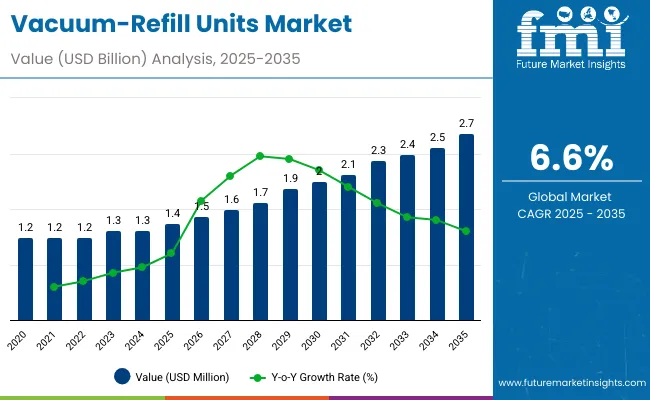

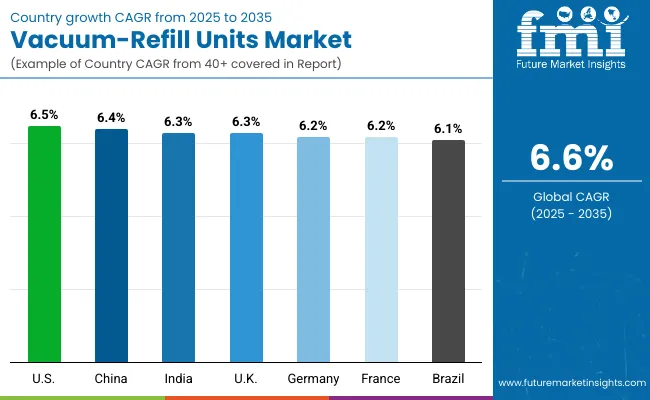

The vacuum-refill units market will expand from USD 1.4 billion in 2025 to USD 2.7 billion by 2035, registering a CAGR of 6.6%. Growth is fuelled by automation across cosmetics, personal care, and household product lines. Fully automatic units dominate owing to their precision, reduced spillage, and sanitation advantages. Multi-station refill configurations enhance productivity in high-speed liquid packaging. Between 2025 and 2030, USD 0.6 billion growth will emerge from AI-driven control adoption. By 2035, sustainability-focused vacuum technology and refillable formats will further accelerate market expansion.

| Metric | Value |

|---|---|

| Industry Size (2025E) | USD 1.4 billion |

| Industry Value (2035F) | USD 2.7 billion |

| CAGR (2025 to 2035) | 6.6% |

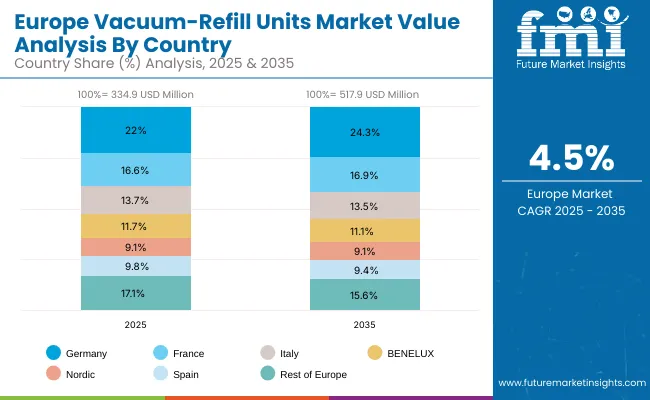

Between 2020 and 2024, automation in liquid refilling and hygiene compliance drove adoption of vacuum-based refill systems. Leading packaging manufacturers introduced multi-station modular units supporting refillable bottle formats. By 2035, the market will reach USD 2.7 billion as refill automation aligns with global sustainability goals. Smart vacuum systems with energy-efficient designs and sensor-based monitoring will enhance scalability across Asia-Pacific, while Europe and North America will prioritize cleanroom integration and circular manufacturing.

The market is growing due to the surge in demand for sustainable, refillable packaging and cleaner production systems. Automated vacuum-refill units reduce contamination, improve dosing accuracy, and minimize waste, making them ideal for cosmetics and hygiene products. Increasing industrial automation and corporate sustainability mandates drive the adoption of high-efficiency refill technologies, supported by government regulations promoting waste reduction and energy-efficient packaging solutions.

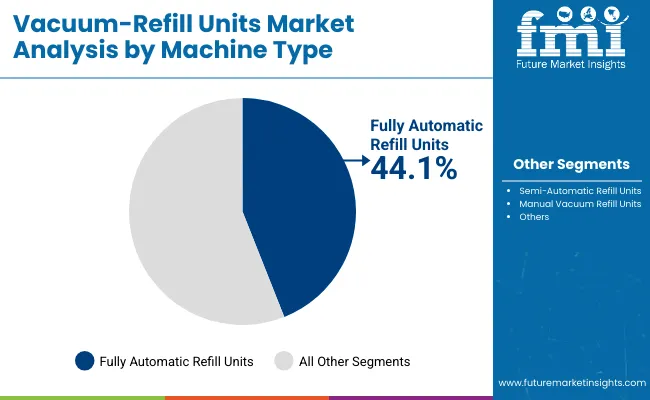

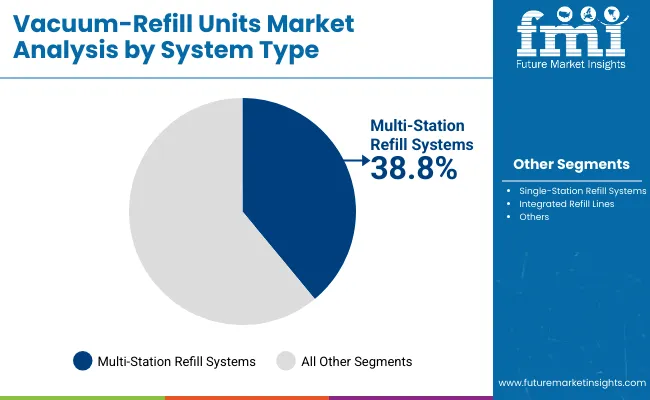

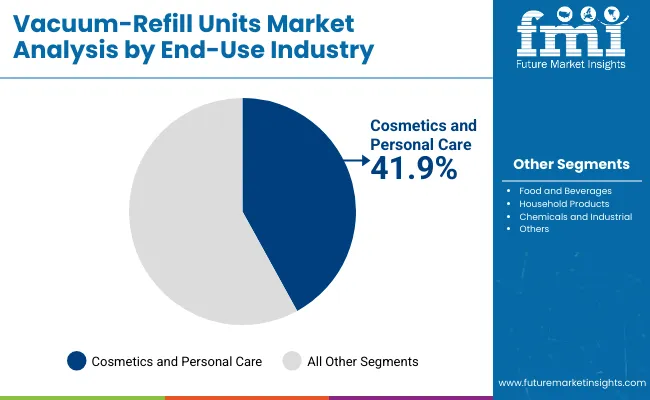

The market is segmented by machine type, system type, end-use industry, and region. Machine types include fully automatic, semi-automatic, and manual refill units. System types cover multi-station, single-station, and integrated refill lines. End-use industries include cosmetics and personal care, food and beverages, household products, and chemicals.

Fully automatic vacuum-refill units, with 44.1% market share in 2025, lead due to speed, consistency, and operator safety. These systems provide efficient throughput and precision in liquid packaging. By 2035, integration with AI-based sensors and servo systems will improve performance and reduce cycle times, enabling sustainable and hygienic manufacturing in high-volume production facilities across the personal care and food sectors.

Multi-station refill systems, accounting for 38.8% share in 2025, support high-speed filling across multiple containers simultaneously. Their automation-friendly design minimizes downtime and boosts plant output. By 2035, upgrades in AI-driven flow balancing and predictive maintenance will enhance performance and energy efficiency, ensuring seamless integration into continuous packaging lines across cosmetics, chemical, and beverage industries.

Cosmetics and personal care will account for 41.9% share in 2025, driven by global adoption of refillable bottles, creams, and lotions. Precision-controlled vacuum filling ensures clean, uniform packaging. By 2035, integration of sustainable materials, digital flow regulation, and vision-assisted filling systems will strengthen market share as beauty manufacturers emphasize eco-friendly, reusable packaging formats worldwide.

The global vacuum-refill units market is expanding rapidly as automation and sustainability merge to redefine packaging operations. Asia-Pacific dominates industrial installations through large-scale adoption across FMCG and personal care sectors, while Europe emphasizes regulatory compliance and energy-efficient automation. North America focuses on refill packaging infrastructure and hygienic automation to meet consumer sustainability goals. Growth is supported by modular system design, AI-based control mechanisms, and the global transition toward eco-refill models.

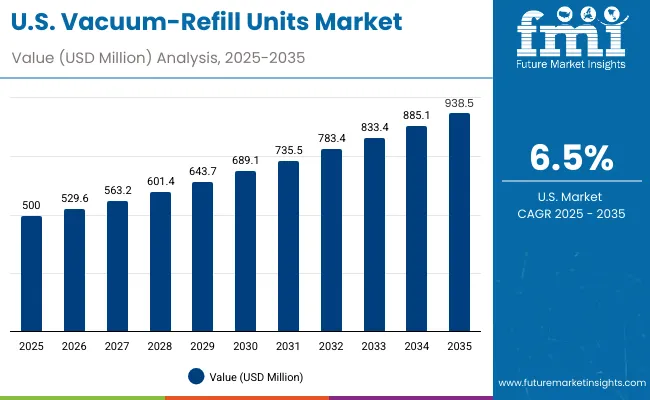

The USA will grow at 6.5% CAGR, driven by automation in personal care and food refilling operations. AI-driven control systems are enhancing product consistency and hygiene compliance. Modular refill lines are being integrated across cosmetic and household brands to optimize sustainability and packaging circularity. Increasing regulatory scrutiny on contamination control and refill hygiene is further accelerating adoption across automated refill systems.

Germany will expand at 6.2% CAGR, propelled by engineering excellence and sustainability mandates. Compact refill modules are being introduced to optimize limited floor spaces and energy efficiency in manufacturing facilities. Regulatory incentives supporting circular packaging models are boosting cosmetic and detergent refill solutions. Automation and robotics integration ensure compliance with EU eco-packaging standards and Industry 4.0 digitalization goals.

The UK will grow at 6.3% CAGR, focusing on premium eco-refill packaging within luxury and personal care sectors. Cleanroom-compliant refill systems are increasingly deployed for allergen-free and sustainable formulations. Local refill brands are expanding production capacity with smart, automated refill lines. The emphasis on traceability and digital operations ensures greater transparency and alignment with sustainability certifications.

China will grow at 6.4% CAGR, supported by rising automation across FMCG and personal care sectors. Domestic equipment manufacturers are expanding production of AI-enabled multi-station refill systems. Digital diagnostics and predictive maintenance features are improving operational reliability and system uptime. With government initiatives promoting green packaging, modular and energy-efficient refill systems are gaining strong market momentum.

India will grow at 6.3% CAGR, driven by automation incentives and rapid adoption of sustainable refilling models. Demand for low-cost, modular refill units is increasing across cosmetics and homecare categories. Smart control integration is enhancing process precision and reducing material wastage. Growth in refill-based FMCG retail models is reinforcing the shift toward affordable automation and eco-packaging adoption.

Japan will grow at 6.9% CAGR, with strong focus on compact, precise, and robotic vacuum-refill systems. Integration of advanced robotics is improving throughput and operational accuracy in high-end packaging facilities. Sustainable automation practices are receiving government support under decarbonization goals. Modular system configurations are enabling quicker changeovers and higher productivity across premium packaging sectors.

South Korea will lead with 7.0% CAGR, backed by K-beauty industry automation and smart refill innovation. Advanced robotic refill systems are being adopted to scale efficiency and reduce labor dependency. Energy-efficient refill lines are gaining traction in cosmetics and personal care plants. Integration of intelligent packaging and real-time monitoring is enhancing product traceability and boosting export potential.

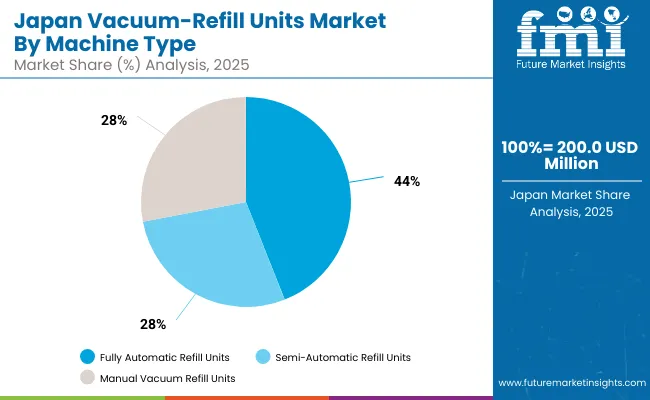

Japan’s vacuum-refill units market, valued at USD 200.0 million in 2025, is led by fully automatic refill units due to their efficiency and precision in high-volume industrial operations. Semi-automatic refill units hold strong adoption in mid-scale facilities requiring balance between automation and flexibility. Manual vacuum refill units remain relevant for smaller production lines and customized processes. Japan’s advancements in automation and mechatronics continue to push demand for intelligent, productivity-boosting refill technologies.

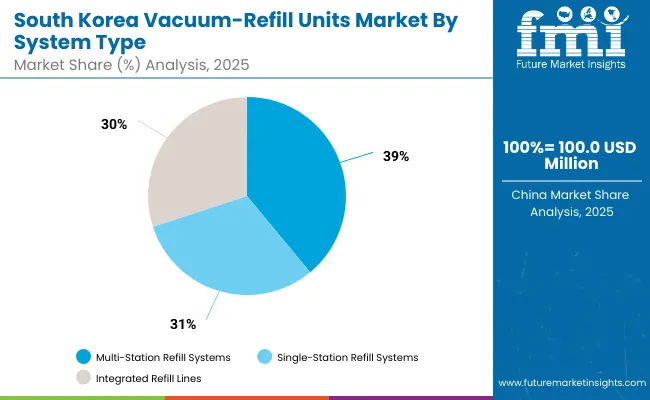

South Korea’s vacuum-refill units market, valued at USD 100.0 million in 2025, is dominated by single-station refill systems, offering simplicity and versatility for medium-scale operations. Multi-station refill systems are gaining traction for enhancing throughput and reducing downtime in industrial packaging. Integrated refill lines are increasingly deployed for end-to-end automation, improving operational safety and accuracy. South Korea’s strong manufacturing infrastructure supports wider adoption of smart, automated refill systems across production facilities.

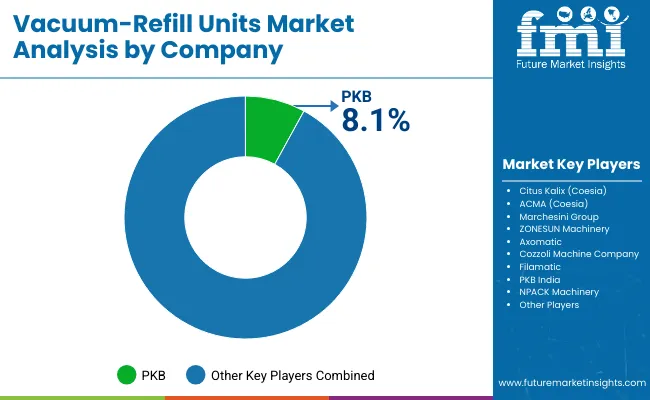

The market is moderately consolidated with PKB, CitusKalix (Coesia), ACMA (Coesia), Marchesini Group, ZONESUN Machinery, Axomatic, Cozzoli Machine Company, Filamatic, PKB India, and NPACK Machinery as leading participants. These players focus on precision automation, sustainability, and smart technology integration. PKB and CitusKalix dominate luxury cosmetic refill solutions, while Marchesini and ACMA expand high-speed pharmaceutical systems. Asian companies like ZONESUN and NPACK lead in modular and affordable automated refilling systems.

Key Developments of Vacuum-Refill Units Market

| Item | Value |

| Quantitative Units | USD 1.4 Billion |

| By Machine Type | Fully Automatic, Semi-Automatic, Manual |

| By System Type | Multi-Station, Single-Station, Integrated Lines |

| By End-Use Industry | Cosmetics & Personal Care, Food & Beverages, Household, Chemicals |

| Key Companies Profiled | PKB, Citus Kalix (Coesia), ACMA (Coesia), Marchesini Group, ZONESUN Machinery, Axomatic, Cozzoli Machine Company, Filamatic, PKB India, NPACK Machinery |

| Additional Attributes | Market driven by automation, sustainability, and eco-refill technology integration. |

The Vacuum-Refill Units Market is valued at USD 1.4 billion in 2025.

The Vacuum-Refill Units Market is projected to reach USD 2.7 billion by 2035.

The Vacuum-Refill Units Market is expected to grow at a CAGR of 6.6% during 2025-2035.

The Fully Automatic Refill Units segment leads with a 44.1% share in 2025.

The Asia-Pacific region, led by South Korea (7.0% CAGR), demonstrates the highest growth potential.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Dental Units Market Size and Share Forecast Outlook 2025 to 2035

Linear Slide Units Market Size and Share Forecast Outlook 2025 to 2035

Heat Therapy Units Market Analysis - Size, Share, and Forecast 2025 to 2035

Handheld GPS Units Market

Slurrification Units Market Size and Share Forecast Outlook 2025 to 2035

Mobile Sterile Units Market Analysis – Growth, Applications & Outlook 2025–2035

Vapour Recovery Units Market Size and Share Forecast Outlook 2025 to 2035

Market Share Insights of Vapour Recovery Unit Providers

Oxygen Delivery Units Market

Business Storage Units Market Size and Share Forecast Outlook 2025 to 2035

Roller Press Gear Units Market Size and Share Forecast Outlook 2025 to 2035

Portable Charging Units Market Size and Share Forecast Outlook 2025 to 2035

UK Mobile Sterile Units Market Growth – Innovations, Trends & Forecast 2025-2035

Automotive Display Units Market Growth - Trends & Forecast 2025 to 2035

Port Fuel Injection Units Market Size and Share Forecast Outlook 2025 to 2035

Japan Mobile Sterile Units Market Analysis – Size & Industry Trends 2025-2035

Industrial Condensing Units Market Size and Share Forecast Outlook 2025 to 2035

Spinal Osteosynthesis Units Market Trends – Industry Forecast 2025 to 2035

Free Standing Display Units Market by Material & End-Use Forecast 2025 to 2035

Market Share Distribution Among Free Standing Display Units Providers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA