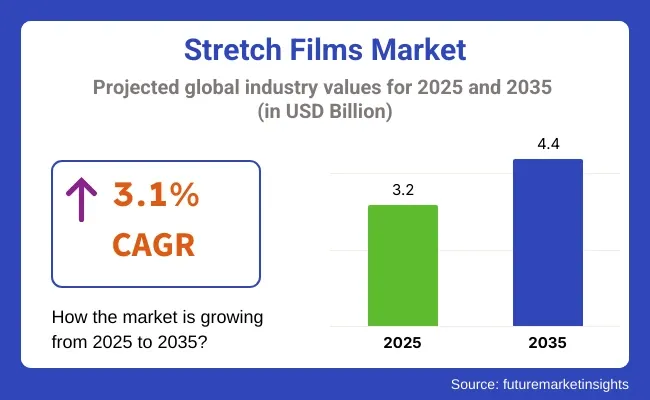

The global stretch films market is worth USD 3.2 billion in 2025 and is poised to expand to USD 4.4 billion by 2035, which shows a CAGR of 3.1%. This growth is primarily driven by the increasing demand for stretch films in various industries, particularly in packaging, where they are used to secure and protect goods during transportation and storage.

The rise of e-commerce and retail activities, coupled with the need for efficient and cost-effective packaging solutions, is expected to significantly propel the demand for stretch films in the coming years. Stretch films provide excellent load stability, resistance to moisture, and protection from dust and contaminants, which contributes to their widespread adoption across key sectors.

Looking ahead, the market for stretch films is likely to benefit from continuous advancements in film technology. Innovations such as pre-stretched films, which offer enhanced performance and reduced material usage, are expected to create new opportunities for growth. The increasing focus on sustainability will also likely drive the adoption of biodegradable and recyclable stretch films.

Moreover, the ongoing trend of automation in packaging processes is likely to increase the demand for stretch films, as automated systems require high-performance films to optimize packaging efficiency. As industries continue to emphasize reducing waste and improving packaging performance, the stretch films market is likely to experience a steady increase in demand.

Government regulations in the stretch films market are becoming more stringent, with a focus on sustainability and reducing the environmental impact of packaging materials. Many countries have introduced regulations to reduce plastic waste and encourage the use of recyclable, biodegradable, or compostable materials in packaging.

These regulations are driving manufacturers to develop stretch films made from renewable resources or materials that can be easily recycled after use. As governments enforce and introduce new policies, the industry is adapting to meet these requirements, ensuring that stretch films remain a vital part of sustainable packaging solutions.

The below table presents the expected CAGR for the global stretch films market over several semi-annual periods spanning from 2024 to 2034.

| Particular | Value CAGR |

|---|---|

| H1 (2024 to 2034) | 1.0% |

| H2 (2024 to 2034) | 2.2% |

| H1 (2025 to 2035) | 1.9% |

| H2 (2025 to 2035) | 3.0% |

In the first half (H1) of the decade from 2024 to 2034, the business is predicted to surge at a CAGR of 1.0%, followed by a slightly higher growth rate of 2.2% in the second half (H2) of the same decade. Moving into the subsequent period, from H1 2025 to H2 2035, the CAGR is projected to decrease slightly to 1.9% in the first half and remain relatively moderate at 3.0% in the second half. In the first half (H1) the market witnessed a decrease of 90 BPS while in the second half (H2), the market witnessed an increase of 80 BPS.

The market is segmented based on material, manufacturing process, end use, and region. By material, the market is divided into polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and other plastics (polystyrene (PS), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyethylene terephthalate (PET)). In terms of manufacturing process, it is segmented into cast blown film and stretch blown film.

Based on end use, the market is categorized into construction, food & beverage, pharmaceuticals, consumer products, paper, textile, and chemicals & fertilizers. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia & Pacific, and the Middle East & Africa.

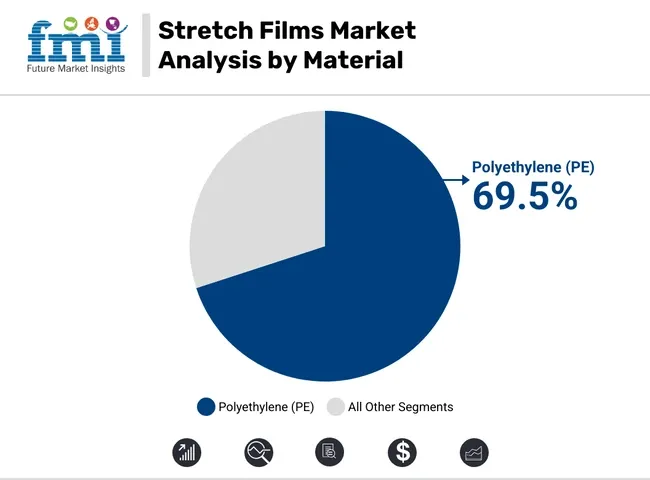

The polyethylene (PE) segment is projected to dominate the stretch films market, holding a share of 69.5% in 2025. This growth is primarily driven by the increasing demand for flexible packaging solutions, especially in the food & beverage sector. Polyethylene is highly valued for its durability, flexibility, and cost-effectiveness, making it the preferred material for stretch films. It provides a high degree of stretchability, which is essential for securing and protecting goods during transportation and storage. Moreover, its low cost and ease of production enhance its appeal, making it a widely used material in the packaging industry.

Polyethylene’s superior strength, puncture resistance, and excellent clarity further contribute to its dominance. As sustainability becomes a key focus across industries, polyethylene (PE) continues to be favored for its recyclability and relatively minimal environmental impact compared to other materials.

While polypropylene (PP), polyvinyl chloride (PVC), and other plastics remain important, they are growing at a slower pace due to higher costs and less versatility. These materials find use in specific, niche applications, but they do not match the growth trajectory of polyethylene in the stretch films market. As demand for sustainable packaging solutions increases, polyethylene (PE) will continue to play a central role in the market.

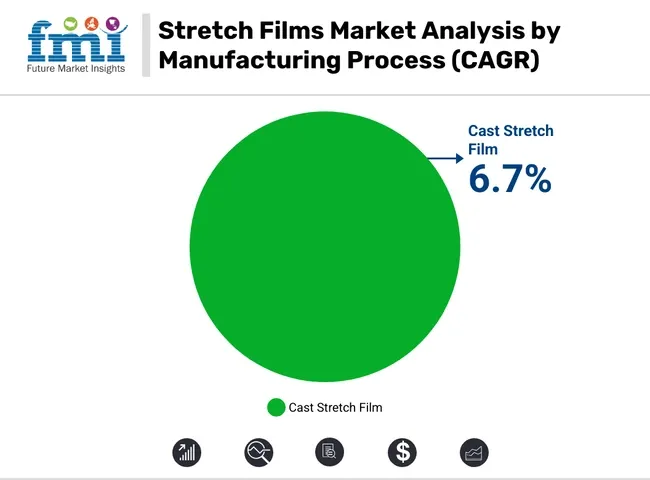

The cast stretch film segment is projected to grow at a CAGR of 6.7% from 2025 to 2035. Cast stretch films are favored for their cost-efficiency, higher clarity, and consistent thickness. The cast extrusion process allows for faster production speeds, making it a more economical option for manufacturers, while still maintaining uniform film quality. These films are particularly preferred for applications requiring high stretchability and strong cling properties. Cast films provide superior stretch ability, which minimizes material usage and enhances cost-effectiveness.

They are easy to use in automated applications and deliver high clarity, making them ideal for wrapping and securing products such as pallets and boxes. In addition to their functional benefits, cast stretch films are less noisy and have superior optics, making them ideal for consumer-facing applications. They provide excellent puncture resistance and can secure products efficiently without requiring high forces, which reduces operational costs.

While blown stretch film continues to be used for various applications, cast stretch films are growing at a faster rate due to their superior stretch properties, reduced costs, and higher clarity. These advantages have made cast stretch films the material of choice for logistics and packaging applications, particularly in industries like food and beverage, pharmaceuticals, and e-commerce.

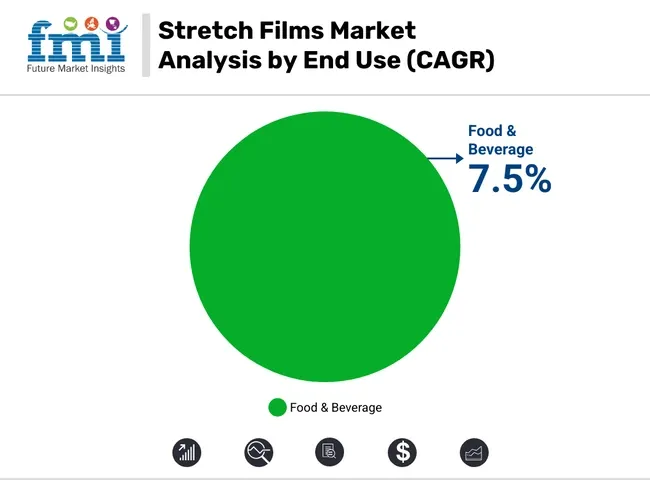

The food & beverage segment is projected to experience the fastest growth, with a CAGR of 7.5% from 2025 to 2035. Stretch films provide essential protection against contamination, moisture, and physical damage, making them the preferred packaging solution for the food industry. They are used extensively in packaging food items such as meat, fresh produce, dairy, and beverages.

As the food industry moves towards safer, more efficient packaging solutions, the demand for stretch films is expected to grow significantly. This is particularly true for the food & beverage sector, where packaging must meet stringent hygiene standards and ensure the longevity of products. The rise of convenience foods and increased e-commerce in the food sector further fuels demand for flexible, secure packaging that maintains product quality.

Additionally, polyethylene (PE), particularly LLDPE, is the most widely used material in food packaging due to its superior strength, flexibility, and puncture resistance, ensuring products are well-protected during transport and storage. As the sector grows, driven by the increasing demand for packaged and processed foods, stretch films will continue to play a critical role in food preservation, helping products retain freshness and quality for longer periods. This trend is expected to lead the charge for stretch films during the forecast period.

Surging Demand for Stretch Films for Durable & Protective Packaging Solutions across Industries

Demand from durable and protective packaging is pushing the global stretch films market upward Food & beverages, pharmaceuticals and consumer electronics use stretch films to safely secure their product at the moment of storage as well as shipping. Stretch films are used like a protective packaging against physical destruction, moisture as well as pollutants so that a product will be not damaged while staying safe in its supply chain.

In the food and beverage industry, stretch films guarantee freshness; in pharmaceuticals, ensure product integrity and hygiene compliance; while in consumer electronics, prevent damage due to impacts or environment-related causes. The growth in these markets drives their need for reliable and protective packaging and surges the demand for stretch films.

Need for Secured Packaging for Supply Chain Optimization Drives Stretch Films Demand

Companies across various sectors have focused on improving the logistics efficiency to make smooth flow of goods and also reduce costs. For this purpose, stretch films are employed for bundling products on pallets, which ensures that products don't move during transit. The films ensure that products reach their destination without any damage, thereby reducing returns and customer complaints.

Additionally, stretch films are lightweight, reducing the associated transport costs and increasing fuel efficiency, making them a preferred packaging solution. Stretch films have a dominant role in supply chain optimization, which is an important driver for the global stretch films market, as these support faster and more reliable operations in different sectors.

Environmental Concerns and Recycling Challenges of Plastic May Impact Stretch Films Market Growth

As stretch films are made from different types of plastics, it contributes the amount of amount plastic waste generated across various regions. Most business enterprises and consumers are now actively searching for alternatives to traditional plastic packaging as the level of awareness about the environment increases, especially in those industries where sustainability has become the core priority.

The problem is that many stretch films cannot be recycled because of the thin, flexible, and stickiness nature of these films. This reduces their compatibility with recycling systems, thus limiting their ability to align with circular economy practices. The limited recyclability and environmental impact of stretch films may thus become a challenge for growth in the market with the increasing regulations and consumer pressure for more eco-friendly options.

Tier 1 companies comprise market leaders capturing significant market share in Stretch Films market. These market leaders are characterized by high production capacity and a wide product portfolio. These market leaders are distinguished by their extensive expertise in manufacturing across multiple packaging formats and a broad geographical reach, underpinned by a robust consumer base.

They provide a wide range of series including recycling and manufacturing utilizing the latest technology and meeting the regulatory standards providing the highest quality. Prominent companies within tier 1 include Berry Global Group Inc., Sigma Plastics Group, TG Group of Companies, Trioworld Group and Paragon Films.

Tier 2 companies include mid-size players having presence in specific regions and highly influencing the local market. These are characterized by a strong presence overseas and strong market knowledge. These market players have good technology and ensure regulatory compliance but may not have advanced technology and wide global reach.

Prominent companies in tier 2 include Intertape Polymer Group Inc., Scientex Berhad, Inteplast Group, Anchor Packaging Inc., POLIFILM, Coveris Holdings S.A., Signode Industrial Group LLC, THE FROMM GROUP and Tilak Polypack Private Limited.

Tier 3 includes the majority of small-scale companies operating at the local presence and serving niche markets. These companies are notably oriented towards fulfilling local market demands and are consequently classified within the tier 3 share segment. They are small-scale players and have limited geographical reach. Tier 3, within this context, is recognized as an unorganized market, denoting a sector characterized by a lack of extensive structure and formalization when compared to organized competitors.

The section below covers the future forecast for the stretch films market in terms of countries. Information on key countries in several parts of the globe, including North America, Latin America, East Asia, South Asia and Pacific, Western Europe, Eastern Europe and MEA is provided. USA is expected to account for a CAGR of 2.1% through 2035. In Europe, Spain is projected to witness a CAGR of 2.0% by 2035.

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| USA | 2.1% |

| Germany | 0.9% |

| China | 5.6% |

| UK | 1.2% |

| Spain | 2.0% |

| India | 6.3% |

| Canada | 3.2% |

E-commerce in the USA has grown at a very fast rate, which has increased the demand for stretch films. Online retail continues to grow, and the need for secure and efficient packaging solutions has become critical. Stretch films are ideal solutions for securing products during shipment so that they are not damaged when traveling long distances.

Stretch films are also important for the wrapping of palletized goods as well as for protecting individual products by e-commerce companies, especially in high-volume sales events. With the emergence of direct-to-consumer shipments and increased complexity of supply chains, stretch films are now critical for maintaining product integrity and improving customer satisfaction through safe delivery.

The construction boom in the UK, especially in large-scale infrastructure projects and urban housing developments such as the HS2 railway and major housing estates, has increased the demand for packaging solutions. Construction firms rely on stretch films to secure critical materials such as steel, and heavy machinery during transport and storage. Stretch films are used on a large scale for bundling of steel beam and construction equipment in bundles while preventing shifting during transport, moisture damage, and contamination.

In light of growing complexity projects such as just-in-time delivery models and multi-site developments, stretch films form a very convenient flexible solution to address material protection and overcome the logistical problem of tight timelines.

Key Players in Stretch Films Market

In terms of material, the industry is segmented into polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and other plastics. Polyethylene (PE) further includes LDPE and LLDPE.

In terms of manufacturing process, the market for stretch films is divided into cast stretch film and blown stretch film.

End users related of stretch film are construction, food and beverage, pharmaceuticals, consumer products, paper, textile, chemicals and fertilizers.

Key Countries of North America, Latin America, East Asia, South Asia & Pacific, Western Europe, Eastern Europe and Middle East & Africa are covered.

The global stretch films industry is projected to witness CAGR of 3.1% between 2025 and 2035.

The global stretch films industry stood at USD 3,161.6 million in 2024.

Global stretch films industry is anticipated to reach USD 4,401.8 million by 2035 end.

South Asia & Pacific is set to record a CAGR of 5.0% in assessment period.

The key players operating in the global stretch films industry include Berry Global Group Inc., Sigma Plastics Group, TG Group of Companies, Trioworld Group and Paragon Films.

Table 1: Global Market Value (US$ Million) Forecast by Region, 2019 to 2034

Table 2: Global Market Volume (Tons) Forecast by Region, 2019 to 2034

Table 3: Global Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 4: Global Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 5: Global Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 6: Global Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 7: Global Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 8: Global Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 9: North America Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 10: North America Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 11: North America Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 12: North America Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 13: North America Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 14: North America Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 15: North America Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 16: North America Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 17: Latin America Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 18: Latin America Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 19: Latin America Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 20: Latin America Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 21: Latin America Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 22: Latin America Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 23: Latin America Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 24: Latin America Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 25: Western Europe Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 26: Western Europe Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 27: Western Europe Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 28: Western Europe Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 29: Western Europe Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 30: Western Europe Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 31: Western Europe Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 32: Western Europe Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 33: Eastern Europe Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 34: Eastern Europe Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 35: Eastern Europe Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 36: Eastern Europe Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 37: Eastern Europe Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 38: Eastern Europe Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 39: Eastern Europe Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 40: Eastern Europe Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 41: South Asia and Pacific Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 42: South Asia and Pacific Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 43: South Asia and Pacific Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 44: South Asia and Pacific Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 45: South Asia and Pacific Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 46: South Asia and Pacific Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 47: South Asia and Pacific Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 48: South Asia and Pacific Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 49: East Asia Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 50: East Asia Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 51: East Asia Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 52: East Asia Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 53: East Asia Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 54: East Asia Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 55: East Asia Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 56: East Asia Market Volume (Tons) Forecast by End-use, 2019 to 2034

Table 57: Middle East and Africa Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 58: Middle East and Africa Market Volume (Tons) Forecast by Country, 2019 to 2034

Table 59: Middle East and Africa Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 60: Middle East and Africa Market Volume (Tons) Forecast by Material, 2019 to 2034

Table 61: Middle East and Africa Market Value (US$ Million) Forecast by Manufacturing Process, 2019 to 2034

Table 62: Middle East and Africa Market Volume (Tons) Forecast by Manufacturing Process, 2019 to 2034

Table 63: Middle East and Africa Market Value (US$ Million) Forecast by End-use, 2019 to 2034

Table 64: Middle East and Africa Market Volume (Tons) Forecast by End-use, 2019 to 2034

Figure 1: Global Market Value (US$ Million) by Material, 2024 to 2034

Figure 2: Global Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 3: Global Market Value (US$ Million) by End-use, 2024 to 2034

Figure 4: Global Market Value (US$ Million) by Region, 2024 to 2034

Figure 5: Global Market Value (US$ Million) Analysis by Region, 2019 to 2034

Figure 6: Global Market Volume (Tons) Analysis by Region, 2019 to 2034

Figure 7: Global Market Value Share (%) and BPS Analysis by Region, 2024 to 2034

Figure 8: Global Market Y-o-Y Growth (%) Projections by Region, 2024 to 2034

Figure 9: Global Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 10: Global Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 11: Global Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 12: Global Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 13: Global Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 14: Global Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 15: Global Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 16: Global Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 17: Global Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 18: Global Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 19: Global Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 20: Global Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 21: Global Market Attractiveness by Material, 2024 to 2034

Figure 22: Global Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 23: Global Market Attractiveness by End-use, 2024 to 2034

Figure 24: Global Market Attractiveness by Region, 2024 to 2034

Figure 25: North America Market Value (US$ Million) by Material, 2024 to 2034

Figure 26: North America Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 27: North America Market Value (US$ Million) by End-use, 2024 to 2034

Figure 28: North America Market Value (US$ Million) by Country, 2024 to 2034

Figure 29: North America Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 30: North America Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 31: North America Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 32: North America Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 33: North America Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 34: North America Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 35: North America Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 36: North America Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 37: North America Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 38: North America Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 39: North America Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 40: North America Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 41: North America Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 42: North America Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 43: North America Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 44: North America Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 45: North America Market Attractiveness by Material, 2024 to 2034

Figure 46: North America Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 47: North America Market Attractiveness by End-use, 2024 to 2034

Figure 48: North America Market Attractiveness by Country, 2024 to 2034

Figure 49: Latin America Market Value (US$ Million) by Material, 2024 to 2034

Figure 50: Latin America Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 51: Latin America Market Value (US$ Million) by End-use, 2024 to 2034

Figure 52: Latin America Market Value (US$ Million) by Country, 2024 to 2034

Figure 53: Latin America Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 54: Latin America Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 55: Latin America Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 56: Latin America Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 57: Latin America Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 58: Latin America Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 59: Latin America Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 60: Latin America Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 61: Latin America Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 62: Latin America Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 63: Latin America Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 64: Latin America Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 65: Latin America Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 66: Latin America Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 67: Latin America Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 68: Latin America Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 69: Latin America Market Attractiveness by Material, 2024 to 2034

Figure 70: Latin America Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 71: Latin America Market Attractiveness by End-use, 2024 to 2034

Figure 72: Latin America Market Attractiveness by Country, 2024 to 2034

Figure 73: Western Europe Market Value (US$ Million) by Material, 2024 to 2034

Figure 74: Western Europe Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 75: Western Europe Market Value (US$ Million) by End-use, 2024 to 2034

Figure 76: Western Europe Market Value (US$ Million) by Country, 2024 to 2034

Figure 77: Western Europe Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 78: Western Europe Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 79: Western Europe Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 80: Western Europe Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 81: Western Europe Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 82: Western Europe Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 83: Western Europe Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 84: Western Europe Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 85: Western Europe Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 86: Western Europe Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 87: Western Europe Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 88: Western Europe Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 89: Western Europe Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 90: Western Europe Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 91: Western Europe Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 92: Western Europe Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 93: Western Europe Market Attractiveness by Material, 2024 to 2034

Figure 94: Western Europe Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 95: Western Europe Market Attractiveness by End-use, 2024 to 2034

Figure 96: Western Europe Market Attractiveness by Country, 2024 to 2034

Figure 97: Eastern Europe Market Value (US$ Million) by Material, 2024 to 2034

Figure 98: Eastern Europe Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 99: Eastern Europe Market Value (US$ Million) by End-use, 2024 to 2034

Figure 100: Eastern Europe Market Value (US$ Million) by Country, 2024 to 2034

Figure 101: Eastern Europe Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 102: Eastern Europe Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 103: Eastern Europe Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 104: Eastern Europe Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 105: Eastern Europe Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 106: Eastern Europe Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 107: Eastern Europe Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 108: Eastern Europe Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 109: Eastern Europe Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 110: Eastern Europe Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 111: Eastern Europe Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 112: Eastern Europe Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 113: Eastern Europe Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 114: Eastern Europe Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 115: Eastern Europe Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 116: Eastern Europe Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 117: Eastern Europe Market Attractiveness by Material, 2024 to 2034

Figure 118: Eastern Europe Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 119: Eastern Europe Market Attractiveness by End-use, 2024 to 2034

Figure 120: Eastern Europe Market Attractiveness by Country, 2024 to 2034

Figure 121: South Asia and Pacific Market Value (US$ Million) by Material, 2024 to 2034

Figure 122: South Asia and Pacific Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 123: South Asia and Pacific Market Value (US$ Million) by End-use, 2024 to 2034

Figure 124: South Asia and Pacific Market Value (US$ Million) by Country, 2024 to 2034

Figure 125: South Asia and Pacific Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 126: South Asia and Pacific Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 127: South Asia and Pacific Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 128: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 129: South Asia and Pacific Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 130: South Asia and Pacific Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 131: South Asia and Pacific Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 132: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 133: South Asia and Pacific Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 134: South Asia and Pacific Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 135: South Asia and Pacific Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 136: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 137: South Asia and Pacific Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 138: South Asia and Pacific Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 139: South Asia and Pacific Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 140: South Asia and Pacific Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 141: South Asia and Pacific Market Attractiveness by Material, 2024 to 2034

Figure 142: South Asia and Pacific Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 143: South Asia and Pacific Market Attractiveness by End-use, 2024 to 2034

Figure 144: South Asia and Pacific Market Attractiveness by Country, 2024 to 2034

Figure 145: East Asia Market Value (US$ Million) by Material, 2024 to 2034

Figure 146: East Asia Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 147: East Asia Market Value (US$ Million) by End-use, 2024 to 2034

Figure 148: East Asia Market Value (US$ Million) by Country, 2024 to 2034

Figure 149: East Asia Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 150: East Asia Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 151: East Asia Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 152: East Asia Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 153: East Asia Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 154: East Asia Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 155: East Asia Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 156: East Asia Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 157: East Asia Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 158: East Asia Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 159: East Asia Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 160: East Asia Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 161: East Asia Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 162: East Asia Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 163: East Asia Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 164: East Asia Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 165: East Asia Market Attractiveness by Material, 2024 to 2034

Figure 166: East Asia Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 167: East Asia Market Attractiveness by End-use, 2024 to 2034

Figure 168: East Asia Market Attractiveness by Country, 2024 to 2034

Figure 169: Middle East and Africa Market Value (US$ Million) by Material, 2024 to 2034

Figure 170: Middle East and Africa Market Value (US$ Million) by Manufacturing Process, 2024 to 2034

Figure 171: Middle East and Africa Market Value (US$ Million) by End-use, 2024 to 2034

Figure 172: Middle East and Africa Market Value (US$ Million) by Country, 2024 to 2034

Figure 173: Middle East and Africa Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 174: Middle East and Africa Market Volume (Tons) Analysis by Country, 2019 to 2034

Figure 175: Middle East and Africa Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 176: Middle East and Africa Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 177: Middle East and Africa Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 178: Middle East and Africa Market Volume (Tons) Analysis by Material, 2019 to 2034

Figure 179: Middle East and Africa Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 180: Middle East and Africa Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 181: Middle East and Africa Market Value (US$ Million) Analysis by Manufacturing Process, 2019 to 2034

Figure 182: Middle East and Africa Market Volume (Tons) Analysis by Manufacturing Process, 2019 to 2034

Figure 183: Middle East and Africa Market Value Share (%) and BPS Analysis by Manufacturing Process, 2024 to 2034

Figure 184: Middle East and Africa Market Y-o-Y Growth (%) Projections by Manufacturing Process, 2024 to 2034

Figure 185: Middle East and Africa Market Value (US$ Million) Analysis by End-use, 2019 to 2034

Figure 186: Middle East and Africa Market Volume (Tons) Analysis by End-use, 2019 to 2034

Figure 187: Middle East and Africa Market Value Share (%) and BPS Analysis by End-use, 2024 to 2034

Figure 188: Middle East and Africa Market Y-o-Y Growth (%) Projections by End-use, 2024 to 2034

Figure 189: Middle East and Africa Market Attractiveness by Material, 2024 to 2034

Figure 190: Middle East and Africa Market Attractiveness by Manufacturing Process, 2024 to 2034

Figure 191: Middle East and Africa Market Attractiveness by End-use, 2024 to 2034

Figure 192: Middle East and Africa Market Attractiveness by Country, 2024 to 2034

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Stretch and Shrink Films Market Size and Share Forecast Outlook 2025 to 2035

UVI Stretch Films Market Size and Share Forecast Outlook 2025 to 2035

USA Stretch Hood Films Market Size and Share Forecast Outlook 2025 to 2035

Cast Stretch Films Market Size and Share Forecast Outlook 2025 to 2035

Blown Stretch Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

Biodegradable Stretch Films Market - Analysis Size, Share, and Forecast 2025 to 2035

Stretch Film Industry Analysis in DACH Size and Share Forecast Outlook 2025 to 2035

Stretch Film Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Stretch Mark Prevention Creams Market Size and Share Forecast Outlook 2025 to 2035

Stretch Sleeve and Shrink Sleeve Labels Market Size and Share Forecast Outlook 2025 to 2035

Stretch Marks Treatment Market Size and Share Forecast Outlook 2025 to 2035

Stretcher Accessories Market Size and Share Forecast Outlook 2025 to 2035

Stretch Film Packs Market Insights on Type, Product, Application, Industry, and Region - 2025 to 2035

Stretch Mark Removal Products Market Insights - Growth & Forecast 2025 to 2035

Stretch Hood Films Market Analysis by Up to 50 microns, 50-100 microns, 100-150 microns, 150 microns & above Through 2035

Stretchable Electronics Market Trends - Growth & Forecast 2025 to 2035

Stretch Wrapper Market Growth - Demand & Forecast 2025 to 2035

Stretch Blow Molding Machines Market Segmentation based on Technology Type, Orientation Type, End Use, and Region: A Forecast for 2025 and 2035

Stretchable Conductive Material Analysis by Material, Fillers, Stretching Mechanism, Fabrication, Function, Application, End-User and Region - Forecast for 2025 to 2035

Market Share Insights of Leading Stretch Blow Molding Machines Providers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA