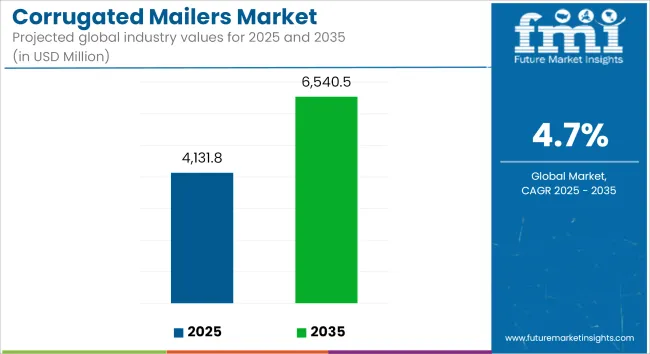

The corrugated mailers market is projected to grow from USD 4.1 Billion in 2025 to USD 6.5 Billion by 2035, registering a CAGR of 4.7% during the forecast period. Sales in 2024 reached USD 4.0 Billion, reflecting steady demand across various sectors. Growth has been driven by increasing applications in food & beverage, e-commerce, retail, and logistics industries, where corrugated mailers are essential for efficient and sustainable packaging solutions.

The market's expansion is further supported by advancements in packaging technology and the rising demand for recyclable and lightweight materials. Additionally, the rise in online shopping and the need for sustainable packaging solutions have contributed to the increased use of corrugated mailers, thereby supporting market expansion.

In January 2024, WestRock Company announced plans to build a new corrugated box plant in Pleasant Prairie, Wisconsin, to meet growing demand from customers in the Great Lakes region.

“Investing in a new state-of-the-art corrugated converting facility elevates our production capabilities and better supports our end market strategy and margin improvement targets,” said David B. Sewell, chief executive officer, WestRock.

“We are pleased to expand our presence in an area of critical demand like the Great Lakes and are confident that by implementing production initiatives such as these, we will continue to solidify WestRock’s position as the supplier of choice.”

| Attributes | Key Insights |

|---|---|

| Estimated Size, 2025 | USD 4.1 Billion |

| Projected Size, 2035 | USD 6.5 Billion |

| Value-based CAGR (2025 to 2035) | 4.7% |

A shift in product segmentation and material usage has been observed within the corrugated mailers industry. B-flute corrugated mailers have dominated the market due to their strength-to-weight ratio and exceptional protection properties.

However, C-flute mailers are gaining traction, especially in applications requiring enhanced cushioning and rigidity. Innovations in corrugated materials are enhancing performance characteristics, contributing to the market's growth.

The adoption of lightweight and recyclable materials aligns with environmental regulations and consumer preferences, further driving the demand for corrugated mailers.

Environmental concerns and regulatory pressures have driven innovation in the corrugated mailers market. Sustainability and innovation have played pivotal roles in shaping the corrugated mailers market. The development of eco-friendly packaging solutions has been prioritized to meet environmental regulations and consumer preferences.

Advancements in corrugated design have led to improved strength and durability, enhancing product protection. Integration of smart features, such as easy-open designs and tamper-evident seals, has been implemented to ensure user convenience and product safety.

These innovations have not only reduced the environmental footprint of packaging products but have also opened new avenues for application in various industries.

The market is segmented based on product type, wall type, distribution channel, end use, and region. By product type, the market includes A flute, B flute, C flute, E flute, and F flute variants. In terms of wall type, the market is categorized into single-wall, double-wall, and triple-wall constructions.

By distribution channel, the market is segmented into online retail channels, offline retail channels, direct-to-consumer (D2C), and business-to-business models. In terms of end use, the market comprises e-commerce & retail, electronics, pharmaceuticals, food & beverage, personal care & cosmetics, and industrial goods.

Regionally, the market is analyzed across North America, Latin America, East Asia, South Asia & Pacific, Eastern Europe, Western Europe, Oceania, and the Middle East & Africa.

Single-wall corrugated mailers have been projected to represent 68.3% of the overall market in 2025, owing to their suitability for lightweight to medium-weight goods and their cost-efficient production profile.

These mailers are widely utilized across consumer goods, subscription box services, and food delivery sectors where shipping durability is required without over-engineering.

Their structural simplicity and ease of handling have aligned them well with e-commerce growth and direct-to-consumer shipping models. As the demand for sustainable and recyclable shipping solutions rises, single-wall variants have been preferred due to their lower material use and recyclability credentials.

Most manufacturers offer FSC-certified or post-consumer recycled material options that meet the sustainability benchmarks of global retail brands.

Additionally, printing compatibility on single-wall surfaces enhances brand presentation without compromising the structural integrity during shipment.

Automation in box folding and sealing processes has further elevated the appeal of single-wall configurations in high-throughput fulfillment centers. With increased integration into supply chains driven by Omni channel retail, these mailers are expected to remain a cornerstone in flexible logistics frameworks.

Their adaptability across sizes and customization features has added to their popularity among SMEs and multinational packaging operations alike. In markets prioritizing cost, sustainability, and efficiency, single-wall corrugated mailers are forecasted to maintain dominance through the forecast period.

Innovations in barrier coatings and water-based adhesives are also improving their resistance to moisture and handling wear, expanding their applicability across ambient and chilled supply chains.

The food & beverage segment has been estimated to account for 14.6% of the corrugated mailers market in 2025, driven by the growth in online grocery platforms, meal kits, and cold chain deliveries.

Corrugated mailers have been extensively used to transport dry, packaged, and semi-perishable foods that require cushioning, stack ability, and print-ready surfaces for regulatory and branding needs.

They have enabled producers to achieve tamper evidence, transit durability, and cost savings without compromising on presentation. Sustainable fiber-based mailers are increasingly adopted by food manufacturers aiming to reduce single-use plastic in tertiary packaging.

Kraft liners, recycled fluting, and compostable adhesives are now routinely incorporated into mailers designed for retail-ready and direct delivery use. Corrugated designs also facilitate high stacking strength and shock absorption, critical for fragile items such as glass jars, snack boxes, and bottled beverages.

Temperature-sensitive shipments, including fresh produce and dairy, have been paired with insulated liners and gel packs inside corrugated mailers to maintain integrity without resorting to EPS or polymer-based boxes. This compatibility with thermal regulation accessories has helped extend the application of mailers within perishables and ready-to-eat segments. Corrugated materials also support compliance with food-grade transit requirements by using FDA-approved inner linings.

With the foodservice ecosystem increasingly embracing doorstep delivery, corrugated mailers are expected to experience sustained demand. The sector’s move toward green logistics and packaging waste minimization is likely to reinforce this preference, especially as fiber-based innovation continues to replace legacy foam and plastic shipping formats.

The below table presents the expected CAGR for the global corrugated mailers market over several semi-annual periods spanning from 2025 to 2035. In the first half (H1) of the decade from 2024 to 2034, the business is predicted to surge at a CAGR of 4.4%, followed by a higher slight high growth rate of 5.0% in the second half (H2) of the same decade.

| Particular | Value CAGR |

|---|---|

| H1 | 4.4% (2024 to 2034) |

| H2 | 5.0% (2024 to 2034) |

| H1 | 4.3% (2025 to 2035) |

| H2 | 5.1% (2025 to 2035) |

Moving into the subsequent period, from H1 2024 to H2 2035, the CAGR is projected to decrease to 4.3% in the first half and increase to 5.1% in the second half. In the first half (H1) the market witnessed a decrease of 10 BPS while in the second half (H2), the market witnessed an increase of 10 BPS.

B Flute Mailers Dominate E-Commerce Packaging for Fragile Goods

A key catalyst of a large demand for protective packaging is the e-commerce industry growing at an impressive rate, mainly in fragile or high-value product industries like electronics, cosmetics, and small appliances.

A customer wants their buys to reach their homes without sustaining damage, whereas a company seeks minimum cost in the packaging of goods for the assured safe movement through transport. B Flute corrugated mailers find the most appeal in such goods as they come with excellent balances of strength to lightness.

Medium thickness would cushion fragile things against impacts and compression; such mailers also would not weigh the goods heavily due to its thin nature, which would minimize the overall transportation costs for this type of an e-commerce-based business looking forward to cost-efficient services.

The B Flute mailers are also customizable, meaning businesses can tailor packaging to their specific product needs. With protection, cost-effectiveness, and customization, B Flute corrugated mailers become a preferred choice in the growing e-commerce market for fragile items.

Custom-Printed Corrugated Mailers Transform Packaging into Branding Powerhouse

The use of corrugated mailers has increasingly been considered as something more than a packaging solution in the commercial sector-they are also powerful branding tools. Companies, especially in retailing, recognize that custom-printed B Flute mailers improve customer experience and add value.

In such mailers, they can have their logos, colors, and other unique designs displayed on the packaging, thereby extending the branding aspect. These mailers are very vibrant in fashion, beauty, and the consumer electronics wherein the un-boxing experience strongly contributes to satisfying the customer with the brand experience.

Customization of packaging allows a brand not only to affirm its image, but also delivers a memorable consumer moment of positive association through repeat business. Moreover, in a highly competitive market, the only thing that can differentiate the company from others is unique and branded packaging.

Therefore, this is an essential element of marketing strategies that can help build long-term customer relationships and increase brand visibility.

Space Constraints Challenge Efficiency of Bulk Protective Mailers Storage

Large-scale business shippers sometimes face significant space and handling hurdles when using two- or three-pack corrugated mailers in order to have adequate protection to their products shipped. These enhanced protection mailers are bulkier and take much more storage area than the corresponding lighter, more flimsy alternatives.

Firms with limited warehouses often face difficulty in logistics while handling large quantities that need dedicated warehousing space but reduce the floor area for carrying inventory.

In addition, these mailers can be cumbersome to store and, therefore, difficult to manage the inventory; thus, accessing the needed packaging material may become an inefficient task. In other cases, extra storage infrastructure will have to be purchased, further increasing operational costs.

Consequently, companies need to weigh the requirements of robust, protective packaging against the pragmatic realities of warehouse space and inventory flow, which makes it a critical consideration in supply chain management for businesses that handle large volumes of shipments.

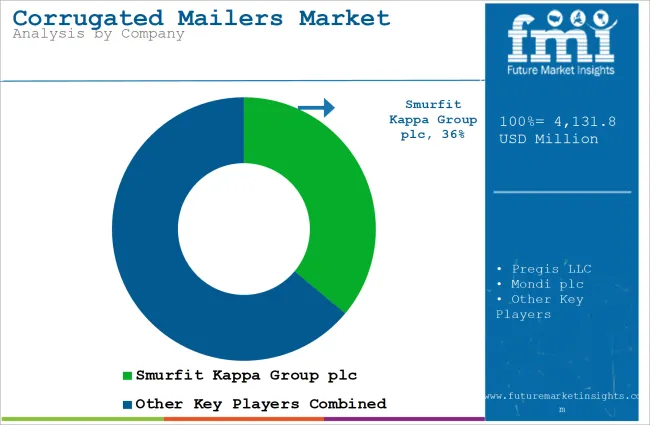

Tier 1 company leaders are characterized by high production technology and a wide product portfolio. These market leaders are distinguished by their extensive expertise in manufacturing and reconditioning across multiple packaging formats and a broad geographical reach, underpinned by a robust consumer base.

They provide a wide range of series including reconditioning, recycling, and manufacturing utilizing the latest technology and meeting the regulatory standards providing the highest quality. Prominent companies within Tier 1 include Smurfit Kappa Group plc, Pregis LLC, Mondi plc, DS Smith plc, WestRock Company, International Paper Company.

Tier 2 companies are characterized by a strong presence overseas and strong market knowledge. These market players have good technology and ensure regulatory compliance but may not have advanced technology and wide global reach.

Prominent companies in Tier 2 include GWP Group, Accurate Box Company, Inc., VSL Packaging Company USA, PakFactory, Shanghai DE Printed Box, Northwest Paper Box, U-Pack, Box Market.

Tier 3 includes the majority of small-scale companies operating at the local presence and serving niche markets. These companies are notably oriented towards fulfilling local market demands and are consequently classified within the tier 3 share segment. They are small-scale players and have limited geographical reach.Tier 3, within this context, is recognized as an unorganized market, denoting a sector characterized by a lack of extensive structure and formalization when compared to organized competitors.

The section below covers the industry analysis for the corrugated mailers market for different countries. Market demand analysis on key countries in several regions of the globe, including North America, Asia Pacific, Europe, and others, is provided.

USA is anticipated to remain at the forefront in North America, with a CAGR of 3.5% through 2035. In South Asia & Pacific, India is projected to witness a CAGR of 5.7% by 2035.

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| USA | 3.5% |

| Canada | 2.8% |

| Brazil | 4.3% |

| Argentina | 3.8% |

| Germany | 2.7% |

| China | 5.2% |

| India | 5.7% |

Major growth driver for the USA corrugated mailers market in the e-commerce sector would be increasing demand for packaging solutions designed to protect fragile and high-value shipments. With rising online sales of electronics, beauty products, and subscription-based services, companies are using corrugated mailers extensively because they are superior to protect and have lighter weight properties. Specifically, B Flute mailers are more in demand because they offer proper cushioning without contributing much to shipping.

This is because free shipping or discounted shipping charge is always in demand due to competition. More importantly, there is high demand for green packaging because the consumer favors biodegradable and recyclable mailers and corrugated mailers are categorized as those types.

The USA-based retailers are utilizing corrugated mailers as a custom-printed mailer in order to develop brand recognition and provide the customer with an enriched experience within the dynamic and fast-paced landscape of e-commerce.

Steady growth demand for sustainable packaging solutions in the industrial and commercial sectors, such as electronic and automotive parts is generating major demand for the corrugated mailers market of Germany. A significant manufacturing base in the world pertaining to automobiles and precision engineering requires providing secure shipment but environmental friendly as such commodities are considered to be sensitive with high value.

Corrugated mailers are commercially the most common because they are strong, light, and commercially available in every package size to protect the product domestically or internationally.

Increasing government environmental policies of Germany and greater demand of consumers and companies toward a green environment have also started to focus on recyclable as well as biodegradable packaging products.

The other use of the same branding and labeling technique of corrugated mailers on German businesses for high utility with the ability of trackability on supply chain traceability as well as creating a professional image for the brand especially in B2B transactions.

Key players operating in the corrugated mailers market are investing in the development of innovative sustainable solutions and also entering into partnerships. Key corrugated mailers providers have also been acquiring smaller players to grow their presence to further penetrate the corrugated mailers market across multiple regions.

Recent Industry Developments in the Corrugated Mailers Market

The global corrugated mailers industry is projected to witness CAGR of 4.7% between 2025 and 2035.

The global corrugated mailers industry stood at USD 4,007.6 million in 2024.

The global corrugated mailers industry is anticipated to reach USD 6,540.5 million by 2035 end.

South Asia & Pacific region is set to record the highest CAGR of 5.0% in the assessment period.

The key players operating in the global corrugated mailers industry include Smurfit Kappa Group plc, Pregis LLC, Mondi plc, DS Smith plc, WestRock Company, International Paper Company, GWP Group, and Accurate Box Company, Inc.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Corrugated Box Machine Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Automotive Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Fanfold Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Board Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Equipment Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Box Making Machine Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Fanfold Market Analysis - Size, Share, and Forecast 2025 to 2035

Corrugated and Folding Carton Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Pharmaceutical Packaging Market Analysis Size, Share & Forecast 2025 to 2035

Corrugated Pallet Wrap Market Growth - Demand & Forecast 2025 to 2035

Corrugated Plastic Box Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Box Market Size, Share & Forecast 2025 to 2035

Corrugated Bubble Wrap Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Paper Machine Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Box Printer Slotter Machine Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Pallet Containers Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Corrugated Open-head Drums Market Growth - Size & Forecast 2025 to 2035

Corrugated Fiberboard Market Analysis - Size, Demand & Forecast 2025 to 2035

Corrugated Plastic Trays Market Growth, Trends and Outlook from 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA