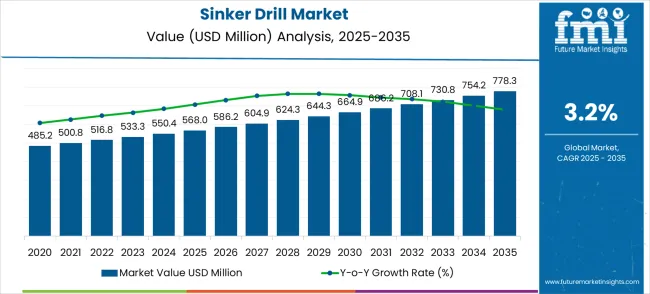

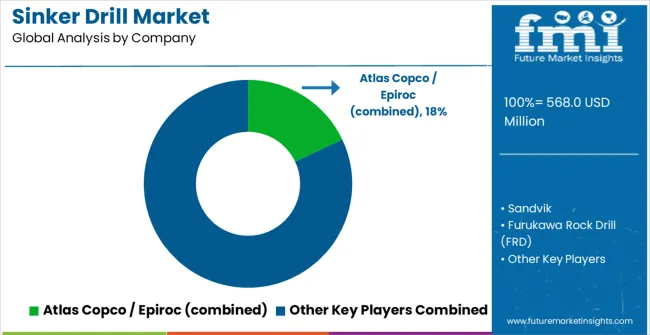

The Sinker Drill Market is estimated to be valued at USD 568.0 million in 2025 and is projected to reach USD 778.3 million by 2035, registering a compound annual growth rate (CAGR) of 3.2% over the forecast period.

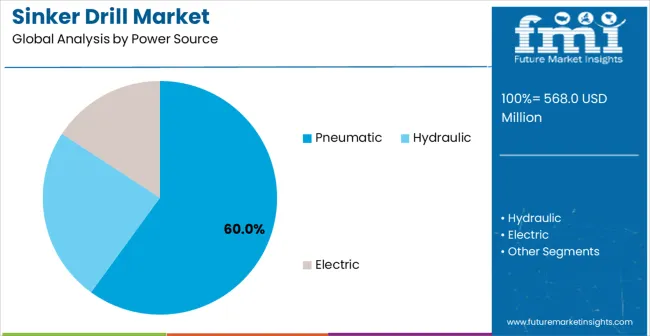

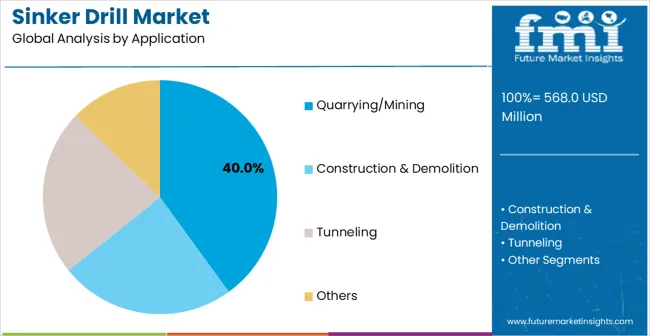

Pneumatic 60.0% and quarrying/mining 40.0%

| Metric | Value |

|---|---|

| Sinker Drill Market Estimated Value in (2025 E) | USD 568.0 million |

| Sinker Drill Market Forecast Value in (2035 F) | USD 778.3 million |

| Forecast CAGR (2025 to 2035) | 3.2% |

Market expansion is being supported by the continuous growth of global mining activities across established and emerging markets and the corresponding need for efficient drilling equipment that ensures optimal excavation performance and operational safety. Modern mining operations require sophisticated drilling systems that can deliver precise drilling control, reduced operational downtime, and enhanced productivity while operating under diverse geological conditions and environmental requirements. The superior drilling capacity and durability characteristics of high-quality sinker drills make them essential equipment in mining operations where drilling performance directly impacts extraction efficiency and project profitability.

The growing emphasis on mining safety standards and operational efficiency enhancement is driving demand for advanced drilling equipment from certified manufacturers with proven track records of quality and reliability in mining applications. Mining companies and construction contractors are increasingly investing in premium sinker drills that offer extended service life while maintaining consistent drilling performance and system efficiency. Regulatory requirements and mining standards are establishing performance benchmarks that favor high-quality drilling equipment with superior engineering properties and resistance to operational stresses.

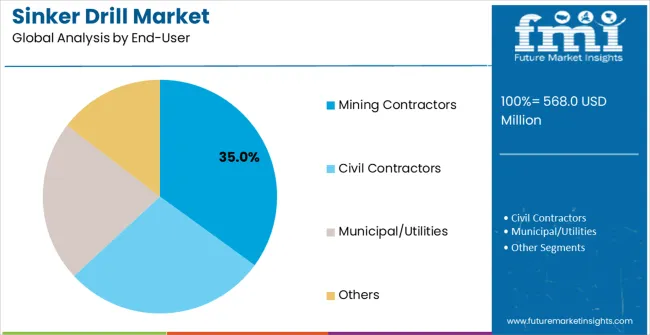

The sinker drill market is segmented by power source, application, end-user, , and geographic regions. By power source, sinker drill market is divided into Pneumatic, Hydraulic, and Electric. In terms of application, sinker drill market is classified into Quarrying/Mining, Construction & Demolition, Tunneling, and Others. Based on end-user, sinker drill market is segmented into Mining Contractors, Civil Contractors, Municipal/Utilities, and Others. Regionally, the sinker drill industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The market is segmented by power source, application, end-user, and region. By power source, the market is divided into pneumatic, hydraulic, electric, and other configurations. Based on application, the market is categorized into quarrying/mining, construction & demolition, tunneling, and municipal/utilities segments. By end-user, the market includes mining contractors, civil contractors, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

Pneumatic power source configurations are projected to account for 60% of the sinker drill market in 2025. This leading share is supported by the proven reliability and cost-effectiveness of pneumatic systems in drilling operations and the widespread availability of compressed air systems in mining and construction facilities. Pneumatic sinker drills offer excellent power-to-weight ratios, making them ideal for portable drilling operations and challenging work environments where mobility and operational flexibility are essential. The segment benefits from technological advancements that have improved air consumption efficiency, noise reduction, and maintenance requirements.

Modern pneumatic sinker drills incorporate advanced air motor technologies, precision-engineered components, and specialized control systems that deliver exceptional drilling performance while maintaining operational simplicity and reliability under demanding working conditions. These innovations have significantly improved drilling efficiency while preserving compatibility with various compressed air systems and reducing operational costs through enhanced energy efficiency and reduced maintenance requirements. The mining sector particularly drives demand for pneumatic solutions, as mining operations require reliable drilling equipment that can meet stringent performance standards and operational requirements.

Quarrying/Mining applications are expected to represent 40% of sinker drill demand in 2025. This significant share reflects the substantial volume of mining and quarrying activities globally and the need for specialized drilling equipment that meets extraction operation requirements and safety standards. Mining operations require consistent supplies of sinker drills for mineral extraction, quarrying activities, and exploration drilling across diverse geological formations and operational environments. The segment benefits from ongoing mining industry growth and increasing emphasis on drilling efficiency and safety in extraction operations.

Quarrying/Mining applications demand exceptional equipment reliability to ensure consistent drilling performance throughout operational periods while meeting stringent mining safety standards and regulatory compliance requirements. These applications require sinker drills capable of withstanding harsh mining environments, geological variations, and long-term operation under demanding conditions and production schedules. The growing emphasis on mining productivity and operational efficiency, particularly in surface mining requiring sophisticated drilling systems for blast hole preparation and extraction optimization, drives consistent demand for high-quality mining drilling equipment.

Mining Contractors are projected to account for 35% of the sinker drill market in 2025. This substantial share is supported by the growing trend of outsourcing drilling operations to specialized contractors who possess expertise in efficient drilling techniques and equipment management. Mining contractors require versatile and reliable drilling equipment that can perform across multiple project sites and geological conditions while maintaining operational efficiency and cost-effectiveness. The segment benefits from the increasing complexity of mining projects requiring specialized drilling expertise and equipment management capabilities.

Modern mining contractors demand sinker drills that offer superior operational flexibility, reduced maintenance requirements, and enhanced productivity to support diverse client requirements and project specifications. These contractors operate across various mining environments, from surface quarrying operations to underground development projects, requiring equipment that can adapt to different operational conditions while maintaining consistent performance standards. The growing emphasis on specialized mining services and project-based operations drives demand for contractors who can provide comprehensive drilling solutions with proven track records of operational excellence.

The sinker drill market is advancing steadily due to continuing global mining industry growth and increasing recognition of the importance of drilling equipment reliability in operational efficiency and safety. However, the market faces challenges, including raw material price volatility affecting equipment costs, increasing adoption of automated drilling systems requiring significant capital investments, and varying mining regulations across different regional markets affecting equipment specifications. Environmental laws and sustainability requirements continue to influence equipment design and market development patterns.

The growing deployment of automated control systems, digital monitoring technologies, and smart drilling solutions is enabling superior operational efficiency and enhanced safety characteristics in sinker drill applications. Advanced automation systems and digital integration provide enhanced precision control, real-time performance monitoring, and predictive maintenance capabilities compared to traditional manual drilling systems. These innovations are particularly valuable for mining operations that require reliable equipment capable of meeting automated production systems and demanding operational conditions.

Modern drilling equipment manufacturers are incorporating electric power systems and hybrid pneumatic-electric technologies that provide enhanced energy efficiency and reduced environmental impact compared to traditional pneumatic systems. Integration of electric motors, battery systems, and intelligent power management creates opportunities for advanced drilling equipment that supports both high-performance drilling operations and environmental sustainability requirements. Advanced control technologies and energy management systems also support the development of more sophisticated drilling solutions for modern mining and construction applications.

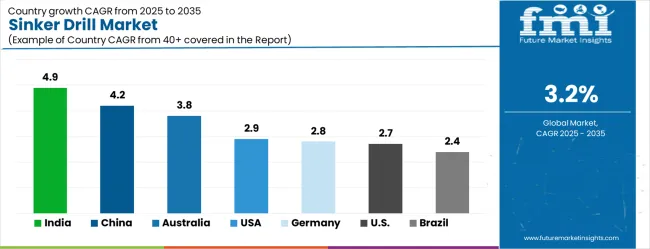

| Country | CAGR (2025-2035) |

|---|---|

| India | 4.9% |

| China | 4.2% |

| Australia | 3.8% |

| United States | 2.9% |

| Germany | 2.8% |

The sinker drill market is growing steadily, with India leading at a 4.9% CAGR through 2035, driven by massive mining industry expansion, increasing infrastructure development projects, and comprehensive industrial development programs supporting both domestic consumption and export markets. China follows at 4.2%, supported by extensive mining operations, expanding construction activities, and increasing investments in mining equipment modernization, serving domestic and global markets. Australia records strong growth at 3.8%, emphasizing mining industry leadership, advanced mining technologies, and operational excellence in mineral extraction operations. The United States shows steady growth at 2.9%, focusing on mining equipment replacement, infrastructure development, and advanced drilling technologies. Germany maintains consistent expansion at 2.8%, supported by engineering excellence and precision manufacturing capabilities. South Korea demonstrates solid growth at 3.5%, emphasizing technological innovation and industrial development. Japan shows steady growth at 3.1%, focusing on precision engineering and manufacturing excellence.

The report covers an in-depth analysis of 40+ countries; five top-performing countries are highlighted below.

Revenue from sinker drills in India is projected to exhibit the highest growth rate with a CAGR of 4.9% through 2035, driven by massive mining industry expansion and comprehensive infrastructure development, creating substantial opportunities for drilling equipment suppliers across coal mining, mineral extraction, and construction sectors. The country's growing mining production capacity and expanding infrastructure projects are creating significant demand for both traditional pneumatic and advanced electric drilling equipment. Major mining companies and construction contractors are establishing comprehensive local equipment procurement to support large-scale operations and meet growing demand for efficient drilling solutions.

Revenue from sinker drills in China is expanding at a CAGR of 4.2%, supported by extensive mining operations and comprehensive construction industry development, creating sustained demand for reliable drilling equipment across diverse mining categories and industrial segments. The country's dominant mining position and expanding infrastructure capabilities are driving demand for drilling equipment that provides consistent performance while supporting cost-effective operational requirements. Mining equipment manufacturers are investing in local production facilities to support growing mining operations and construction demand.

Demand for sinker drills in Australia is projected to grow at a CAGR of 3.8%, supported by the country's leadership in mining operations and advanced extraction technologies requiring sophisticated drilling equipment for mineral extraction and quarrying operations. Australian mining companies are implementing high-quality drilling systems that support advanced mining techniques, operational efficiency, and comprehensive safety protocols. The market is characterized by a focus on operational excellence, equipment reliability, and compliance with stringent mining performance and safety standards.

Revenue from sinker drills in the United States is growing at a CAGR of 2.9%, driven by mining equipment replacement programs and increasing infrastructure development, creating sustained opportunities for drilling equipment suppliers serving both mining operations and construction contractors. The country's mature mining sector and expanding construction industry are creating demand for drilling equipment that supports diverse operational requirements while maintaining performance standards. Mining companies and contractors are developing equipment procurement strategies to support operational efficiency and regulatory compliance.

Demand for sinker drills in Germany is expanding at a CAGR of 2.8%, driven by engineering excellence and precision manufacturing capabilities supporting advanced drilling equipment development and comprehensive industrial applications. The country's established manufacturing expertise and premium industrial market segments are creating demand for high-quality drilling equipment that supports operational performance and engineering standards. Equipment manufacturers and industrial suppliers are maintaining comprehensive development capabilities to support diverse industrial requirements.

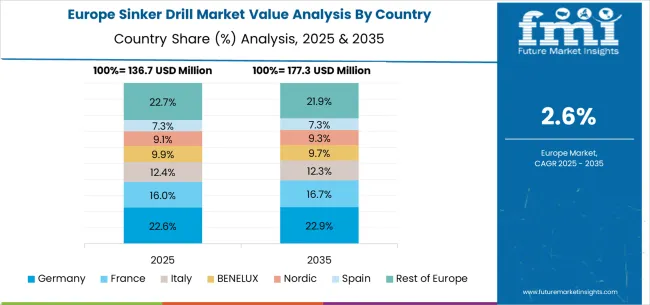

The sinker drill market in Europe is projected to grow from USD 142.0 million in 2025 to USD 194.6 million by 2035, registering a CAGR of 3.2% over the forecast period. Germany is expected to maintain its leadership position with a 35.2% market share in 2025, remaining stable at 35.0% by 2035, supported by its advanced mining equipment manufacturing sector, precision engineering capabilities, and comprehensive innovation expertise serving European and international mining markets.

The United Kingdom follows with a 22.8% share in 2025, projected to reach 23.1% by 2035, driven by mining equipment modernization programs, advanced drilling technology development capabilities, and growing focus on operational efficiency solutions for premium mining operations. France holds an 18.4% share in 2025, expected to maintain 18.2% by 2035, supported by quarrying industry demand and advanced drilling technology applications, but facing challenges from market competition and economic considerations.

Italy commands a 12.6% share in 2025, projected to reach 12.8% by 2035, while Spain accounts for 7.3% in 2025, expected to reach 7.5% by 2035. The Netherlands maintains a 3.7% share in 2025, growing to 3.8% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Switzerland, and Austria, is anticipated to hold 18.6% in 2025, declining slightly to 18.4% by 2035, attributed to mixed growth patterns with strong expansion in some Nordic mining markets balanced by moderate growth in smaller countries implementing mining equipment modernization programs.

The sinker drill market is defined by competition among established mining equipment manufacturers, specialized drilling system providers, and emerging industrial technology firms. Companies are investing in advanced drilling technology, manufacturing process optimization, quality management systems, and global distribution capabilities to deliver reliable, efficient, and cost-effective drilling equipment. Strategic partnerships, technological advancement, and geographic expansion are central to strengthening product portfolios and market presence.

Atlas Copco/Epiroc (combined), operating globally, offers comprehensive mining drilling solutions with a focus on advanced technology, operational excellence, and mining industry partnerships, holding an 18% market share. Sandvik provides specialized drilling equipment with emphasis on manufacturing efficiency and operational reliability. Furukawa Rock Drill (FRD), a Japanese drilling equipment specialist, delivers advanced drilling technologies with a focus on precision engineering and mining applications. These leading companies demonstrate strong market presence through technological innovation and comprehensive service capabilities.

Summit drilling equipment providers include Doofor, offering specialized drilling solutions with a focus on operational performance and customer service excellence. Montabert delivers comprehensive drilling systems with emphasis on pneumatic technology and technical support. Chicago Pneumatic provides drilling equipment with a focus on industrial applications and global distribution networks. Soosan offers specialized drilling solutions with emphasis on cost-effective manufacturing and regional market development.

Emerging market participants include Mindrill and Yamamoto Rock Splitter, offering specialized drilling expertise, innovative technologies, and technical support across global and regional mining markets, with a focus on advanced drilling capabilities and operational efficiency solutions.

The sinker drill market underpins mining efficiency enhancement, operational safety optimization, industrial productivity improvement, and infrastructure development reliability. With mining industry growth, advancing drilling technologies, and increasing construction demand, the sector must balance equipment quality, operational efficiency, and cost competitiveness. Coordinated contributions from governments, mining associations, equipment manufacturers, mining companies, and investors will accelerate the transition toward advanced, reliable, and highly efficient drilling systems.

| Items | Values |

|---|---|

| Quantitative Units | USD 568 Million |

| Power Source | Pneumatic, Hydraulic, Electric, Others |

| Application | Quarrying/Mining, Construction & Demolition, Tunneling, Municipal/Utilities |

| End-User | Mining Contractors, Civil Contractors, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Germany, India, China, Australia, South Korea, Japan, and over 40+ other countries |

| Key Companies Profiled | Atlas Copco/Epiroc (combined), Sandvik, Furukawa Rock Drill (FRD), Doofor, Montabert, Chicago Pneumatic, Soosan, Mindrill, Yamamoto Rock Splitter |

| Additional Attributes | Dollar sales by power source/application, regional demand (NA, EU, APAC), competitive landscape, pneumatic vs. electric adoption, automation/digital integration, and smart drilling innovations driving productivity, safety, and efficiency |

The global sinker drill market is estimated at USD 568.0 million in 2025 and is projected to reach USD 778.3 million by 2035, expanding at a CAGR of 3.2% during the forecast period.

The pneumatic segment leads the market with a 60% share in 2025, owing to its reliability, cost-effectiveness, and suitability for mining and construction operations requiring portable and durable drilling equipment.

The quarrying/mining segment accounts for 40% of demand in 2025, supported by global mining expansion, safety compliance, and the need for efficient equipment in mineral extraction and quarrying activities.

The strongest growth is observed in India (4.9% CAGR), followed by China (4.2%) and Australia (3.8%), driven by large-scale mining expansion, infrastructure development, and adoption of advanced drilling systems. North America and Europe also remain significant markets due to modernization and equipment replacement programs.

Key players include Atlas Copco/Epiroc, Sandvik, Furukawa Rock Drill (FRD), Montabert, Doofor, Chicago Pneumatic, Soosan, Mindrill, and Yamamoto Rock Splitter, all of whom are focusing on advanced drilling technologies, automation integration, and global service support.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Sinker Type EDM Market Size and Share Forecast Outlook 2025 to 2035

Drilling Tools Market Size and Share Forecast Outlook 2025 to 2035

Drill Drivers Market Size and Share Forecast Outlook 2025 to 2035

Drill Shank Adapter Market Size and Share Forecast Outlook 2025 to 2035

Drilling Type EDM Market Size and Share Forecast Outlook 2025 to 2035

Drill Pipe Market Size and Share Forecast Outlook 2025 to 2035

Drilling Machines Market Size and Share Forecast Outlook 2025 to 2035

Drill Bit Market Size and Share Forecast Outlook 2025 to 2035

Drilling and Completion Fluids Market Diapers Market Analysis - Size, Share & Forecast 2025 to 2035

Drilling Polymers Market Analysis, Growth, Applications and Outlook 2025 to 2035

PDC Drill Bits Market Size and Share Forecast Outlook 2025 to 2035

Rock Drill Shank Adaptor Market Size and Share Forecast Outlook 2025 to 2035

Core Drill Automatic Feeding Machine Market

Laser Drilling Equipment Market Size and Share Forecast Outlook 2025 to 2035

Mining Drilling Service Market Size and Share Forecast Outlook 2025 to 2035

Rotary Drilling Rig Market Size and Share Forecast Outlook 2025 to 2035

Radial Drilling Machine Market Growth & Demand 2025 to 2035

Mining Drill Market Growth – Trends & Forecast 2025 to 2035

Rapid U-drills Market Size and Share Forecast Outlook 2025 to 2035

Onshore Drilling Waste Management Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA