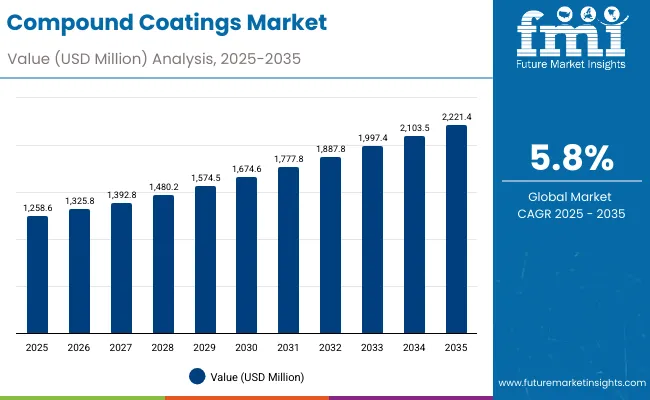

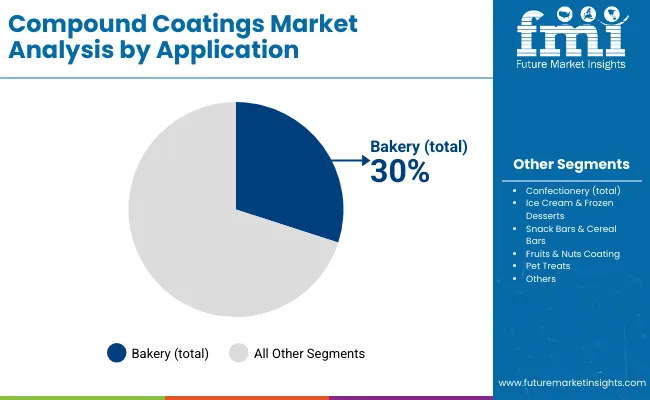

The compound coatings market is projected to grow from USD 1,258.6 million in 2025 to USD 2,221.4 million by 2035, registering a CAGR of 5.8%. Demand remains closely linked to activity in food manufacturing, confectionery production, and bakery operations, where compound coatings function as critical product enhancement components. Food manufacturing continues to represent the largest application environment at 30.0% for bakery applications, supported by deeper product differentiation operations, increased consumer appeal requirements, and the need for coatings that can withstand continuous, high-performance production cycles. Confectionery manufacturing similarly drives consumption as premium product development and specialty coating applications expand the use of chocolate and specialized coating systems.

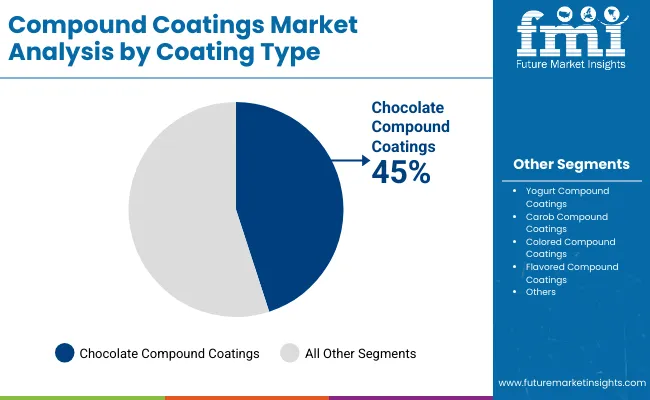

Chocolate compound coatings account for 45.0% of the market due to compatibility with standard food equipment and established performance characteristics. However, adoption of specialty coatings is increasing in applications where flavor differentiation, visual appeal, and texture enhancement are prioritized, particularly in confectionery environments where premium coating failure leads to high product quality costs.

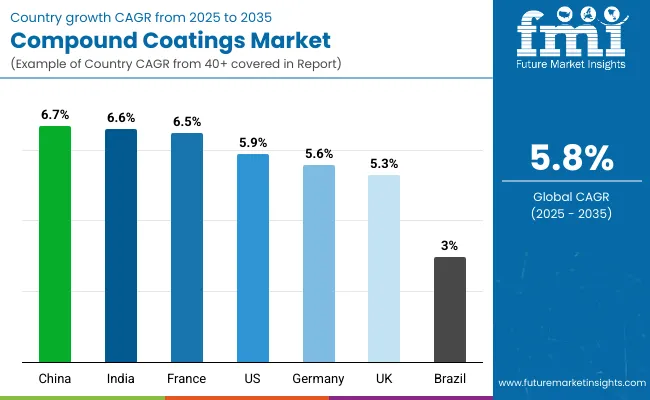

Advances in fat technology, coating formulation, and application processing are improving service life and performance reliability. Regionally, East Asia leads growth, with China (6.7% CAGR) and India (6.6% CAGR) driven by food manufacturing expansion and confectionery investment, while more mature markets such as the United States, Germany, the United Kingdom show steady replacement-driven demand tied to modernization and equipment upgrading cycles.

Compound Coatings Market Key Takeaways

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 1,258.6 million |

| Forecast Value in (2035F) | USD 2,221.4 million |

| Forecast CAGR (2025 to 2035) | 5.8% |

The market dynamics driving compound coatings adoption are fundamentally shaped by escalating consumer preference for indulgent food products, regulatory pressures for clean label ingredients, and the food industry's transformation toward premium coating methodologies. Consumer demand evolution has intensified quality expectations and flavor innovation challenges across major food manufacturing regions, compelling producers and food processors to implement more sophisticated coating enhancement strategies. Simultaneously, government regulations and food safety mechanisms in many jurisdictions increasingly incentivize efficient coating technologies through quality standards, ingredient guidelines, and product mandates that make specialized compound coating systems economically attractive investments.

Technological advancement in fat technology, coating formulation, and application processing platforms has dramatically enhanced the capabilities and accessibility of compound coating systems. Modern formulations leverage advanced fat replacement technologies, specialized coating techniques, and application methods to provide optimized product enhancement and improved manufacturing efficiency, enabling immediate response to changing consumer preferences and proactive product development. The integration of coating expertise, performance monitoring, formulation calculations, and application protocols enables these systems to optimize coating performance based on actual product requirements rather than predetermined coating specifications, resulting in significant quality improvements and enhanced consumer appeal outcomes.

The food manufacturing sector's increasing adoption of premium coating technologies has created substantial demand for integrated coating enhancement solutions that complement existing production management systems. Compound coatings now interface seamlessly with food production software, enabling comprehensive data collection and analysis that supports broader manufacturing decision-making processes. This integration capability has proven particularly valuable for large-scale commercial food operations where coordinated management of multiple product lines and coating types requires sophisticated formulation and monitoring capabilities.

Between 2025 and 2030, the compound coatings market is projected to expand from USD 1,258.6 million to USD 1,674.6 million, resulting in a value increase of USD 416.0 million, which represents 43.2% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for premium coating technologies, increasing applications in food product differentiation and consumer appeal enhancement, and growing penetration in emerging food manufacturing markets. Coating manufacturers are expanding their production capabilities to address the growing demand for customized compound coating formulations in various food segments and product enhancement programs.

From 2030 to 2035, the market is forecast to grow from USD 1,674.6 million to USD 2,221.4 million, adding another USD 546.8 million, which constitutes 56.8% of the overall ten-year expansion. This period is expected to be characterized by the expansion of advanced food coating infrastructure, the integration of cutting-edge coating technologies, and the development of customized compound coating systems for specific food applications. The growing adoption of premium food manufacturing and product automation will drive demand for ultra-high efficiency compound coatings with enhanced performance specifications and consistent quality characteristics.

Between 2020 and 2025, the compound coatings market experienced steady expansion, driven by increasing recognition of coating enhancement importance in food manufacturing operations and growing acceptance of premium coating systems in complex food markets. The market developed as manufacturers recognized the need for high-efficiency coating technologies to address product differentiation requirements and improve overall manufacturing productivity. Research and development activities have begun to emphasize the importance of advanced coating technologies in achieving better quality and performance in food production processes.

Market expansion is being supported by the increasing demand for premium food coating infrastructure and the corresponding need for high-performance coating systems in food applications across global manufacturing and food processing operations. Modern food operators are increasingly focused on advanced coating technologies that can improve product appeal, reduce production costs, and enhance consumer satisfaction while meeting stringent quality requirements. The proven efficacy of compound coatings in various food applications makes them an essential component of comprehensive product enhancement strategies and manufacturing modernization programs.

The growing emphasis on premium food manufacturing and advanced product differentiation is driving demand for ultra-efficient coating systems that meet stringent performance specifications and operational requirements for specialized applications. Food manufacturers' preference for reliable, high-performance coating systems that can ensure consistent product quality is creating opportunities for innovative coating technologies and customized food solutions. The rising influence of consumer preference protocols and food quality standards is also contributing to increased adoption of premium-grade compound coatings across different food applications and manufacturing systems requiring advanced coating technology.

| Source / Institution | Key Findings | Relevance to Industry Insight |

|---|---|---|

| Food and Agriculture Organization (FAO) | Compound coatings made with vegetable fats are a cost-effective alternative to conventional chocolate, offering better heat resistance, lower production costs, and simpler handling in warm or humid environments. | Confirms the suitability of compound coatings for tropical manufacturing regions and cost-sensitive confectionery production. |

| Institute of Food Technologists (IFT) | Compound coatings eliminate the need for tempering and provide stable melting and textural characteristics, unlike cocoa butter-based chocolates. | Demonstrates ease of processing and manufacturing consistency advantages for large-scale production. |

| U.S. Department of Agriculture (USDA - Agricultural Research Service) | Vegetable fat-based coatings improve product durability, prevent fat bloom, and extend shelf stability during storage and distribution. | Validates compound coatings’ role in improving shelf life and product quality retention in distribution chains. |

| University of Guelph - Department of Food Science | Specialty fat systems in compound coatings ensure desirable viscosity, gloss, and rheological uniformity, making them suitable for high-volume confectionery applications. | Reinforces the processing uniformity, thermal resilience, and visual appeal benefits crucial for industrial confectionery producers. |

The market is segmented by coating type, fat type, application, form, end use, technology, product claim, and region. By coating type, the market is divided into chocolate compound coatings, yogurt compound coatings, carob compound coatings, colored compound coatings, and flavored compound coatings. Based on fat type, the market is categorized into cocoa butter replacers (CBR), cocoa butter substitutes (CBS), cocoa butter equivalents (CBE), palm kernel oil-based, and other vegetable oil-based formulations.

In terms of application, the market is segmented into confectionery (candy bars, pralines, and bonbons), bakery (biscuits, cookies, cakes, and muffins), ice cream and frozen desserts, snack bars and cereal bars, fruits and nuts coating, and pet treats. By form, the market is classified into chips, blocks, liquid, and powder variants. Based on end use, the market is divided into food manufacturers (industrial/B2B), foodservice, and retail (DIY baking and toppings). By technology, the market is categorized into spray coating, enrobing, panning, dipping, and molding. Based on product claims, the market is segmented into sugar-free, vegan, organic, gluten-free, and non-GMO products. Regionally, the market spans North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

The chocolate compound coatings segment is projected to account for 45.0% of the compound coatings market in 2025, reaffirming its position as the category's dominant type. Food manufacturers increasingly recognize the optimal balance of performance and consumer appeal offered by chocolate compound coatings for most food applications, particularly in confectionery manufacturing and bakery processes. This type addresses both performance requirements and long-term operational considerations while providing reliable coating enhancement across diverse food applications.

This type forms the foundation of most food manufacturing protocols for coating applications, as it represents the most widely accepted and commercially viable level of coating technology in the industry. Food standards and extensive operational testing continue to strengthen confidence in chocolate compound coating formulations among food manufacturing and processing providers. With increasing recognition of the performance-cost optimization requirements in food manufacturing, chocolate compound systems align with both operational efficiency and consumer appeal goals, making them the central growth driver of comprehensive food manufacturing strategies.

The chocolate segment benefits from established consumer preference and broad application versatility across confectionery, bakery, and dessert categories. Modern food manufacturers utilize chocolate compound coatings to achieve consistent flavor profiles, controlled melting characteristics, and enhanced shelf stability while maintaining cost competitiveness compared to pure chocolate alternatives. Advanced formulations incorporate specialized fat systems and flavor enhancement technologies that deliver authentic chocolate taste and texture while providing operational advantages in large-scale production environments.

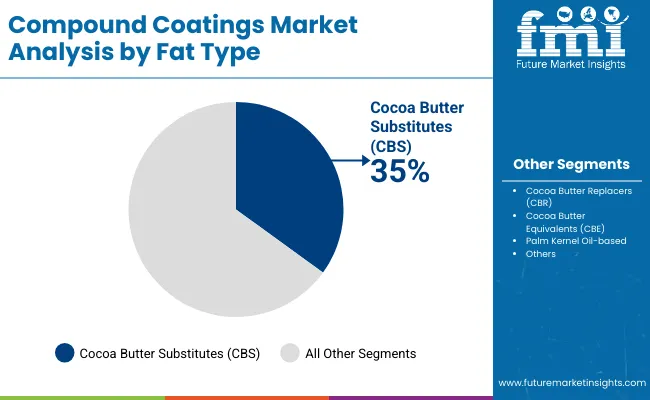

Cocoa butter substitutes (CBS) is projected to represent 35.0% of compound coatings demand in 2025, underscoring its role as the primary fat type segment driving market adoption and growth. Food manufacturers recognize that coating applications, including complex confectionery operations, specialized texture requirements, and multi-stage food systems, often require advanced CBS formulations that standard fat technologies cannot adequately provide. CBS offer enhanced processing flexibility and operational compliance in food coating applications.

The segment is supported by the growing complexity of food manufacturing operations, requiring sophisticated fat systems, and the increasing recognition that advanced fat technologies can improve product quality and operational outcomes. Additionally, manufacturers are increasingly adopting evidence-based coating guidelines that recommend specific CBS formulations for optimal food manufacturing efficiency. As understanding of food coating complexity advances and manufacturing requirements become more stringent, CBS will continue to play a crucial role in comprehensive coating strategies within the food market.

CBS technology provides manufacturers with the ability to achieve chocolate-like properties without the temperature sensitivity and processing limitations of cocoa butter. This flexibility enables extended shelf life, improved heat resistance, and enhanced workability during coating application processes, making CBS formulations particularly valuable for industrial food production and tropical market applications where temperature stability is critical.

Bakery applications are projected to represent 30.0% of compound coatings demand in 2025, demonstrating their critical role as the primary application segment driving market expansion and adoption. Food manufacturers recognize that bakery product requirements, including complex coating processes, specialized texture needs, and multi-level enhancement systems, often require advanced compound coatings that standard coating technologies cannot adequately provide. Bakery-focused compound coatings offer enhanced product appeal and operational compliance in food manufacturing applications.

The bakery segment spans diverse product categories including biscuits & cookies (60% of bakery segment) and cakes & muffins (40% of bakery segment), each requiring specialized coating formulations. Biscuit and cookie applications demand coatings that provide crunch retention, moisture barrier properties, and extended shelf life, while cake and muffin coatings focus on visual appeal, flavor enhancement, and texture contrast. Modern bakery operations increasingly rely on compound coatings to achieve product differentiation, premium positioning, and consistent quality across large-scale production runs.

The compound coatings market is advancing steadily due to increasing recognition of coating enhancement importance and growing demand for high-efficiency coating systems across the food manufacturing and processing sectors. However, the market faces challenges, including complex formulation processes, potential for quality variations during storage and handling, and concerns about supply chain consistency for specialized food ingredients. Innovation in coating technologies and customized food manufacturing protocols continues to influence product development and market expansion patterns.

Expansion of Advanced Food Manufacturing Facilities and Coating Technologies

The growing adoption of advanced food manufacturing facilities is enabling the development of more sophisticated compound coating production and performance control systems that can meet stringent operational requirements. Specialized food manufacturing facilities offer comprehensive coating services, including advanced application and monitoring processes that are particularly important for achieving high-efficiency requirements in food applications. Advanced manufacturing infrastructure provides access to premium services that can optimize product quality and reduce production costs while maintaining cost-effectiveness for large-scale food operations.

Integration of Smart Food Production Systems and Quality Management Systems

Modern food manufacturing organizations are incorporating digital technologies such as real-time performance monitoring, automated coating systems, and production integration to enhance compound coating deployment and distribution processes. These technologies improve product quality, enable continuous operational monitoring, and provide better coordination between manufacturers and food processors throughout the production cycle. Advanced digital platforms also enable customized performance specifications and early identification of potential quality deviations or supply disruptions, supporting reliable food production.

| Countries | CAGR (2025 to 2035) |

|---|---|

| China | 6. 7 % |

| India | 6.6% |

| France | 6.5% |

| USA | 5.9 % |

| Germany | 5.6% |

| UK | 5.3% |

| Brazil | 3.0% |

The compound coatings market is experiencing varied growth globally, with India both leading at a 6.6% CAGR through 2035, driven by the expansion of food manufacturing infrastructure development, increasing confectionery production capabilities, and growing domestic demand for high-efficiency coating systems. France follows at 6.5%, supported by food industry expansion, growing recognition of advanced coating technology importance, and expanding bakery capacity.

USA records 5.9% growth, with a focus on developing the food manufacturing infrastructure and premium coating industries. Germany demonstrates 5.6% growth, emphasizing food manufacturing infrastructure expansion and systematic coating approaches. UK demonstrates 5.3% growth, emphasizing coating infrastructure expansion and systematic food manufacturing approaches. Brazil demonstrates 3.0% growth, representing a moderate market with established food manufacturing frameworks.

Revenue from compound coatings in China is projected to exhibit robust growth with a CAGR of 6.7% through 2035, driven by ongoing food industry expansion and increasing recognition of high-efficiency coating systems as essential food manufacturing components for complex production processes. The country's expanding food manufacturing infrastructure and growing availability of specialized coating capabilities are creating significant opportunities for compound coating adoption across both domestic and export-oriented food facilities. Major international and domestic coating companies are establishing comprehensive formulation and distribution networks to serve the growing population of manufacturers and food facilities requiring high-performance coating systems.

The Chinese government's strategic emphasis on food manufacturing infrastructure modernization and quality advancement is driving substantial investments in specialized coating capabilities. This policy support, combined with the country's large domestic food market and expanding confectionery requirements, creates a favorable environment for the compound coating market development. Government initiatives supporting food industry development are driving demand for high-efficiency coating systems throughout major manufacturing centers, including Guangdong, Shandong, and Jiangsu regions.

Revenue from compound coatings in India is expanding at a CAGR of 6.6%, supported by increasing food manufacturing accessibility, growing coating technology awareness, and developing market presence across the country's major food production clusters. The country's large food processing sector and increasing recognition of advanced coating systems are driving demand for effective high-efficiency coating solutions in both confectionery production and food manufacturing applications. International food companies and domestic providers are establishing comprehensive distribution channels to serve the growing demand for quality coating systems.

India's food manufacturing sector continues to benefit from favorable industry policies, expanding production capabilities, and cost-competitive food infrastructure development. The country's focus on becoming a global food processing hub is driving investments in specialized coating technology and food manufacturing infrastructure. Rising awareness about advanced coating options and improving manufacturing capabilities are creating opportunities for specialized coating systems across food production and manufacturing settings in major hubs like Maharashtra, Tamil Nadu, and Gujarat.

France's advanced food manufacturing market demonstrates sophisticated coating technology deployment with documented compound coating effectiveness in food production departments and manufacturing centers through integration with existing production systems and quality infrastructure. The country leverages culinary expertise in coating technology and food production systems integration to maintain a 6.5% CAGR through 2035. Food manufacturing centers, including major production areas, showcase premium installations where compound coatings integrate with comprehensive food information systems and quality platforms.

French manufacturers prioritize system reliability and food compliance in infrastructure development, creating demand for premium systems with advanced features, including performance validation and integration with French food standards. The market benefits from established food industry infrastructure and a willingness to invest in advanced coating technologies that provide long-term operational benefits and compliance with food regulations. Major food regions demonstrate increasing adoption of specialized coating systems supporting both domestic consumption and export requirements.

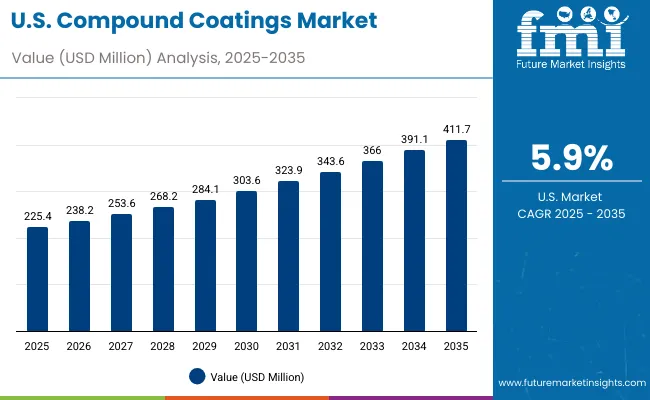

USA's market expansion benefits from diverse food manufacturing demand, including coating infrastructure modernization in major production regions, technology development programs, and government food programs that increasingly incorporate compound coating solutions for infrastructure enhancement applications. The country maintains a 5.9% CAGR through 2035, driven by rising food industry awareness and increasing adoption of coating benefits, including superior product capabilities and reduced complexity. Market dynamics focus on cost-effective coating solutions that balance advanced technology features with affordability considerations important to American food manufacturers.

Growing food manufacturing infrastructure creates demand for modern coating systems in new production facilities and food equipment modernization projects. Regional food manufacturing requirements are driving a diverse product portfolio from basic coating systems to advanced technology platforms. Import dependency challenges are offset by potential local development partnerships with international coating manufacturers. Government food industry initiatives are beginning to influence procurement standards and manufacturing infrastructure requirements across California, Illinois, New York, and other major food production regions.

Germany demonstrates steady market development with a 5.6% CAGR through 2035, distinguished by food manufacturers' preference for high-quality coating systems that integrate seamlessly with existing production equipment and provide reliable long-term operation in specialized food applications. The market prioritizes advanced features, including precision coating algorithms, performance validation, and integration with comprehensive food production platforms that reflect German food manufacturing expectations for technological advancement and operational excellence.

Premium focus on precision systems with advanced coating algorithms and high-reliability capabilities for food applications requiring exceptional performance standards drives market development. Integration requirements with existing food information systems and production management platforms support comprehensive manufacturing automation. The market emphasizes compound coating reliability and long-term performance in food applications with strict operational requirements. Strong preference for locally manufactured systems that comply with German engineering standards and food regulations shapes competitive dynamics throughout major food production regions.

UK's market expansion benefits from diverse food manufacturing demand, including coating infrastructure modernization in major production regions, technology development programs, and government food programs that increasingly incorporate compound coating solutions for infrastructure enhancement applications. The country maintains a 5.3% CAGR through 2035, driven by rising food industry awareness and increasing adoption of coating benefits, including superior product capabilities and operational efficiency.

Market dynamics focus on cost-effective coating solutions that balance advanced technology features with affordability considerations important to British food manufacturers. Growing food manufacturing infrastructure creates demand for modern coating systems in new production facilities and equipment modernization projects. Regional food manufacturing requirements are driving a diverse product portfolio from basic coating systems to advanced technology platforms supporting England, Scotland, Wales, and Northern Ireland food production regions.

Brazil demonstrates modest market development with a 3.0% CAGR through 2035, reflecting mature food markets and established food manufacturing infrastructure. The country's extensive food processing industry and established confectionery production systems create steady demand for coating solutions, though growth rates remain moderate compared to emerging markets. Brazilian food manufacturers focus on cost-effective coating systems that provide reliable performance while maintaining competitive production costs in domestic food markets.

The market is characterized by large-scale food operations requiring consistent coating quality and supply chain reliability. Coating manufacturers serving Brazilian markets emphasize bulk delivery capabilities, regional production facilities, and pricing stability to support extensive food manufacturing operations. Government food policies supporting production efficiency create opportunities for coating technologies that improve manufacturing conversion rates. Major food-producing states drive demand for efficient coating systems that support both domestic consumption and regional market requirements.

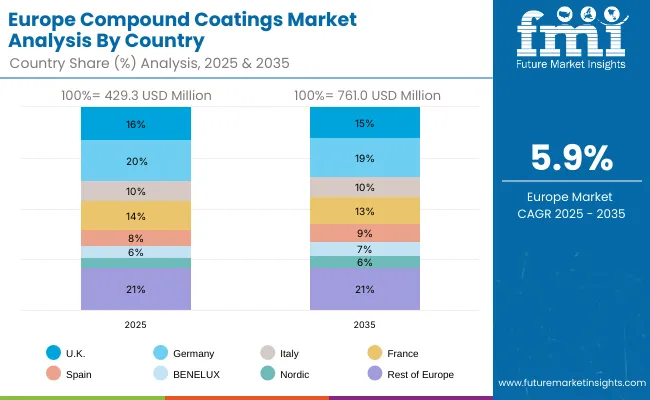

The compound coatings market in Europe is projected to grow significantly, with individual country performance varying across the region. Germany is expected to maintain its leadership position with a market value of USD 85.9 million in 2025, supported by its advanced food manufacturing infrastructure, precision coating management capabilities, and strong confectionery presence throughout major production regions.

UK follows with USD 68.7 million in 2025, driven by advanced coating protocols, food innovation integration, and expanding manufacturing networks serving both domestic and international markets. France holds USD 60.1 million in 2025, supported by food manufacturing infrastructure expansion and growing adoption of high-efficiency coating systems. Italy commands USD 42.9 million in 2025, while Spain accounts for USD 34.3 million in 2025. The Rest of Europe region, including Nordic countries, Eastern Europe, and smaller Western European markets, holds USD 137.4 million in 2025, representing diverse market opportunities with established food manufacturing and coating infrastructure capabilities.

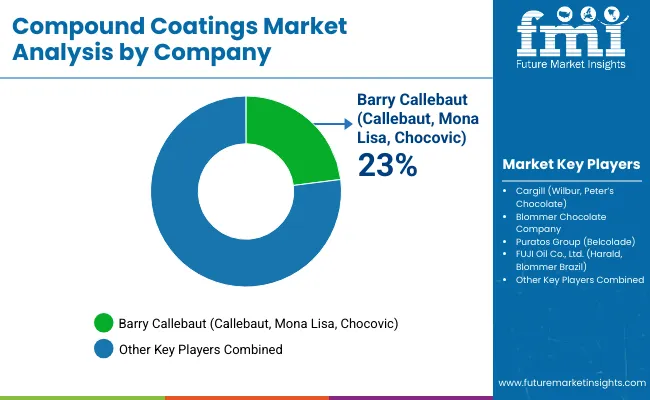

The compound coatings market is characterized by competition among established food ingredient companies, specialty coating companies, and food technology suppliers focused on delivering high-efficiency, consistent, and reliable coating systems. Companies are investing in coating technology advancement, performance enhancement, strategic partnerships, and customer technical support to deliver effective, efficient, and reliable food solutions that meet stringent manufacturing and processing requirements. Product optimization, performance validation protocols, and supply chain strategies are central to strengthening product portfolios and market presence.

Barry Callebaut leads the market with a 23.0% market share, offering comprehensive high-efficiency compound coatings with a focus on performance consistency and quality reliability for food manufacturing applications. Cargill provides specialized coating systems with emphasis on food manufacturing applications and comprehensive technical support services. Blommer Chocolate Company focuses on advanced coating technologies and customized food solutions for coating systems serving global markets. Puratos Group delivers established coating systems with strong performance management and customer service capabilities.

FUJI Oil operates with a focus on bringing innovative coating technologies to specialized food applications and emerging markets. Companies provide comprehensive coating system portfolios, including advanced food manufacturing services, across multiple food applications and production management processes. Coating manufacturers specialize in customized coating solutions and performance management systems for food systems with emphasis on manufacturing compliance. Food suppliers provide reliable supply chain solutions and technical expertise to enhance market accessibility and customer access to essential coating systems.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 1,258.6 Million |

| Coating Type | Chocolate Compound Coatings, Yogurt Compound Coatings, Carob Compound Coatings, Colored Compound Coatings, Flavored Compound Coatings |

| Fat Type | Cocoa Butter Replacers (CBR), Cocoa Butter Substitutes (CBS), Cocoa Butter Equivalents (CBE), Palm Kernel Oil-based, Other Vegetable Oil-based |

| Application | Confectionery, Bakery, Ice Cream & Frozen Desserts, Snack Bars & Cereal Bars, Fruits & Nuts Coating, Pet Treats |

| Form | Chips, Blocks, Liquid, Powder |

| End Use | Food Manufacturers (Industrial/B2B), Foodservice, Retail (DIY Baking & Toppings) |

| Technology | Spray Coating, Enrobing, Panning, Dipping, Molding |

| Product Claim | Sugar-Free, Vegan, Organic, Gluten-Free, Non-GMO |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | China, USA, Germany, Japan, India, South Korea, France and 40+ countries |

| Key Companies Profiled | Barry Callebaut, Cargill, Blommer Chocolate Company, Puratos Group, and FUJI Oil |

| Additional Attributes | Dollar sales by coating type and fat type, regional demand trends, competitive landscape, food manufacturer preferences for specific coating systems, integration with specialty food supply chains, innovations in coating technologies, performance monitoring, and product optimization |

The global compound coatings market is estimated to be valued at USD 1,258.6 million in 2025.

The market size for the compound coatings market is projected to reach USD 2,221.4 million by 2035.

The compound coatings market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key coating types in the compound coatings market are chocolate, yogurt, carob, colored, and flavored compound coatings.

In terms of coating type, chocolate compound coatings are expected to command 45.0% share in the compound coatings market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Compound Semiconductor Hall Elements Market Size and Share Forecast Outlook 2025 to 2035

Compounds Market Size and Share Forecast Outlook 2025 to 2035

Compound Chocolate Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Compound Semiconductor Materials Market Growth - Trends & Forecast 2025 to 2035

Compound Horse Feedstuff Market Analysis by Feed Type, Horse Activity, and Ingredient Composition Through 2035

Compound Feed Market Analysis by Ingredients, Form, Livestock and Region through 2035

Compounded Topical Drugs Market Analysis – Size, Share & Forecast 2024-2034

Compound Semiconductor Market Analysis – Growth & Forecast 2024-2034

Compounding Systems Market

Compounded Bioidentical Hormone Therapy Market

Wire Compounds and Cable Compounds Market Growth - Trends & Forecast 2025 to 2035

Joint Compound Market Size and Share Forecast Outlook 2025 to 2035

Lemon Compound Market Size and Share Forecast Outlook 2025 to 2035

Flavor Compounds Market Size and Share Forecast Outlook 2025 to 2035

Orange Compound Market Size and Share Forecast Outlook 2025 to 2035

Lithium Compound Market Forecast Outlook 2025 to 2035

Potting Compound Market Size and Share Forecast Outlook 2025 to 2035

Plastic Compounding Market Size, Growth, and Forecast 2025 to 2035

Purging Compounds Market

Platinum Compounds Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA