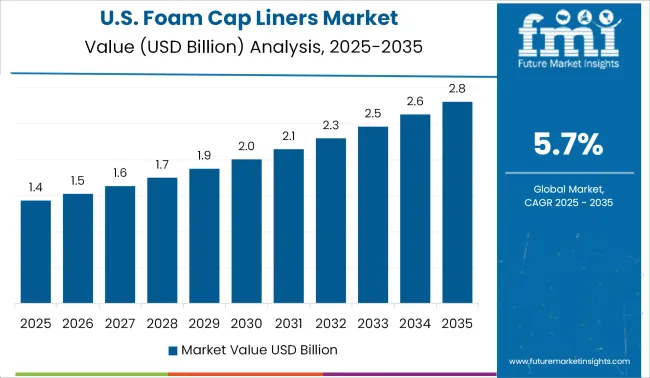

The Foam Cap Liners Market is estimated to be valued at USD 3.9 billion in 2025 and is projected to reach USD 6.8 billion by 2035, registering a compound annual growth rate (CAGR) of 5.7% over the forecast period.

The foam cap liners market is witnessing consistent growth as industries prioritize secure, tamper evident, and contamination-free packaging solutions. Rising regulatory scrutiny in pharmaceuticals, food, and chemical sectors has increased demand for reliable sealing technologies, enhancing the adoption of foam liners that ensure product integrity during transit and storage.

Manufacturers are responding to this demand by developing liners with improved barrier properties, easy application, and compatibility with a wide range of container materials. Market momentum is also being fueled by innovations in liner materials and designs that align with sustainability goals while meeting functional performance standards.

Growing emphasis on cost efficiency, coupled with heightened awareness of product safety among end users, is paving the way for broader adoption. Future growth opportunities are expected to emerge from emerging economies where packaged goods consumption is rising, supported by investments in advanced manufacturing capabilities and compliance with evolving global standards.

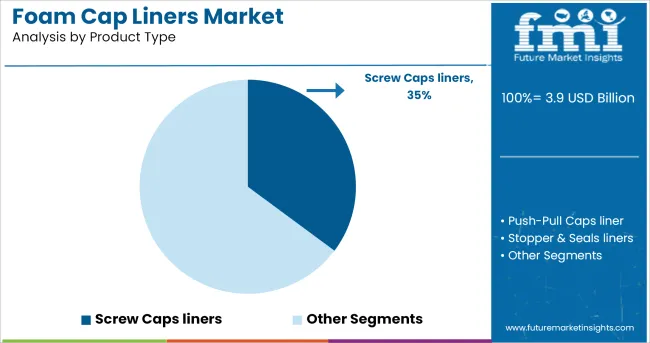

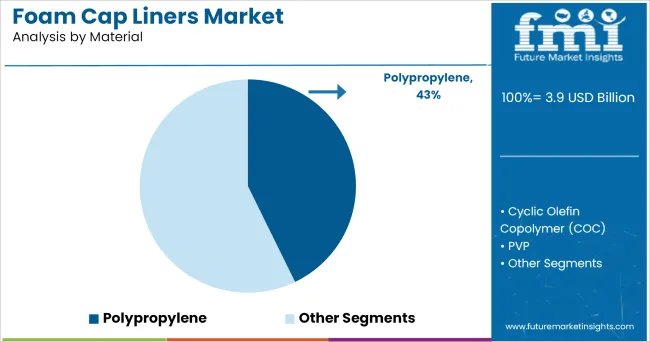

The market is segmented by Product Type, Material, and End User and region. By Product Type, the market is divided into Screw Caps liners, Push-Pull Caps liner, Stopper & Seals liners, Pin hole cap liners, and Others. In terms of Material, the market is classified into Polypropylene, Cyclic Olefin Copolymer (COC), PVP, Elastomer, and Others.

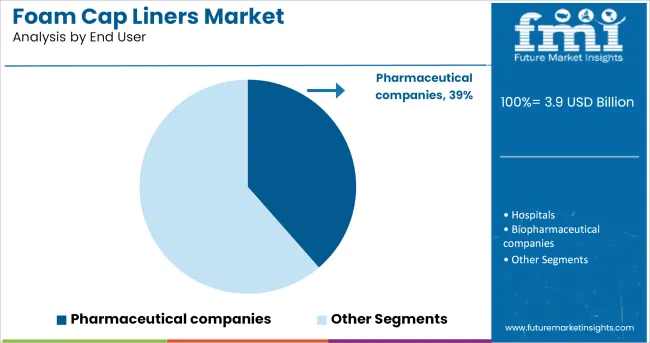

Based on End User, the market is segmented into Pharmaceutical companies, Hospitals, Biopharmaceutical companies, Medical Device Companies, and Diagnostic Labs. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by product type, screw caps liners are anticipated to hold 35.2% of the total market revenue in 2025, positioning them as the leading product type. This dominance has been shaped by the versatility and widespread compatibility of screw caps across industries, enabling seamless integration of foam liners within standardized closures.

Their ability to provide consistent sealing performance, coupled with cost effective manufacturing, has reinforced their adoption. Screw caps liners are favored for their simplicity in application and removal, which enhances operational efficiency on high speed filling lines.

Furthermore, their compatibility with diverse bottle designs and materials has extended their utility across pharmaceuticals, food, and personal care products, ensuring their continued preference among manufacturers seeking reliable, scalable solutions.

Segmented by material, polypropylene is projected to account for 42.8% of the market revenue in 2025, maintaining its leadership position. This prominence is attributed to polypropylene’s favorable mechanical and chemical properties, which make it an ideal choice for foam cap liners exposed to a variety of contents and conditions.

Its lightweight nature, resistance to moisture and chemicals, and ability to maintain integrity over a wide temperature range have made it the preferred material for manufacturers aiming to balance performance with cost-effectiveness.

The recyclability of polypropylene has further strengthened its appeal, aligning with sustainability initiatives while meeting stringent regulatory requirements. Its processability and consistent quality in mass production have supported its sustained leadership in the material segment.

When segmented by end user, pharmaceutical companies are expected to capture 38.6% of the market revenue in 2025, affirming their position as the foremost consumer group. This leadership has been driven by the critical need for product integrity, contamination prevention, and regulatory compliance within the pharmaceutical industry.

Foam cap liners have been increasingly deployed by pharmaceutical companies to ensure airtight sealing, extend shelf life, and safeguard against tampering all essential in maintaining patient safety and brand trust.

Their adoption has been bolstered by the sector’s stringent quality standards and the growing complexity of pharmaceutical formulations requiring specialized packaging. The ability of foam liners to support serialization and traceability initiatives has further reinforced their uptake, making them indispensable to pharmaceutical manufacturers committed to product safety and regulatory adherence.

Growing demand of new foam cap liners for prevention of leakage, prevent oxidation of product, increase half-life of product, tamper evident liners drive this market. Moreover, launch of innovative product and technological advancements in cap liners for foam will fuel the growth of this market.

Foam cap liners has gaining attention over past few years due to high promotion of contactless cap liners and child resistance closures. Contactless multi dose delivery cap is an extraordinary innovative packaging material, for the packaging industry.

It offers a total protected, simple arrangement for administration, and gives favourable results in good clinical practices, and in this manner its utilization is high for liquids. This act as major driver.

The USA remains one of the largest markets for foam cap liners globally. USA will hold significant foam cap liners market share throughout the course of the forecast period. Due to acceptance of innovative and user-friendly cap liners by American population so leading manufacture develop more innovative liners.

For instance, in 2024 mold closures are made from High Density Polyethylene, a recyclable plastic resin known for its exceptional moisture and vapour barrier properties (MVTR) and stiffness. These containers are in liner size of 33 and 36 mm, for liquid.

Demand for foam cap liners will be increasing in USA and Canada due to the consumer is looking for product which is easy to access, easy to use, fulfil the demand and need, easy to get foam. These factors create huge opportunities for the manufacturer to develop the consumer-friendly foam cap liners. Acceptance of this cap are some other factors fueling the market growth in the country.

Foam cap liners demand has gained traction in European countries in recent years due to adaption of aseptic environment and hygiene in healthcare facilities. The company in Europe are consistently focuses on product development.

As the majority of the company’s revenue is generated from caps liners, the company has been introducing new caps liners in the market to sustain its profitability.

For Instances, In April 2024, MENSHEN is collaborated with interpack for the indispensable event for the food, pharmaceutical, cosmetics and non-food sectors such as cleaning agents or the chemical industry for packaging material.

Some of the leading manufacturers and suppliers of foam cap liners include

Many leading manufacturers and service providers have strategic acquisition to for strengthen their position for sales. In September 2024, Bericap latest expansions were the start of a production facility in Malaysia to grow their sales.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

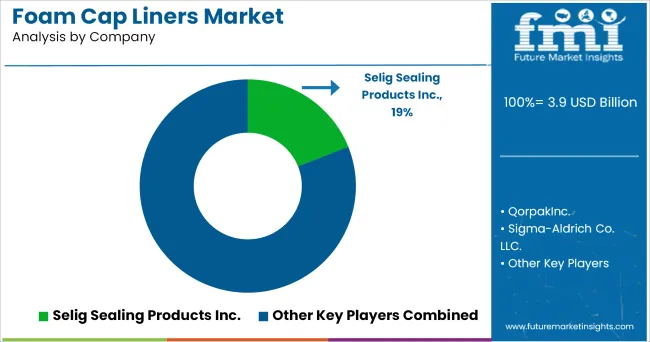

The global foam cap liners market is estimated to be valued at USD 3.9 billion in 2025.

The market size for the foam cap liners market is projected to reach USD 6.8 billion by 2035.

The foam cap liners market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types in foam cap liners market are screw caps liners, push-pull caps liner, stopper & seals liners, pin hole cap liners and others.

In terms of material, polypropylene segment to command 42.8% share in the foam cap liners market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Understanding Market Share Trends in Foam Cap Liners

Foam Market Size and Share Forecast Outlook 2025 to 2035

Foam-Free Pad Formers Market Size and Share Forecast Outlook 2025 to 2035

Foam Cups Market Size and Share Forecast Outlook 2025 to 2035

Foam Bottle Technology Market Size and Share Forecast Outlook 2025 to 2035

Foaming Agents Market Size and Share Forecast Outlook 2025 to 2035

Foam Glass Granulate Market Size and Share Forecast Outlook 2025 to 2035

Foam Plastics Market Size and Share Forecast Outlook 2025 to 2035

Foaming Creamer Market Size and Share Forecast Outlook 2025 to 2035

Foam Tape Market Size and Share Forecast Outlook 2025 to 2035

Foam Glass Market Size and Share Forecast Outlook 2025 to 2035

Foamer Pump Market Size, Share & Forecast 2025 to 2035

Foam Food Container Market Size and Share Forecast Outlook 2025 to 2035

Foam Mesh Sleeves Market Growth - Demand & Forecast 2025 to 2035

Foam Edge Protectors Market Size and Share Forecast Outlook 2025 to 2035

Foamer Bottle Market Size and Share Forecast Outlook 2025 to 2035

Foam Pouch Market Analysis - Demand, Size & Industry Outlook 2025 to 2035

Foam Cooler Box Market Analysis - Growth & Trends 2025 to 2035

Foam Packaging Inserts Market Analysis, Size, Share & Forecast 2025 to 2035

Foam Labels Market Trends and Growth 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA