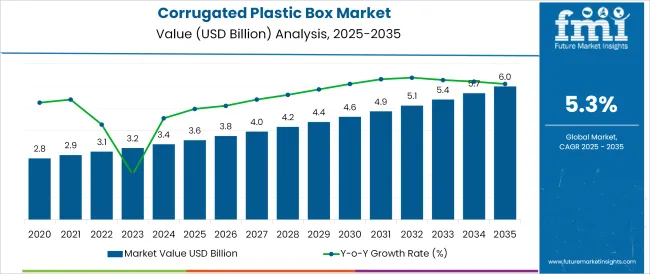

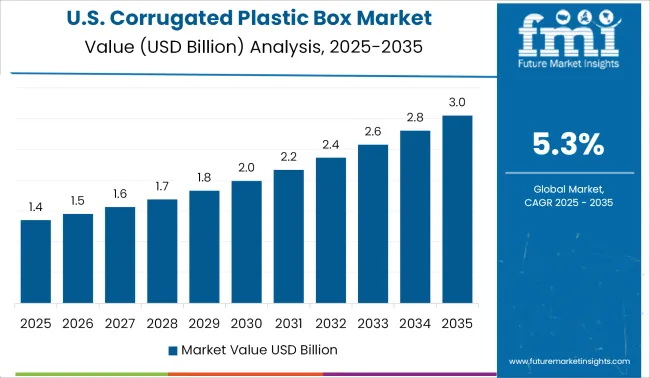

The Corrugated Plastic Box Market is estimated to be valued at USD 3.6 billion in 2025 and is projected to reach USD 6.0 billion by 2035, registering a compound annual growth rate (CAGR) of 5.3% over the forecast period.

The corrugated plastic box market is gaining considerable traction due to increasing demand for reusable, lightweight, and impact-resistant packaging across industrial and commercial applications. Polypropylene based corrugated plastic boxes are being favored over traditional corrugated cardboard due to their enhanced resistance to moisture, chemicals, and repetitive handling.

Manufacturers are prioritizing sustainability by offering recyclable and returnable packaging options, especially in sectors like automotive, electronics, and agriculture. The integration of RFID, barcode labelling, and modular stacking features is enhancing inventory traceability and warehouse automation compatibility. Global logistics operators and OEMs are shifting to corrugated plastic formats to reduce long-term packaging costs and improve shipment protection during transit and storage.

As ESG mandates and lean packaging strategies expand globally, the corrugated plastic box market is expected to witness sustained adoption across industries seeking durable, foldable, and environmentally aligned packaging solutions.

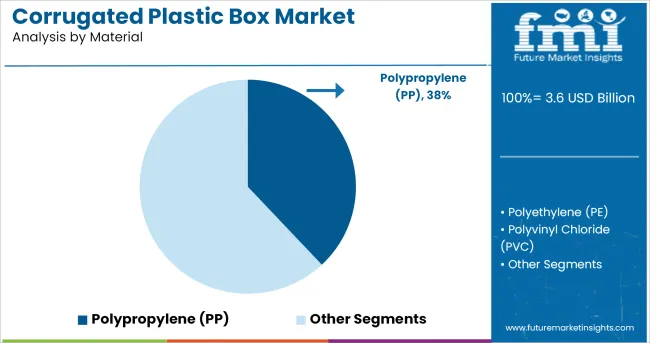

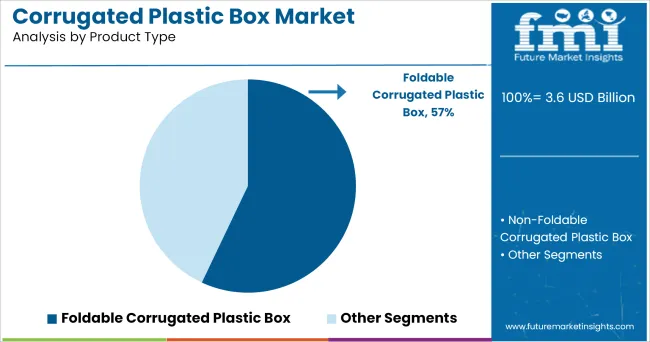

The market is segmented by Material, Product Type, and End-Use Industry and region. By Material, the market is divided into Polypropylene (PP), Polyethylene (PE), Polyvinyl Chloride (PVC), and Others (PS, etc.). In terms of Product Type, the market is classified into Foldable Corrugated Plastic Box and Non-Foldable Corrugated Plastic Box.

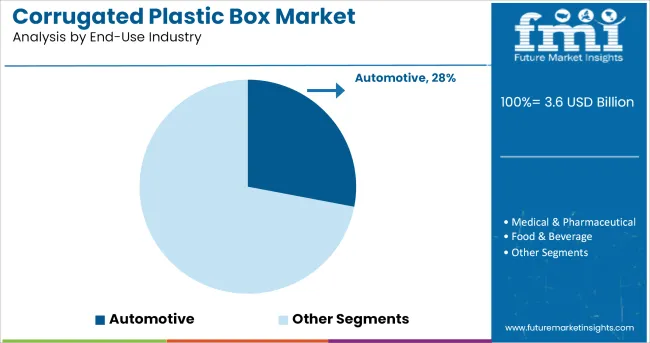

Based on End-Use Industry, the market is segmented into Automotive, Medical & Pharmaceutical, Food & Beverage, Electronics & Electricals, Building & Construction, and Others (Agriculture, Cosmetic, etc.). Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Polypropylene is projected to account for 38.0% of the total revenue share in the corrugated plastic box market by 2025, positioning it as the leading material. Its dominance is attributed to superior properties such as water resistance, high tensile strength, and chemical inertness which are critical in industrial and logistics environments.

PP’s lightweight nature contributes to cost-effective transportation, while its recyclability supports sustainable packaging mandates. Additionally, its compatibility with various fabrication methods, including ultrasonic welding and die cutting, allows for versatile product customization.

The material’s long lifecycle, minimal maintenance, and ability to retain structural integrity under mechanical stress have made it the preferred choice for reusable corrugated packaging formats across multiple end-use sectors.

The foldable variant is expected to lead the product type segment with a 57.0% revenue share in 2025. Its growth is primarily driven by rising demand for space saving and reusable packaging solutions that reduce return logistics costs and warehouse footprint. Foldable designs support efficient stacking and can be collapsed flat when not in use, offering operational advantages for storage and reverse logistics

Their increasing use in industrial distribution, automotive supply chains, and retail ready displays has solidified their market presence. Manufacturers are enhancing foldable boxes with interlocking tabs, reinforced edges, and quick-assembly features, which contribute to improved durability and user convenience.

The shift toward circular supply chains and returnable transit packaging has further bolstered the adoption of foldable corrugated plastic boxes as a sustainable and cost effective solution.

The automotive industry is anticipated to represent 28.0% of the corrugated plastic box market revenue in 2025, emerging as the largest end use segment. This leadership is being driven by the sector’s need for durable, reusable, and part-specific packaging solutions that safeguard components during in-plant transfers and cross facility logistics

Automotive OEMs and suppliers are increasingly standardizing packaging with lightweight, impact resistant boxes that can withstand heavy mechanical handling and minimize damage during transit. Corrugated plastic boxes are being adopted for their compatibility with returnable systems and their contribution to waste reduction in just-in-time manufacturing environments.

Additionally, the customizability of inserts and compartments supports the packaging of delicate parts like electronic modules, bumpers, and headlights. As automotive production becomes more global and modular, the demand for cost-effective, reusable packaging with high load-bearing capacity is expected to continue rising, reinforcing the segment’s dominant market position.

A corrugated plastic box is similar to corrugated cardboard which is made from plastic sheets that are hollow from inside. Corrugated plastic box is light in weight compared to ordinary plastic or metal box which adds to the cost-benefit during transportation or shipping.

Corrugated plastic box is preferred as secondary packaging solution in various end-use industries such as automotive, electronics, medical, food & beverage and others. These corrugated plastic boxes can be reused and recycled which gains popularity among the end-users.

A corrugated plastic box is a convenient and smarter alternative to cardboard, paper, and wooden packaging. Corrugated plastic box possesses various attractive features such as waterproof exterior, reusable, light in weight, and others which gain traction among the end-users and this is anticipated to drive the demand for corrugated plastic box during the forecasted period.

The high wet strengthen of the corrugated plastic box fuels the demand for corrugated plastic boxes among the end-users. A corrugated plastic box can carry multiple items at a time as it has demarcations within the box. It also can carry heavy material due to its strength, hardness, and stiffness which makes it popular among the other ordinary boxes.

Corrugated plastic box has the capability of retaining its structure under all different types of condition which ensure the safety of the product that is packed.

Moreover, a corrugated plastic box can be made according to the requirement of the user which adds to the benefit of the corrugated plastic box. The user need not worry to dispose of the corrugated plastic box as it can be returned back to the shipper or the seller as they can use it again.

The corrugated plastic box is environmentally sustainable and viable which supports the sustainability concern. On the back of all the above factors, the demand for a corrugated plastic box is anticipated to augment during the forecasted period.

Technology such as RFID (Radio Frequency Identification system) can be attached to the corrugated plastic box which helps to track the location of the product and reduces the chances of loss of box during transit. Also, this ensures the return of the box after its use so that it can be reused for storing or transporting some other items.

The system helps in quick identification of the location of the corrugated plastic box which gains popularity among the end-users High adoption of such technology oriented corrugated plastic boxes is offering opportunities to the manufacturers to maximize their sales in the market.

The cost limits the market growth of a corrugated plastic box as the corrugated plastic box are costlier as compared to other ordinary boxes due to their various benefit added feature. Also, the corrugated plastic box is not an entirely eco-friendly solution which hampers the market growth of the corrugated plastic box up to some extent.

The global key players for the corrugated plastic box are

Some of the APAC players include Corlite Packaging Industries Sdn. Bhd., CLPG Packaging Industries Sdn. Bhd., Classic Enterprises Pvt Ltd, and others.

The key players operating in the corrugated plastic box market are trying to expand their production capacity by expanding their facilities to cater for the increasing demand for safe and proper secondary packaging among the end-use industries. Also, the players are trying to expand their footprint through mergers & acquisitions with local players.

The growing preference for returnable packaging in the United States fuels the demand for the corrugated plastic boxes. The corrugated plastic box can be returned back to the shipper or seller and can be reused to store or transport other items which gain popularity among the end-users.

The end-use industry prefers the returnable packaging solution in order to save cost as well as to reduce wastage which supplements the sales of a corrugated plastic box in the United States. Moreover, the high wet strength and lightweight boost the demand for a corrugated plastic box in the United States.

The increasing trade activities in India propel the demand for proper and safe secondary packaging to protect the product during shipment which creates a market growth opportunity for the corrugated plastic box.

The corrugated plastic box has been preferred due to its various benefit such as being waterproof, carries multiple items, and others. Therefore, the increasing trade of various industrial and non-industrial products creates a growth opportunity for the corrugated plastic box market.

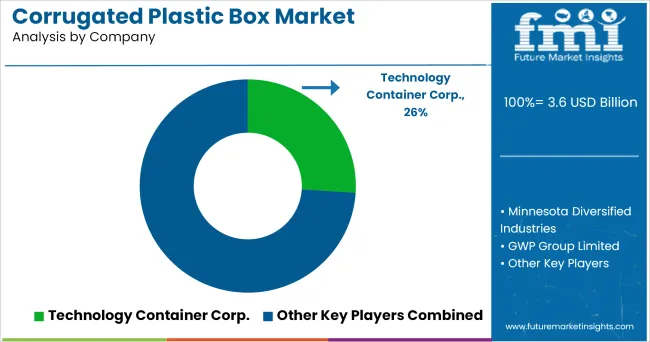

The global corrugated plastic box market is estimated to be valued at USD 3.6 billion in 2025.

The market size for the corrugated plastic box market is projected to reach USD 6.0 billion by 2035.

The corrugated plastic box market is expected to grow at a 5.3% CAGR between 2025 and 2035.

The key product types in corrugated plastic box market are polypropylene (pp), polyethylene (pe), polyvinyl chloride (pvc) and others (ps, etc.).

In terms of product type, foldable corrugated plastic box segment to command 57.0% share in the corrugated plastic box market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Insights of the Corrugated Plastic Box Industry

Corrugated Automotive Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Fanfold Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Board Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Equipment Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Fanfold Market Analysis - Size, Share, and Forecast 2025 to 2035

Corrugated and Folding Carton Packaging Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Pharmaceutical Packaging Market Analysis Size, Share & Forecast 2025 to 2035

Corrugated Pallet Wrap Market Growth - Demand & Forecast 2025 to 2035

Corrugated Bubble Wrap Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Paper Machine Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Pallet Containers Market Size and Share Forecast Outlook 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Corrugated Mailers Market Size, Share & Forecast 2025 to 2035

Corrugated Open-head Drums Market Growth - Size & Forecast 2025 to 2035

Corrugated Fiberboard Market Analysis - Size, Demand & Forecast 2025 to 2035

Corrugated Wraps Market Analysis from 2025 to 2035

Market Share Breakdown of Leading Corrugated Bubble Wrap Manufacturers

Breaking Down Market Share in Corrugated Automotive Packaging

Market Positioning & Share in Corrugated Fanfold Industry

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA