The Core Plate Varnishes Market is estimated to be valued at USD 8.2 billion in 2025 and is projected to reach USD 15.8 billion by 2035, registering a compound annual growth rate (CAGR) of 6.8% over the forecast period.

| Metric | Value |

|---|---|

| Core Plate Varnishes Market Estimated Value in (2025 E) | USD 8.2 billion |

| Core Plate Varnishes Market Forecast Value in (2035 F) | USD 15.8 billion |

| Forecast CAGR (2025 to 2035) | 6.8% |

The Core Plate Varnishes market is experiencing notable expansion as demand grows for efficient insulation materials in electrical equipment manufacturing. Core plate varnishes are being widely adopted to enhance dielectric strength, protect against corrosion, and ensure long-term durability of electrical steel laminations used in transformers, motors, and generators. The rising focus on energy efficiency and performance reliability in power distribution systems is reinforcing the need for high-quality varnishes.

Increasing investment in renewable energy infrastructure, smart grids, and industrial automation is further boosting market demand. Chemical advancements that provide superior adhesion, heat resistance, and environmental compliance are shaping product development trends. Additionally, regulatory pressures around volatile organic compounds are encouraging innovation in environmentally friendly formulations.

As electricity consumption continues to grow globally and the replacement rate of aging power infrastructure increases, the market is set to benefit from higher adoption across utilities and industrial applications Continuous research and development efforts aimed at enhancing product performance and sustainability are expected to drive further growth in the coming decade.

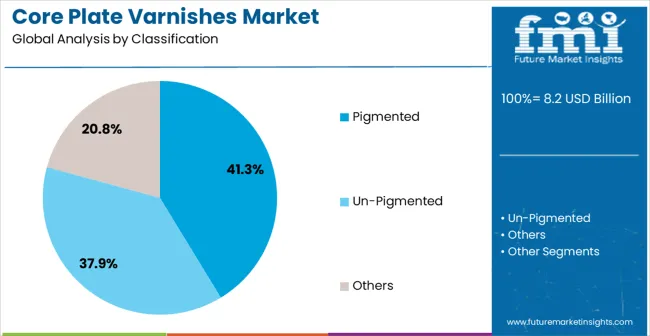

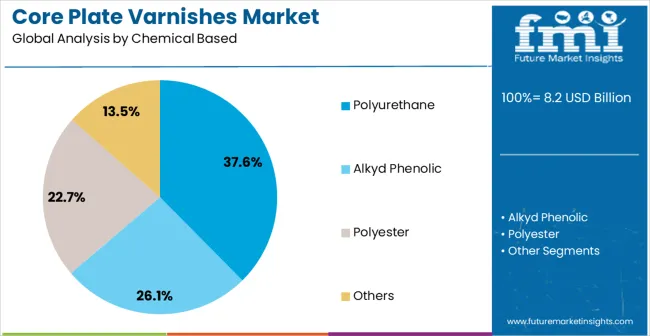

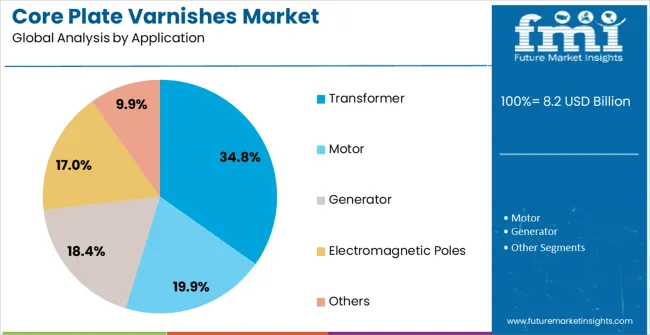

The core plate varnishes market is segmented by classification, chemical based, application, and geographic regions. By classification, core plate varnishes market is divided into Pigmented, Un-Pigmented, and Others. In terms of chemical based, core plate varnishes market is classified into Polyurethane, Alkyd Phenolic, Polyester, and Others. Based on application, core plate varnishes market is segmented into Transformer, Motor, Generator, Electromagnetic Poles, and Others. Regionally, the core plate varnishes industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The pigmented classification segment is projected to hold 41.3% of the market revenue in 2025, making it the leading classification type. This dominance is being reinforced by the segment’s ability to provide superior coverage, visual identification, and improved corrosion resistance compared to clear varnishes. Pigmented varnishes enhance the protective layer on electrical steel laminations, ensuring reliable insulation and reducing the risk of short circuits or performance degradation.

Their widespread adoption in transformer and motor manufacturing reflects the segment’s ability to deliver both functional and aesthetic advantages. Advances in formulation technologies have further improved the adhesion, heat stability, and chemical resistance of pigmented varnishes, aligning with evolving performance requirements in the electrical industry.

As manufacturers seek reliable and cost-effective solutions that comply with international safety and environmental standards, pigmented varnishes are expected to maintain their leadership Their proven ability to extend equipment lifespan while supporting operational efficiency positions them as a critical driver of growth in the Core Plate Varnishes market.

The polyurethane chemical based segment is anticipated to account for 37.6% of the market revenue in 2025, establishing it as the leading chemical type. Polyurethane varnishes are being widely chosen due to their excellent flexibility, abrasion resistance, and chemical stability, which are essential for insulating electrical steel laminations under high thermal and mechanical stress. Their ability to provide strong adhesion and superior dielectric properties ensures reliable performance in demanding applications such as high-voltage transformers and industrial motors.

Polyurethane-based varnishes also exhibit resistance to moisture and environmental factors, making them suitable for varied operating conditions. Advances in formulation have enabled the development of low-VOC and eco-friendly polyurethane products, aligning with global sustainability goals and regulatory compliance requirements.

The versatility of polyurethane, combined with its proven performance advantages, has reinforced its widespread use across electrical equipment manufacturing As industries increasingly demand long-lasting and efficient insulation materials, polyurethane varnishes are expected to sustain their leadership in the market.

The transformer application segment is projected to hold 34.8% of the market revenue in 2025, positioning it as the largest application area. Growth in this segment is being driven by the rising global demand for reliable power transmission and distribution infrastructure. Core plate varnishes are critical in transformer manufacturing, where they prevent inter-laminar short circuits, minimize eddy current losses, and extend operational lifespans.

The increasing deployment of transformers in renewable energy grids, urban power networks, and industrial facilities is reinforcing varnish demand. Furthermore, the ongoing replacement of aging power infrastructure in developed economies and rapid electrification in emerging markets are creating new growth opportunities. Transformer manufacturers are prioritizing varnishes that provide superior thermal endurance and mechanical stability to ensure uninterrupted operation in diverse environments.

Regulatory emphasis on energy efficiency standards is also propelling the adoption of advanced varnishes that reduce energy losses As power consumption continues to rise worldwide, transformers will remain a primary end-use driver, sustaining the segment’s leading role in the Core Plate Varnishes market.

Over the decade, consumption of energy has significantly increased over the globe, owing to various factors such as, increasing rate of habitation in urban and rural sector, commercial workspace, growing industrial establishments, per capita consumption, and many more. Most of the energy is lost during transmission from the generation site to distribution centres. In order to recover this energy and minimization of losses, insulation plays an important role in optimizing the power transmission process.

Core plate varnishes is one of the insulation components to the electrical devices and machines. Manufacturers have developed water borne and heat absorbing varnishes to insulate the electrical steel. Properties present in the core plate varnishes reduce the eddy current losses of the electrical components which enhance the efficiency and life of the components.

These core plate varnishes used to insulate the electrical components such as, motor, generators, transformers, and other electromagnetic poles. The application of core plate varnish in saving the energy is a special technology in which coated laminations of the electrical core are not held together by mechanical or welding connection.

Core plate varnishes applies in two steps, in the first step the electrical components coated with varnishes and keep it for drying in an oven in the second step the insulated components undergoes high temperature and pressure test.

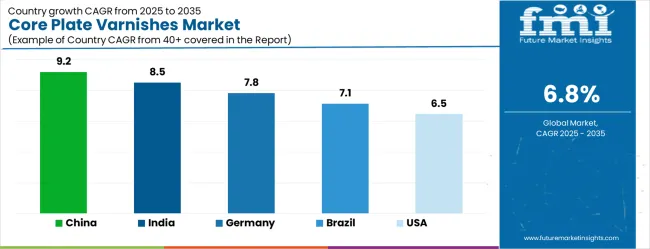

| Country | CAGR |

|---|---|

| China | 9.2% |

| India | 8.5% |

| Germany | 7.8% |

| Brazil | 7.1% |

| USA | 6.5% |

| UK | 5.8% |

| Japan | 5.1% |

The Core Plate Varnishes Market is expected to register a CAGR of 6.8% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.2%, followed by India at 8.5%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.1%, yet still underscores a broadly positive trajectory for the global Core Plate Varnishes Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.8%. The USA Core Plate Varnishes Market is estimated to be valued at USD 3.1 billion in 2025 and is anticipated to reach a valuation of USD 3.1 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 401.1 million and USD 224.7 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 8.2 Billion |

| Classification | Pigmented, Un-Pigmented, and Others |

| Chemical Based | Polyurethane, Alkyd Phenolic, Polyester, and Others |

| Application | Transformer, Motor, Generator, Electromagnetic Poles, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

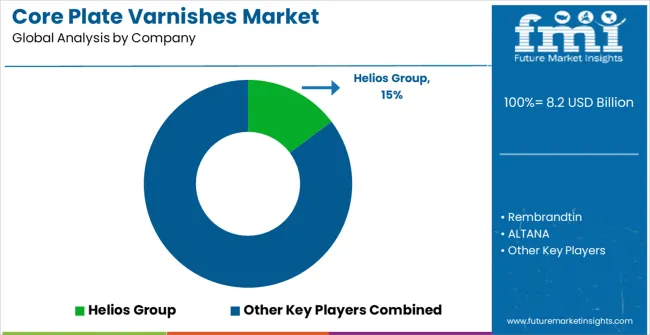

| Key Companies Profiled | Helios Group, Rembrandtin, ALTANA, Toyo Ink, Bakelite Hylam Limited, Axalta, Mader, Super Urecoat Industries, Sichuan Dongfang Insulating Material, AEV Ltd, and Hitachi Chemical Co. Ltd |

The global core plate varnishes market is estimated to be valued at USD 8.2 billion in 2025.

The market size for the core plate varnishes market is projected to reach USD 15.8 billion by 2035.

The core plate varnishes market is expected to grow at a 6.8% CAGR between 2025 and 2035.

The key product types in core plate varnishes market are pigmented, un-pigmented and others.

In terms of chemical based, polyurethane segment to command 37.6% share in the core plate varnishes market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Plate Chain Elevator Market Size and Share Forecast Outlook 2025 to 2035

Platelet Shaker Market Size and Share Forecast Outlook 2025 to 2035

Plate and Frame Heat Exchanger Market Size and Share Forecast Outlook 2025 to 2035

Platelet Concentration Systems Market Size and Share Forecast Outlook 2025 to 2035

Platelet Rich Plasma Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Plate Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Platelet Function Test Market Report - Growth & Forecast 2025 to 2035

Plate Heat Exchanger Market Growth - Trends & Forecast 2025 to 2035

Plates Market

Core Drill Automatic Feeding Machine Market

Core Banking Solution Market Report – Growth & Forecast 2017-2027

Tinplate Packaging Market Size and Share Forecast Outlook 2025 to 2035

Hotplate Stirrers Market Size and Share Forecast Outlook 2025 to 2035

Template Preparation Kits Market

Miniplate for Bone Fixation Market Size and Share Forecast Outlook 2025 to 2035

Woodcore Access Floor Market Size and Share Forecast Outlook 2025 to 2035

Drawplate Market Size and Share Forecast Outlook 2025 to 2035

Air Core Fixed Shunt Reactor Market Size and Share Forecast Outlook 2025 to 2035

Air Core Variable Shunt Reactor Market Size and Share Forecast Outlook 2025 to 2035

PCR Plate Sealer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA