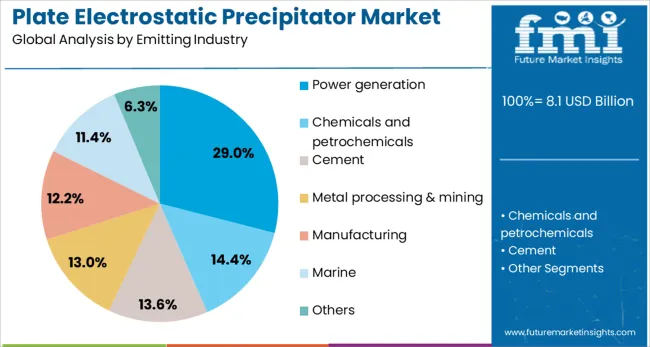

The power generation segment is expected to hold 29% of the Plate Electrostatic Precipitator market revenue share in 2025, establishing it as the leading emitting industry. This segment’s prominence has been driven by the critical need to control particulate emissions from coal-fired and biomass power plants.

With increasing regulatory scrutiny and environmental mandates, utility providers have prioritized the installation and upgrading of electrostatic precipitators to reduce airborne pollutants and improve air quality. The continued reliance on thermal power in many regions, particularly in developing economies, has sustained the demand for high-capacity dust collection systems.

Additionally, government-led environmental reforms and emission trading schemes have incentivized utilities to adopt cleaner technologies, thereby accelerating implementation within this segment. The operational reliability, scalability, and proven efficiency of plate electrostatic precipitators have made them the technology of choice in power generation facilities seeking long-term compliance and cost stability in their environmental management strategies..

The plate electrostatic precipitator market is driven by emission control mandates, industrial modernization, and smart monitoring integration. Regional expansions and service-based models are shaping future growth trajectories globally.

The demand for plate electrostatic precipitators is strongly driven by stricter emission control standards imposed by environmental authorities. Power generation plants, cement manufacturers, and steel producers face stringent particulate matter reduction targets. Compliance with these regulations necessitates the adoption of high-efficiency ESP systems capable of handling large gas volumes and fine particulate matter. Governments in Asia-Pacific and Europe have intensified monitoring and penalty frameworks, accelerating retrofits and new installations. Industries are prioritizing emission control investments to avoid production halts and financial liabilities. These regulatory frameworks have established plate ESPs as an essential solution for meeting operational and environmental compliance requirements in heavy industrial sectors globally.

Plate electrostatic precipitators continue to maintain dominance in coal-fired and biomass-based power plants, cement manufacturing, and metal processing industries. Their ability to handle high flue gas temperatures, corrosive environments, and large-scale particulate collection gives them an advantage over alternative filtration systems. With aging thermal power infrastructure requiring modernization, retrofitting of ESP units has become a significant revenue stream. Growing industrialization in developing countries further supports demand for ESPs to maintain clean operational environments. Their design flexibility and scalability make plate ESPs suitable for both new facilities and existing plants undergoing compliance-driven upgrades, strengthening their role in emission management strategies.

Advancements in control systems are transforming the operational efficiency of plate electrostatic precipitators. Digital monitoring technologies enable real-time detection of voltage fluctuations, spark occurrences, and dust load variations, improving system reliability. Power optimization features integrated into high-voltage rectifier systems allow energy-efficient operations, reducing operational costs. Predictive maintenance tools are being widely adopted to minimize downtime and extend equipment life. These digital enhancements not only optimize performance but also help industries align with stricter compliance mandates through data-driven reporting. As connectivity becomes standard in industrial operations, ESP systems integrated with smart control platforms are emerging as a competitive differentiator.

The plate ESP market is witnessing intense competition among key players who are focusing on product upgrades, corrosion-resistant electrode designs, and aftermarket service contracts. Strategic partnerships with EPC contractors are enabling suppliers to expand their presence in fast-growing regions such as Asia-Pacific and the Middle East. Vendors are also investing in hybrid ESP systems capable of integrating with bag filters for enhanced performance in challenging applications. Additionally, service-oriented business models like remote monitoring and performance guarantees are gaining traction, offering manufacturers recurring revenue streams. Regional policy incentives for air quality improvement and plant modernization programs are expected to create strong growth opportunities in the coming years.

| Country | CAGR |

|---|---|

| China | 8.5% |

| India | 7.9% |

| Germany | 7.2% |

| France | 6.6% |

| UK | 6.0% |

| USA | 5.4% |

| Brazil | 4.7% |

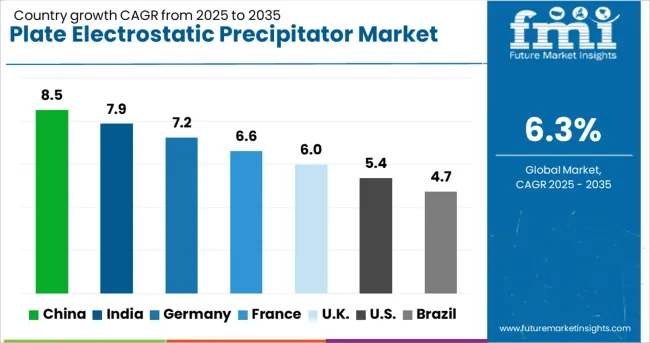

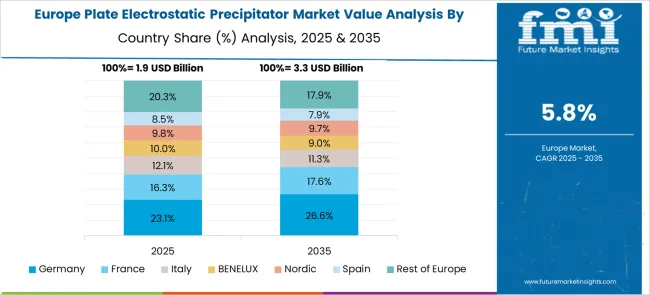

The plate electrostatic precipitator market is projected to grow at a global CAGR of 6.3% between 2025 and 2035, fueled by strict industrial emission regulations, plant modernization programs, and the demand for high-efficiency particulate collection systems. China leads with a CAGR of 8.5%, driven by rapid expansion in coal-based power generation, large-scale industrial retrofits, and government-mandated air quality improvement initiatives. India follows at 7.9%, supported by accelerated investments in cement, steel, and energy sectors, along with national clean air programs targeting industrial emissions. Germany records 7.2%, driven by stringent EU emission norms, modernization of waste-to-energy plants, and retrofitting projects in legacy power infrastructure. The United Kingdom grows at 6.0%, influenced by the transition toward low-emission industrial processes and enhanced adoption of hybrid filtration systems. The United States achieves a CAGR of 5.4%, reflecting stable demand in industrial retrofits and increased emphasis on operational efficiency for emission control systems. The analysis spans more than 40 regions, with these six nations representing key benchmarks for investment strategies and capacity expansion in the global plate electrostatic precipitator market.

China is expected to post a CAGR of 8.5% during 2025–2035, outperforming the global average of 6.3%, as industries push for higher efficiency in emission control. Between 2020–2024, growth stood at 5.9%, supported by early-stage investments in ESP retrofitting and basic compliance measures. The sharp increase in the next decade is attributed to strict environmental policies under the Blue Sky program, significant upgrades in coal-fired power plants, and adoption of digital performance monitoring for ESP units. Expansion of cement and steel sectors, coupled with the government’s industrial decarbonization agenda, reinforces high demand for plate ESP systems in China.

India is projected to grow at a 7.9% CAGR for 2025–2035, compared to 5.2% during 2020–2024, reflecting a major shift in emission control strategies. The earlier phase saw moderate adoption limited to major power plants and large industrial hubs due to cost constraints. Post-2024, stricter enforcement of air quality regulations, combined with expansions in cement, metal, and power sectors, has spurred demand for high-efficiency plate ESP systems. Government programs like the National Clean Air initiative and industrial modernization schemes have further accelerated growth, making India one of the top markets for ESP technology in Asia-Pacific.

Germany’s CAGR rises to 7.2% for 2025–2035, up from 4.8% during 2020–2024, due to stringent EU environmental standards and industrial upgrades. Initial growth was slow because many plants already had baseline pollution control systems. The surge in the next decade is driven by modernization of waste-to-energy facilities, tighter particulate emission norms, and strong emphasis on hybrid ESP-bag filter solutions for complex industrial processes. Germany is also leveraging advanced monitoring systems for predictive maintenance to ensure compliance, making plate ESP adoption a core part of industrial sustainability programs in energy-intensive sectors.

The UK’s CAGR climbs from 4.2% during 2020–2024 to 6.0% in 2025–2035, showing a strong rebound driven by industrial compliance measures. Initial growth lagged due to dependency on imported components and delayed modernization in older power units. From 2025 onward, stricter air quality frameworks, along with growing retrofitting programs in waste-to-energy plants and biomass facilities, pushed demand for plate ESP solutions. Government incentives for cleaner industrial operations and partnerships with global ESP manufacturers further strengthened adoption. Digital-enabled maintenance and hybrid filtration models became preferred solutions, aligning with evolving environmental performance standards.

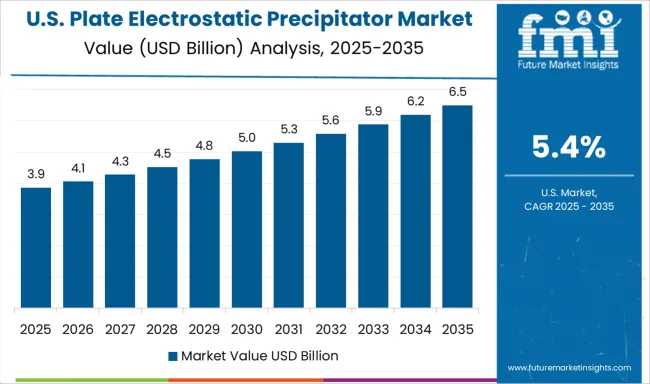

The USA CAGR will increase to 5.4% during 2025–2035, compared to 3.8% between 2020–2024, as industries prioritize emission compliance and operational efficiency. The earlier phase was marked by limited retrofitting activities and reliance on existing control technologies in coal-based plants. Growth in the next decade stems from industrial diversification into biomass and waste-to-energy segments, along with policy-driven upgrades in steel and cement sectors. Increasing investment in predictive diagnostics and high-voltage optimization for ESP systems will further fuel market expansion. Regional demand is supported by corporate sustainability goals and tightening state-level emission mandates.

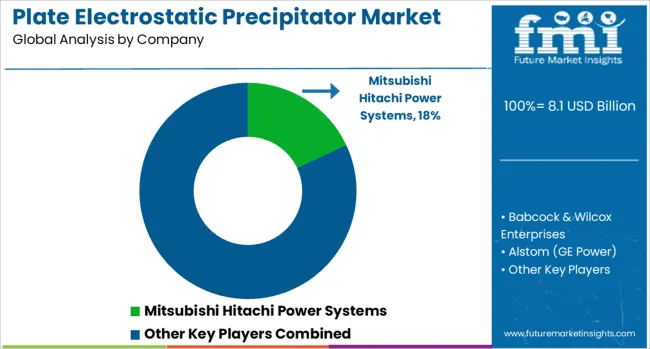

The plate electrostatic precipitator market is marked by strong competition among leading industrial technology providers focused on emissions control solutions for power and heavy industries. Mitsubishi Hitachi Power Systems (MHPS) leads the market with advanced ESP systems designed for high-efficiency particulate removal in coal-fired and biomass power plants, emphasizing energy optimization and long-term reliability. Babcock & Wilcox Enterprises is a key player offering robust ESP designs and turnkey retrofitting services for thermal power plants, cement kilns, and industrial boilers, supported by a strong aftermarket service portfolio. Alstom (GE Power) plays a strategic role in integrating ESP systems with flue gas desulfurization units, delivering solutions that ensure compliance with stringent global emission standards. Parker Hannifin Corporation differentiates through advanced filtration and gas treatment technologies, integrating ESP units with modular filtration systems to enhance adaptability across industries.

Other notable contributors such as Croll-Reynolds specialize in niche applications and custom-engineered systems for industrial exhaust cleaning, contributing to market diversity. Competitive dynamics revolve around the integration of smart control technologies for real-time monitoring, predictive maintenance solutions to reduce downtime, and high-voltage optimization for improved collection efficiency. Players are prioritizing product innovations in electrode design, corrosion-resistant materials, and digital-enabled ESP retrofits to address stricter environmental regulations. Strategic initiatives also include partnerships with EPC firms, expansion into Asia-Pacific for capacity-driven opportunities, and the development of hybrid filtration systems combining ESP with baghouse units for enhanced particulate removal in challenging industrial environments. These strategies position the leading companies to capture significant growth in a market driven by compliance mandates and demand for operational efficiency.

On June 30, 2025, Parker announced a USD 1 billion all-cash acquisition of Curtis Instruments, expected to add $320 million in FY25 sales, including enhanced capabilities in instrumentation and control technologies that complement emission control applications.

| Item | Value |

|---|---|

| Quantitative Units | USD 8.1 Billion |

| System | Dry and Wet |

| Emitting Industry | Power generation, Chemicals and petrochemicals, Cement, Metal processing & mining, Manufacturing, Marine, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Mitsubishi Hitachi Power Systems, Babcock & Wilcox Enterprises, Alstom (GE Power), Parker Hannifin Corporation, and Others (Croll-Reynolds, etc.) |

The global plate electrostatic precipitator market is estimated to be valued at USD 8.1 billion in 2025.

The market size for the plate electrostatic precipitator market is projected to reach USD 15.0 billion by 2035.

The plate electrostatic precipitator market is expected to grow at a 6.3% CAGR between 2025 and 2035.

The key product types in plate electrostatic precipitator market are dry and wet.

In terms of emitting industry, power generation segment to command 29.0% share in the plate electrostatic precipitator market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Plate Chain Elevator Market Size and Share Forecast Outlook 2025 to 2035

Platelet Shaker Market Size and Share Forecast Outlook 2025 to 2035

Plate and Frame Heat Exchanger Market Size and Share Forecast Outlook 2025 to 2035

Platelet Concentration Systems Market Size and Share Forecast Outlook 2025 to 2035

Platelet Rich Plasma Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Platelet Function Test Market Report - Growth & Forecast 2025 to 2035

Plate Heat Exchanger Market Growth - Trends & Forecast 2025 to 2035

Plates Market

Tinplate Packaging Market Size and Share Forecast Outlook 2025 to 2035

Hotplate Stirrers Market Size and Share Forecast Outlook 2025 to 2035

Template Preparation Kits Market

Miniplate for Bone Fixation Market Size and Share Forecast Outlook 2025 to 2035

Drawplate Market Size and Share Forecast Outlook 2025 to 2035

PCR Plate Sealer Market Size and Share Forecast Outlook 2025 to 2035

Gold-plated Palladium Bonding Wire Market Size and Share Forecast Outlook 2025 to 2035

Cold Plates Market Size and Share Forecast Outlook 2025 to 2035

Microplate Handling Instruments Market Size and Share Forecast Outlook 2025 to 2035

Core Plate Varnishes Market Size and Share Forecast Outlook 2025 to 2035

Ship Plate Market Size and Share Forecast Outlook 2025 to 2035

Microplate Washer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA