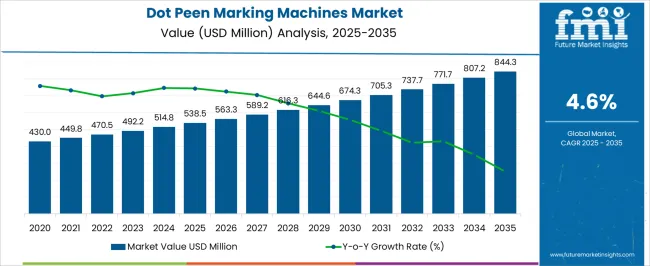

The dot peen marking machines market is projected to grow from USD 538.5 million in 2025 to USD 844.3 million by 2035, representing a CAGR of 4.6%. This growth highlights a substantial absolute dollar opportunity of USD 305.8 million over the decade. The increasing use of dot peen marking in manufacturing, automotive, aerospace, and metal fabrication sectors is driving demand. Industries are adopting automated and durable marking solutions for traceability and compliance purposes, supporting steady revenue expansion.

Companies entering this market can capitalize on the predictable growth trajectory to strategically expand their offerings and capture market share. Over the next ten years, the USD 305.8 million opportunity underscores a favorable business environment for stakeholders in the dot peen marking machines market. By 2035, market demand will reflect both replacement of older marking systems and the growing need for reliable part identification across industries. Strategic investments in manufacturing capabilities, distribution networks, and regional presence will allow companies to maximize returns. The steady CAGR of 4.6% suggests a balanced yet profitable growth pattern, encouraging market players to align production and sales strategies with anticipated industry demand, ensuring long-term revenue gains.

| Metric | Value |

|---|---|

| Dot Peen Marking Machines Market Estimated Value in (2025 E) | USD 538.5 million |

| Dot Peen Marking Machines Market Forecast Value in (2035 F) | USD 844.3 million |

| Forecast CAGR (2025 to 2035) | 4.6% |

In the early growth phase of the dot peen marking machines market, revenue expansion is often gradual, driven by initial adoption in key sectors like automotive and aerospace. From 2025 onward, with a market size of USD 538.5 million and a CAGR of 4.6%, companies focus on establishing distribution channels, building customer awareness, and optimizing product offerings. Early growth emphasizes targeting niche applications and addressing industry-specific requirements, such as durability and precision in marking. The absolute dollar opportunity during this phase is moderate, allowing firms to test strategies, gather feedback, and refine operations without the pressures of rapid scaling, laying the foundation for long-term stability.

In the late growth phase, approaching 2035 and a market size of USD 844.3 million, the dot peen marking machines market experiences accelerated revenue capture due to broader adoption across multiple industries and the replacement of older systems. Market strategies shift toward scaling production, expanding into new regions, and leveraging economies of scale.

The absolute dollar opportunity in this phase is substantial, representing the majority of the USD 305.8 million growth over the decade. Companies benefit from established brand recognition and stronger customer networks, enabling them to capture market share efficiently while sustaining the CAGR of 4.6%, resulting in a mature, profitable stage of market development.

The dot peen marking machines market is advancing due to rising automation in manufacturing, increased traceability regulations, and the growing need for permanent marking in metal components. These machines offer high precision and durability, making them ideal for automotive, aerospace, and industrial applications where serialized and tamper-proof identification is essential.

The market is also benefiting from advancements in software integration and control systems, which allow seamless connectivity with automated production lines. Additionally, expanding demand in developing economies for product authentication and regulatory compliance is further fueling market adoption.

As industries embrace Industry 4.0 practices, dot peen systems are being increasingly integrated with real-time data tracking and quality assurance protocols.

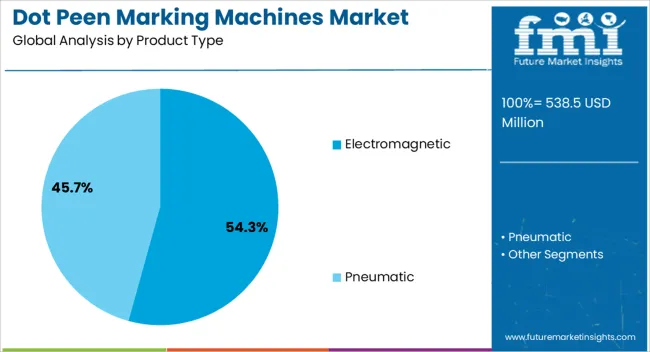

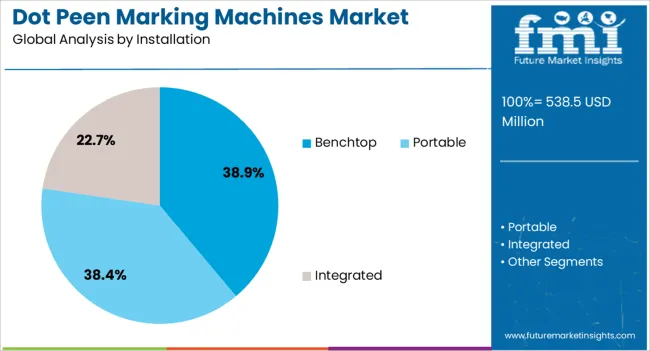

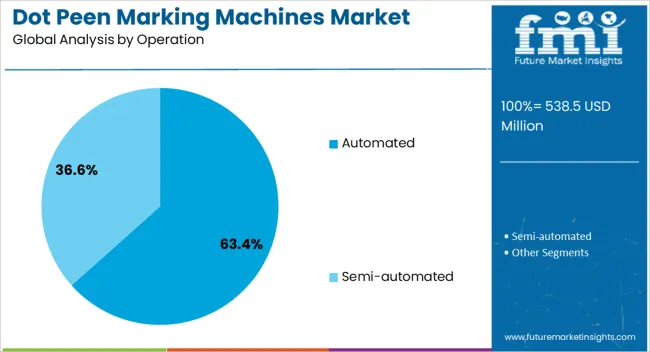

The dot peen marking machines market is segmented by product type, installation, operation, application, distribution channel, and geographic regions. By product type, dot peen marking machines market is divided into Electromagnetic and Pneumatic. In terms of installation, dot peen marking machines market is classified into Benchtop, Portable, and Integrated. Based on operation, dot peen marking machines market is segmented into Automated and Semi-automated.

By application, dot peen marking machines market is segmented into Automotive, Aerospace, Medical devices, Electronics, Industrial tools and equipment, Construction, and Others. By distribution channel, dot peen marking machines market is segmented into Direct sales and Indirect sales. Regionally, the dot peen marking machines industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Electromagnetic dot peen machines are expected to dominate the market with a 54.3% share in 2025, driven by their superior marking precision, operational consistency, and ease of use. These machines are particularly favored in sectors requiring deep, high-contrast marks on hard materials such as steel or aluminum.

Their non-pneumatic design eliminates dependency on air compressors, making them more compact and energy-efficient. Additionally, electromagnetic systems are quieter and offer better control over stylus impact, enhancing the clarity and longevity of marks.

Their adaptability across diverse part sizes and integration ease with computerized systems have reinforced their status as the most popular product type in modern manufacturing environments.

Benchtop installations are set to capture 38.9% of the market share by 2025, leading the installation type category. Their compact footprint, cost-efficiency, and suitability for controlled environments such as workshops and quality control labs make them ideal for small-to-medium production settings.

These machines offer excellent operator accessibility and are often chosen for tasks requiring repeatability and fine detail. Benchtop systems are also easier to maintain and calibrate, and their stability allows for consistent marking accuracy.

The ability to handle a variety of part shapes and materials with minimal setup changes has made benchtop models a reliable choice for industrial and component-level marking applications.

Automated operation is projected to lead the operational mode segment with a 63.4% share in 2025. This growth is propelled by the widespread adoption of smart manufacturing practices that prioritize speed, repeatability, and error reduction.

Automated dot peen systems can be seamlessly integrated into robotic arms, conveyors, and CNC environments, enabling uninterrupted marking processes within high-throughput production lines. They reduce human intervention, thereby minimizing labor costs and increasing overall plant efficiency.

With enhanced software compatibility and remote-control capabilities, automated systems are becoming essential for traceability and quality compliance in automotive, defense, and industrial supply chains.

The dot peen marking machines market is growing as industries increasingly require durable, precise, and permanent marking solutions for traceability, compliance, and branding. These machines are widely used in automotive, aerospace, metal fabrication, electronics, and manufacturing sectors to engrave serial numbers, logos, barcodes, and QR codes on metal and hard surfaces.

Rising regulatory standards for traceability, anti-counterfeiting measures, and quality control are driving adoption. Manufacturers that offer high-speed, reliable, and customizable dot peen marking solutions with advanced software integration are positioned to capture opportunities in diverse industrial applications worldwide.

Market growth faces challenges due to the high upfront cost of dot peen marking machines and the need for skilled operators. Advanced machines with automated systems, CNC integration, and multi-axis capabilities require significant investment. Additionally, training staff to handle software, program marking patterns, and maintain the equipment can be resource-intensive. Some small and medium enterprises may prefer alternative marking solutions such as laser or ink-based methods due to lower initial costs. Manufacturers must focus on providing cost-effective, user-friendly machines, comprehensive training programs, and technical support to help end-users overcome barriers and maximize the value of dot peen marking solutions.

Market trends are shaped by the adoption of automation, digital traceability, and Industry 4.0 integration. Dot peen marking machines are increasingly incorporated into automated production lines, enabling real-time tracking of parts and seamless integration with ERP and manufacturing execution systems. Advanced software allows programmable marking, barcode generation, and quality reporting, improving operational efficiency and reducing errors. Multi-axis machines and robotic integration enhance flexibility for complex components. These trends reflect the growing demand for smart, connected, and precise marking solutions that improve productivity, ensure regulatory compliance, and provide end-to-end traceability across industrial processes.

The market offers significant opportunities driven by growing manufacturing sectors and stricter regulatory compliance needs. Automotive, aerospace, defense, and electronics industries require permanent, tamper-proof markings for quality assurance and traceability. Anti-counterfeiting measures, product recalls, and serialization mandates increase the demand for reliable marking solutions. Emerging markets with expanding industrial production provide additional growth potential. Companies that provide durable, high-speed, and customizable dot peen machines with strong technical support and software integration capabilities are well-positioned to capitalize on these opportunities across global industrial sectors.

Market growth is restrained by technical limitations, competition, and supply chain constraints. Dot peen machines may be slower than laser marking for certain applications and are limited to materials that can withstand mechanical marking. Competition from alternative marking technologies, including laser, inkjet, and etching solutions, may reduce adoption.

Supply chain challenges in sourcing precision components, motors, and electronic controllers can delay production and delivery. Maintenance requirements and the need for operator training further add to operational costs. Until technological enhancements, streamlined supply chains, and differentiation strategies are widely implemented, market growth may remain concentrated in industries where mechanical, durable marking is essential.

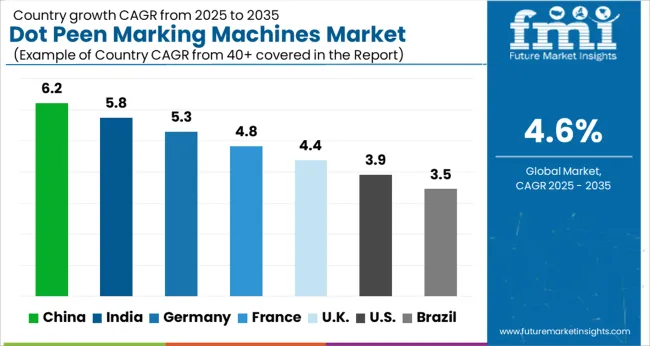

| Country | CAGR |

|---|---|

| China | 6.2% |

| India | 5.8% |

| Germany | 5.3% |

| France | 4.8% |

| UK | 4.4% |

| USA | 3.9% |

| Brazil | 3.5% |

The global dot peen marking machines market is projected to grow at a CAGR of 4.6% through 2035, supported by increasing demand across automotive, aerospace, and metal fabrication industries. Among BRICS nations, China has been recorded with 6.2% growth, driven by large-scale production and deployment in automotive component marking and industrial manufacturing, while India has been observed at 5.8%, supported by rising adoption in metal processing, tooling, and machinery industries. In the OECD region, Germany has been measured at 5.3%, where production and utilization in precision marking, traceability, and industrial identification have been steadily maintained. The United Kingdom has been noted at 4.4%, reflecting consistent use in aerospace, automotive, and industrial metalwork applications, while the USA has been recorded at 3.9%, with production and deployment across industrial, aerospace, and automotive sectors being steadily increased. This report includes insights on 40+ countries; the top five markets are shown here for reference.

The market for dot peen marking machines in China is growing at a CAGR of 6.2%, driven by industrial automation, automotive manufacturing, and metal fabrication industries. Manufacturers are providing advanced marking systems to improve traceability, part identification, and quality control in production lines. Government initiatives supporting smart manufacturing and industrial modernization are promoting adoption. Pilot projects in automotive and metalworking facilities demonstrate operational benefits including precise marking, reduced errors, and enhanced production efficiency. Collaborations between domestic manufacturers, research institutes, and industrial enterprises are improving marking speed, accuracy, and software integration. The rising demand for traceable and durable markings in automotive and industrial components is boosting the dot peen marking machines market in China.

The market for dot peen marking machines in India is expanding at a CAGR of 5.8%, supported by automotive, aerospace, and metal fabrication sectors. Manufacturers are supplying marking systems to ensure precise part identification, compliance with traceability standards, and improved quality control. Government initiatives promoting Make in India and industrial modernization are encouraging adoption. Pilot deployments in automotive and aerospace facilities demonstrate operational benefits including improved marking accuracy, faster production cycles, and reduced rework. Partnerships between local manufacturers, technology providers, and industrial enterprises enhance durability, software compatibility, and marking precision. Growth in industrial manufacturing and emphasis on traceability continue to drive the market in India.

The market for dot peen marking machines in Germany is recording a CAGR of 5.3%, driven by automotive, industrial manufacturing, and metalworking industries. Manufacturers are supplying high-precision marking systems to meet stringent traceability and quality standards. Government initiatives supporting industrial innovation and automation encourage market adoption. Pilot projects in automotive and industrial facilities demonstrate benefits including precise part marking, improved workflow efficiency, and enhanced compliance with industry standards. Collaborations between research institutes, manufacturers, and industrial enterprises improve marking accuracy, software integration, and operational reliability. Germany’s focus on precision manufacturing and industrial automation supports continued market growth.

The market for dot peen marking machines in the United Kingdom is growing at a CAGR of 4.4%, supported by automotive, aerospace, and industrial fabrication sectors. Manufacturers are supplying marking machines for traceability, quality assurance, and improved part identification. Government initiatives promoting industrial automation and manufacturing efficiency foster adoption. Pilot implementations in automotive and metalworking facilities demonstrate operational benefits including faster marking, reduced errors, and improved production tracking. Collaborations between manufacturers, research institutes, and industrial enterprises enhance system integration, marking precision, and durability. Rising industrial automation and demand for traceable parts continue to drive market growth in the United Kingdom.

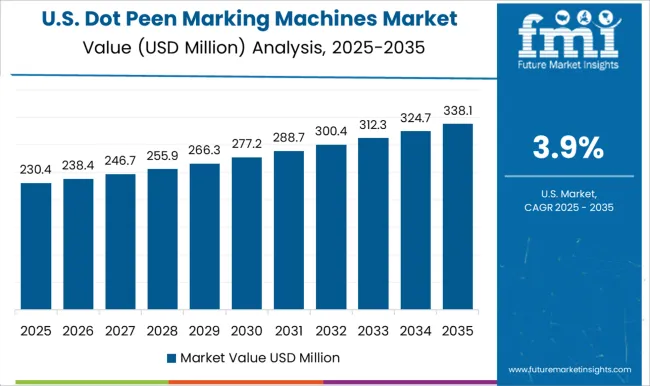

The market for dot peen marking machines in the United States is expanding at a CAGR of 3.9%, driven by automotive, aerospace, and metal fabrication sectors. Manufacturers are providing marking systems to ensure traceability, compliance, and quality control in production lines. Government programs supporting industrial innovation and automation encourage adoption.

Pilot projects in automotive and aerospace facilities show operational benefits including faster marking, higher accuracy, and improved production efficiency. Collaborations between technology providers, manufacturers, and industrial enterprises enhance software integration, precision, and system reliability. Growth in manufacturing sectors requiring traceable and durable markings supports market expansion in the United States.

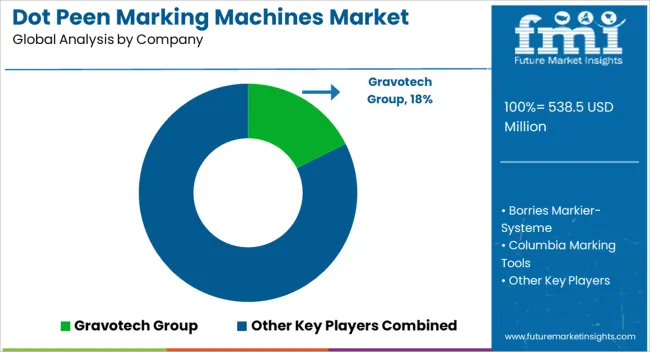

The dot peen marking machines market features moderate consolidation, with several global players competing alongside regional and niche manufacturers. Leading companies such as Telesis Technologies, Gravotech, SIC Marking, PRYOR Technology, Technomark, Östling Marking Systems, Markator, Nichol Industries, Kwikmark, and Jeil Mtech dominate the competitive landscape. These firms compete on hardware performance, including pin durability, marking depth, and speed, as well as on software integration, user interface, and connectivity with industrial automation systems.

Price competitiveness is crucial for regional players, especially in emerging markets, while established brands emphasize product reliability, after-sales service, and long-term maintenance contracts to secure industrial clients. Technological differentiation, such as integration with vision systems, data logging, and Industry 4.0-ready platforms, has become a key factor in winning contracts from automotive, aerospace, and heavy machinery sectors. Geographically, North America and Europe have mature demand driven by strict traceability regulations, whereas Asia-Pacific is experiencing rapid growth due to industrial expansion and rising adoption of portable and inline systems. Competitive strategies focus on partnerships, localized distribution, and continuous R&D to improve marking precision, software compatibility, and operational efficiency across industries.

| Item | Value |

|---|---|

| Quantitative Units | USD 538.5 Million |

| Product Type | Electromagnetic and Pneumatic |

| Installation | Benchtop, Portable, and Integrated |

| Operation | Automated and Semi-automated |

| Application | Automotive, Aerospace, Medical devices, Electronics, Industrial tools and equipment, Construction, and Others |

| Distribution Channel | Direct sales and Indirect sales |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Gravotech Group, Borries Markier-Systeme, Columbia Marking Tools, COUTH, Dapra Marking Systems, Hitachi, Kwikmark, MarkinBOX USA, MECCO, Nichol Industries, Ostling Etchmark, Pannier, Pryor Technology, SIC Marking, and Technomark |

| Additional Attributes | Dollar sales in the Dot Peen Marking Machines Market vary by type including pneumatic, electric, and portable machines, application across automotive, aerospace, metal fabrication, and electronics industries, and region covering North America, Europe, and Asia-Pacific. Growth is driven by rising demand for permanent and traceable part marking, industrial automation, and quality control compliance. |

The global dot peen marking machines market is estimated to be valued at USD 538.5 million in 2025.

The market size for the dot peen marking machines market is projected to reach USD 844.3 million by 2035.

The dot peen marking machines market is expected to grow at a 4.6% CAGR between 2025 and 2035.

The key product types in dot peen marking machines market are electromagnetic and pneumatic.

In terms of installation, benchtop segment to command 38.9% share in the dot peen marking machines market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Endotracheal Tube Market - Growth & Demand Outlook 2025 to 2035

Endotracheal Tube Cuffs Market

Ga 68 DOTATOC Market

Fuchs Endothelial Corneal Dystrophy (FECD) Market Size and Share Forecast Outlook 2025 to 2035

Quantum Dot Market Analysis by Application, End-Use Industry, Material Type, Technology, and Region Through 2035

Vascular Endothelial Growth Factor Inhibitor Market

Veterinary Endotracheal Tubes Market Size and Share Forecast Outlook 2025 to 2035

Lathe Machines Market

Sorter Machines Market Size and Share Forecast Outlook 2025 to 2035

Virtual Machines Market by Type, by Enterprise Size, by Industry & Region Forecast till 2035

Bandsaw Machines Market Growth - Trends & Forecast 2025 to 2035

Sleeving Machines Market Size and Share Forecast Outlook 2025 to 2035

Drilling Machines Market Size and Share Forecast Outlook 2025 to 2035

Spinning Machines Market Size and Share Forecast Outlook 2025 to 2035

Knitting Machines Market Size and Share Forecast Outlook 2025 to 2035

Stamping Machines Market Growth and Outlook 2025 to 2035

Twist Tie Machines Market Size and Share Forecast Outlook 2025 to 2035

Cartoning Machines Market from 2025 to 2035

Flow Wrap Machines Market by Horizontal & Vertical Systems Through 2025 to 2035

Flake Ice Machines Market - Industry Growth & Market Demand 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA