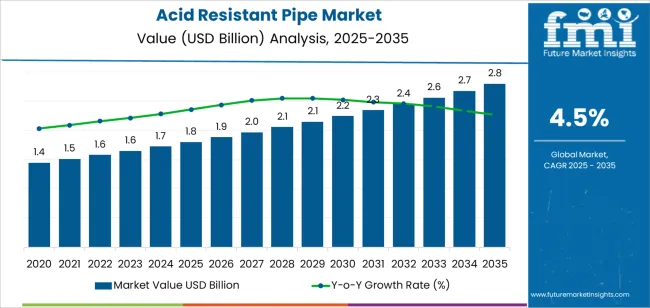

The global acid resistant pipe market is projected to reach USD 2,795 million by 2035, recording an absolute increase of USD 995 million over the forecast period. The market is valued at USD 1,800 million in 2025 and is expected to grow at a CAGR of 4.5% over the assessment period. The overall market size is expected to grow by approximately 1.6 times during the same period, supported by expanding chemical processing infrastructure worldwide, driving demand for corrosion-resistant piping solutions and increasing investments in industrial safety and environmental compliance projects globally.

Industrial facilities handling corrosive chemicals face persistent challenges with pipeline integrity and maintenance costs, where acid resistant pipes typically deliver 30-40 year service life compared to 5-10 years for unprotected carbon steel in aggressive environments, making specialized piping essential for long-term operational reliability. The chemical processing sector's need for safe fluid transport creates sustained demand for advanced corrosion-resistant systems that can withstand concentrated acids, alkalis, and aggressive chemical compounds across diverse operating conditions. Government regulations mandating secondary containment and leak prevention standards drive adoption in chemical plants, fertilizer production facilities, and mining operations, where pipeline failures pose significant environmental and safety risks.

The market's expansion reflects broader industrial trends toward enhanced safety protocols and environmental stewardship in hazardous material handling operations. Chemical manufacturers increasingly recognize that investing in premium corrosion-resistant piping systems delivers substantial lifecycle cost advantages through reduced maintenance frequency, eliminated emergency repairs, and extended asset service life. Fertilizer producers adopt specialized piping solutions to handle phosphoric acid and other aggressive compounds that rapidly degrade conventional materials, ensuring continuous production without costly shutdowns. Mining and metallurgical operations deploy acid resistant piping for hydrometallurgical processes and tailings management, where material failure creates significant environmental remediation liabilities.

Emerging markets demonstrate accelerating adoption as industrialization drives chemical production capacity expansion and regulatory frameworks mature to address environmental protection and workplace safety concerns. Established industrial regions continue steady demand through infrastructure replacement cycles and facility modernization programs targeting aging assets installed before current corrosion engineering standards became prevalent. Technology advancement in composite materials and lining systems expands application ranges while improving cost competitiveness against metallic alternatives, though material selection complexity and installation expertise requirements remain adoption barriers for smaller operators. Higher initial capital costs compared to conventional piping and specialized installation requirements may limit adoption rates among smaller industrial operators and regions with less stringent safety regulations.

Between 2025 and 2030, the acid resistant pipe market is projected to expand from USD 1,800 million to USD 2,245 million, resulting in a value increase of USD 445 million, which represents 44.7% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for chemical processing infrastructure and industrial safety solutions, product innovation in composite materials and advanced lining technologies, as well as expanding integration with environmental protection and emission control systems. Companies are establishing competitive positions through investment in advanced manufacturing technologies, corrosion testing capabilities, and strategic market expansion across chemical processing, fertilizer production, and industrial wastewater applications.

From 2030 to 2035, the market is forecast to grow from USD 2,245 million to USD 2,795 million, adding another USD 550 million, which constitutes 55.3% of the overall ten-year expansion. This period is expected to be characterized by the expansion of specialized corrosion-resistant systems, including advanced composite formulations and integrated monitoring solutions tailored for specific chemical exposure requirements, strategic collaborations between pipe manufacturers and engineering contractors, and an enhanced focus on lifecycle cost optimization and maintenance reduction. The growing emphasis on plant safety enhancement and environmental compliance will drive demand for advanced, high-performance acid resistant piping solutions across diverse industrial applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 1,800 million |

| Market Forecast Value (2035) | USD 2,795 million |

| Forecast CAGR (2025-2035) | 4.5% |

The acid resistant pipe market grows by enabling industrial operators to achieve superior pipeline longevity and operational safety while reducing maintenance costs and environmental risks. Chemical processing facilities face mounting pressure to improve worker safety and environmental protection, with acid resistant piping solutions typically reducing maintenance shutdowns by 60-70% compared to carbon steel systems, making corrosion-resistant materials essential for continuous operation reliability. The industrial safety sector's need for leak-free fluid transport creates demand for advanced materials that can withstand pH levels from 0 to 14, elevated temperatures, and abrasive slurries across demanding process conditions.

Regulatory frameworks mandating secondary containment, emissions control, and workplace safety standards drive adoption in chemicals, fertilizers, and mining applications, where pipeline integrity has a direct impact on operational continuity and regulatory compliance. The global shift toward sustainable manufacturing and environmental stewardship accelerates acid resistant pipe demand as facilities seek to prevent leaks and minimize environmental incidents. Expanding chemical production capacity in emerging markets creates additional demand for specialized piping systems designed for aggressive service conditions. High material costs, specialized installation requirements, and limited availability of qualified fabricators and installers may restrict adoption rates among cost-sensitive industrial operators in regions with developing industrial infrastructure.

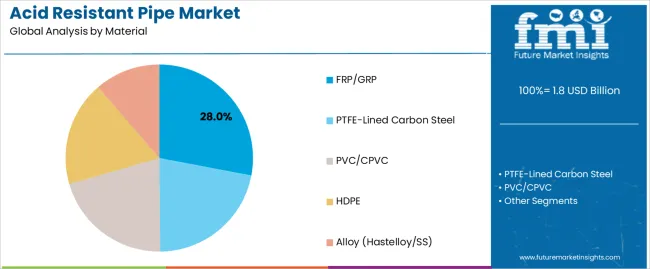

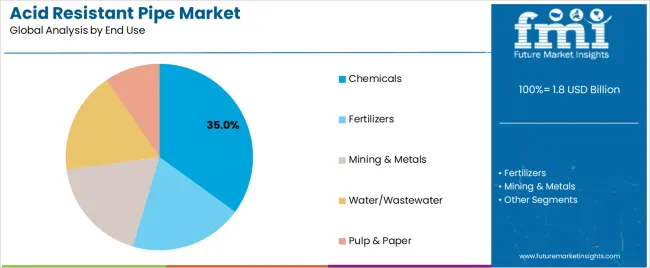

The market is segmented by material, end use, diameter, installation, and region. By material, the market is divided into FRP/GRP, PTFE-lined carbon steel, PVC/CPVC, HDPE, and alloy (Hastelloy/SS). Based on end use, the market is categorized into chemicals, fertilizers, mining & metals, water/wastewater, and pulp & paper. By diameter, the market includes <4", 4-12", 12-24", and >24". By installation, the market is segmented into above-ground, buried, plant retrofit, and offshore/marine. Regionally, the market is divided into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa.

The FRP/GRP segment represents the dominant force in the acid resistant pipe market, capturing approximately 28% of total market share in 2025. This advanced category encompasses formulations featuring glass-reinforced polyester, vinyl ester composites, and epoxy-based systems, delivering comprehensive corrosion resistance with exceptional strength-to-weight ratios. The FRP/GRP segment's market leadership stems from its superior chemical resistance across broad pH ranges, long service life exceeding 40 years, and lower installation costs compared to metallic alloy alternatives.

The PTFE-lined carbon steel segment maintains a substantial 22% market share, serving operators who require the mechanical strength of steel with chemical inertness for highly aggressive environments. The PVC/CPVC segment accounts for 20% market share, offering cost-effective solutions for moderate temperature and pressure applications. HDPE pipes hold 15% share through flexible installation capabilities and excellent chemical resistance for buried applications. The alloy segment commands 15% share, featuring Hastelloy and stainless steel options for extreme conditions requiring metallic piping.

Key advantages driving the FRP/GRP segment include resistance to concentrated acids, alkalis, and salts without surface degradation, lightweight construction reducing installation time and structural support requirements, smooth interior surfaces minimizing pressure drop and preventing deposit buildup, and compatibility with fabricated fittings enabling custom system configurations for complex process layouts.

The chemicals segment dominates the acid resistant pipe market with approximately 35% market share in 2025, reflecting the extensive requirements for corrosion-resistant piping in acid production, alkali processing, and specialty chemical manufacturing operations. The chemicals segment's market leadership is reinforced by widespread adoption across sulfuric acid plants, hydrochloric acid facilities, and caustic soda production units, which require materials capable of withstanding continuous exposure to concentrated chemical solutions.

The fertilizers segment represents 20% market share through specialized applications in phosphoric acid production, ammonia synthesis, and compound fertilizer manufacturing. The water/wastewater segment accounts for 20% share, driven by municipal treatment plants and industrial wastewater systems handling acidic effluents. Mining & metals operations hold 15% share for hydrometallurgical processing and acid leaching applications. The pulp & paper segment maintains 10% share for bleach plant operations and chemical recovery systems.

Key market dynamics supporting end-use preferences include chemicals sector requiring the highest performance specifications for concentrated acid service, fertilizers operations balancing cost and performance for phosphoric acid transfer, water treatment facilities emphasizing long-term reliability for underground installations, and mining applications demanding abrasion resistance alongside chemical protection for slurry transport.

The market is driven by three concrete demand factors tied to industrial safety and operational efficiency. First, expanding chemical production capacity creates increasing requirements for corrosion-resistant piping infrastructure, with global chemical output growing 3-4% annually in major manufacturing regions, requiring reliable acid handling systems for process integrity. Second, regulatory mandates for environmental protection and workplace safety drive facility upgrades, with acid resistant piping reducing leak incidents by 80-90% compared to inadequately protected systems while minimizing maintenance-related exposures. Third, lifecycle cost advantages of corrosion-resistant materials accelerate adoption, as facility managers recognize that higher initial investment generates returns through extended service life, reduced maintenance shutdowns, and elimination of replacement cycles associated with conventional piping.

Market restraints include high upfront capital costs affecting project economics, particularly for smaller industrial operators where acid resistant piping can represent 15-20% of total process piping budgets compared to 5-8% for carbon steel equivalents. Installation complexity requires specialized fabrication skills and certified welding procedures, creating contractor availability challenges in regions with limited industrial infrastructure development. Material selection uncertainties arise from the wide range of chemical exposures and operating conditions, as incorrect specification can lead to premature failures requiring costly replacements during early service life.

Key trends indicate accelerated adoption in Asia Pacific chemical complexes, particularly China and India, where rapid industrialization drives demand for modern chemical processing infrastructure with comprehensive safety systems. Technology advancement trends toward hybrid pipe systems combining metallic strength with polymer corrosion resistance, integrated leak detection capabilities, and advanced composite formulations with enhanced temperature ratings are enabling next-generation product development. The market shows increasing preference for thermoplastic-lined steel systems in applications balancing mechanical strength requirements with chemical resistance needs, though composite material innovations could shift preferences if performance gaps close while maintaining cost advantages.

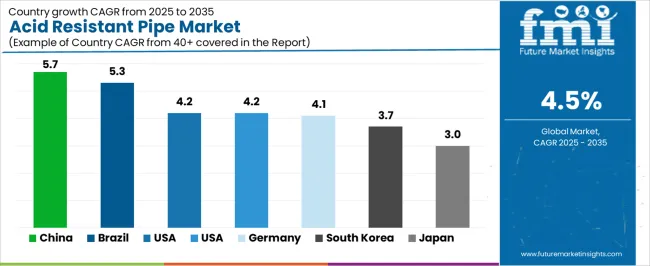

| Country | CAGR (2025-2035) |

|---|---|

| China | 5.7% |

| Brazil | 5.3% |

| USA | 4.2% |

| UK | 4.2% |

| Germany | 4.1% |

| South Korea | 3.7% |

| Japan | 3% |

The acid resistant pipe market is gaining momentum worldwide, with China taking the lead thanks to aggressive chemical industry expansion and petrochemical complex development programs. Close behind, Brazil benefits from fertilizer production growth and mining sector modernization, positioning itself as a strategic growth hub in Latin America. The USA shows strong advancement, where chemical plant upgrades and environmental compliance requirements strengthen its role in the North American industrial supply chain. Germany demonstrates robust growth through chemical industry leadership and stringent environmental standards, signaling continued investment in corrosion-resistant infrastructure. Meanwhile, the United Kingdom maintains steady progress driven by aging infrastructure replacement and industrial safety regulations, while South Korea stands out for its petrochemical expansion with comprehensive process safety systems, and Japan continues to record consistent progress through maintenance-driven replacement cycles. Together, China and Brazil anchor the global expansion story, while established markets build stability and diversity into the market's growth path.

The report covers an in-depth analysis of 40 countries; 7 top-performing countries are highlighted below.

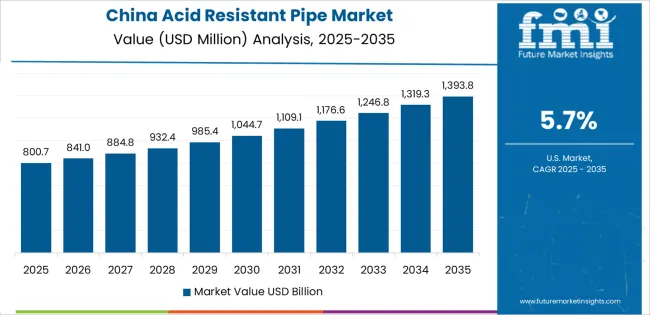

China demonstrates the strongest growth potential in the acid resistant pipe market with a CAGR of 5.7% through 2035. The country's leadership position stems from comprehensive chemical industry expansion programs, intensive petrochemical complex development, and aggressive environmental protection targets driving adoption of corrosion-resistant piping systems. Growth is concentrated in major industrial regions, including Jiangsu, Shandong, Zhejiang, and Guangdong, where chemical manufacturers and fertilizer producers are implementing advanced piping infrastructure for domestic supply and export competitiveness. Distribution channels through engineering contractors, industrial distributors, and direct manufacturer relationships expand deployment across chemical parks and industrial zones. The country's chemical industry development policies provide support for safety infrastructure upgrades, including standards for corrosion-resistant materials in hazardous chemical service.

Key market factors include chemical industry concentration in coastal industrial zones with comprehensive safety infrastructure development programs, government support through environmental protection regulations and industrial safety standards mandating corrosion-resistant piping, comprehensive supply chain ecosystem including established pipe manufacturers and fabrication facilities with proven capabilities, and technology integration featuring advanced composite materials, quality control systems, and installation certification infrastructure.

In São Paulo, Minas Gerais, and Rio de Janeiro regions, the adoption of acid resistant piping systems is accelerating across fertilizer production facilities, mining operations, and pulp processing plants, driven by industrial expansion and environmental compliance initiatives. The market demonstrates strong growth momentum with a CAGR of 5.3% through 2035, linked to comprehensive phosphate fertilizer production expansion and increasing focus on environmental protection solutions. Brazilian industrial operators are implementing corrosion-resistant piping programs and integrity management platforms to improve operational reliability while meeting environmental regulations in sensitive watersheds. The country's industrial safety framework creates sustained demand for certified corrosion-resistant materials, while increasing emphasis on operational efficiency drives adoption of piping systems that minimize maintenance requirements.

Leading industrial development regions, including São Paulo, Paraná, and Minas Gerais, are driving acid resistant pipe system adoption. Government regulatory programs enable compliance support for environmental protection and workplace safety standards. Technology collaboration agreements are accelerating deployment with international pipe manufacturers and engineering contractors. Policy support through environmental licensing requirements and industrial safety regulations is linked to infrastructure modernization programs.

The USA market leads in infrastructure replacement based on aging chemical plant upgrades and comprehensive safety regulation compliance across Gulf Coast and Northeast industrial regions. The country shows solid potential with a CAGR of 4.2% through 2035, driven by chemical facility modernization programs and increasing regulatory requirements for environmental protection across major industrial regions, including Texas, Louisiana, Ohio, and Pennsylvania. American operators are adopting advanced corrosion-resistant piping for compliance with EPA regulations and OSHA workplace safety standards, particularly in chemical manufacturing requiring long-term reliability and in facilities with stringent leak prevention requirements. Technology deployment channels through engineering contractors, industrial distributors, and direct manufacturer relationships expand coverage across diverse chemical processing operations.

Leading market segments include chemical processing operations in Gulf Coast region implementing comprehensive piping upgrade programs, technology partnerships with pipe manufacturers achieving compliance with industry codes and standards, strategic collaborations between facility operators and engineering firms enabling turnkey piping system installations, and focus on lifecycle cost reduction and maintenance optimization incentivizing advanced corrosion-resistant solutions.

Germany's acid resistant pipe market demonstrates sophisticated implementation focused on chemical industry infrastructure and environmental protection compliance, with documented integration of advanced corrosion-resistant systems achieving operational reliability improvements in major chemical complexes. The country maintains steady growth momentum with a CAGR of 4.1% through 2035, driven by chemical industry leadership and stringent environmental regulations requiring comprehensive leak prevention systems. Major industrial regions, including North Rhine-Westphalia, Bavaria, Baden-Württemberg, and Lower Saxony, showcase advanced deployment of FRP/GRP and lined pipe systems that integrate seamlessly with existing process infrastructure and comprehensive safety management programs.

Key market characteristics include chemical industry concentration in major industrial clusters driving advanced piping requirements with emphasis on safety, technology partnerships enabling reliable corrosion resistance through certified materials and installation procedures, collaboration between chemical producers and engineering contractors ensuring comprehensive system integration and performance validation, and emphasis on environmental protection and operational efficiency through advanced material selection and integrity management systems.

In chemical processing zones across Northern England, Scotland, and the Southeast, facility operators are implementing acid resistant piping programs to meet Health and Safety Executive requirements and environmental protection standards, with documented case studies showing improved operational reliability in aging industrial facilities. The market shows solid growth potential with a CAGR of 4.2% through 2035, linked to infrastructure replacement needs and regulatory compliance requirements for chemical handling and storage operations. British operators are adopting certified corrosion-resistant materials and comprehensive integrity management approaches to maintain safe operations while complying with stringent regulations governing hazardous material handling in industrial facilities.

Market development factors include aging infrastructure replacement in established chemical facilities requiring comprehensive piping system upgrades, regulatory compliance requirements providing drivers for corrosion-resistant material adoption in chemical service, strategic partnerships between facility operators and specialized contractors expanding market coverage for complex installations, and emphasis on operational safety and environmental protection through advanced material selection and quality assurance systems.

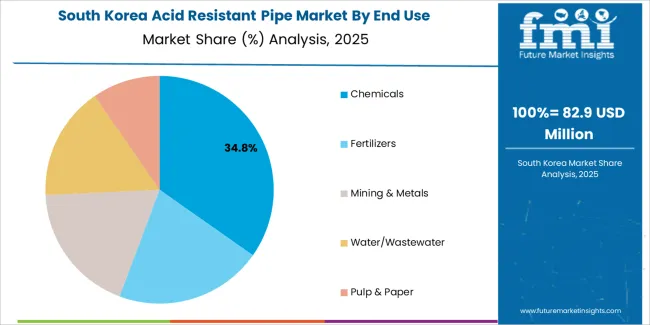

South Korea's acid resistant pipe market demonstrates mature implementation focused on petrochemical complex infrastructure and comprehensive process safety systems, with documented integration achieving high reliability standards in large-scale chemical facilities. The country maintains steady growth through petrochemical industry expansion and safety regulation compliance, with a CAGR of 3.7% through 2035, driven by continuing investments in chemical production capacity and comprehensive safety infrastructure requirements. Major industrial regions, including Ulsan, Yeosu, and Daesan, showcase advanced deployment of corrosion-resistant piping systems where material selection programs integrate international standards with domestic safety requirements.

Key market characteristics include petrochemical industry concentration driving specialized piping requirements with comprehensive safety specifications, certification support programs ensuring compliance with Korean industrial standards and international codes, technology partnerships between international pipe suppliers and Korean engineering contractors enabling advanced system implementation, and emphasis on process safety management and operational excellence through rigorous material qualification and installation procedures.

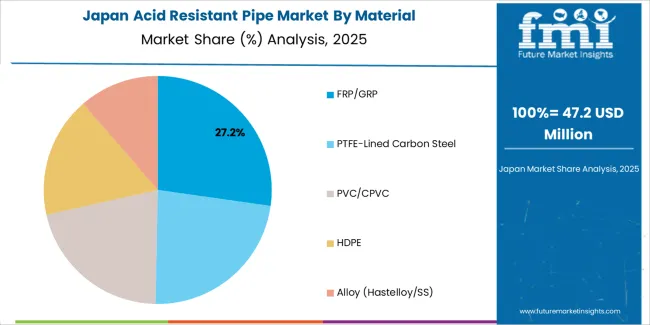

Japan's acid resistant pipe market demonstrates sophisticated implementation focused on chemical facility maintenance and stringent quality standards, with documented integration of corrosion-resistant systems achieving extended service life in demanding industrial applications. The country maintains steady growth momentum with a CAGR of 3% through 2035, driven by replacement demand in aging chemical facilities and emphasis on operational reliability aligned with comprehensive maintenance philosophies. Major industrial regions, including the Keihin, Hanshin, and Chukyo industrial zones, showcase advanced deployment of lined pipe systems and composite materials that integrate seamlessly with existing facility infrastructure and comprehensive quality management programs.

Key market characteristics include established chemical industry with mature infrastructure requiring ongoing replacement and upgrade programs, technology partnerships enabling advanced corrosion resistance through certified materials meeting JIS standards, collaboration between facility operators and specialized contractors ensuring quality installation and commissioning procedures, and emphasis on long-term reliability and minimal maintenance through rigorous material selection and quality control processes.

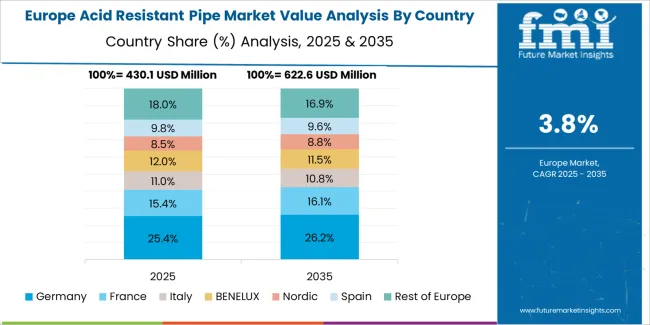

The acid resistant pipe market in Europe is projected to grow from USD 475 million in 2025 to USD 745 million by 2035, registering a CAGR of 4.6% over the forecast period. Germany is expected to maintain its leadership position with a 28.5% market share in 2025, declining slightly to 27.8% by 2035, supported by its extensive chemical industry infrastructure and major industrial centers, including North Rhine-Westphalia, Bavaria, and Baden-Württemberg production regions.

The United Kingdom follows with a 19.2% share in 2025, projected to reach 19.5% by 2035, driven by comprehensive infrastructure replacement programs and industrial safety regulations requiring corrosion-resistant piping systems. France holds a 16.8% share in 2025, expected to rise to 17.1% by 2035 through ongoing chemical facility modernization and environmental compliance initiatives. Italy commands a 12.5% share in both 2025 and 2035, backed by specialty chemical production and industrial processing operations. Spain accounts for 9.5% in 2025, rising to 9.8% by 2035 on chemical sector expansion and mining operations. The Netherlands maintains 5.2% in 2025, reaching 5.4% by 2035 on petrochemical complex infrastructure. The Rest of Europe region is anticipated to hold 8.3% in 2025, expanding to 8.9% by 2035, attributed to increasing acid resistant pipe adoption in Nordic countries and emerging Central & Eastern European chemical facilities implementing safety infrastructure programs.

The Japanese acid resistant pipe market demonstrates a mature and quality-focused landscape, characterized by sophisticated integration of FRP/GRP and lined pipe systems with existing chemical processing infrastructure across petrochemical facilities, specialty chemical production, and industrial water treatment operations. Japan's emphasis on operational reliability and preventive maintenance drives demand for certified corrosion-resistant materials that support long-term facility integrity and minimal unplanned shutdowns in critical process applications. The market benefits from strong partnerships between international pipe manufacturers and domestic engineering contractors including major industrial firms, creating comprehensive service ecosystems that prioritize material quality and installation standards. Industrial centers in the Keihin, Hanshin, and Chukyo regions showcase advanced corrosion-resistant piping implementations where material selection programs achieve extended service life through rigorous quality control and comprehensive commissioning procedures.

The South Korean acid resistant pipe market is characterized by growing international technology provider presence, with companies maintaining significant positions through comprehensive engineering support and quality certification capabilities for petrochemical and chemical processing applications. The market demonstrates increasing emphasis on process safety and operational excellence, as Korean facility operators increasingly demand certified corrosion-resistant materials that integrate with domestic safety standards and sophisticated process control systems deployed across major petrochemical complexes. Regional pipe manufacturers are gaining market share through strategic partnerships with international suppliers, offering specialized services including Korean industrial code compliance and project-specific engineering support for large-scale chemical facility installations. The competitive landscape shows increasing collaboration between multinational pipe suppliers and Korean engineering contractors, creating hybrid service models that combine international material technology with local installation expertise and project management capabilities.

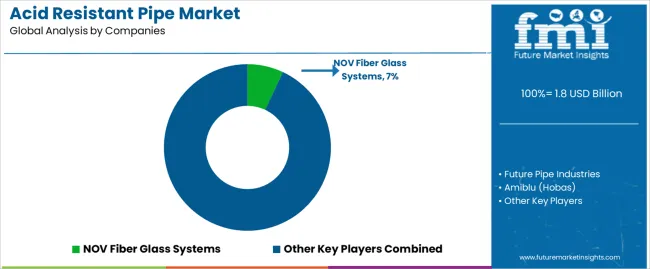

The acid resistant pipe market features approximately 20-25 meaningful players with moderate fragmentation, where the top three companies control roughly 15-18% of global market share through established distribution networks and diverse product portfolios. Competition centers on material performance reliability, certification compliance, and technical support capabilities rather than price competition alone. NOV Fiber Glass Systems leads with approximately 7% market share through its comprehensive FRP piping portfolio and global project execution capabilities.

Market leaders include NOV Fiber Glass Systems, Future Pipe Industries, and Amiblu (Hobas), which maintain competitive advantages through global manufacturing infrastructure, extensive material testing capabilities, and deep expertise in corrosion engineering across multiple chemical applications, creating trust and reliability advantages with chemical processing operators. These companies leverage research and development capabilities in composite material optimization and ongoing technical support relationships to defend market positions while expanding into specialty chemical and mining applications.

Challengers encompass Georg Fischer (GF Piping) and IPEX, which compete through specialized thermoplastic systems and strong regional presence in key industrial markets. Material specialists, including AGRU, Sekisui Chemical, and Crane Resistoflex, focus on specific polymer technologies or application segments, offering differentiated capabilities in fabrication technologies, custom engineering services, and specialized material grades. Saint-Gobain and Lubrizol (Corzan CPVC) maintain positions through branded material systems and comprehensive technical support programs.

Regional players and emerging composite manufacturers create competitive pressure through localized fabrication advantages and rapid response capabilities, particularly in high-growth markets including China and India, where proximity to industrial clusters provides advantages in logistics costs and project scheduling. Market dynamics favor companies that combine proven material performance with comprehensive engineering support offerings that address the complete piping system design from material selection through installation commissioning and ongoing integrity management.

Acid resistant pipes represent specialized corrosion protection solutions that enable industrial operators to achieve 30-40 year service life in aggressive chemical environments compared to 5-10 years for inadequately protected systems, delivering superior operational reliability and safety with minimal maintenance requirements in demanding industrial applications. With the market projected to grow from USD 1,800 million in 2025 to USD 2,795 million by 2035 at a 4.5% CAGR, these corrosion-resistant piping systems offer compelling advantages including leak prevention, lifecycle cost reduction, and environmental protection, making them essential for chemicals processing (35% market share), fertilizers production (20% share), and industrial operations handling corrosive fluids that compromise conventional piping materials through rapid degradation. Scaling market adoption and infrastructure development requires coordinated action across industrial safety regulations, material certification standards, pipe manufacturers, engineering contractors, and industrial capital investment.

How Governments Could Spur Local Production and Adoption?

Government agencies can establish comprehensive industrial safety standards that mandate corrosion-resistant piping for chemical handling applications, provide technical guidance for material selection in hazardous service, and create certification frameworks that ensure consistent quality across domestic manufacturing facilities. Research funding should support university programs investigating composite material development, corrosion testing methodologies, and lifecycle assessment frameworks that optimize material selection for specific chemical exposures. Infrastructure development incentives can provide grants for establishing regional testing laboratories and technical training centers that support skilled installer development and certification programs for specialized fabrication techniques.

Environmental protection programs should promote corrosion-resistant piping through leak prevention initiatives, establish secondary containment requirements that incentivize reliable material selection, and create compliance frameworks that recognize lifecycle environmental benefits of durable piping systems. Industrial development policies can support domestic manufacturing capacity through technology transfer agreements, quality management system development, and market access programs that connect local manufacturers with major industrial projects requiring certified corrosion-resistant materials.

How Industry Bodies Could Support Market Development?

Industry associations can define standardized testing protocols for chemical resistance, temperature performance, and mechanical properties across FRP/GRP (28% market dominance) and thermoplastic-lined piping systems, enabling reliable material qualification and project specification confidence. Best management practices should establish comprehensive guidelines for material selection processes, installation procedures, and integrity management programs that ensure optimal performance across different chemical exposures and operating conditions.

Supply chain integration standards can create traceability frameworks for material certification, fabrication documentation, and quality assurance records that facilitate seamless integration across engineering design and construction phases. Technical training programs should establish education frameworks for design engineers, installation contractors, and facility maintenance personnel on corrosion principles, material properties, and system design considerations that ensure successful project implementation and long-term reliability.

How OEMs and Technology Players Could Strengthen the Ecosystem?

Pipe manufacturers can develop next-generation composite formulations with enhanced temperature capability, improved mechanical properties, and optimized chemical resistance profiles that expand application ranges while maintaining cost competitiveness. Processing technology innovation should provide advanced filament winding equipment, automated lining systems, and quality control platforms that ensure consistent product quality across production batches and manufacturing facilities.

Application-specific solutions can offer engineering-designed systems for high-value chemical processing, specialized configurations for mining slurry service, and customized material grades that address specific corrosion challenges while maintaining structural integrity requirements. Comprehensive technical support services should build engineering assistance programs including corrosion analysis, system design review, and installation supervision that help facility operators achieve optimal material selection and implementation approaches.

How Suppliers Could Navigate the Shift?

Pipe suppliers can develop application-focused product lines for chemicals processing (35% market dominance), fertilizers production (20% share), and water treatment applications, with material systems optimized for each sector's specific chemical exposures and operating conditions. Geographic market strategy should establish manufacturing and distribution capabilities in high-growth markets like China (5.7% CAGR) and Brazil (5.3% CAGR), while maintaining technical support presence in established industrial markets like the USA (4.2% CAGR) and Germany (4.1% CAGR).

Technology differentiation should invest in proprietary composite formulations, advanced lining technologies, and comprehensive quality assurance systems that provide superior corrosion resistance and enable premium positioning in competitive industrial piping markets. Customer partnership models can develop long-term relationships with chemical operators, engineering contractors, and industrial maintenance providers through collaborative material qualification programs, application training services, and performance guarantees that strengthen customer loyalty and repeat business opportunities.

How Investors and Financial Enablers Could Unlock Value?

Investment opportunities exist in established pipe manufacturers for production capacity expansion, material technology development, and quality certification systems that serve growing demand in chemicals and fertilizers markets. Supply chain infrastructure financing should provide capital for establishing regional fabrication facilities, testing laboratories, and distribution networks that reduce costs while ensuring consistent product availability across industrial regions.

Innovation investments can back material science companies developing advanced composites, coating technologies, and hybrid piping systems that enhance corrosion resistance while addressing cost barriers. Market integration strategies should support partnerships between pipe manufacturers and engineering contractors, finance comprehensive technical support programs, and enable market consolidation that creates full-service corrosion-resistant piping solution providers serving multiple industrial segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 1,800 million |

| Material | FRP/GRP, PTFE-Lined Carbon Steel, PVC/CPVC, HDPE, Alloy (Hastelloy/SS) |

| End Use | Chemicals, Fertilizers, Mining & Metals, Water/Wastewater, Pulp & Paper |

| Diameter | <4", 4-12", 12-24", >24" |

| Installation | Above-Ground, Buried, Plant Retrofit, Offshore/Marine |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East & Africa |

| Country Covered | China, Brazil, USA, UK, Germany, South Korea, Japan, and 40 countries |

| Key Companies Profiled | NOV Fiber Glass Systems, Future Pipe Industries, Amiblu (Hobas), Georg Fischer (GF Piping), IPEX, AGRU, Sekisui Chemical, Crane Resistoflex, Saint-Gobain, Lubrizol (Corzan CPVC) |

| Additional Attributes | Dollar sales by material, end use, diameter, and installation categories, regional adoption trends across Asia Pacific, Europe, and North America, competitive landscape with pipe manufacturers and engineering contractors, fabrication facility requirements and specifications, integration with industrial safety programs and environmental compliance initiatives, innovations in composite materials and lining technologies, and development of specialized piping systems with enhanced corrosion resistance and installation efficiency capabilities. |

The global acid resistant pipe market is estimated to be valued at USD 1.8 billion in 2025.

The market size for the acid resistant pipe market is projected to reach USD 2.8 billion by 2035.

The acid resistant pipe market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in acid resistant pipe market are frp/grp, ptfe-lined carbon steel, pvc/cpvc, hdpe and alloy (hastelloy/ss).

In terms of end use, chemicals segment to command 35.0% share in the acid resistant pipe market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Acid Coil Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Acid Filling and Leveling Machine Market Size and Share Forecast Outlook 2025 to 2035

Acid Chlorides Market Size and Share Forecast Outlook 2025 to 2035

Acid-Sensitive APIs Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Acidified Whey Protein Market Analysis - Size, Share & Trends 2025 to 2035

Acid Dyes Market Growth - Trends & Forecast 2025 to 2035

Acidity Regulator Market Growth - Trends & Forecast 2025 to 2035

Acid Proof Lining Market Trends 2025 to 2035

Acid Citrate Dextrose Tube Market Trends – Growth & Industry Outlook 2024-2034

Acid Orange Market

Antacids Market Analysis – Size, Trends & Forecast 2025 to 2035

Lead Acid Battery Market Size and Share Forecast Outlook 2025 to 2035

Lead Acid Battery Recycling Market Size and Share Forecast Outlook 2025 to 2035

Feed Acidifier Market Analysis Size Share and Forecast Outlook 2025 to 2035

Food Acidulants Market Growth - Key Trends, Size & Forecast 2024 to 2034

Boric Acid Market Forecast and Outlook 2025 to 2035

Folic Acid Market Size and Share Forecast Outlook 2025 to 2035

Oleic Acid Market Size and Share Forecast Outlook 2025 to 2035

Dimer Acid-based (DABa) Polyamide Resin Market Size and Share Forecast Outlook 2025 to 2035

Humic Acid Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA