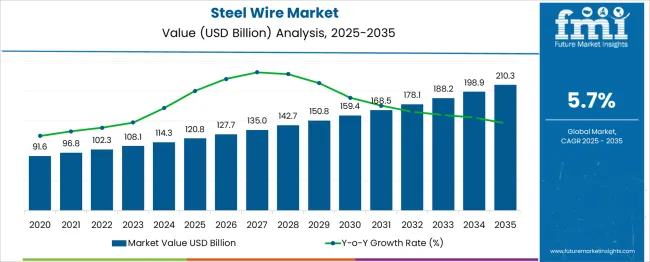

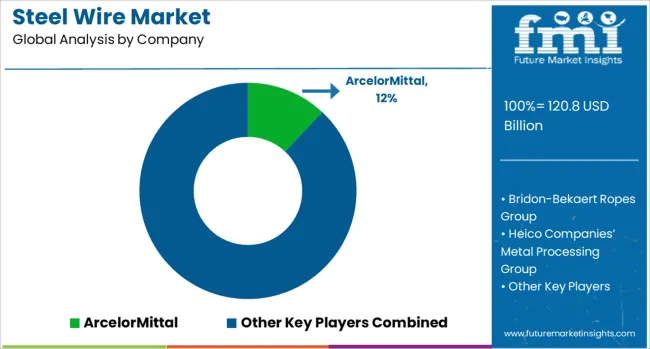

The global steel wire market is likely to grow from USD 120.8 billion in 2025 to approximately USD 210.3 billion by 2035, recording an absolute increase of USD 89.48 billion over the forecast period. This translates into a total growth of 74.1%, with the market forecast to expand at a compound annual growth rate (CAGR) of 5.7% between 2025 and 2035. The overall market size is expected to grow by nearly 1.74X during the same period, supported by the increasing infrastructure development activities, growing automotive production, and rising demand for energy transmission and distribution systems across emerging economies.

Between 2025 and 2030, the steel wire market is projected to expand from USD 120.8 billion to USD 162.5 billion, resulting in a value increase of USD 41.7 billion, which represents 46.6% of the total forecast growth for the decade. This phase of growth will be shaped by increasing infrastructure development projects, expanding automotive manufacturing capacity, and growing energy sector investments requiring extensive wire and cable systems. Steel producers are modernizing production facilities and investing in advanced wire drawing technologies to meet evolving quality requirements and market demand.

From 2030 to 2035, the market is forecast to grow from USD 162.5 billion to USD 210.28 billion, adding another USD 47.78 billion, which constitutes 53.4% of the overall ten-year expansion. This period is expected to be characterized by technological advancement in steel wire manufacturing processes, development of high-performance specialty wire grades, and increasing adoption in renewable energy infrastructure projects. The growing focuses on construction materials and energy-efficient transmission systems will drive demand for advanced steel wire products and innovative application solutions.

Between 2020 and 2025, the steel wire market experienced substantial growth driven by global infrastructure recovery programs, increasing construction activities, and expanding automotive production following economic stabilization. The market developed as manufacturers invested in capacity expansion and technological improvements to serve growing demand from construction, automotive, and energy sectors worldwide.

| Metric | Value |

|---|---|

| Steel Wire Market Value (2025) | USD 120.8 billion |

| Steel Wire Market Forecast Value (2035) | USD 210.3 billion |

| Steel Wire Market Forecast CAGR | 5.7% |

Market expansion is being supported by the increasing infrastructure development activities worldwide and the corresponding demand for steel wire products in construction, transportation, and energy applications. Modern infrastructure projects require extensive use of steel wire for reinforcement applications, cable systems, and structural components that provide strength, durability, and reliability under demanding operational conditions. Government investment in infrastructure modernization, urbanization programs, and transportation network expansion is creating demand for high-quality steel wire products across diverse applications.

The growing automotive industry and expanding energy sector are driving demand for specialized steel wire products that meet specific performance requirements for safety-critical applications and long-term operational reliability. Automotive manufacturers utilize steel wire for tire reinforcement, springs, cables, and various structural components that require precise dimensional tolerances and superior mechanical properties. The expanding renewable energy projects and electrical grid modernization programs are creating new market opportunities for specialty wire products designed for power transmission and distribution applications.

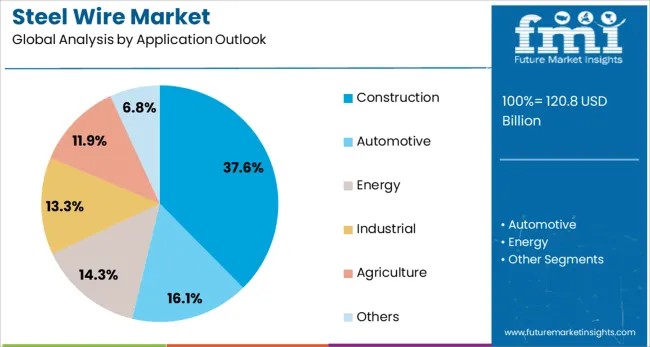

The market is segmented by material, application, and region. By material, the market is divided into carbon steel, stainless steel, and alloy steel. Based on application, the market is categorized into construction, automotive, energy, industrial, agriculture, and others. Regionally, the market is divided into China, India, Germany, France, UK, USA, and Brazil.

Carbon steel is projected to account for 62.5% of the steel wire market in 2025. This leading share is supported by the widespread adoption of carbon steel wire in construction applications, automotive manufacturing, and general industrial uses due to its excellent strength characteristics, cost effectiveness, and versatile processing capabilities. Carbon steel wire provides reliable performance across diverse applications while maintaining competitive pricing that supports large-scale infrastructure and manufacturing projects. The segment benefits from established production capabilities, comprehensive supply chains, and extensive application expertise developed over decades of industrial use.

Construction applications are expected to represent 37.6% of steel wire demand in 2025. This dominant share reflects the critical role of steel wire in modern construction projects, including concrete reinforcement, structural cables, fencing systems, and various building components that require strength and durability. Modern construction methods increasingly rely on steel wire products for earthquake resistance, structural integrity, and long-term performance under challenging environmental conditions. The segment benefits from global infrastructure development programs, urbanization trends, and increasing focuses on green construction practices that utilize recycled steel materials.

The steel wire market is advancing steadily due to increasing infrastructure investment, growing automotive production, and expanding energy sector development worldwide. However, the market faces challenges including raw material price volatility, environmental regulations affecting steel production, and increasing competition from alternative materials in certain applications. Technological advancement continues to influence production processes and market development patterns.

The growing development of advanced steel wire grades is enabling superior performance characteristics including enhanced strength, corrosion resistance, and fatigue life for demanding applications in automotive, energy, and industrial sectors. Modern steel wire production incorporates sophisticated alloying techniques, precision drawing processes, and specialized coating technologies that deliver consistent quality and reliable performance under extreme operating conditions. These technological improvements support expanding applications in renewable energy projects, high-performance automotive systems, and specialized industrial equipment requiring premium steel wire products.

Steel wire manufacturers are increasingly implementing green production practices and comprehensive recycling programs that reduce environmental impact while maintaining product quality and cost effectiveness. Advanced production facilities incorporate energy-efficient processes, waste reduction technologies, and recycled steel content that support environmental compliance requirements and customer eco-friendly objectives. Green manufacturing approaches enable continued market growth while addressing regulatory requirements and customer preferences for environmentally responsible steel wire products.

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.7% |

| India | 7.1% |

| Germany | 6.6% |

| France | 6.0% |

| UK | 5.4% |

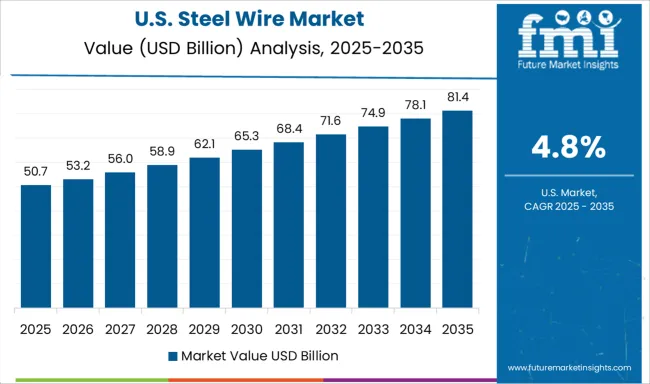

| USA | 4.8% |

| Brazil | 4.3% |

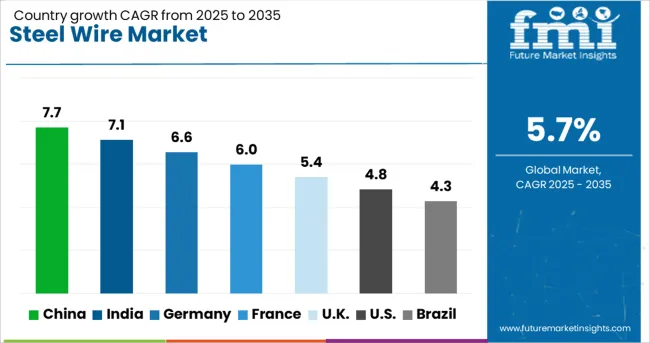

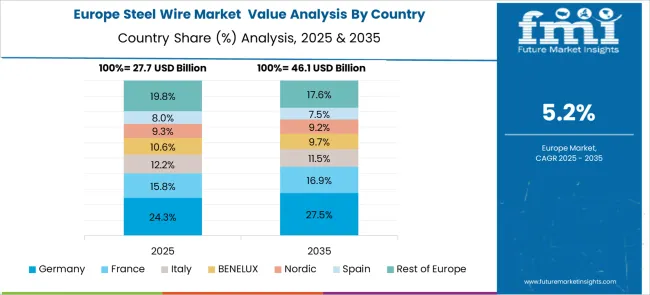

The steel wire market demonstrates varied growth patterns across key countries, with China leading at a 7.6% CAGR through 2035, driven by massive infrastructure development programs, expanding manufacturing capacity, and comprehensive urbanization initiatives requiring extensive steel wire applications. India follows at 7.1%, supported by rapid infrastructure modernization, growing automotive industry, and increasing energy sector investments. Germany maintains strong growth at 6.5%, focusing on advanced manufacturing technologies and premium-quality steel wire production. France advances at 5.9%, focusing on construction sector development and energy infrastructure modernization. The UK grows at 5.4%, supported by infrastructure investment programs and manufacturing sector recovery. The USA shows steady growth at 4.8%, driven by established infrastructure maintenance and automotive industry requirements. Brazil records solid growth at 4.2%, benefiting from regional development programs and increasing industrial activities. The report covers an in-depth analysis of 40+ countries; seven top-performing OECD countries are highlighted below.

Revenue from steel wire in China is projected to exhibit the highest growth rate with a CAGR of 7.6% through 2035, driven by extensive infrastructure development programs, massive urbanization projects, and comprehensive manufacturing capacity expansion across construction, automotive, and energy sectors. The country's infrastructure modernization initiatives prioritize high-quality steel wire products for transportation networks, energy transmission systems, and urban development projects that require reliable performance and long-term durability. Major steel producers are investing in advanced wire drawing technologies and specialty product development to serve growing domestic demand and expanding export opportunities.

Revenue from steel wire in India is expanding at a CAGR of 7.1%, supported by rapid infrastructure modernization programs, growing automotive manufacturing capacity, and increasing energy sector development requiring extensive wire and cable systems. The country's expanding construction industry includes residential developments, commercial projects, and industrial facilities that utilize steel wire for reinforcement applications and structural components. Steel producers are modernizing production facilities and expanding capacity to serve growing domestic demand while developing export capabilities for regional markets.

Demand for steel wire in Germany is projected to grow at a CAGR of 6.5%, supported by the country's focuses on advanced manufacturing technologies, precision engineering applications, and premium-quality steel wire production capabilities. German manufacturers focus on high-performance wire grades for automotive applications, industrial machinery, and specialized engineering projects that require superior strength characteristics and dimensional precision. The market is characterized by technological innovation, stringent quality standards, and comprehensive product development programs that serve demanding industrial applications.

Demand for steel wire in France is expanding at a CAGR of 5.9%, driven by construction sector development, energy infrastructure modernization, and comprehensive urban development projects requiring reliable steel wire products. French manufacturers emphasize quality production standards and specialized applications that serve construction reinforcement, automotive components, and energy transmission systems. The market benefits from technological advancement, environmental compliance requirements, and growing focuses on green construction practices utilizing recycled steel materials.

Demand for steel wire in the UK is projected to grow at a CAGR of 5.4%, driven by infrastructure investment programs, manufacturing sector recovery, and comprehensive development projects requiring steel wire applications across construction and industrial sectors. British manufacturers are modernizing production capabilities and investing in advanced technologies that improve product quality and operational efficiency. The market is supported by government infrastructure programs, construction industry development, and increasing focuses on eco-friendly manufacturing practices.

Demand for steel wire in the USA is expanding at a CAGR of 4.8%, supported by established infrastructure maintenance programs, automotive industry requirements, and comprehensive manufacturing capabilities serving diverse applications across construction, transportation, and energy sectors. American steel producers maintain mature production facilities and comprehensive product portfolios that address established market requirements and emerging application opportunities. The market benefits from stable demand patterns, technological innovation, and established supply chain relationships across major industrial sectors.

Demand for steel wire in Brazil is projected to grow at a CAGR of 4.2%, driven by regional development programs, increasing industrial activities, and expanding construction sector requiring steel wire products for infrastructure projects and manufacturing applications. Brazilian steel producers are gradually expanding production capacity and modernizing facilities to serve growing domestic demand and regional export opportunities. The market is supported by construction industry growth, infrastructure development, and increasing industrial manufacturing activities.

The steel wire market is defined by competition among integrated steel producers, specialized wire manufacturers, and regional steel processing companies. Companies are investing in advanced production technologies, capacity expansion programs, product development initiatives, and comprehensive service offerings to deliver high-quality steel wire products that meet diverse customer requirements and industry specifications. Strategic partnerships, technological innovation, and geographic expansion are central to strengthening market positions and supporting customer needs across multiple application sectors.

ArcelorMittal, Luxembourg-based, offers comprehensive steel wire solutions with focus on innovation, quality assurance, and integrated production capabilities serving global construction and industrial markets. Bridon-Bekaert Ropes Group, Belgium, provides specialized wire rope and cable products with focuses on high-performance applications and technical expertise. Heico Companies' Metal Processing Group, USA, delivers precision wire processing and specialty products for demanding applications. Optimus Steel, regional producer, focuses on cost-effective solutions and reliable supply chain management.

HBIS GROUP, China, emphasizes large-scale production capabilities and comprehensive product portfolios for domestic and export markets. KOBE STEEL, Japan, provides advanced steel wire technologies with focus on automotive and industrial applications. WireCo WorldGroup, USA, delivers specialized wire rope and cable solutions for industrial and energy applications. JFE Steel Corporation, Japan, offers integrated steel production and advanced wire products. Nippon Steel Corporation, Japan, provides premium steel wire grades and comprehensive technical support. Insteel Industries, USA, focuses on concrete reinforcement products and construction applications.

| Items | Values |

|---|---|

| Quantitative Units | USD 120.8 billion |

| Material Outlook | Carbon Steel, Stainless Steel, Alloy Steel |

| Application Outlook | Construction, Automotive, Energy, Industrial, Agriculture, Others |

| Regions Covered | China, India, Germany, France, UK, USA, Brazil |

| Key Companies Profiled | ArcelorMittal, Bridon-Bekaert Ropes Group, Heico Companies' Metal Processing Group, Optimus Steel, HBIS GROUP, KOBE STEEL, WireCo WorldGroup, JFE Steel Corporation, Nippon Steel Corporation, Insteel Industries |

| Additional Attributes | Dollar sales by material type and application sector, regional demand trends across key markets, competitive landscape with established steel producers and specialized wire manufacturers, customer preferences for standard versus specialty wire grades, integration with construction planning and automotive manufacturing processes, innovations in high-performance alloys and coating technologies. |

The global steel wire market is estimated to be valued at USD 120.8 billion in 2025.

The market size for the steel wire market is projected to reach USD 210.3 billion by 2035.

The steel wire market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types in steel wire market are carbon steel, stainless steel and alloy steel.

In terms of application outlook, construction segment to command 37.6% share in the steel wire market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Steel Wire Reinforced Polyethylene Pipe Market Size and Share Forecast Outlook 2025 to 2035

Stainless Steel Submerged Arc Welding Wire Market Size and Share Forecast Outlook 2025 to 2035

Steel Drum Market Size and Share Forecast Outlook 2025 to 2035

Steel Drums & IBCs Market Size and Share Forecast Outlook 2025 to 2035

Steel Roll-on Tube Market Size and Share Forecast Outlook 2025 to 2035

Steel Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Steel Salvage Drums Market Size and Share Forecast Outlook 2025 to 2035

Steel Strapping Market Size and Share Forecast Outlook 2025 to 2035

Steel Drum Industry Analysis in Southeast Asia Size and Share Forecast Outlook 2025 to 2035

Steel Studs Market Size and Share Forecast Outlook 2025 to 2035

Steel Rebar Market Size and Share Forecast Outlook 2025 to 2035

Steel Sections Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Steel Market Size, Growth, and Forecast 2025 to 2035

Steel Containers Market Analysis by Product Type, Capacity Type, End Use, and Region through 2025 to 2035

Steel Pipe Market Growth - Trends & Forecast 2025 to 2035

Key Players & Market Share in the Steel Containers Industry

Competitive Overview of Steel Drum Market Share

Examining Market Share Trends in Steel Drums and IBCs Industry

Japan Steel Drum Market Analysis – Trends & Forecast 2023-2033

Korea Steel Drum Market Growth – Trends & Forecast 2023-2033

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA