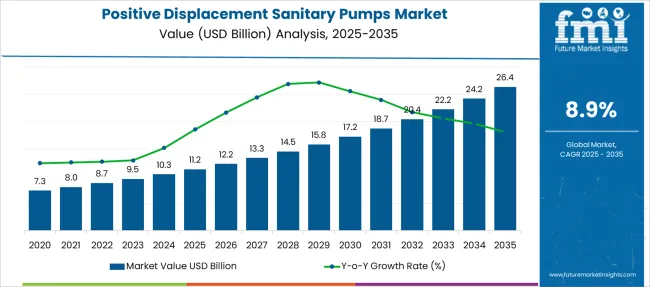

The Positive Displacement Sanitary Pumps Market is estimated to be valued at USD 11.2 billion in 2025 and is projected to reach USD 26.4 billion by 2035, registering a compound annual growth rate (CAGR) of 8.9% over the forecast period.

| Metric | Value |

|---|---|

| Positive Displacement Sanitary Pumps Market Estimated Value in (2025 E) | USD 11.2 billion |

| Positive Displacement Sanitary Pumps Market Forecast Value in (2035 F) | USD 26.4 billion |

| Forecast CAGR (2025 to 2035) | 8.9% |

The positive displacement sanitary pumps market is experiencing steady growth, driven by the expanding demand for hygienic pumping solutions across industries that require strict sanitation standards. Increased focus on food safety and quality in the food and beverage sector has prompted adoption of sanitary pumps that ensure contamination-free processing.

Advances in pump design have improved efficiency, durability, and ease of cleaning, making these pumps more attractive for processing liquids with high viscosity or shear sensitivity. Growing automation and modernization in production facilities have further fueled demand.

Regulatory emphasis on compliance with sanitation standards has accelerated the replacement of older pumps with sanitary-grade equipment. The market outlook is optimistic as the food and beverage industry continues to expand globally, supported by rising consumer demand for processed and packaged products. Segment growth is expected to be driven primarily by the rotary positive displacement sanitary pumps due to their efficiency and reliability, and the food and beverage sector as the leading end-use market.

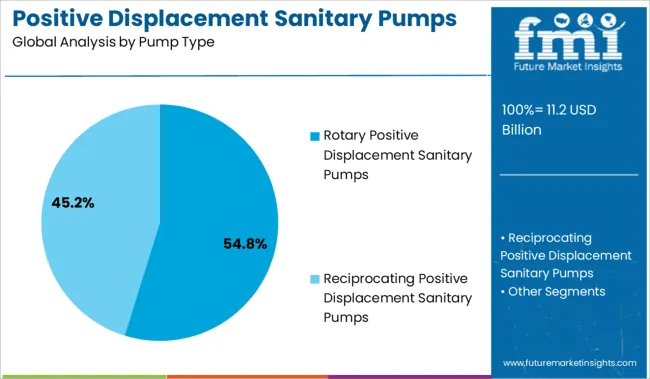

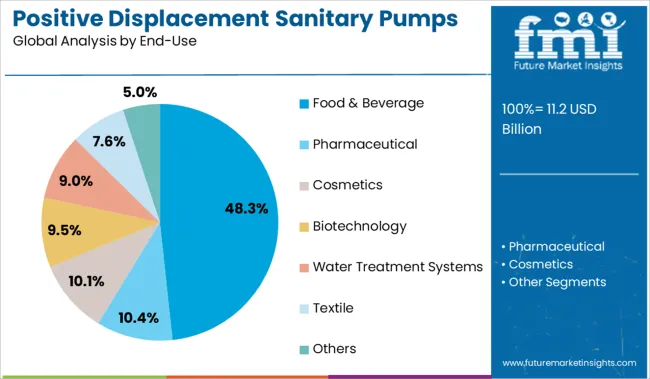

The market is segmented by Pump Type and End-Use and region. By Pump Type, the market is divided into Rotary Positive Displacement Sanitary Pumps and Reciprocating Positive Displacement Sanitary Pumps. In terms of End-Use, the market is classified into Food & Beverage, Pharmaceutical, Cosmetics, Biotechnology, Water Treatment Systems, Textile, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The rotary positive displacement sanitary pumps segment is projected to account for 54.8% of the market revenue in 2025, holding its position as the dominant pump type. This segment’s growth is largely due to the pumps’ ability to handle viscous fluids gently and efficiently while maintaining sanitary conditions.

The rotary mechanism allows for consistent flow rates regardless of pressure changes, which is essential in food and beverage processing. Additionally, these pumps are valued for their compact design and ease of maintenance.

The increasing complexity of processing techniques in the food industry has elevated the importance of reliable sanitary pumps, making the rotary type a preferred choice. Their adaptability to various fluids such as dairy, sauces, and beverages contributes to their market leadership.

The food and beverage segment is expected to represent 48.3% of the positive displacement sanitary pumps market revenue in 2025, maintaining its leading position as the primary end-use industry. Growth in this segment has been propelled by the expanding global demand for processed foods, dairy products, and beverages that require hygienic and precise fluid handling.

Food safety regulations and industry standards have mandated the use of pumps that prevent contamination and support easy cleaning and sanitation. The rise of automation and high-volume production lines has increased the need for pumps that provide consistent flow without compromising product quality.

Additionally, the variety of products processed in this sector, ranging from viscous sauces to delicate liquids, necessitates versatile pump technologies like rotary positive displacement sanitary pumps. This end-use segment is expected to continue driving market growth as the food and beverage industry evolves.

As per the Positive Displacement Sanitary Pumps Market research by Future Market Insights - a market research and competitive intelligence provider, historically, from 2020 to 2024, the market value of the Positive Displacement Sanitary Pumps Market increased at around 9.5% CAGR.

The changing lifestyles and swelled disposable income have increased demand for pre-packaged consumables, which has boosted the food and beverage industry. This has subsequently raised the need for sanitary pumps in the industry. Depending on the viscosity, fat content, and weight of the components, several types of pumps are used in the food and beverage industry to distribute products such as oils, liquids, smoothies, sauces, and dough.

The ability to move products around while they are being processed is required by the majority of medium and large-scale food and beverage industries. Furthermore, these pumps have become an unavoidable requirement in pharmaceutical and cosmetic manufacturing facilities. Chemical compounds, syrups, ointments, gels, and liquids are properly stored and packed using only entirely sterile sanitary pumps and piping systems, saving time and preventing any type of chemical reaction induced by air pollutants.

Also, growing consumer awareness of food safety and medicine use has compelled key positive displacement sanitary pump manufacturers, notably in Europe and America, to adhere to sanitary and safety standards.

The key factor driving demand for positive displacement sanitary pumps is increased awareness of industries about the serious consequences of failing to adopt safety and sanitation measures during critical stages of food handling. This has also resulted in a greater emphasis on strict sanitary regulations in the food and beverage business.

In a range of operations, the key players in the pharmaceutical sector follow these severe sanitary regulations. In recent years, the regulatory framework that governs sanitary practices across the industry has become increasingly broad and strict in order to address safety and sanitation issues in a variety of sectors, including supply chain and fluid handling.

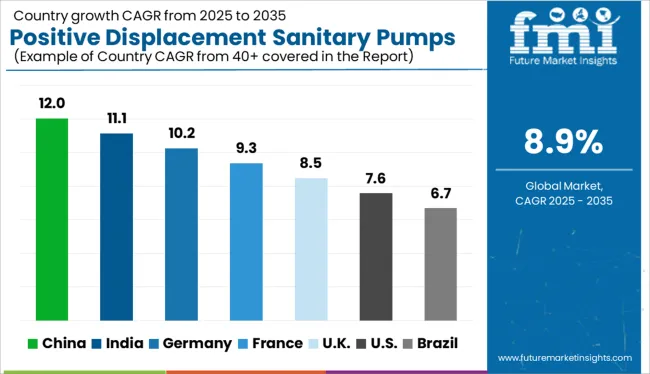

The growing trend of urbanization in the manufacturing and industrial sectors, particularly in emerging economies such as China and India is predicted to drive the demand for positive displacement sanitary pumps.

Furthermore, the growing adoption of intelligent or smart pump systems in the industrial sector, owing primarily to the growing demand for real-time feedback on tracking the location of a bug in the system or overall system performance, is expected to drive overall demand for the global market for positive displacement sanitary pumps.

Asia Pacific is the most lucrative region with the highest projected growth. APAC will account for over half of market growth. Due to their capacity to handle a wide range of fluids, positive displacement sanitary pumps are frequently used for hygienic applications in the food and beverage and pharmaceutical industries. New positive displacement sanitary pumps, including twin-screw pumps, are also helping the industry flourish.

Governments across Asia-Pacific have enacted stringent legislation and regulations to govern wastewater treatment in urban and industrial areas. To address water shortage issues, operators must construct water treatment systems in their facilities. As a consequence, the positive displacement pump market is expected to benefit significantly from sewage treatment in the near future.

The market in China is expected to account for the highest market share of USD 26.4 Billion by the end of 2035. The wide use of Positive Displacement Sanitary Pumps in water and wastewater treatment facilities is the key driver of market expansion. The region's oil and gas exploration facilities are expected to be updated and modernized, which would improve the market.

Furthermore, mounting worries about water scarcity have encouraged Chinese governments to promote wastewater treatment and recycling. These pumps allow faster installation with better and more effective results while significantly decreasing carbon footprints, which is boosting market expansion.

CIRCOR International had built a new manufacturing facility in Weihai, China. CIRCOR designs flow and motion control devices for the most demanding and mission-critical applications worldwide, including valves, sensors, actuation, pumps, motors, and regulators.

Once operational, the new facility will enable CIRCOR to offer its Asian clients a larger choice of flow control solutions. CIRCOR Weihai currently produces centrifugal and three-screw positive displacement pumps for the industrial and commercial maritime industries.

Rotary segment is forecasted to grow at the highest CAGR of over 8.2% during 2025-2035. The implementation of contemporary agricultural technology to increase total factor productivity in order to fulfil expanding agricultural commodity demand is expected to benefit the sales of rotary pump.

Rising standards and discretionary spending, as well as process manufacturing, are projected to fuel the rotary pumps demand.

Increased smart manufacturing facilities with pumps networked to the cloud are expected to provide important information such as machine condition and history, which will be the rotary pump industry's future.

When compared to traditional positive displacement (PDP) pumps, the rotary lobe pump has extremely high efficiency. As a consequence, energy usage is greatly reduced. Given that energy bills make up a considerable portion of life cycle costs, this is a significant gain.

The substantial adaptability of a wide range of pumped media can assist in reducing expenses even further: The rotating lobe pump can be used for a variety of manufacturing operations in various circumstances. As a result, spare component storage costs are decreased, as are training costs.

The Food & Beverage segment is forecasted to grow at the highest CAGR of over 9% during 2025-2035. Selecting the correct sanitary positive displacement pump is crucial in today's food and beverage processing environment for enhancing operational efficiency and product consistency while minimizing waste and downtime.

Food makers may now choose from a number of PD pump technologies. They may accomplish a broad variety of performance capacities, pressures, and viscosities when utilized together. However, not all PD pumps are the same. In addition, not every pump is suitable for every application.

The two most common technologies for sanitary PD applications are rotary lobe and circumferential piston pumps. They are nearly similar, and depending on the manufacturer, these two pumps can be built with identical components such as shafts and housings.

Positive displacement twin screw pumps are being utilized more often in food and beverage applications. The two-spindle configuration causes the product to move axially.

Reduced pulsation in this pump minimizes pump wear and enhances product handling. Twin screw pumps are the costliest of the three varieties of PD pumps.

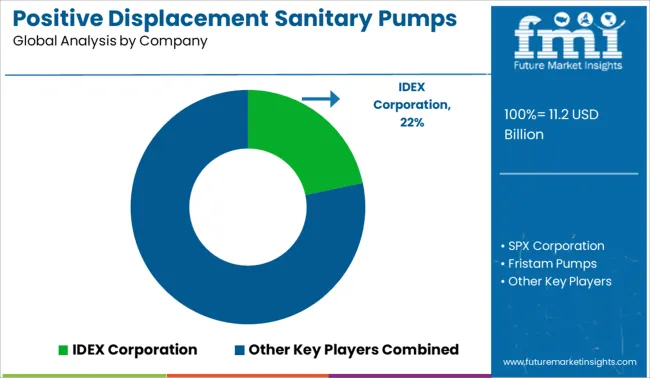

Among the leading players in the global Positive Displacement Sanitary Pumps market are SPX Corporation, Fristam Pumps, IDEX Corporation, Alfa Laval AB, and PSG Dover. To gain a competitive advantage in the industry, these market players are investing in product launches, partnerships, mergers and acquisitions, and expansions.

Due to the growing demand for the product around the world, many new companies are expected to enter the market. This is expected to increase competition on a worldwide scale.

Additionally, market growth is expected to be fueled by collaborations among current players to improve quality throughout the research period. Over the projection period, established market players are expected to diversify their portfolios and offer one-stop solutions to combat fierce competition.

In September 2024, Flotronic Pumps, a UK-based specialist manufacturer of PD sanitary pumps, air driven double diaphragm pumps, and components, has been acquired by Unibloc Pump. The innovative single bolt design of Flotronic Pumps lowers process downtime by simplifying pump assembly and disassembly, resulting in lower running costs and best-in-class air pump performance.

In June 2024, Anderson Process has acquired Premier Pump Inc., a long-standing Cleveland pump distributor and service provider. The acquisition is being made to capitalize on the two firms' complementary product and service capabilities, as well as to support Anderson Process's aim of becoming one of the Midwest's largest and most comprehensive specialized process equipment distributors. Premier Pump Inc.'s purchase will broaden the company's reach and provide assistance in the Eastern Midwest zone.

Similarly, recent developments related to companies in Positive Displacement Sanitary Pumps services have been tracked by the team at Future Market Insights, which are available in the full report.

The global positive displacement sanitary pumps market is estimated to be valued at USD 11.2 billion in 2025.

The market size for the positive displacement sanitary pumps market is projected to reach USD 26.4 billion by 2035.

The positive displacement sanitary pumps market is expected to grow at a 8.9% CAGR between 2025 and 2035.

The key product types in positive displacement sanitary pumps market are rotary positive displacement sanitary pumps, _rotary lobe, _twin screw, _progressive cavity, _eccentric disc, _gear, _sinusoidal, _hose, reciprocating positive displacement sanitary pumps, _piston/plunger and _diaphragm.

In terms of end-use, food & beverage segment to command 48.3% share in the positive displacement sanitary pumps market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Positive Patient Identification Market Size and Share Forecast Outlook 2025 to 2035

Positive Airway Pressure Devices Market Size and Share Forecast Outlook 2025 to 2035

Positive Air Pressure Devices Market Size and Share Forecast Outlook 2025 to 2035

Positive Displacement Blowers Market Size and Share Forecast Outlook 2025 to 2035

Positive Displacement Pumps Market Growth - Trends & Forecast 2025 to 2035

HER2 Positive Gastric Cancer Market Size and Share Forecast Outlook 2025 to 2035

Continuous Positive Airway Pressure (CPAP) Market Analysis – Size, Share & Forecast Outlook 2025 to 2035

OPEP Device Market Analysis – Growth & Forecast 2024-2034

UK Continuous Positive Airway Pressure (CPAP) Market Trends – Growth, Demand & Analysis 2025-2035

BRCA Mutation-Positive Ovarian Cancer Market

NTRK Fusion Gene Positive Advanced Solid Tumors Market Size and Share Forecast Outlook 2025 to 2035

China Continuous Positive Airway Pressure Devices Market Outlook – Share, Growth & Forecast 2025-2035

India Continuous Positive Airway Pressure (CPAP) Market Trends – Size, Share & Growth 2025-2035

Germany Continuous Positive Airway Pressure (CPAP) Market Insights – Size, Trends & Forecast 2025-2035

United States Continuous Positive Airway Pressure (CPAP) Market Report – Trends, Demand & Forecast 2025-2035

Strand Displacement Amplification Market - Growth & Outlook 2025 to 2035

Variable Displacement Compressor Market Size and Share Forecast Outlook 2025 to 2035

Automotive Variable Displacement Pumps Market Size and Share Forecast Outlook 2025 to 2035

Pumps Market Size and Share Forecast Outlook 2025 to 2035

Pumps and Trigger Spray Market Trends - Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA