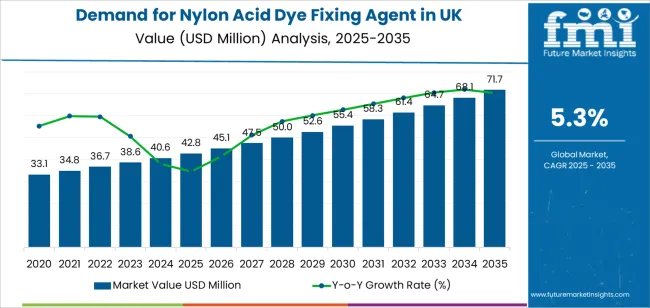

The demand for nylon acid dye fixing agent in UK is projected to grow from USD 42.8 million in 2025 to approximately USD 69.1 million by 2035, recording an absolute increase of USD 26.3 million over the forecast period. This translates into total growth of 61.4%, with demand forecast to expand at a compound annual growth rate (CAGR) of 5.3% between 2025 and 2035. This equals growth of about 1.61 times over the decade. The expansion is linked to rising output in textile finishing, greater attention to colorfastness quality, and the shift of manufacturers toward dyeing methods that reduce reprocessing, water usage, and dye runoff. Demand is highest in clothing production where nylon-based apparel, performance textiles, sportswear, uniforms, and fashion-forward segments require color stability during washing and UV exposure.

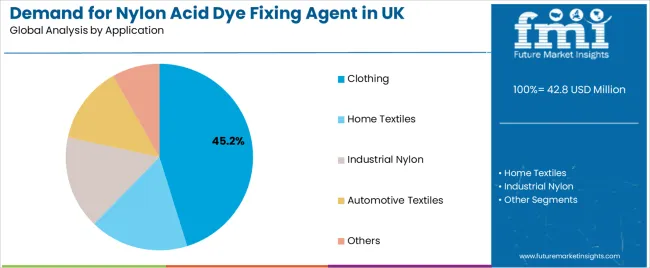

Clothing accounts for 45.2% of total demand in 2025, reflecting the continued preference for nylon blends in activewear and outdoor fabrics. Home textiles contribute to a steady demand as upholstery, carpets, curtains, and interior materials rely on controlled shade consistency and high resistance to fading. England leads regional consumption, supported by textile-finishing hubs, chemical-processing clusters, and technology partnerships focused on improving dye penetration and fixation control. Scotland follows with activity concentrated in specialty textile producers and fabric treatment facilities. Growth is further encouraged by integration of automated dyeing systems, where fixation agents are dosed using process control programs that reduce operator variability.

Between 2025 and 2030, sales of UK nylon acid dye fixing agent are projected to expand from USD 42.8 million to USD 54.1 million, resulting in a value increase of USD 11.3 million, which represents 43% of the total forecast growth for the decade. This phase of growth will be shaped by rising textile manufacturing applications across UK, particularly in dyeing centers where advanced fixing agent adoption and quality enhancement standards are accelerating chemical deployment.

Increasing integration of automated processing systems in textile production applications and growing adoption of specialized fixation technologies continue to drive demand. Textile companies are expanding their processing capabilities to address the growing complexity of modern dyeing requirements and textile manufacturing specifications, with UK operations leading investments in advanced fixing systems.

From 2030 to 2035, demand is forecast to grow from USD 54.1 million to USD 69.1 million, adding another USD 15 million, which constitutes 57% of the overall ten-year expansion. This period is expected to be characterized by expansion of next-generation dyeing technologies, integration of advanced chemical processing systems and quality control protocols, and development of specialized textile manufacturing pathways across different production applications. The growing adoption of precision dyeing principles and enhanced textile processing requirements, particularly in England and Scotland regions, will drive demand for more sophisticated fixing agent systems and specialized chemical formulations.

Between 2020 and 2025, UK nylon acid dye fixing agent demand experienced steady expansion, driven by increasing textile processing requirements in manufacturing sectors and growing awareness of fixing agent benefits for color retention and dyeing reliability improvement. The sector developed as textile manufacturers and dyeing service providers, especially in major industrial corridors, recognized the need for proven chemical solutions and reliable processing management to achieve operational targets while meeting textile quality expectations and regulatory compliance requirements. Suppliers and textile manufacturers began emphasizing proper fixation optimization and application integration to maintain operational efficiency and commercial viability.

| Metric | Value |

|---|---|

| UK Nylon Acid Dye Fixing Agent Sales Value (2025) | USD 42.8 million |

| UK Nylon Acid Dye Fixing Agent Forecast Value (2035) | USD 69.1 million |

| UK Nylon Acid Dye Fixing Agent Forecast CAGR (2025-2035) | 5.3% |

Demand expansion is being supported by the accelerating emphasis on textile manufacturing excellence and dyeing process optimization nationwide, with UK maintaining its position as a textile technology and chemical innovation leadership region, and the corresponding need for effective fixing systems for textile processing, color management, and manufacturing reliability integration. Modern textile companies rely on fixing agent technologies to ensure operational competitiveness, regulatory compliance, and optimal performance achievement toward textile-focused manufacturing operations. Advanced dyeing requirements necessitate comprehensive chemical solutions including specialized fixation processing, color retention capabilities, and quality enhancement infrastructure to address diverse application needs and textile specifications.

The growing emphasis on textile manufacturing expansion and increasing quality regulations, particularly dyeing excellence commitments across UK, are driving demand for fixing systems from proven chemical suppliers with appropriate formulation expertise and quality management capabilities. Textile companies and manufacturing enterprises are increasingly investing in fixing agent sourcing and integrated chemical solutions to enhance operational profiles, access dyeing optimization trends, and demonstrate technology leadership in competitive textile environments. Manufacturing policies and quality compliance requirements are establishing standardized dyeing pathways that require fixing systems and performance assurance, with UK textile operations often pioneering large-scale implementation of advanced fixing agent technologies.

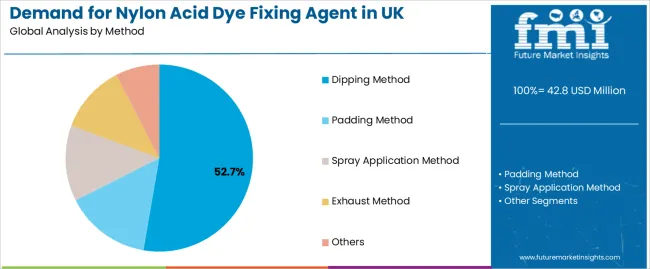

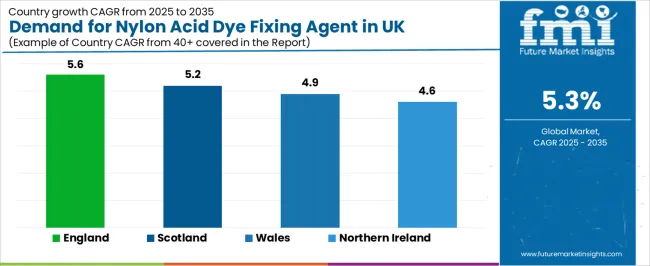

Demand is segmented by method, application, and region. By method, sales are divided into dipping method, padding method, spray application method, exhaust method, and others. In terms of application, sales are segmented into clothing, home textiles, industrial nylon, automotive textiles, and others. Regionally, demand is divided into England, Scotland, Wales, and Northern Ireland, with England representing a key growth and innovation hub for fixing agent technologies.

The dipping method segment is projected to account for 52.7% of UK nylon acid dye fixing agent demand in 2025, making it the leading method category across the sector. This dominance reflects the operational reliability and textile compatibility of dipping systems for existing textile manufacturing facilities and dyeing applications where chemical control is optimized through proven immersion processes. In UK, where substantial textile infrastructure requires fixing integration without complete process replacement, dipping method systems provide practical pathways for dyeing enhancement while maintaining operational continuity.

Continuous innovations are improving chemical effectiveness, processing compatibility characteristics, and textile integration parameters, enabling manufacturers to achieve high performance standards while maintaining operational flexibility. The segment's strong position is reinforced by the extensive existing textile infrastructure requiring fixing adoption and growing availability of dipping method suppliers with proven commercial experience.

Clothing applications are expected to represent 45.2% of UK nylon acid dye fixing agent demand in 2025, highlighting the critical importance of garment manufacturing requiring specialized fixing solutions. Textile facilities including apparel production, fashion manufacturing, specialty processing, and commercial garment applications generate consistent demand for fixing agent systems that are technically and economically favorable for clothing production applications. The segment benefits from chemical characteristics that often provide superior color retention compared to conventional fixing alternatives, reducing operational complexity and costs.

Garment manufacturing also accesses enhanced quality performance through fixing agent processing that improve dyeing reliability and textile appeal. In UK, where clothing manufacturing innovation represents substantial portions of textile industry development, fixing deployment requires agent integration across diverse garment operations. In England and Scotland regions, where clothing concentrations are significant, fixing agent demand is elevated by emphasis on maintaining operational excellence while achieving dyeing optimization integration targets.

UK nylon acid dye fixing agent demand is advancing steadily due to increasing textile dyeing requirements and growing recognition of fixing agent necessity for textile development, with England region serving as a key driver of innovation and application development. The sector faces challenges including competition from alternative fixing technologies, need for specialized chemical infrastructure development, and ongoing concerns regarding dyeing integration complexity and cost considerations. Textile guidelines and processing initiatives, particularly chemical programs in England and Scotland regions, continue to influence fixing agent selection and deployment timelines.

The enhancement of textile dyeing regulations, gaining particular significance through textile industry quality guidelines and excellence campaigns, is enabling fixing agent suppliers to achieve differentiation without prohibitive development costs, providing predictable demand patterns through textile requirements and dyeing preferences. Enhanced dyeing standards offering substantial opportunities for fixing systems and agent applications provide foundational dynamics while allowing suppliers to secure textile agreements and application partnerships. These trends are particularly valuable for first-mover suppliers and premium fixing development that require substantial technology investments without immediate cost advantages.

Modern fixing agent suppliers and chemical companies are establishing advanced processing networks and centralized chemical management facilities that improve operational efficiency through formulation standardization and economies of scale. Integration of automated dosing systems, real-time quality monitoring, and coordinated chemical management enables more efficient fixing agent operation across multiple textile sources. Advanced chemical concepts also support next-generation textile applications including specialized dyeing integration, technology cluster optimization, and regional fixing agent supply networks that optimize system-level economics while enabling comprehensive chemical control across textile regions, with UK developments increasingly adopting collaborative chemical models to reduce individual manufacturer costs and accelerate deployment.

| Region | CAGR (2025-2035) |

|---|---|

| England | 5.6% |

| Scotland | 5.2% |

| Wales | 4.9% |

| Northern Ireland | 4.6% |

UK nylon acid dye fixing agent demand is witnessing consistent growth, supported by rising textile dyeing excellence, expanding chemical requirements, and the deployment of advanced fixing agent technologies across regions. England leads the nation with a 5.6% CAGR, reflecting progressive textile trends, substantial chemical technology innovation, and early adoption of premium fixing systems. Scotland follows with a 5.2% CAGR, driven by extensive textile infrastructure, favorable technology demographics, and concentration of dyeing operations that enhance application development. Wales grows at 4.9%, as textile modernization and technology efficiency opportunities increasingly drive fixing agent deployment. Northern Ireland demonstrates growth at 4.6%, supported by expanding textile facilities and regional dyeing initiatives.

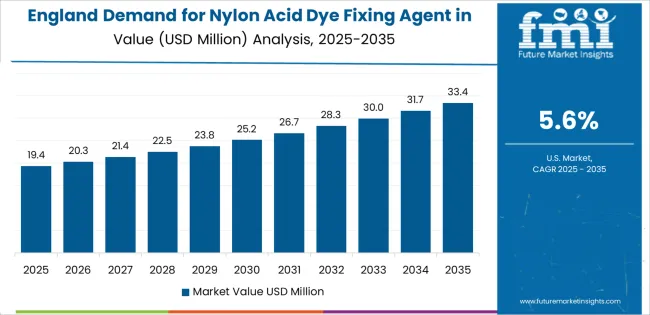

Demand for nylon acid dye fixing agent in England is projected to exhibit exceptional growth with a CAGR of 5.6% through 2035, driven by progressive textile manufacturing preferences, substantial technology development creating premium chemical opportunities, and concentration of innovation across London and surrounding regions. As the dominant region with extensive textile infrastructure and dyeing-focused operational policies, England's emphasis on comprehensive textile excellence and technology leadership is creating significant demand for advanced fixing agent systems with proven performance and reliable application potential. Major textile manufacturers and chemical suppliers are establishing comprehensive dyeing development programs to support technology innovation and premium chemical deployment across diverse applications.

Demand for nylon acid dye fixing agent in Scotland is expanding at a CAGR of 5.2%, supported by extensive textile facilities including chemical processing, textile operations, and manufacturing establishments generating concentrated demand favorable for fixing systems. The region's operational characteristics, featuring substantial textile operations and dyeing requirements ideal for chemical integration, provide natural advantages. Textile industry expertise concentrated in Glasgow, Edinburgh, and regional technology corridors facilitates application development and operational management. Fixing agent suppliers and manufacturers are implementing comprehensive dyeing strategies to serve expanding textile-focused requirements throughout Scotland.

Demand for nylon acid dye fixing agent in Wales is growing at a CAGR of 4.9%, driven by substantial textile facilities from chemical operations, dyeing engineering, and regional technology requiring fixing pathways. The region's textile base, supporting critical technology operations, is increasingly adopting fixing agent technologies to maintain competitiveness while meeting dyeing expectations. Manufacturers and chemical suppliers are investing in processing integration systems and regional supply infrastructure to address growing fixing agent management requirements.

Demand for nylon acid dye fixing agent in Northern Ireland is advancing at a CAGR of 4.6%, supported by expanding textile facilities, regional technology development including specialized applications, and growing emphasis on chemical solutions across the region. Textile modernization and manufacturing facility expansion are driving consideration of fixing agent systems as operational enhancement pathways. Technology companies and chemical suppliers are developing regional capabilities to support emerging fixing agent deployment requirements.

UK nylon acid dye fixing agent demand is defined by competition among specialized chemical manufacturers, textile suppliers, and dyeing service providers, with major chemical corporations maintaining significant influence through supply chain resources and technology development capabilities. Companies are investing in fixing agent technology advancement, supply chain optimization, distribution network structures, and comprehensive application services to deliver effective, reliable, and scalable chemical solutions across UK textile manufacturing and dyeing applications. Strategic partnerships, technology infrastructure development, and first-mover application execution are central to strengthening competitive positioning and presence across textile manufacturing, garment production, and chemical distribution applications.

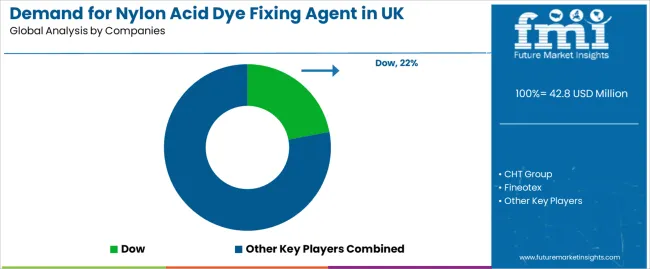

Dow, internationally recognized chemical leader, leads with 22% share, offering comprehensive fixing agent supply including manufacturing, technology, and distribution services with focus on textile applications, performance reliability, and cost optimization across UK operations. CHT Group, operating with extensive UK distribution, provides integrated chemical solutions leveraging dyeing expertise, quality assurance development, and textile manufacturing capabilities.

Fineotex delivers full-service fixing agent processing including chemical technology, performance testing, and supply management serving UK and international textile projects. Sarex emphasizes comprehensive chemical solutions with integrated fixing, quality control, and distribution capabilities leveraging textile sector expertise. Silvateam offers fixing agent application development and quality assurance operations for textile and manufacturing applications across UK operations.

The nylon acid dye fixing agent demand in UK is positioned for consistent expansion, growing from USD 42.8 million in 2025 to USD 69.1 million by 2035, reflecting a 5.3% CAGR. Rising adoption of textile dyeing systems in chemical processing, garment production, and manufacturing applications is driving growth as manufacturers seek high-quality chemical compounds that maximize dyeing efficiency and comply with stringent textile standards. Additionally, demand from clothing manufacturing and specialized home textile applications strengthens opportunities for both industrial-grade and consumer-grade fixing agent solutions.

| Item | Value |

|---|---|

| Quantitative Units | USD 69.1 million |

| Method | Dipping Method, Padding Method, Spray Application Method, Exhaust Method, Others |

| Application | Clothing, Home Textiles, Industrial Nylon, Automotive Textiles, Others |

| Regions Covered | England, Scotland, Wales, Northern Ireland |

| Key Companies | Dow; CHT Group; Fineotex; Sarex; Silvateam; Senka Thailand; Syntha Group; Dymatic Chemicals; Taiwan Dyestuffs & Pigments Corp.; Hailsun Chemical |

| Additional Attributes | Sales by method and application segment; regional demand trends across England, Scotland, Wales, and Northern Ireland; competitive landscape with established chemical suppliers and specialized fixing agent manufacturers; textile operator preferences for dipping method versus other fixing technologies; integration with textile dyeing programs and chemical policies (notably advanced in England region) |

The global demand for nylon acid dye fixing agent in uk is estimated to be valued at USD 42.8 million in 2025.

The market size for the demand for nylon acid dye fixing agent in uk is projected to reach USD 71.7 million by 2035.

The demand for nylon acid dye fixing agent in uk is expected to grow at a 5.3% CAGR between 2025 and 2035.

The key product types in demand for nylon acid dye fixing agent in uk are dipping method, padding method, spray application method, exhaust method and others.

In terms of application, clothing segment to command 45.2% share in the demand for nylon acid dye fixing agent in uk in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Demand Signal Repository Solutions Market Size and Share Forecast Outlook 2025 to 2035

Demand Side Management Market Size and Share Forecast Outlook 2025 to 2035

Demand Response Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

North America Shipping Supplies Market Trends – Innovations & Growth 2024-2034

Demand of Kozani Saffron in Greece Analysis - Size, Share & Forecast 2025 to 2035

Demand for Bronte Pistachio in Italy Analysis - Size, Share & Forecast 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Western Europe Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Japan Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Gaming Monitor in Korea Size and Share Forecast Outlook 2025 to 2035

Glycine Soja (Soybean) Seed Extract Market Size and Share Forecast Outlook 2025 to 2035

Demand and Trend Analysis of Yeast in Japan - Size, Share, and Forecast Outlook 2025 to 2035

Demand and Trends Analysis of Stevia in Japan Size and Share Forecast Outlook 2025 to 2035

Demand of Pistachio-based desserts & ingredients in France Analysis - Size, Share & Forecast 2025 to 2035

Japan Women’s Intimate Care Market Trends – Growth & Forecast 2024-2034

Western Europe Men’s Skincare Market Analysis – Forecast 2023-2033

Demand and Trend Analysis of Fabric Stain Remover in Korea Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Japan Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Korea Size and Share Forecast Outlook 2025 to 2035

Demand and Sales Analysis of Paper Cup in Western Europe Size and Share Forecast Outlook 2025 to 2035

Demand of MFGM-enriched Powders & RTDs in European Union Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA