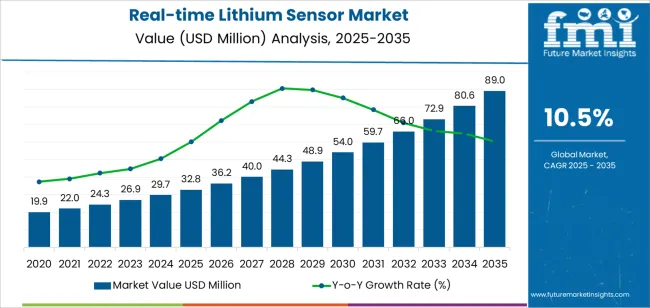

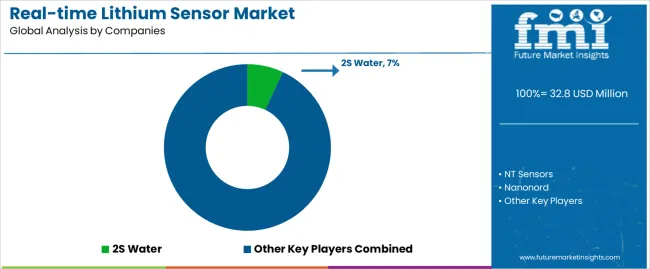

The real-time lithium sensor market is expected to grow from USD 32.8 million in 2025 to USD 88.9 million by 2035, representing robust expansion, demonstrating accelerating adoption of advanced sensing technologies and growing investment in lithium monitoring infrastructure across battery manufacturing, automotive, and industrial applications worldwide.

The real-time lithium sensor market operates within a dynamic landscape characterized by expanding lithium-ion battery production, automotive electrification initiatives, and growing demand for precise lithium concentration monitoring across industrial processes, research applications, and quality control systems. Market dynamics reflect increasing investment in battery technology infrastructure, accelerating adoption of advanced monitoring equipment, and rising demand for real-time sensing solutions that support diverse manufacturing protocols and research methodologies.

Battery manufacturing procurement patterns demonstrate shifting preferences toward integrated monitoring systems that combine concentration accuracy, real-time measurement capabilities, and programmable control features. Automotive manufacturers and battery producers prioritize equipment reliability, measurement precision, and operational flexibility when selecting monitoring solutions for critical applications, including battery cell production, electrolyte analysis, lithium extraction processes, and quality assurance procedures.

The real-time lithium sensor market benefits from expanding electric vehicle production activities across automotive, battery manufacturing, and research sectors, driving demand for sophisticated monitoring equipment that enables precise lithium concentration measurement. Growing emphasis on battery performance optimization and standardization creates opportunities for manufacturers offering validated sensing systems with comprehensive documentation and quality assurance capabilities.

Technology advancement influences market evolution through integration of digital monitoring systems, wireless connectivity capabilities, and enhanced accuracy features that improve manufacturing efficiency and process outcomes. Manufacturers focus on developing sensing solutions that accommodate varying concentration ranges, measurement frequencies, and environmental parameters while maintaining precise lithium detection throughout extended operation periods.

The real-time lithium sensor market demonstrates strong growth fundamentals driven by expanding battery production activities, automotive electrification infrastructure development, and increasing demand for precision lithium monitoring equipment across multiple industrial applications and research disciplines.

The first half of the decade (2025-2030) will witness market growth from USD 32.8 million to approximately USD 48.7 million, adding USD 15.9 million in value, representing 28% of the total forecast period expansion. This phase will be characterized by rapid adoption of wireless monitoring systems, driven by automotive industry modernization programs and increasing demand for programmable sensing solutions across battery production applications.

The latter half (2030-2035) will experience accelerated growth from USD 48.7 million to USD 88.9 million, representing an addition of USD 40.2 million or 72% of the decade's expansion. This period will be defined by mass market penetration of advanced lithium sensing technologies, integration with manufacturing execution systems, and seamless connectivity with existing production infrastructure.

| Period | Primary Revenue Buckets | Share | Notes |

|---|---|---|---|

| Today | External sensors (industrial, automotive) | 62% | Traditional configurations, established facilities |

| Built-in monitoring systems | 31% | Integrated installations, battery production | |

| Custom & specialized systems | 7% | Premium installations, research applications | |

| Future (3-5 yrs) | Advanced external systems | 58-61% | Enhanced precision, wireless connectivity |

| High-accuracy built-in systems | 33-36% | Battery production lines, automotive facilities | |

| Industry applications | 19-23% | Battery manufacturing, lithium processing | |

| Automobile applications | 22-26% | Electric vehicles, charging systems | |

| Scientific research applications | 16-20% | Laboratory analysis, development testing | |

| Water treatment systems | 12-16% | Industrial processing, environmental monitoring | |

| Other specialized applications | 8-12% | Custom research, industrial testing |

| Metric | Value |

|---|---|

| Market Value (2025) | USD 32.8 million |

| Market Forecast (2035) | USD 88.9 million |

| Growth Rate | 10.5% CAGR |

| Leading Type | External Sensor |

| Primary Application | Industry Segment |

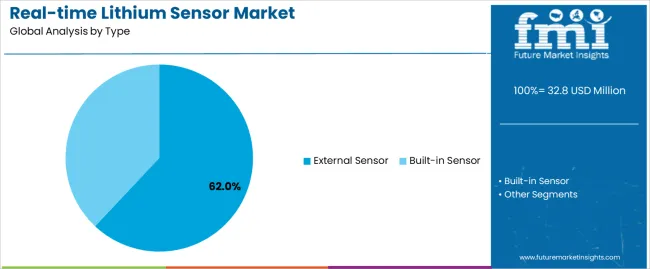

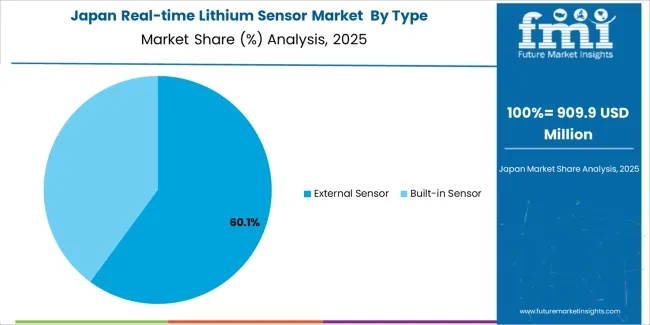

Primary Classification: The market segments by type into external and built-in systems, representing evolution from traditional measurement to sophisticated real-time lithium sensing technologies for comprehensive industrial monitoring optimization.

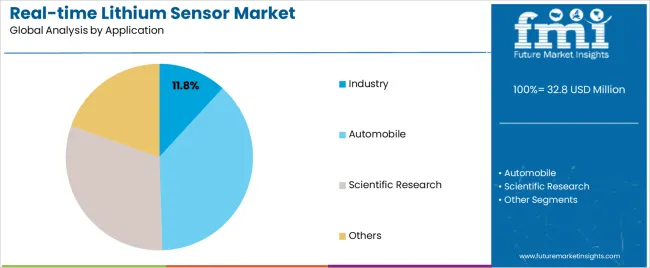

Secondary Classification: Application segmentation divides the real-time lithium sensor market into industry, automobile, scientific research, and others, reflecting distinct requirements for concentration ranges, measurement accuracy, and monitoring protocol specifications.

Tertiary Classification: End-use segmentation covers battery manufacturers, automotive companies, research institutions, water treatment facilities, and quality control laboratories, while distribution channels span direct sales, industrial equipment distributors, and specialized sensor suppliers.

Regional Classification: Geographic distribution covers North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia Pacific, and Middle East & Africa, with developed markets leading adoption while emerging economies show accelerating growth patterns driven by manufacturing infrastructure development programs.

The segmentation structure reveals technology progression from traditional lithium measurement toward sophisticated real-time sensing systems with enhanced precision capabilities, while application diversity spans from basic monitoring to specialized analytical procedures requiring precise concentration detection solutions.

Market Position: External sensor systems command the leading position in the real-time lithium sensor market with 62% market share through proven measurement technologies, including efficient detection mechanisms, reliable sensing capabilities, and industrial performance optimization that enable manufacturing operators to achieve optimal concentration monitoring across diverse production and quality control environments.

Value Drivers: The segment benefits from manufacturing facility preference for flexible monitoring systems that provide consistent lithium detection, operational reliability, and process flexibility without requiring extensive system integration. Advanced external sensing features enable enhanced measurement accuracy, precise concentration control, and integration with existing monitoring systems, where detection precision and process reliability represent critical operational requirements.

Competitive Advantages: External sensor systems differentiate through proven operational reliability, flexible installation characteristics, and integration with established manufacturing management systems that enhance production effectiveness while maintaining optimal measurement standards suitable for diverse industrial applications.

Key market characteristics:

Built-in sensor systems maintain a 31% market position in the real-time lithium sensor market due to their integrated configuration advantages and seamless operation benefits. These systems appeal to facilities requiring embedded monitoring solutions with enhanced automation profiles for continuous production operations. Market growth is driven by battery manufacturing expansion, emphasizing integrated sensing solutions and operational excellence through optimized process control designs.

Market Context: Industry applications demonstrate strong growth in the real-time lithium sensor market with 11.8% CAGR due to widespread adoption of battery manufacturing technologies and increasing focus on lithium processing operations, extraction optimization, and industrial applications that maximize production effectiveness while maintaining concentration accuracy standards.

Appeal Factors: Industrial operators prioritize system reliability, measurement precision, and integration with existing manufacturing infrastructure that enables coordinated monitoring procedures across multiple production protocols. The segment benefits from substantial battery manufacturing investment and automotive electrification programs that emphasize acquisition of advanced sensing systems for lithium concentration optimization and industrial processing applications.

Growth Drivers: Battery manufacturing programs incorporate lithium sensors as essential components for production operations, while automotive development increases demand for monitoring capabilities that comply with quality standards and minimize process variability.

Market Challenges: Varying production protocols and concentration complexity may limit system standardization across different manufacturing facilities or process scenarios.

Application dynamics include:

Automobile applications capture 26% market share through electric vehicle requirements in automotive manufacturing, battery integration facilities, and vehicle testing applications. These facilities demand high-performance sensing systems capable of supporting automotive protocols while providing concentration precision and operational reliability capabilities.

Scientific research applications account for 18% market share, including development laboratories, battery research facilities, and academic operations requiring precise sensing capabilities for lithium analysis and research optimization.

Market Context: Battery Manufacturers dominate the real-time lithium sensor market with 10.8% CAGR, reflecting the primary demand source for real-time lithium sensor technology in production optimization and quality control.

Business Model Advantages: Battery Manufacturers provide direct market demand for standardized sensing systems, driving volume production and cost optimization while maintaining precision control and performance consistency requirements.

Operational Benefits: Battery Manufacturer applications include production optimization, manufacturing efficiency, and quality assurance that drive consistent demand for sensing systems while providing access to the latest lithium monitoring technologies.

| Category | Factor | Impact | Why It Matters |

|---|---|---|---|

| Driver | Electric vehicle expansion & battery manufacturing growth (automotive electrification, production scaling) | ★★★★★ | Growing battery market requires advanced sensing systems with enhanced lithium detection capabilities and precision properties proven effective across manufacturing applications. |

| Driver | Industrial automation & lithium processing advancement (extraction optimization, quality control) | ★★★★★ | Transforms monitoring requirements from "basic detection" to "precision real-time sensing"; operators that offer advanced sensing systems and monitoring features gain competitive advantage. |

| Driver | Manufacturing digitization & process optimization (data integration, automated monitoring) | ★★★★☆ | Modern production facilities need sophisticated, connected sensing systems; demand for automated and integrated monitoring solutions expanding addressable market. |

| Restraint | High sensor cost & budget constraints (especially for smaller manufacturers) | ★★★★☆ | Smaller production facilities defer sensing system upgrades; increases price sensitivity and slows advanced equipment adoption in cost-conscious markets. |

| Restraint | Alternative monitoring technology competition (traditional sensors, laboratory analysis) | ★★★☆☆ | Conventional monitoring alternatives offer established supply chains and lower costs, potentially limiting real-time sensor adoption in traditional applications. |

| Trend | Wireless connectivity integration & data analytics enhancement (IoT monitoring, cloud systems) | ★★★★★ | Advanced connectivity properties, precision optimization, and data analytics transform operations; technology integration and performance enhancement become core value propositions. |

| Trend | Manufacturing integration & automated monitoring (MES connectivity, process control) | ★★★★☆ | Smart sensing systems for specific applications and protocols; specialized monitoring and targeted optimization capabilities drive competition toward integrated solutions. |

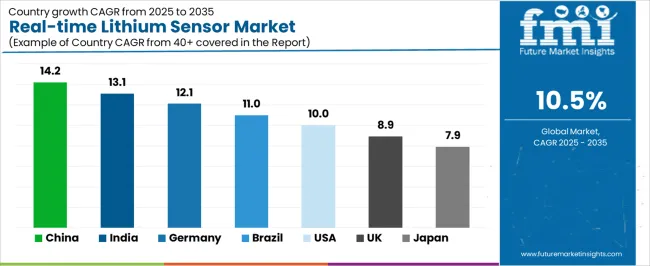

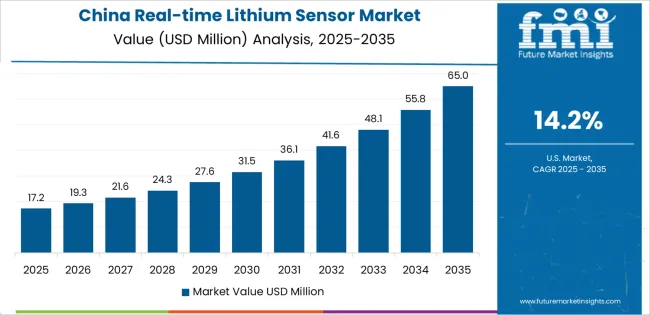

The real-time lithium sensor market demonstrates varied regional dynamics with Growth Leaders including China (14.2% growth rate) and India (13.1% growth rate) driving expansion through battery manufacturing infrastructure development and automotive electrification initiatives. Steady Performers encompass Germany (12.1% growth rate), Brazil (11.0% growth rate), and developed regions, benefiting from established automotive facilities and battery technology sector growth. Mature Markets feature United States (10.0% growth rate), United Kingdom (8.9% growth rate), and Japan (7.9% growth rate), where manufacturing advancement and production optimization requirements support consistent growth patterns.

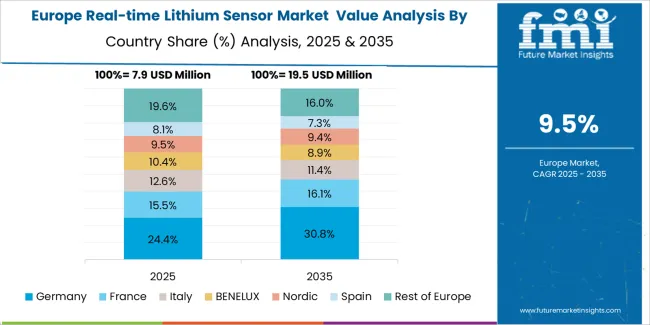

Regional synthesis reveals East Asian markets leading adoption through battery production expansion and automotive development, while North American countries maintain steady expansion supported by electric vehicle advancement and manufacturing infrastructure investment. European markets show strong growth driven by automotive applications and manufacturing integration trends.

| Region/Country | 2025-2035 Growth | How to win | What to watch out |

|---|---|---|---|

| China | 14.2% | Focus on cost-effective production solutions | Regulatory changes; local competition |

| India | 13.1% | Lead with precision monitoring systems | Import restrictions; infrastructure barriers |

| Germany | 12.1% | Provide premium automotive systems | Over-regulation; lengthy approvals |

| Brazil | 11.0% | Offer value-oriented solutions | Currency fluctuations; import duties |

| United States | 10.0% | Push technology integration | Compliance costs; scaling challenges |

| United Kingdom | 8.9% | Focus on automotive applications | Economic impacts; funding constraints |

| Japan | 7.9% | Emphasize precision manufacturing | Traditional preferences; adoption rates |

China establishes fastest market growth through aggressive battery manufacturing infrastructure development programs and comprehensive automotive electrification expansion, integrating advanced lithium sensor systems as standard components in battery production facilities and automotive manufacturing plants. The country's 14.2% growth rate reflects government initiatives promoting electric vehicle development and domestic battery manufacturing capabilities that mandate use of precision sensing systems in lithium processing and battery production facilities. Growth concentrates in major manufacturing hubs, including Shenzhen, Shanghai, and Beijing, where production development showcases integrated monitoring systems that appeal to manufacturing operators seeking concentration precision capabilities and industrial applications.

Chinese manufacturers are developing cost-effective sensing solutions that combine domestic production advantages with advanced lithium detection features, including enhanced measurement accuracy and improved performance capabilities. Distribution channels through industrial equipment suppliers and manufacturing facility integrators expand market access, while government support for electric vehicle development supports adoption across diverse automotive and battery segments.

Strategic Market Indicators:

In Mumbai, Delhi, and Bangalore, battery facilities and automotive operators are implementing real-time lithium sensor systems as standard equipment for production optimization and manufacturing efficiency applications, driven by increasing government automotive investment and battery development programs that emphasize importance of precision monitoring capabilities. The real-time lithium sensor market holds a 13.1% growth rate, supported by government manufacturing initiatives and automotive modernization programs that promote advanced sensing systems for battery and automotive facilities. Indian operators are adopting sensing systems that provide consistent lithium detection and performance features, particularly appealing in urban regions where production optimization and manufacturing excellence represent critical industrial requirements.

Market expansion benefits from growing battery manufacturing capabilities and international technology partnerships that enable domestic production of advanced sensing systems for automotive and battery applications. Technology adoption follows patterns established in industrial equipment, where precision and performance drive procurement decisions and operational deployment.

Market Intelligence Brief:

Germany's advanced automotive market demonstrates sophisticated lithium sensor deployment with documented precision effectiveness in battery applications and automotive facilities through integration with existing manufacturing systems and production infrastructure. The country leverages engineering expertise in automotive technologies and precision systems integration to maintain a 12.1% growth rate. Manufacturing centers, including Bavaria, Baden-Württemberg, and North Rhine-Westphalia, showcase premium installations where sensing systems integrate with comprehensive production platforms and facility management systems to optimize manufacturing efficiency and process effectiveness.

German manufacturers prioritize system quality and EU compliance in automotive development, creating demand for premium systems with advanced features, including facility integration and data management systems. The real-time lithium sensor market benefits from established automotive infrastructure and willingness to invest in advanced manufacturing technologies that provide long-term operational benefits and compliance with international automotive standards.

Market Intelligence Brief:

Brazil's market expansion benefits from diverse automotive demand, including battery manufacturing modernization in São Paulo and Rio de Janeiro, industrial facility upgrades, and government automotive programs that increasingly incorporate precision sensing solutions for production applications. The country maintains a 11.0% growth rate, driven by rising manufacturing activity and increasing recognition of lithium monitoring benefits, including accurate concentration control and enhanced production effectiveness.

Market dynamics focus on cost-effective sensing solutions that balance precision performance with affordability considerations important to Brazilian manufacturing operators. Growing automotive industrialization creates continued demand for modern sensing systems in new production infrastructure and facility modernization projects.

Strategic Market Considerations:

United States establishes market leadership through comprehensive automotive programs and advanced battery manufacturing infrastructure development, integrating lithium sensor systems across electric vehicle and battery applications. The country's 10.0% growth rate reflects established manufacturing relationships and mature industrial technology adoption that supports widespread use of precision sensing systems in automotive and battery facilities. Growth concentrates in major manufacturing centers, including California, Michigan, and Texas, where automotive technology showcases mature deployment that appeals to manufacturing operators seeking proven precision capabilities and production optimization applications.

American manufacturing providers leverage established distribution networks and comprehensive technical support capabilities, including system design programs and training support that create customer relationships and operational advantages. The real-time lithium sensor market benefits from mature regulatory standards and manufacturing requirements that mandate sensing system use while supporting technology advancement and production optimization.

Market Intelligence Brief:

United Kingdom's automotive market demonstrates integrated lithium sensor deployment with documented precision effectiveness in battery applications and automotive facilities through integration with existing manufacturing systems and production infrastructure. The country maintains a 8.9% growth rate, supported by manufacturing efficiency programs and production effectiveness requirements that promote precision sensing systems for automotive applications. Manufacturing facilities across England, Scotland, and Wales showcase systematic installations where sensing systems integrate with comprehensive production platforms to optimize precision and manufacturing outcomes.

UK manufacturing providers prioritize system reliability and production compatibility in sensing procurement, creating demand for validated systems with proven precision features, including performance monitoring integration and data management systems. The real-time lithium sensor market benefits from established automotive infrastructure and quality requirements that support manufacturing technology adoption and production effectiveness.

Market Intelligence Brief:

Japan's market growth benefits from precision automotive demand, including advanced battery manufacturing facilities in Tokyo and Osaka, quality integration, and precision enhancement programs that increasingly incorporate sensing solutions for production applications. The country maintains a 7.9% growth rate, driven by manufacturing technology advancement and increasing recognition of precision sensing benefits, including accurate lithium detection and enhanced production outcomes.

Market dynamics focus on high-precision sensing solutions that meet Japanese quality standards and precision effectiveness requirements important to manufacturing operators. Advanced automotive technology adoption creates continued demand for sophisticated sensing systems in production facility infrastructure and manufacturing modernization projects.

Strategic Market Considerations:

The European real-time lithium sensor market is projected to grow from USD 6.8 million in 2025 to USD 17.2 million by 2035, registering a CAGR of 9.7% over the forecast period. Germany is expected to maintain its leadership position with a 41.8% market share in 2025, supported by its advanced automotive infrastructure and major battery manufacturing centers.

United Kingdom follows with a 26.5% share in 2025, driven by comprehensive manufacturing programs and automotive development initiatives. France holds a 17.3% share through specialized automotive applications and battery compliance requirements. Italy commands a 9.1% share, while Spain accounts for 5.3% in 2025. The rest of Europe region is anticipated to gain momentum, expanding its collective share from 2.4% to 2.7% by 2035, attributed to increasing automotive adoption in Nordic countries and emerging battery facilities implementing manufacturing modernization programs.

| Stakeholder | What they actually control | Typical strengths | Typical blind spots |

|---|---|---|---|

| Global brands | Distribution reach, broad product catalogs, brand recognition | Wide availability, proven precision, multi-region support | Product refresh cycles; customer dependency on brand validation |

| Technology innovators | Sensing R&D; advanced measurement technologies; enhanced performance properties | Latest technologies first; attractive ROI on precision effectiveness | Service density outside core regions; scaling complexity |

| Regional specialists | Local compliance, fast delivery, nearby customer support | "Close to customer" support; pragmatic pricing; local regulations | Technology gaps; talent retention in customer service |

| Full-service providers | Complete manufacturing programs, system integration, performance monitoring | Lowest operational risk; comprehensive support | Service costs if overpromised; technology obsolescence |

| Niche specialists | Specialized applications, custom systems, research services | Win premium applications; flexible configurations | Scalability limitations; narrow market focus |

| Item | Value |

|---|---|

| Quantitative Units | USD 32.8 million |

| Type | External Sensor, Built-in Sensor |

| Application | Industry, Automobile, Scientific Research, Others |

| End Use | Battery Manufacturers, Automotive Companies, Research Institutions, Water Treatment Facilities, Quality Control Laboratories |

| Regions Covered | North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia Pacific, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, Canada, France, Australia, and 25+ additional countries |

| Key Companies Profiled | 2S Water, NT Sensors, Nanonord, Element3, RIKEN KEIKI, Advanced Sensors, Lithium Analytics, Precision Monitoring Systems, Industrial Sensor Technologies |

| Additional Attributes | Dollar sales by type and application categories, regional adoption trends across East Asia, North America, and Western Europe, competitive landscape with sensor manufacturers and system integrators, manufacturing operator preferences for measurement effectiveness and precision control, integration with production platforms and data management systems, innovations in sensing technology and measurement enhancement, and development of advanced monitoring solutions with enhanced performance and production optimization capabilities. |

The global real-time lithium sensor market is estimated to be valued at USD 32.8 million in 2025.

The market size for the real-time lithium sensor market is projected to reach USD 89.0 million by 2035.

The real-time lithium sensor market is expected to grow at a 10.5% CAGR between 2025 and 2035.

The key product types in real-time lithium sensor market are external sensor and built-in sensor.

In terms of application, industry segment to command 11.8% share in the real-time lithium sensor market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Lithium Compound Market Forecast Outlook 2025 to 2035

Lithium Silicon Battery Market Size and Share Forecast Outlook 2025 to 2035

Lithium Mining Market Size and Share Forecast Outlook 2025 to 2035

Lithium & Lithium-ion Battery Electrolyte Market Size and Share Forecast Outlook 2025 to 2035

Lithium Battery Shear Wrenches Market Size and Share Forecast Outlook 2025 to 2035

Lithium Hydroxide Market Size and Share Forecast Outlook 2025 to 2035

Lithium-sulfur Solid-state Batteries Market Size and Share Forecast Outlook 2025 to 2035

Lithium Extraction From Brine Technology Market Size and Share Forecast Outlook 2025 to 2035

Lithium Cobalt Oxide Market Size and Share Forecast Outlook 2025 to 2035

Lithium Iron Phosphate Market Size and Share Forecast Outlook 2025 to 2035

Lithium Iron Phosphate (LIP) Battery Market Size and Share Forecast Outlook 2025 to 2035

Lithium-Ion Battery Market Size and Share Forecast Outlook 2025 to 2035

Lithium ion Stationary Battery Storage Market Size and Share Forecast Outlook 2025 to 2035

Lithium and Lithium Ion Battery Electrolyte Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Lithium Ion Residential Solar Energy Storage Market Size and Share Forecast Outlook 2025 to 2035

Lithium Ion Battery Separator Market Growth & Trends 2025 to 2035

Lithium Ion Battery Dispersant Market Growth – Trends & Forecast 2024-2034

Lithium Ion Battery Material Market Growth – Trends & Forecast 2024-2034

Lithium Iodide Market

Lithium Bromide Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA