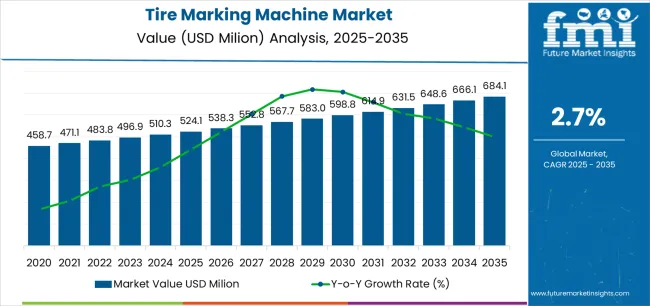

The tire marking machine industry stands at the threshold of a decade-long expansion trajectory that promises to reshape tire manufacturing technology, product identification solutions, and automotive component traceability applications across permanent marking, temporary marking, and specialty tire production sectors. The market's journey from USD 524.1 million in 2025 to USD 684.1 million by 2035 represents substantial growth, demonstrating the accelerating adoption of advanced marking formulations and automated technology across tire manufacturing, quality control, and specialty identification applications.

The first half of the decade (2025-2030) will witness the market climbing from USD 524.1 million to approximately USD 593.1 million, adding USD 69.0 million in value, which constitutes 43% of the total forecast growth period. This phase will be characterized by the rapid adoption of inkjet marking systems, driven by increasing tire production volumes and the growing need for efficient identification requirements worldwide. Advanced marking capabilities and flexible automation systems will become standard expectations rather than premium options.

The latter half (2030-2035) will witness sustained growth from USD 593.1 million to USD 684.1 million, representing an addition of USD 91.0 million or 57% of the decade's expansion. This period will be defined by mass market penetration of specialized marking technologies, integration with comprehensive manufacturing platforms, and seamless compatibility with existing tire production infrastructure. The market trajectory signals fundamental shifts in how manufacturers approach traceability optimization and quality management, with participants positioned to benefit from sustained demand across multiple machine types and marking applications.

The tire marking machine market demonstrates distinct growth phases with varying market characteristics and competitive dynamics. Between 2025 and 2030, the market progresses through its technology adoption phase, expanding from USD 524.1 million to USD 593.1 million with steady annual increments averaging 2.7% growth. This period showcases the transition from basic marking formulations to advanced inkjet systems with enhanced precision capabilities and integrated quality control systems becoming mainstream features.

The 2025-2030 phase adds USD 69.0 million to market value, representing 43% of total decade expansion. Market maturation factors include standardization of tire manufacturing and traceability protocols, declining component costs for specialized marking formulations, and increasing industry awareness of identification benefits reaching optimal effectiveness in permanent marking and quality control applications. Competitive landscape evolution during this period features established marking equipment manufacturers like Markem-Imaje and Videojet Technologies expanding their tire marking portfolios while specialty manufacturers focus on advanced technology development and enhanced marking capabilities.

From 2030 to 2035, market dynamics shift toward advanced automation integration and global manufacturing expansion, with growth continuing from USD 593.1 million to USD 684.1 million, adding USD 91.0 million or 57% of total expansion. This phase transition centers on specialized marking systems, integration with automated tire production networks, and deployment across diverse manufacturing and quality control scenarios, becoming standard rather than specialized applications. The competitive environment matures with focus shifting from basic marking capability to comprehensive traceability optimization systems and integration with manufacturing execution platforms.

At-a-Glance Metrics

| Metric | Value |

|---|---|

| Market Value (2025) | USD 524.1 million |

| Market Forecast (2035) | USD 684.1 million |

| Growth Rate | 2.7% CAGR |

| Leading Technology | Inkjet Machine Type |

| Primary Application | Permanent Marking Type Segment |

The market demonstrates strong fundamentals with inkjet marking systems capturing a dominant share through advanced printing design and production optimization capabilities. Permanent marking applications drive primary demand, supported by increasing tire traceability production and efficient identification technology requirements. Geographic expansion remains concentrated in developed markets with established tire manufacturing infrastructure, while emerging economies show accelerating adoption rates driven by automotive industry expansion and rising quality standards.

Market expansion rests on three fundamental shifts driving adoption across the tire manufacturing, automotive, and quality control sectors. First, traceability compliance demand creates compelling operational advantages through tire marking machines that provide immediate product identification and quality tracking without compromising production goals, enabling manufacturers to meet stringent regulatory standards while maintaining manufacturing productivity and reducing recall risks. Second, tire production modernization accelerates as manufacturers worldwide seek advanced marking systems that complement traditional production processes, enabling precise identification customization and quality control that align with industry standards and safety regulations.

Third, quality assurance enhancement drives adoption from major tire manufacturers and automotive suppliers requiring effective marking solutions that maximize traceability while maintaining operational productivity during production and inspection operations. Growth faces headwinds from equipment cost challenges that vary across marking technology suppliers regarding the pricing of inkjet systems and laser components, which may limit adoption in cost-sensitive environments. Technical limitations also persist regarding marking durability and surface compatibility concerns that may reduce effectiveness in harsh operating conditions or specialty tire materials, which affect mark legibility and longevity requirements.

The tire marking machine market represents a specialized yet critical manufacturing opportunity driven by expanding global tire production, traceability modernization, and the need for superior product identification in diverse tire applications. As manufacturers worldwide seek to achieve optimal marking effectiveness, reduce identification errors, and integrate advanced marking systems with automated platforms, tire marking machines are evolving from basic identification tools to sophisticated traceability solutions ensuring quality compliance and manufacturing leadership.

The market's growth trajectory from USD 524.1 million in 2025 to USD 684.1 million by 2035 at a 2.7% CAGR reflects fundamental shifts in tire industry regulatory requirements and traceability optimization. Geographic expansion opportunities are particularly pronounced in Asia Pacific markets, while the dominance of inkjet systems and permanent marking applications provides clear strategic focus areas.

Strengthening the dominant inkjet segment through enhanced marking formulations, superior print quality, and automated production systems. This pathway focuses on optimizing ink composition, improving marking performance, extending operational effectiveness to optimal durability rates, and developing specialized formulations for diverse tire applications. Market leadership consolidation through advanced printing engineering and Industry 4.0 integration enables premium positioning while defending competitive advantages against alternative technologies. Expected revenue pool: USD 17.6-23.8 million

Rapid tire production and automotive industry growth across Asia Pacific creates substantial expansion opportunities through local manufacturing capabilities and technology transfer partnerships. Growing tire manufacturing and government automotive initiatives drive sustained demand for advanced marking systems. Localization strategies reduce import costs, enable faster technical support, and position companies advantageously for OEM programs while accessing growing domestic markets. Expected revenue pool: USD 15.3-21.4 million

Expansion within the dominant permanent marking segment (28.0% market share) through specialized marking designs addressing regulatory standards and long-term traceability requirements. This pathway encompasses automated marking systems, quality validation integration, and compatibility with diverse tire manufacturing processes. Premium positioning reflects superior mark durability and comprehensive compliance support supporting modern tire production. Expected revenue pool: USD 13.5-19.3 million

Strategic expansion into temporary marking applications requires enhanced marking capabilities and specialized formulations addressing production tracking operational requirements. This pathway addresses in-process identification performance, production flow enhancement, and removable marking with advanced technology engineering for demanding manufacturing standards. Premium pricing reflects specialized application requirements and flexible marking standards. Expected revenue pool: USD 11.9-17.4 million

Development of specialized laser marking formulations for high-precision applications and specialty tire segments, addressing specific durability requirements and permanent identification demands. This pathway encompasses non-contact marking, high-speed processing, and maintenance-free alternatives for emerging tire technologies. Technology differentiation through advanced laser systems enables diversified revenue streams while reducing dependency on consumable-based platforms. Expected revenue pool: USD 10.5-15.7 million

Expansion of stamping segment through mechanical reliability properties, cost-effective characteristics, and traditional application requirements. This pathway encompasses high-volume production applications, budget-conscious manufacturing, and proven formulations requiring economical marking solutions. Market development through optimized mechanical engineering enables differentiated positioning while accessing cost-conscious markets requiring reliable marking solutions. Expected revenue pool: USD 9.2-14.2 million

Development of connected marking systems addressing automation requirements and data integration needs across tire manufacturing applications. This pathway encompasses IoT connectivity, real-time monitoring, and comprehensive manufacturing execution system documentation. Premium positioning reflects technology leadership and smart manufacturing expertise while enabling access to digitally-focused procurement programs and Industry 4.0 partnerships. Expected revenue pool: USD 8.1-12.8 million

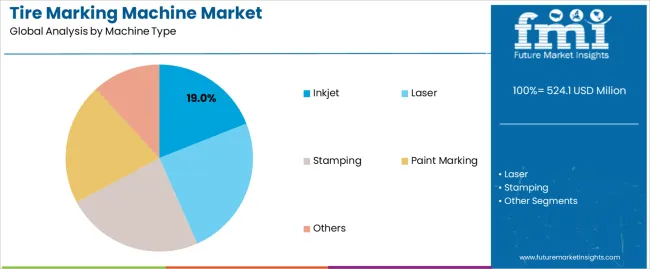

Primary Classification: The market segments by machine type into Inkjet, Laser, Stamping, Paint Marking, and Others categories, representing the evolution from basic mechanical marking to specialized automated solutions for comprehensive tire identification.

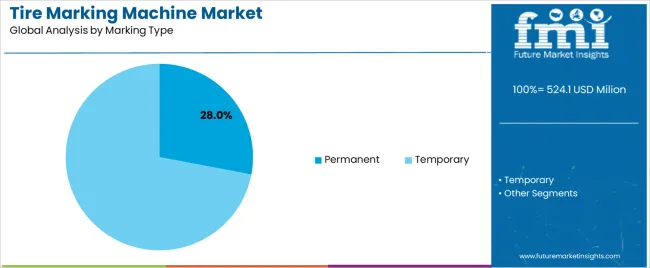

Secondary Classification: Marking type segmentation divides the market into Permanent and Temporary sectors, reflecting distinct requirements for mark durability, regulatory compliance, and application purposes.

The segmentation structure reveals technology progression from standard mechanical-based systems toward specialized marking technologies with enhanced automation and traceability capabilities, while application diversity spans from permanent tire identification to specialized temporary production tracking requiring precise marking solutions.

Market Position: Inkjet marking systems command the leading position in the tire marking machine market, holding a 30% share, due to advanced printing properties. These systems offer superior flexibility, premium speed capabilities, and marking versatility, enabling tire manufacturers to achieve optimal product identification across diverse production environments.

Value Drivers: The segment benefits from manufacturer preference for non-contact marking systems that provide consistent print quality, reduced maintenance complexity, and operational flexibility without requiring physical tire contact. Advanced printing features enable high-speed production integration, variable data printing, and compatibility with diverse tire surfaces, where marking speed and print quality represent critical operational requirements.

Competitive Advantages: Inkjet marking systems differentiate through proven non-contact advantages, consistent ink deposition characteristics, and integration with automated production lines that enhance operational effectiveness while maintaining optimal quality suitable for diverse tire applications.

Key market characteristics:

Laser marking systems maintain high-precision positioning in the tire marking machine market due to their permanent marking properties and maintenance-free advantages. These systems appeal to manufacturers requiring durable identification with superior performance for premium tire applications. Market adoption is driven by quality-focused production, emphasizing reliable permanent solutions and operational efficiency through non-consumable marking systems while maintaining superior mark durability.

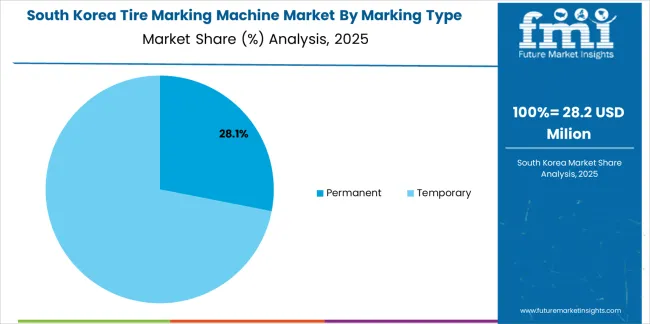

Market Context: Permanent marking applications dominate the tire marking machine market with approximately 28.0% market share due to widespread adoption of durable identification and increasing focus on regulatory compliance, product traceability, and long-term legibility applications that minimize identification failures while maintaining industry standards.

Appeal Factors: Tire manufacturers prioritize marking permanence, regulatory compliance, and integration with existing production infrastructure that enables coordinated identification across product lifecycles. The segment benefits from substantial regulatory investment and traceability programs that emphasize the acquisition of permanent marking for compliance and recall management applications.

Growth Drivers: Tire production expansion programs incorporate permanent marking as standard identification for automotive tire operations, while regulatory compliance growth increases demand for durable marking capabilities that meet safety standards and enable product tracking.

Market Challenges: Varying regulatory requirements and tire material differences may limit marking standardization across different production facilities or tire categories.

Application dynamics include:

Temporary marking applications capture significant market share through specialized production tracking requirements in manufacturing operations, in-process identification, and quality control applications. These scenarios demand removable marking systems capable of maintaining mark clarity while providing exceptional temporary identification and production flow capabilities.

Growth Accelerators: Automotive production expansion drives primary adoption as tire marking machines provide traceability capabilities that enable tire manufacturers to meet regulatory standards without excessive identification costs, supporting quality operations and safety missions that require precise product marking applications. Manufacturing automation infrastructure demand accelerates market expansion as tire producers seek effective marking systems that minimize manual intervention while maintaining operational effectiveness during production and quality control scenarios. Automotive industry spending increases worldwide, creating sustained demand for automated marking systems that complement tire production processes and provide compliance optimization in competitive markets.

Growth Inhibitors: Equipment investment challenges vary across marking technology suppliers regarding the pricing of automated systems and laser components, which may limit operational flexibility and market penetration in regions with capital constraints or cost-sensitive tire operations. Technical performance limitations persist regarding mark durability variations and surface compatibility concerns that may reduce effectiveness in specialty tire materials or harsh operating conditions, affecting identification longevity and legibility requirements. Market fragmentation across multiple tire types and production standards creates compatibility concerns between different marking suppliers and existing manufacturing infrastructure.

Market Evolution Patterns: Adoption accelerates in large-scale tire manufacturing and automotive OEM sectors where traceability justifies equipment costs, with geographic concentration in developed markets transitioning toward mainstream adoption in emerging economies driven by automotive expansion and regulatory awareness. Technology development focuses on enhanced automation designs, improved connectivity integration, and compatibility with Industry 4.0 systems that optimize marking quality and production effectiveness. The market could face disruption if alternative identification technologies or RFID solutions significantly limit the deployment of traditional marking systems in tire applications, though marking's unique combination of cost-effectiveness, proven reliability, and regulatory acceptance continues to make it preferred in tire identification applications.

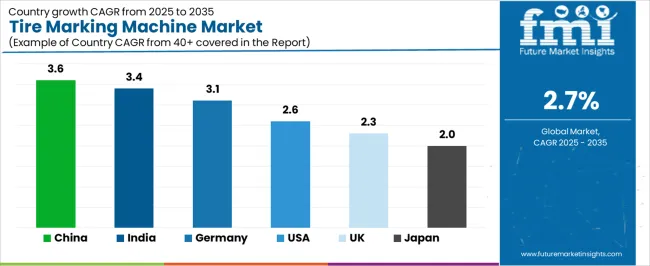

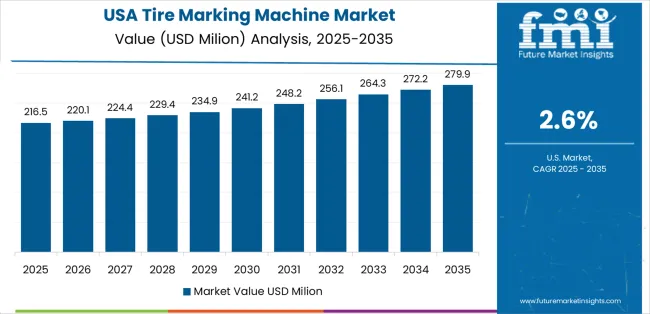

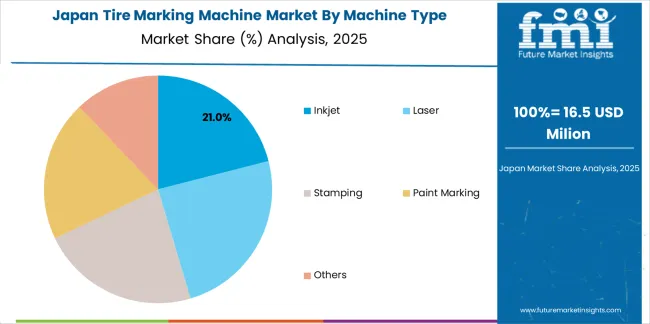

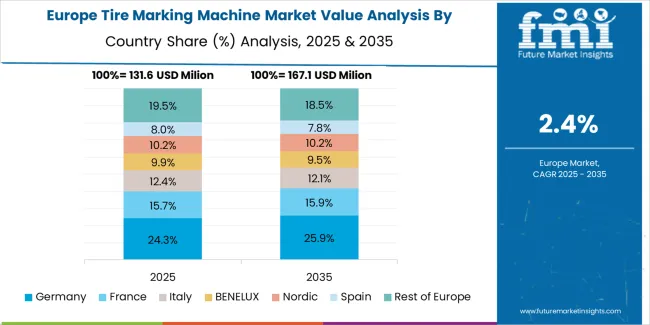

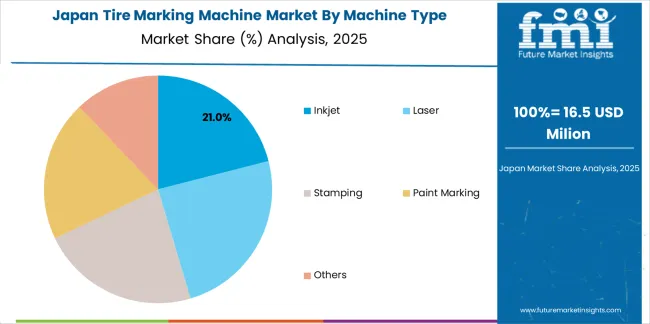

The tire marking machine market demonstrates varied regional dynamics with Growth Leaders including China (3.6% CAGR) and India (3.4% CAGR) driving expansion through tire manufacturing capacity additions and automotive production programs. Steady Performers encompass Germany (3.1% CAGR), United States (2.6% CAGR), and United Kingdom (2.3% CAGR), benefiting from established tire industries and advanced marking adoption. Mature Markets feature Japan (2.0% CAGR), where specialized tire applications and premium marking integration support consistent growth patterns.

| Country | CAGR (2025-2035) |

|---|---|

| China | 3.6% |

| India | 3.4% |

| Germany | 3.1% |

| United States | 2.6% |

| United Kingdom | 2.3% |

| Japan | 2.0% |

Regional synthesis reveals Asia Pacific markets leading adoption through tire manufacturing expansion and automotive production infrastructure development, while European countries maintain steady expansion supported by marking technology advancement and regulatory standardization requirements. North American markets show moderate growth driven by automotive tire applications and traceability integration trends.

The Chinese market emphasizes advanced marking features, including precision identification control and integration with comprehensive tire manufacturing platforms that manage production quality, traceability optimization, and efficiency applications through unified monitoring systems. The country demonstrates strong growth at 3.6% CAGR, driven by tire manufacturing expansion, automotive production initiatives, and emerging quality control development that support marking integration. Chinese tire manufacturers prioritize operational effectiveness with tire marking machines delivering consistent identification performance through advanced printing capabilities and production adaptation features.

Technology deployment channels include major tire manufacturers, specialized marking equipment suppliers, and automotive industry procurement programs that support professional applications for complex tire identification and quality tracking applications. Manufacturing platform integration capabilities with established tire production systems expand market appeal across diverse operational requirements seeking marking efficiency and compliance benefits. The expanding automotive sector and accelerating tire export market create sustained demand, while innovative applications in smart manufacturing and connected tire systems open new growth avenues.

Performance Metrics:

Advanced tire industry in Germany demonstrates sophisticated marking deployment with documented operational effectiveness in premium tire manufacturing applications and high-quality production facilities through integration with existing tire systems and manufacturing infrastructure. The country leverages engineering expertise in automotive manufacturing and production systems integration to maintain strong growth at 3.1% CAGR. Industrial centers, including Hanover, Munich, and Cologne, showcase premium installations where marking systems integrate with comprehensive tire platforms and quality management systems to optimize production traceability and marking effectiveness.

German tire manufacturers prioritize system precision and EU compliance in marking development, creating demand for premium marking systems with advanced features, including automated integration and quality validation systems. The market benefits from established tire manufacturing infrastructure and a willingness to invest in advanced traceability technologies that provide long-term quality benefits and compliance with international automotive and safety standards.

Market Intelligence Brief:

The USA tire marking machine market demonstrates sophisticated deployment across automotive tire applications with documented effectiveness in passenger tire manufacturing and commercial tire facilities through integration with comprehensive quality management systems and operational infrastructure. The country leverages advanced manufacturing capabilities in automotive innovation and compliance optimization technologies to maintain moderate growth at 2.6% CAGR. Industrial centers, including Ohio, Tennessee, and South Carolina, showcase premium installations where marking systems integrate with comprehensive tire platforms and distribution networks to optimize marking efficiency and traceability effectiveness.

American tire manufacturers prioritize marking reliability and regulatory compliance in equipment selection, creating demand for innovative marking systems with advanced features, including automated verification and data integration capabilities. The market benefits from established automotive infrastructure and willingness to invest in advanced traceability technologies that provide long-term compliance benefits and compatibility with DOT and safety standards.

Market Intelligence Brief:

The UK tire marking machine market demonstrates advanced quality deployment with documented operational effectiveness in tire manufacturing applications and automotive supply facilities through integration with existing compliance systems and production infrastructure. The country leverages regulatory expertise in automotive standards and manufacturing systems integration to maintain steady growth at 2.3% CAGR. Industrial centers, including Birmingham, Leeds, and Southampton, showcase premium installations where marking systems integrate with comprehensive quality platforms and tire management systems to optimize regulatory compliance and marking effectiveness.

British tire manufacturers prioritize system reliability and safety compliance in marking development, creating demand for certified marking systems with advanced features, including traceability validation and quality assurance integration. The market benefits from established tire manufacturing infrastructure and commitment to invest in quality traceability technologies that provide long-term operational benefits and compliance with UK and EU automotive standards. Passenger tire applications, commercial tire systems, and specialty tire programs drive diversified demand across multiple tire segments.

Strategic Market Indicators:

Tire marking machine market in India demonstrates rapid expansion deployment with documented operational effectiveness in tire manufacturing applications and automotive production facilities through integration with emerging manufacturing systems and production infrastructure. The country leverages growing industrial capabilities in tire manufacturing and automotive systems integration to achieve high growth at 3.4% CAGR. Industrial centers, including Mumbai, Chennai, and Pune, showcase expanding installations where marking systems integrate with comprehensive tire platforms and distribution networks to optimize market penetration and marking effectiveness.

Indian tire manufacturers prioritize cost efficiency and quality standards in marking development, creating demand for economical marking systems with advanced features, including automated operation integration and quality control systems. The market benefits from expanding tire manufacturing infrastructure and willingness to invest in international-standard traceability technologies that provide marking optimization and compliance with global automotive standards.

Market Intelligence Brief:

Tire marking machine market in Japan demonstrates precision deployment with documented operational effectiveness in ultra-premium tire manufacturing applications and specialty tire facilities through integration with advanced manufacturing systems and quality control infrastructure. The country leverages engineering excellence in precision tire manufacturing and production systems integration to maintain steady growth at 2.0% CAGR. Industrial centers, including Tokyo, Osaka, and Kobe, showcase premium installations where marking systems integrate with comprehensive quality platforms and marking optimization systems to optimize production excellence and identification effectiveness.

Japanese tire manufacturers prioritize system precision and marking excellence in equipment development, creating demand for ultra-premium marking systems with advanced features, including micro-precision printing and quality integration systems. The market benefits from established tire manufacturing infrastructure and commitment to invest in highest-quality traceability technologies that provide superior product positioning and compliance with stringent Japanese automotive standards.

Strategic Market Indicators:

The Tire Marking Machine market in Europe is projected to grow substantially over the forecast period, with Germany expected to maintain its leadership position with a significant market share supported by its advanced tire manufacturing infrastructure and major automotive production centers in Hanover and Munich. France follows with strong market presence, driven by comprehensive tire manufacturing programs and automotive supply initiatives. The United Kingdom holds substantial market share through specialized premium tire activities, quality marking applications, and automotive tire manufacturing. Italy commands notable market presence through strong automotive and tire production projects. Spain accounts for growing market share aided by tire manufacturing expansion and marking technology adoption. The Netherlands maintains steady share driven by specialty tire applications and traceability marking demand. The Rest of Europe region is anticipated to show steady adoption, reflecting consistent growth in Nordic countries, tire manufacturing expansion in Central European markets, and marking technology upgrades across Eastern European automotive production facilities.

In Japan, the Tire Marking Machine market prioritizes inkjet systems, which capture the dominant share of premium tire manufacturing and specialty production installations due to their advanced features, including high-speed printing optimization and seamless integration with existing tire manufacturing infrastructure. Japanese tire manufacturers emphasize reliability, speed, and long-term operational excellence, creating demand for inkjet systems that provide consistent marking capabilities and superior print quality based on manufacturing requirements and quality standards. Laser systems maintain secondary positions primarily in specialized permanent marking applications and premium tire installations where enhanced durability meets operational requirements without compromising production efficiency.

Market Characteristics:

In South Korea, the market structure favors international marking equipment manufacturers, including Markem-Imaje (Dover Corporation), Videojet Technologies (Danaher Corporation), and Domino Printing Sciences (Brother Industries), which maintain dominant positions through comprehensive product portfolios and established tire industry networks supporting both large-scale OEM tire manufacturing and aftermarket tire production installations. These providers offer integrated solutions combining advanced marking systems with professional technical services and ongoing operational support that appeal to Korean tire brands seeking reliable identification solutions. Local equipment contractors and marking specialists capture moderate market share by providing localized service capabilities and competitive pricing for standard tire production installations, while domestic manufacturers focus on specialized applications and cost-effective solutions tailored to Korean tire market characteristics.

Channel Insights:

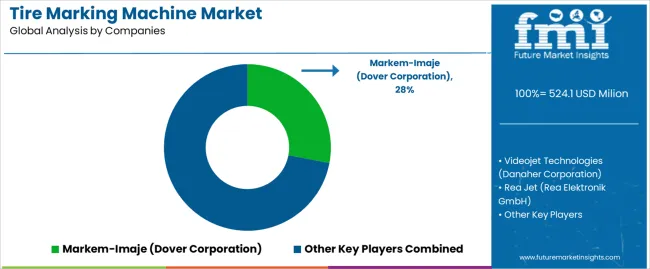

The Tire Marking Machine market operates with moderate concentration, featuring approximately 12-18 meaningful participants, where leading companies control roughly 50-55% of the global market share through established tire industry relationships and comprehensive marking equipment portfolios. Competition emphasizes advanced marking capabilities, system reliability, and production integration rather than price-based rivalry. The leading company, Markem-Imaje (Dover Corporation), commands approximately 28.0% market share through its extensive tire marking machine product line and global tire industry presence.

Market Leaders encompass Markem-Imaje (Dover Corporation), Videojet Technologies (Danaher Corporation), and Rea Jet (Rea Elektronik GmbH), which maintain competitive advantages through extensive coding and marking expertise, global tire manufacturer networks, and comprehensive application integration capabilities that create customer loyalty and support premium positioning. These companies leverage decades of industrial marking experience and ongoing innovation investments to develop advanced tire marking systems with precision identification control and automation features. Technology Innovators include Koenig & Bauer Coding GmbH and regional specialists, which compete through specialized marking technology focus and innovative printing capabilities that appeal to tire manufacturers seeking advanced solutions and quality optimization.

These companies differentiate through rapid technology development cycles and specialized tire application focus. Regional Specialists feature marking equipment manufacturers focusing on specific geographic markets and specialized applications, including heavy-duty commercial tire systems and integrated production solutions. Market dynamics favor participants that combine reliable marking formulations with advanced automation capabilities, including precision print control and automatic quality verification features. Competitive pressure intensifies as traditional industrial marking suppliers expand into specialty tire systems, while specialized automotive equipment companies challenge established players through innovative marking solutions and connected platforms targeting passenger tire and commercial tire segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 524.1 million |

| Machine Type | Inkjet, Laser, Stamping, Paint Marking, Others |

| Marking Type | Permanent, Temporary |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, United States, United Kingdom, Japan, and 20+ additional countries |

| Key Companies Profiled | Markem-Imaje (Dover Corporation), Videojet Technologies (Danaher Corporation), Rea Jet (Rea Elektronik GmbH), Koenig & Bauer Coding GmbH, Domino Printing Sciences (Brother Industries) |

| Additional Attributes | Dollar sales by machine type and marking type categories, regional adoption trends across Asia Pacific, Europe, and North America, competitive landscape with marking equipment manufacturers and tire industry suppliers, manufacturer preferences for marking reliability and production integration, integration with tire manufacturing platforms and quality monitoring systems, innovations in automated marking formulations and identification excellence, and development of Industry 4.0 solutions with enhanced performance and manufacturing optimization capabilities. |

The global tire marking machine market is estimated to be valued at USD 524.1 milion in 2025.

The market size for the tire marking machine market is projected to reach USD 684.1 milion by 2035.

The tire marking machine market is expected to grow at a 2.7% CAGR between 2025 and 2035.

The key product types in tire marking machine market are inkjet, laser, stamping, paint marking and others.

In terms of marking type, permanent segment to command 28.0% share in the tire marking machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Tire Pressure Monitoring System Market Size and Share Forecast Outlook 2025 to 2035

Tire Cord Fabric Market Size and Share Forecast Outlook 2025 to 2035

Tire Retreading Equipment Market Size and Share Forecast Outlook 2025 to 2035

Tire Cobalt Salt Adhesive Market Size and Share Forecast Outlook 2025 to 2035

Tire Curing Bladder Release Agent Market Size and Share Forecast Outlook 2025 to 2035

Tire and Wheel Handling Equipment Market Size and Share Forecast Outlook 2025 to 2035

Tire Pyrolysis Oil Market Size and Share Forecast Outlook 2025 to 2035

Tire Cord and Tire Fabrics Market Size and Share Forecast Outlook 2025 to 2035

Tire Materials Market Insights – Size, Trends & Forecast 2025–2035

Tire & Wheel Cleaners Market Size and Share Forecast Outlook 2025 to 2035

Tire Repair Patch Market Analysis By Type, Application, and Region Through 2035

Tire Inspection System Market - Outlook 2025 to 2035

Tire Curing Press Market Growth - Trends & Forecast 2025 to 2035

Tire Changers - Market Growth - 2025 to 2035,

Tire Storage Rack Market Growth - Trends & Forecast 2025 to 2035

Tire Cord Market

Tire Carousel Market

Tire Testing Machine Market Size and Share Forecast Outlook 2025 to 2035

Tire Cutting Machine Market Trends, Outlook & Forecast 2025 to 2035

Tire Changing Machines Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA