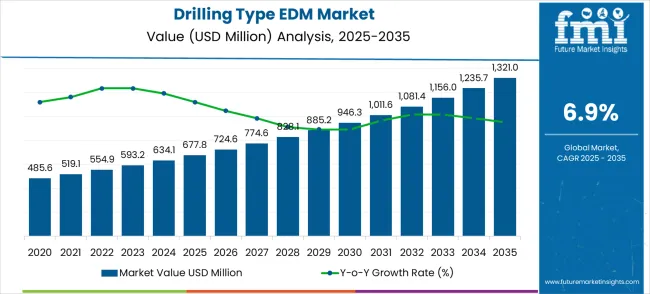

The drilling type EDM market begins its decade journey from a USD 677.8 million foundation in 2025, setting the stage for robust expansion ahead. The first half of the decade witnesses strong momentum building, with market value climbing from USD 724.6 million in 2026 to USD 885.2 million by 2030. This initial phase reflects growing precision manufacturing demands and increasing adoption of advanced machining technologies across aerospace, automotive, and medical device industries.

The latter half will witness accelerated growth dynamics, propelling the market from USD 946.3 million in 2031 to reach USD 1,321.0 million by 2035. Dollar additions during 2030-2035 outpace the earlier period, with annual increments averaging USD 87.2 million compared to USD 41.5 million in the first phase. This progression represents a 94.9% total value increase over the forecast decade.

Market maturation factors include expanding electric vehicle manufacturing, medical device miniaturization trends, and aerospace component complexity advancement. The 6.9% compound annual growth rate positions participants to capitalize on USD 643.2 million in additional market value creation. This trajectory signals robust opportunities for precision machining equipment manufacturers, advanced manufacturing service providers, and industrial automation suppliers across the global high-precision manufacturing landscape.

Market expansion unfolds through two distinct growth periods with different manufacturing technology adoption characteristics for each phase. The 2025-2030 foundation period delivers USD 207.4 million in value additions, representing 30.6% growth from the baseline. Market dynamics during this phase center on precision manufacturing advancement, electric vehicle production scaling, and medical device manufacturing sophistication.

The 2030-2035 acceleration period generates USD 435.8 million in incremental value, reflecting 49.2% growth from the 2030 position. This phase exhibits mature market characteristics with enhanced competition, product innovation strategies, and emerging application development initiatives. Dollar contributions shift from foundational precision manufacturing adoption to market share optimization and technological advancement.

Competitive landscape evolution progresses from traditional manual EDM systems to fully automated electric precision machining platforms. The first period emphasizes product reliability improvement and application range expansion. The second period witnesses intensified competition for premium market segments and geographical territory expansion. Market maturation factors include standardized automation protocols, enhanced precision capabilities, and cross-industry application development across automotive, aerospace, medical, and electronics sectors.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 677.8 million |

| Market Forecast (2035) | USD 1,321.0 million |

| Growth Rate | 6.9% CAGR |

| Leading Segment | Electric Type |

| Primary Application | Automotive |

Market expansion rests on four fundamental shifts driving precision manufacturing and advanced machining demand acceleration: 1. Electric Vehicle Manufacturing Revolution: Global EV transition drives demand for precision drilling of battery components, electric motor parts, and power electronics requiring ultra-precise hole drilling capabilities. Battery pack manufacturing necessitates exact drilling tolerances for cooling systems and electrical connections. Charging infrastructure development requires precision machining of high-voltage components and connector assemblies. 2. Medical Device Miniaturization: Advanced medical implants, surgical instruments, and diagnostic equipment require micro-drilling capabilities for complex geometries and biocompatible materials. Minimally invasive surgical tools demand precision holes in titanium, stainless steel, and advanced ceramics. Drug delivery devices require micro-scale drilling for controlled release mechanisms and sensor integration. 3. Aerospace Component Complexity: Next-generation aircraft engines, lightweight structures, and space exploration vehicles require precision drilling of exotic materials including titanium alloys, Inconel, and carbon fiber composites. Turbine blade cooling holes demand exact drilling patterns for optimal performance. Satellite components require ultra-precise drilling for weight optimization and functionality. 4. Industrial Automation and Smart Manufacturing: Industry 4.0 implementation drives demand for automated EDM systems with integrated monitoring, quality control, and predictive maintenance capabilities. Smart factory initiatives require precision machining equipment supporting unmanned operation and real-time quality verification. Digital manufacturing workflows necessitate EDM systems with data connectivity and process optimization capabilities.

Growth faces headwinds from high capital investment requirements and skilled operator shortages. Alternative machining technologies including laser drilling may create competitive pressure in specific applications. Economic volatility affects capital equipment investment in precision manufacturing sectors.

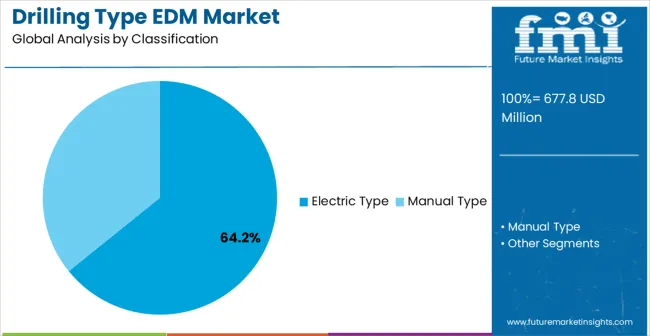

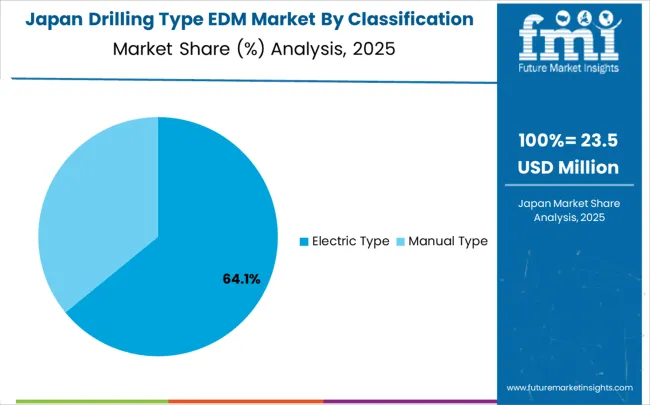

The market is segmented by product type into Electric and Manual categories, with Electric types dominating at 64.2% market share, reflecting increasing consumer preference for automated, efficient solutions. Manual types account for 35.8% of the market, maintaining steady demand in traditional or cost-sensitive applications where simplicity and reliability are prioritized.

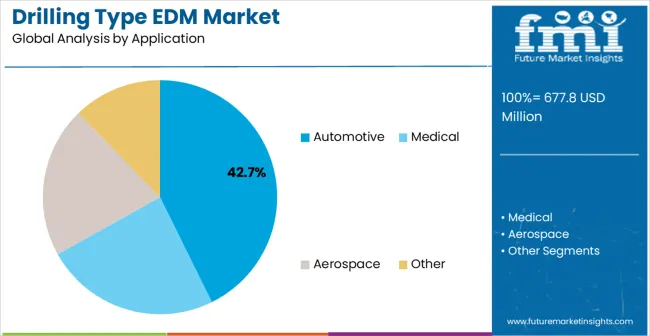

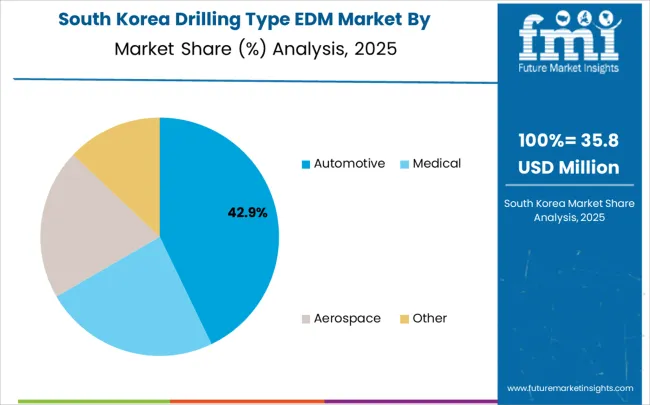

By application, the market spans Automotive (42.7%), Medical (24.6%), Aerospace (19.8%), and Other applications (12.9%). Automotive applications dominate, driven by precision and automation requirements, while Medical and Aerospace sectors highlight the market’s critical role in high-performance, safety-sensitive environments. The Other category captures diverse use cases, demonstrating flexibility across industrial and consumer segments.

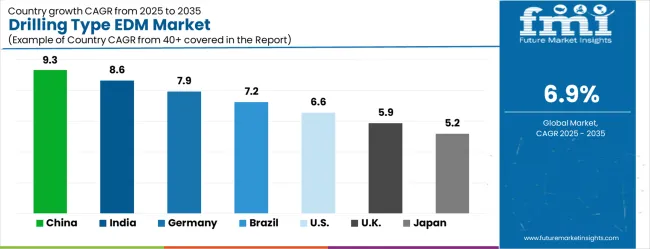

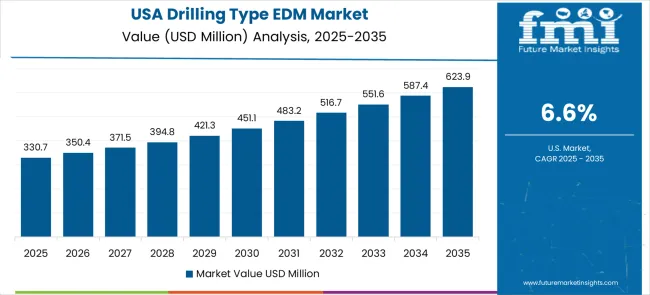

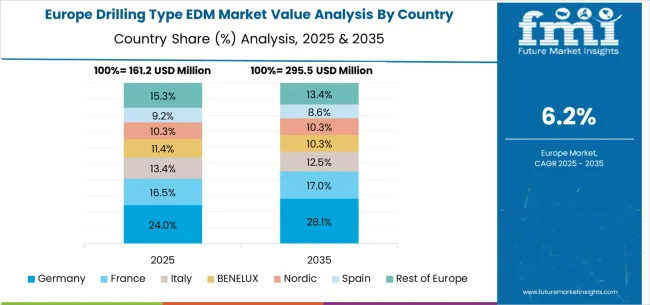

Regionally, the market demonstrates varied growth trajectories. Asia Pacific leads with China showing a 9.3% CAGR and India 8.6% CAGR, reflecting rapid industrialization and adoption of advanced technologies. Europe follows with Germany contributing a 7.9% CAGR, driven by stringent quality standards and automation trends. North America exhibits steady expansion with the U.S. at 6.6% CAGR, while Latin America, LED by Brazil, grows at a 7.2% CAGR, reflecting increasing investment in industrial infrastructure and technology adoption.

Market Position: Electric type drilling EDM systems establish clear market leadership through superior automation capabilities and precision control for high-volume manufacturing applications. Advanced CNC integration provides consistent drilling parameters while enabling complex hole patterns and multi-axis operations. Automated electrode changing and process monitoring capabilities support unmanned operation and quality assurance requirements.

Value Drivers: Enhanced automation reduces operator dependency while improving consistency and throughput for demanding manufacturing applications. Programmable drilling parameters enable optimization for diverse materials and hole specifications supporting flexible manufacturing operations. Real-time monitoring capabilities provide process feedback and quality verification supporting Industry 4.0 integration requirements.

Competitive Advantages: Electric systems offer proven reliability and repeatability in demanding manufacturing environments reducing process variation and improving quality outcomes. Integration capabilities enable connection with manufacturing execution systems and quality management platforms. Automated operation reduces labor requirements while improving safety and production efficiency.

Market Challenges: Higher initial investment costs compared to manual alternatives may limit adoption in budget-constrained applications. Technical complexity requires specialized maintenance capabilities and technical support infrastructure. Power requirements and installation complexity increase facility preparation and operating costs.

Strategic Market Importance: Automotive applications represent the primary demand driver for drilling type EDM across engine components, transmission parts, and electric vehicle systems requiring precision hole drilling. Fuel injection systems, cylinder heads, and turbocharger components require exact drilling tolerances for optimal performance and emissions compliance. Quality requirements mandate precision machining solutions meeting automotive industry standards and regulatory specifications.

Business Logic: Automotive manufacturers prioritize quality and efficiency, making precision drilling technology essential for component performance and regulatory compliance. Performance requirements demand consistent hole quality and dimensional accuracy supporting engine efficiency and emissions compliance. Investment justification occurs through quality improvement, cycle time reduction, and automated production capability.

Forward-looking Implications: Electric vehicle production scaling drives demand for precision drilling of battery cooling systems, motor housings, and power electronics components. Autonomous vehicle development creates opportunities for sensor mounting and electronic component drilling applications. Global automotive production growth sustains demand for precision machining solutions across diverse vehicle platforms.

| Country | CAGR (%) |

|---|---|

| China | 9.3 |

| India | 8.6 |

| Germany | 7.9 |

| Brazil | 7.2 |

| USA | 6.6 |

| UK | 5.9 |

| Japan | 5.2 |

Global market dynamics reveal distinct performance tiers reflecting regional manufacturing capabilities and precision machining adoption. Growth Leaders including China (9.3% CAGR) and India (8.6% CAGR) demonstrate expanding precision manufacturing with advanced machining technology adoption, while Germany (7.9% CAGR) represents European manufacturing excellence and automotive leadership. Steady Performers such as Brazil (7.2% CAGR) and the United States (6.6% CAGR) show consistent demand growth aligned with manufacturing modernization and aerospace development requirements. Mature Markets including the United Kingdom (5.9% CAGR) and Japan (5.2% CAGR) display moderate growth rates reflecting established precision manufacturing capabilities and technology advancement focus.

Regional synthesis indicates Asia Pacific dominance through manufacturing concentration and automotive production leadership. European markets emphasize precision engineering and aerospace applications. North American demand reflects aerospace industry strength and advanced manufacturing adoption.

China establishes market leadership through expanding automotive production and advanced manufacturing capability development. A 9.3% CAGR value reflects extensive electric vehicle manufacturing scaling and precision machining technology adoption requirements. Growth metrics demonstrate sustained expansion supported by government manufacturing upgrade initiatives and automotive industry transformation mandates.

Market dynamics center on electric vehicle production leadership creating demand for precision drilling solutions and battery manufacturing requirements. Automotive component export competitiveness drives adoption of advanced machining technologies for international quality standards. Manufacturing modernization initiatives necessitate precision equipment for Industry 4.0 compliance and operational excellence.

Manufacturing hub concentration in automotive and electronics production zones creates demand density for precision drilling equipment. Technology partnerships bring international machining standards requiring certified precision equipment adoption. Government initiatives support advanced manufacturing capabilities requiring sophisticated precision machining solutions.

Strategic Market Indicators:

India demonstrates robust growth potential through expanding automotive manufacturing and precision machining capability development. An 8.6% CAGR reflects increasing manufacturing sophistication and automotive industry growth supporting advanced drilling technology adoption. Manufacturing sector expansion under government initiatives creates consistent demand for precision machining solutions across applications.

Automotive sector growth drives primary demand through domestic vehicle production and component manufacturing for export markets. Government manufacturing initiatives support domestic precision equipment adoption for import substitution and export competitiveness. Medical device manufacturing expansion creates opportunities for precision drilling applications in surgical instruments and diagnostic equipment.

Market activity centers on technology transfer agreements bringing international precision manufacturing standards to domestic operations. Foreign investment in automotive manufacturing introduces advanced drilling requirements for competitive positioning. Skill development initiatives include training programs for precision machining operation and maintenance.

Market Intelligence Brief:

Demand for drilling type EDM in Germany maintains 7.9% CAGR market leadership through engineering excellence and automotive industry leadership. The market demonstrates established precision manufacturing base with advanced machining capabilities supporting export competitiveness and technology innovation. Automotive and aerospace industries create consistent demand for premium drilling solutions across critical applications.

Precision engineering expertise enables development of advanced drilling technologies for aerospace, automotive, and medical applications. Industry 4.0 leadership drives innovation in smart manufacturing requiring integrated drilling systems with monitoring and control capabilities. Export market leadership necessitates precision equipment supporting international manufacturing facility development.

Advanced manufacturing research initiatives develop new applications for precision drilling in emerging technologies and materials. Technology standard development influences global precision manufacturing practices requiring advanced drilling capabilities. Industrial equipment supplier network requires consistent drilling specifications for manufacturing system integration.

Performance Metrics:

Brazil represents emerging market growth with a 7.2% CAGR through automotive industry expansion and manufacturing capability enhancement. The market reflects increasing precision manufacturing adoption and technology modernization supporting economic development objectives. Automotive production growth creates primary demand for drilling solutions across engine and component manufacturing applications.

Automotive sector expansion drives demand through domestic vehicle production and component manufacturing for regional markets. Aerospace industry development creates opportunities for precision drilling applications in aircraft components and space technology. Medical device manufacturing growth increases demand for precision drilling in surgical instruments and diagnostic equipment.

Market development challenges include economic volatility affecting capital equipment investment and import cost fluctuations impacting technology adoption. Manufacturing competitiveness initiatives support precision equipment investment for productivity improvement and quality enhancement.

Strategic Market Considerations:

United States market demonstrates steady growth with a CAGR of 6.6% through aerospace industry leadership and advanced manufacturing modernization. The market reflects established precision manufacturing base with ongoing technology integration requiring sophisticated drilling solutions. Aerospace and defense applications maintain consistent demand for premium precision drilling capabilities.

Aerospace industry leadership requires specialized drilling solutions for turbine engines, spacecraft components, and defense systems. Medical device manufacturing excellence creates opportunities for precision drilling applications in surgical instruments and implantable devices. Automotive industry modernization drives demand for precision drilling in electric vehicle and advanced powertrain applications.

Innovation initiatives encourage advanced drilling technology development utilizing artificial intelligence and automation capabilities. Manufacturing competitiveness programs support precision equipment investment for domestic production capability and supply chain resilience.

Market Development Indicators:

United Kingdom demonstrates market stability through aerospace industry excellence and medical device manufacturing leadership. A 5.9% CAGR market value reflects established precision manufacturing capabilities with emphasis on high-value applications and technology innovation. Aerospace and medical sectors create demand for premium drilling solutions meeting stringent quality and regulatory requirements.

Aerospace industry concentration maintains demand for precision drilling in jet engine components, aircraft structures, and space applications. Medical device manufacturing excellence requires ultra-precision drilling capabilities for surgical instruments and implantable devices. Advanced manufacturing initiatives support precision technology adoption for competitive positioning and export capability.

Technology innovation emphasizes precision manufacturing advancement requiring sophisticated drilling solutions with automation and quality control integration. International aerospace partnerships create opportunities for precision drilling technology export and collaboration.

Current Market Observations:

Japan maintains technological leadership through precision manufacturing with a 5.2% CAGR excellence and advanced drilling technology development. The market value reflects mature precision manufacturing base with established quality standards and technology innovation focus. Automotive, electronics, and medical applications create demand for sophisticated drilling solutions supporting advanced manufacturing requirements.

Precision manufacturing leadership requires advanced drilling specifications for automotive components, electronics packaging, and medical devices. Technology innovation utilizes cutting-edge drilling systems for robotics integration and flexible manufacturing applications. Quality management system development influences global precision manufacturing practices and drilling technology standards.

Manufacturing technology expertise enables development of advanced drilling solutions meeting stringent performance and quality requirements. Research and development initiatives advance drilling technology integration with smart manufacturing and automation systems.

Market Status Indicators:

The European drilling type EDM market totaled USD 267.8 million in 2025, representing 39.5% of global market share. Germany dominates with 32.4% European market share, leading through precision engineering excellence and automotive industry leadership. Italy contributes USD 62.7 million in precision manufacturing, emphasizing automotive and aerospace applications. The UK market valued at USD 48.3 million shows 5.9% CAGR growth driven by aerospace and medical device manufacturing. France holds USD 41.2 million with aerospace and nuclear industry specialization. Switzerland demonstrates USD 28.6 million with ultra-precision machining focus. Spain projects 6.8% CAGR through automotive and aerospace manufacturing expansion. Nordic countries show USD 22.4 million with advanced manufacturing and technology innovation emphasis. Market integration enables cross-border precision manufacturing standard harmonization with 92-95% advanced drilling technology adoption in established precision manufacturing facilities.

Japan: Precision Engineering and Advanced Automation

Japan's EDM drilling machine market is dominated by electric-type systems, driven by the country's emphasis on automation and precision in manufacturing. The 62.8% market share reflects Japan’s industrial focus on reliability and high-volume production efficiency. Automotive and aerospace manufacturers utilize electric drilling systems for consistent quality and throughput in critical component production. Industry 4.0 adoption creates demand for electric drilling systems supporting smart manufacturing integration and real-time quality monitoring. The precision manufacturing sector produces advanced drilling solutions for domestic and export markets requiring certified performance standards. Engineering services benefit from electric system reliability enabling comprehensive production automation and quality assurance.

Manual-type EDM systems maintain a 37.2% share through specialized applications requiring operator control or cost optimization for low-volume production. Prototype development utilizes manual systems for flexibility and setup simplicity. Specialized materials processing selects manual operation for optimal process control and quality verification.

Market Characteristics:

South Korea's EDM drilling market is led by electric-type systems, reflecting the country’s focus on Industry 4.0 and smart manufacturing. The 65.1% market share is driven by automotive and aerospace sectors demanding precision, efficiency, and high-quality output. Electric drilling systems are essential for producing critical components with consistent throughput. Manufacturers increasingly seek systems capable of real-time monitoring and integration with automated production lines. The engineering sector relies on electric systems for comprehensive production automation and quality assurance, supporting both domestic and export requirements.

Manual-type systems hold a 34.9% share for applications requiring operator control, cost-effective solutions for low-volume production, or prototype development. They are used where flexibility, setup simplicity, and specialized material processing are needed for precise process control and quality verification.

Market Characteristics:

Market structure reflects moderate concentration with established precision machining equipment manufacturers maintaining significant market positions while regional suppliers serve specialized segments. Competition style emphasizes product performance differentiation, technical service capability development, and application expertise. Industry dynamics favor companies combining manufacturing excellence with comprehensive technical support and global service networks.

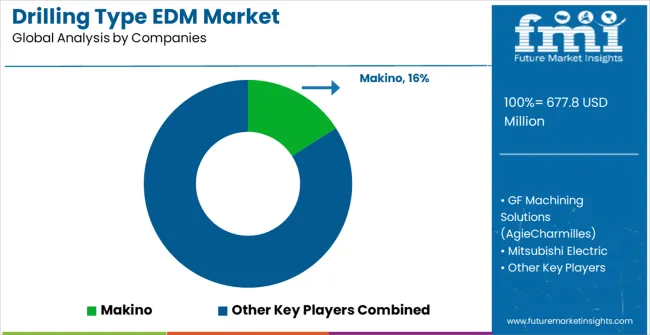

Tier 1 - Global Technology Leaders: Makino, GF Machining Solutions (AgieCharmilles), and similar multinational precision equipment companies dominate through comprehensive drilling EDM portfolios, global service networks, and technology innovation capabilities. Competitive advantages include research and development resources, established customer relationships, and manufacturing scale economies. Market positions reflect brand recognition and reliability reputation across demanding precision manufacturing applications.

Tier 2 - Specialized Equipment Providers: Companies like Mitsubishi Electric, Sodick, and regional manufacturers focus on specific application segments or geographic markets through specialized drilling solutions. Competitive advantages include application expertise, technical service flexibility, and competitive pricing models. Market positioning emphasizes technical specialization and customer relationship development in targeted precision manufacturing segments.

Tier 3 - Regional and Niche Specialists: Smaller companies including CHMER EDM, Excetek, and regional suppliers serve local markets and specialized applications. Competitive advantages include cost competitiveness, local service capabilities, and customization flexibility. Market participation focuses on price-sensitive segments and specialized drilling requirements.

The drilling EDM market underpins aerospace, automotive, energy, and medical component manufacturing by enabling precision micro-hole drilling in hard alloys and complex geometries. With increasing demand for turbine blades, fuel injector nozzles, and minimally invasive surgical tools, the sector is evolving toward higher automation, digital integration, and sustainable machining practices. Coordinated action from governments, industry bodies, OEMs/CNC players, suppliers, and investors is essential to transition toward smarter, greener, and globally competitive EDM ecosystems.

| Item | Value |

|---|---|

| Quantitative Units | USD 677.8 million |

| Product Type | Manual Type, Electric Type |

| Application | Automotive, Medical, Aerospace, Other |

| Regions Covered | North America, Latin America, Europe, East Asia, South Asia & Pacific, Middle East & Africa |

| Countries Covered | United States, Canada, Mexico, Germany, United Kingdom, France, Italy, Spain, Nordic, BENELUX, China, Japan, South Korea, India, ASEAN, Australia, New Zealand, Brazil, Chile, Kingdom of Saudi Arabia, GCC Countries, Turkey, South Africa |

| Key Companies Profiled | Makino, GF Machining Solutions, Mitsubishi Electric, Sodick, Seibu Electric, CHMER EDM, Excetek, ONA EDM, AccuteX, Joemars |

| Additional Attributes | Dollar sales by product categories, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with player descriptions, adoption patterns across industries, integration with smart manufacturing systems, innovations in automation technology and precision capabilities, development of specialized applications with enhanced performance |

The global drilling type EDM market is estimated to be valued at USD 677.8 million in 2025.

The market size for the drilling type EDM market is projected to reach USD 1,321.0 million by 2035.

The drilling type EDM market is expected to grow at a 6.9% CAGR between 2025 and 2035.

The key product types in drilling type EDM market are electric type and manual type.

In terms of application, automotive segment to command 42.7% share in the drilling type EDM market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Drilling Tools Market Size and Share Forecast Outlook 2025 to 2035

Drilling Machines Market Size and Share Forecast Outlook 2025 to 2035

Drilling and Completion Fluids Market Diapers Market Analysis - Size, Share & Forecast 2025 to 2035

Drilling Polymers Market Analysis, Growth, Applications and Outlook 2025 to 2035

Laser Drilling Equipment Market Size and Share Forecast Outlook 2025 to 2035

Mining Drilling Service Market Size and Share Forecast Outlook 2025 to 2035

Rotary Drilling Rig Market Size and Share Forecast Outlook 2025 to 2035

Radial Drilling Machine Market Growth & Demand 2025 to 2035

Onshore Drilling Waste Management Market Size and Share Forecast Outlook 2025 to 2035

Onshore Drilling Fluids Market Growth - Trends & Forecast 2025 to 2035

Crawler Drilling Machine Market

Surface Drilling Rigs Market

Offshore Drilling Riser Market Size and Share Forecast Outlook 2025 to 2035

Multi Pad Drilling Market Size and Share Forecast Outlook 2025 to 2035

Directional Drilling Service Market Forecast Outlook 2025 to 2035

Diamond Core Drilling Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Competitive Overview of Diamond Core Drilling Market Share

Rock-Socketed Drilling Rig Market Size and Share Forecast Outlook 2025 to 2035

Multi-Axis PCB Drilling Machine Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Anchor Drilling Vehicle for Mining Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA