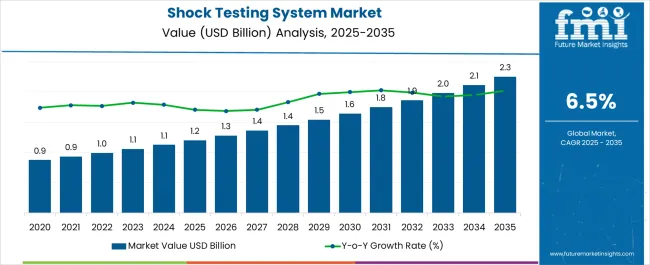

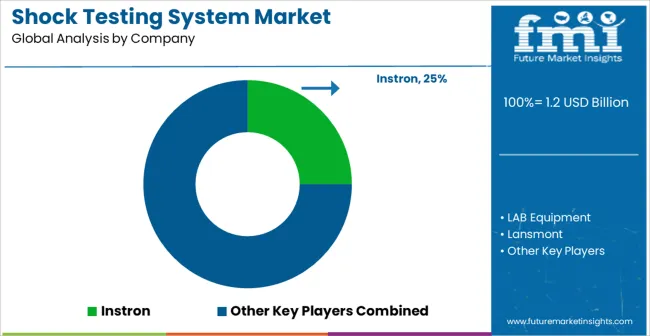

The Shock Testing System Market is estimated to be valued at USD 1.2 billion in 2025 and is projected to reach USD 2.3 billion by 2035, registering a compound annual growth rate (CAGR) of 6.5% over the forecast period.

| Metric | Value |

|---|---|

| Shock Testing System Market Estimated Value in (2025 E) | USD 1.2 billion |

| Shock Testing System Market Forecast Value in (2035 F) | USD 2.3 billion |

| Forecast CAGR (2025 to 2035) | 6.5% |

The Shock Testing System market is experiencing robust expansion, supported by the growing need for product reliability validation across multiple industrial sectors. These systems are widely utilized to simulate real-world impact conditions and ensure that critical equipment and components can withstand sudden forces. The market’s current growth is being influenced by rising demand for high-performance testing in manufacturing, defense, aerospace, automotive, and electronics industries.

Increasing emphasis on product quality standards and safety certifications has further enhanced the adoption of advanced shock testing systems. The ability of these systems to detect material weaknesses and improve product durability has encouraged large-scale investments, especially as industries adopt automation and digitalized testing environments.

Future outlook for the market is favorable, as the integration of smart sensors and software-based monitoring platforms is expected to enable real-time data analysis and predictive maintenance capabilities Growing investment in advanced testing laboratories and the rising importance of lifecycle management across industries are also likely to pave the way for consistent demand over the next decade.

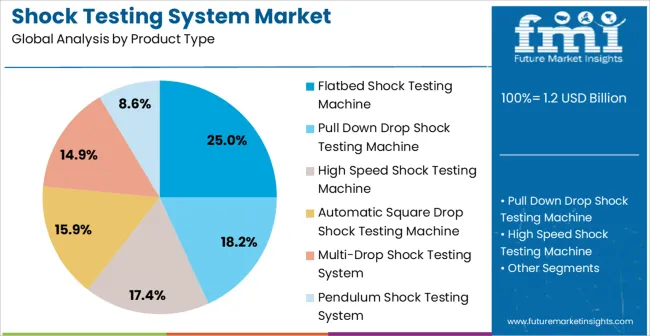

The shock testing system market is segmented by product type, tests, end use, and geographic regions. By product type, shock testing system market is divided into Flatbed Shock Testing Machine, Pull Down Drop Shock Testing Machine, High Speed Shock Testing Machine, Automatic Square Drop Shock Testing Machine, Multi-Drop Shock Testing System, and Pendulum Shock Testing System.

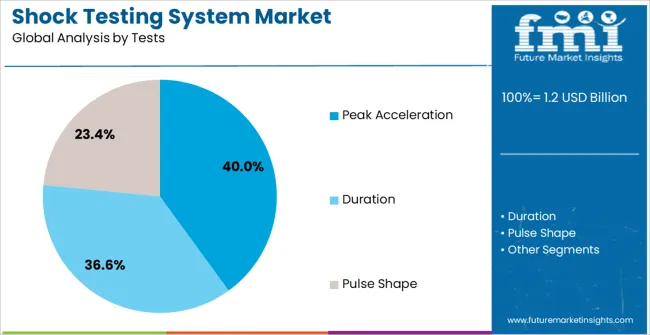

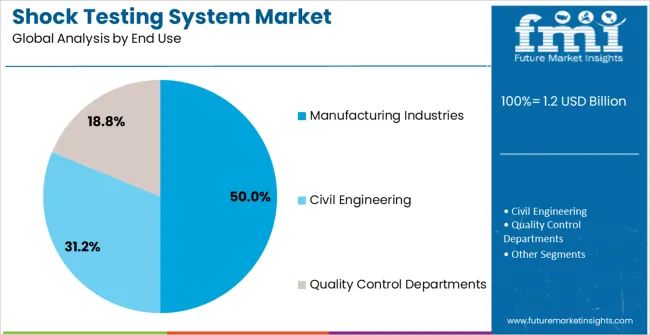

In terms of tests, shock testing system market is classified into Peak Acceleration, Duration, and Pulse Shape. Based on end use, shock testing system market is segmented into Manufacturing Industries, Civil Engineering, and Quality Control Departments.

Regionally, the shock testing system industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Flatbed Shock Testing Machine segment is anticipated to hold 25.00% of the overall Shock Testing System market revenue in 2025, making it the leading product type. This dominance has been attributed to its ability to provide a controlled and repeatable environment for high-intensity impact tests across a broad range of products. Flatbed machines are preferred in industries where large and heavy equipment needs to be tested, as they offer greater surface area and stability for mounting different components.

The growth of this segment has been supported by the increasing focus on heavy machinery and defense-grade equipment testing, where precision and accuracy are paramount. Additionally, the adaptability of flatbed systems to accommodate varied test parameters through software integration has enhanced their relevance in modern testing environments.

Their ability to replicate real-world transportation and operational shocks has further cemented their utility in ensuring compliance with global safety and performance standards As industries place growing emphasis on durability and reliability, the flatbed segment is expected to maintain its market leadership.

The Peak Acceleration segment is projected to command 40.00% of the overall Shock Testing System market revenue in 2025, making it the largest application category. This leadership position has been driven by the increasing requirement to evaluate how products behave under extreme acceleration conditions that simulate sudden impact events. Peak acceleration testing is crucial for industries such as electronics, aerospace, and automotive, where even minor failures under shock can compromise safety and performance.

The segment’s growth has been supported by rising regulatory demands for performance validation and the need for compliance with international quality standards. The integration of data acquisition systems and high-speed monitoring software has improved accuracy, making peak acceleration testing a critical part of modern testing protocols.

Manufacturers have increasingly relied on this method to identify weaknesses early in the production cycle and to enhance product resilience before market deployment With growing attention to safety certification and operational reliability across industries, this application segment is expected to retain its dominant share.

The Manufacturing Industries end-use segment is anticipated to hold 50.00% of the total Shock Testing System market revenue in 2025, representing the largest consumer base. This prominence has resulted from the extensive need to ensure product durability across sectors including automotive, electronics, heavy machinery, and industrial equipment.

Shock testing has become an integral part of quality assurance programs in manufacturing, where the ability to simulate transportation shocks, operational impacts, and accidental drops ensures adherence to customer and regulatory standards. The segment’s growth has been reinforced by increasing adoption of advanced testing laboratories within manufacturing plants, enabling real-time evaluation and faster product validation cycles.

Additionally, the drive toward reducing warranty claims and product recalls has encouraged manufacturers to integrate shock testing systems as a standard practice in their production lines With the expansion of global manufacturing and rising investments in industrial automation, demand for shock testing systems in this sector is expected to remain strong, ensuring the segment’s continued market leadership.

Shock testing systems are used to measure the effect of sudden acceleration triggered by collision, explosion or a drop. They can precisely determine the brittleness of a component. The impact quality or the energy of a shock can be measured by a shock testing system. Shock testing systems are widely used all over the globe to evaluate how a complete system or a component will respond to a particular shock input.

There is a rising need for shock testing systems to prevent damage caused due mechanical shocks during transportation, shipping, weapon firing, rocket stage separation and product handling. Shock testing systems help determine whether a component remains functional when exposed to sudden load or a change in the motion.

Shock testing systems accurately measure peak acceleration, duration and pulse shape. Also, they are used to precisely measure the sensitivity of a component to the input energy impact. The shock testing system is also known as component brittleness analysis.

To enhance product safety and quality, industries are manufacturing advanced shock testing systems that can ensure the precise breakage point, sensitivity and the other characteristics.

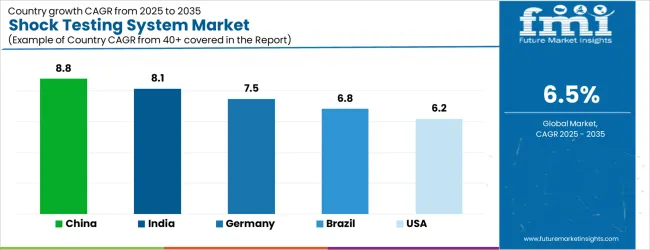

| Country | CAGR |

|---|---|

| China | 8.8% |

| India | 8.1% |

| Germany | 7.5% |

| Brazil | 6.8% |

| USA | 6.2% |

| UK | 5.5% |

| Japan | 4.9% |

The Shock Testing System Market is expected to register a CAGR of 6.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 8.8%, followed by India at 8.1%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates.

Japan posts the lowest CAGR at 4.9%, yet still underscores a broadly positive trajectory for the global Shock Testing System Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.5%.

The USA Shock Testing System Market is estimated to be valued at USD 433.0 million in 2025 and is anticipated to reach a valuation of USD 433.0 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 56.8 million and USD 32.0 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.2 Billion |

| Product Type | Flatbed Shock Testing Machine, Pull Down Drop Shock Testing Machine, High Speed Shock Testing Machine, Automatic Square Drop Shock Testing Machine, Multi-Drop Shock Testing System, and Pendulum Shock Testing System |

| Tests | Peak Acceleration, Duration, and Pulse Shape |

| End Use | Manufacturing Industries, Civil Engineering, and Quality Control Departments |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Instron, LAB Equipment, Lansmont, Shinyei Testing Machinery, LABTONE, Dongling Technologies, Ai Si Li Test Equipment Co., Ltd, and MTS Systems Corporation |

The global shock testing system market is estimated to be valued at USD 1.2 billion in 2025.

The market size for the shock testing system market is projected to reach USD 2.3 billion by 2035.

The shock testing system market is expected to grow at a 6.5% CAGR between 2025 and 2035.

The key product types in shock testing system market are flatbed shock testing machine, pull down drop shock testing machine, high speed shock testing machine, automatic square drop shock testing machine, multi-drop shock testing system and pendulum shock testing system.

In terms of tests, peak acceleration segment to command 40.0% share in the shock testing system market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Shock Sensor Market Size and Share Forecast Outlook 2025 to 2035

Shock Data Logger Market

Shock Test Machines Market

Shock Tube System Market Size and Share Forecast Outlook 2025 to 2035

Anti-shock Trousers Market

Motorcycle Shock Absorbers Market

High Energy Shockwave Therapy Units Market Size and Share Forecast Outlook 2025 to 2035

Cardiogenic Shock Treatment Market Analysis & Forecast for 2025 to 2035

Erectile Dysfunction Shockwave Generators Market

Automotive Gas Charged Shock Absorbers Market Growth - Trends & Forecast 2025 to 2035

Testing, Inspection & Certification Market Growth – Trends & Forecast 2025 to 2035

5G Testing Market Size and Share Forecast Outlook 2025 to 2035

AB Testing Software Market Size and Share Forecast Outlook 2025 to 2035

5G Testing Equipment Market Analysis - Size, Growth, and Forecast 2025 to 2035

Eye Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

HSV Testing Market Size and Share Forecast Outlook 2025 to 2035

IoT Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

HPV Testing and Pap Test Market Size and Share Forecast Outlook 2025 to 2035

GMO Testing Services Market Insights – Food Safety & Regulatory Compliance 2024 to 2034

GMP Testing Services Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA