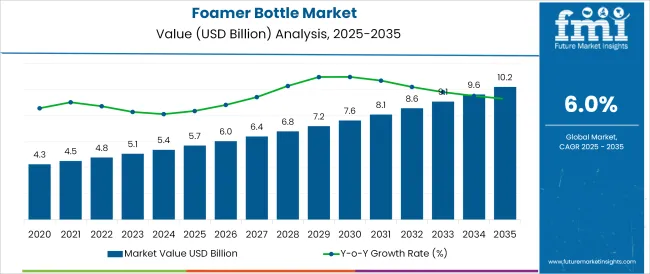

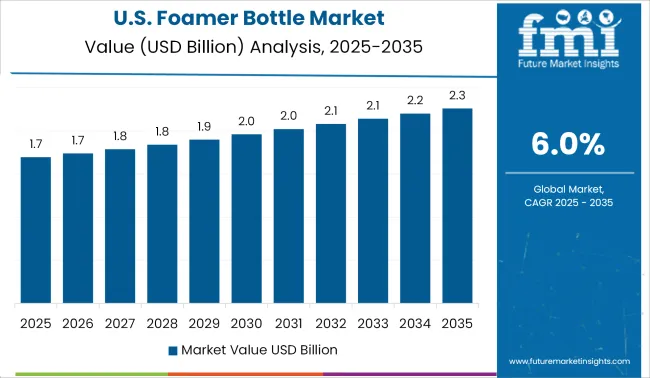

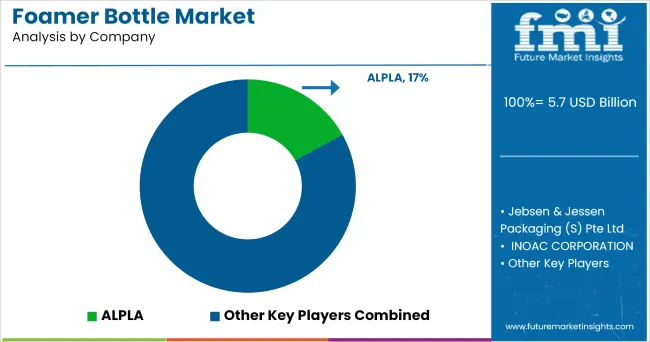

The Foamer Bottle Market is estimated to be valued at USD 5.7 billion in 2025 and is projected to reach USD 10.2 billion by 2035, registering a compound annual growth rate (CAGR) of 6.0% over the forecast period.

The foamer bottle market is witnessing sustained growth, supported by rising demand for controlled, waste-reducing liquid dispensing in personal care, household, and healthcare applications. The shift toward airless and non-aerosol packaging formats is being encouraged by regulatory pressure on volatile organic compounds (VOCs) and consumer preference for hygienic, mess-free use.

Innovations in bottle design and actuator performance have improved foam consistency, enhancing product appeal in skincare, sanitization, and haircare categories. Growing interest in sustainable packaging materials and recyclable polymers is reshaping procurement decisions, with manufacturers investing in high-precision molding systems to ensure lightweight, durable bottle solutions.

Industry participants are increasingly integrating post-consumer recycled (PCR) content and mono-material designs to meet evolving environmental compliance standards. Looking ahead, the market is expected to benefit from increased product launches in the natural and clean beauty segments, where foamer bottles are being adopted as brand differentiators for user experience and dosage control.

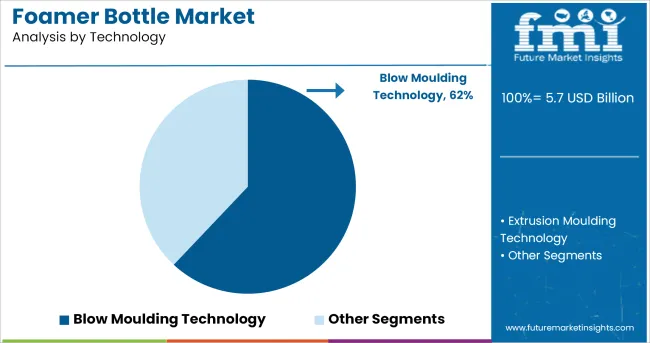

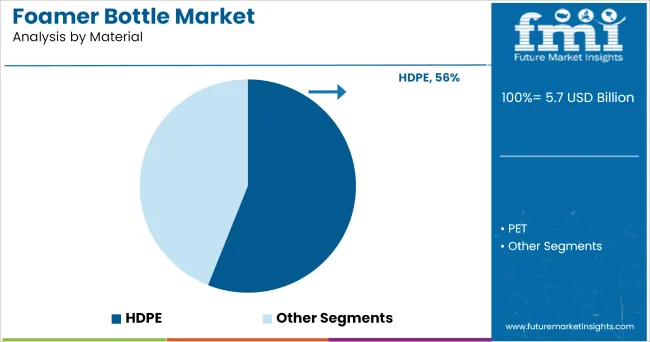

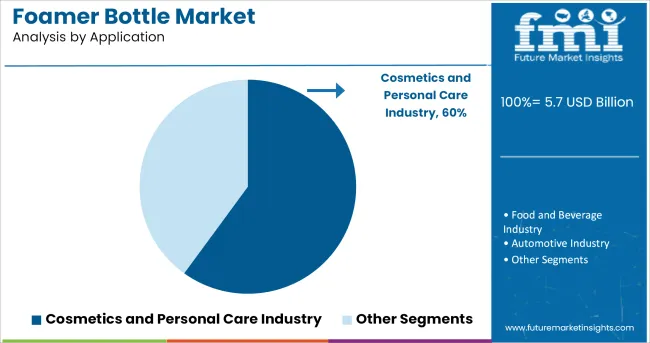

The market is segmented by Technology, Material, and Application and region. By Technology, the market is divided into Blow Moulding Technology and Extrusion Moulding Technology. In terms of Material, the market is classified into HDPE and PET. Based on Application, the market is segmented into Cosmetics and Personal Care Industry, Food and Beverage Industry, Automotive Industry, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

By technology, blow moulding is projected to account for 62% of the total revenue share in the foamer bottle market by 2025, making it the leading segment. This dominance is being driven by the process’s cost-effectiveness, scalability, and ability to produce high-strength, lightweight bottles in complex geometries.

Blow moulding supports rapid manufacturing cycles and enables precision wall thickness control, which is critical for maintaining container integrity under pressure during foam dispensing. Its compatibility with a wide range of polymers, including recyclable and food-grade variants, has expanded its usage across cosmetics, healthcare, and household cleaning sectors.

The ability to integrate neck finishes and customize actuator fittings within a single process further strengthens its position in high-speed filling environments. As brands demand visually distinct, ergonomic packaging that supports sustainability goals, blow moulding remains the preferred technology for delivering both design flexibility and cost-efficiency at commercial volumes.

By material, high-density polyethylene (HDPE) is expected to hold a 56% share of the foamer bottle market in 2025, making it the most widely used resin in this category. HDPE’s dominance is attributed to its excellent chemical resistance, structural rigidity, and recyclability, all of which are essential for safe, long-lasting packaging of foam-based products.

The material’s ability to withstand repeated use without deformation has made it highly suitable for personal care and cleaning products, where consumer handling and refillability are key considerations. HDPE’s compatibility with blow moulding processes allows for high-volume, precision manufacturing with reduced environmental impact.

Moreover, growing adoption of HDPE in closed-loop recycling programs is improving its acceptance among eco-conscious brands. Its lightweight nature contributes to lower transportation costs and improved carbon efficiency, which aligns with corporate sustainability mandates and life-cycle assessment targets across multiple industries.

By application, the cosmetics and personal care industry is projected to lead the foamer bottle market with a 60% revenue share in 2025. This segment’s growth is being driven by rising global demand for hygienic, easy-to-use packaging in skincare, facial cleansers, hand sanitizers, and shaving products.

Foamer bottles offer controlled dispensing, reduce overuse, and enhance the sensory experience features that align well with premium product positioning and consumer expectations in the personal care segment. Brands are increasingly investing in innovative packaging formats that reinforce product differentiation, safety, and sustainability, all of which are delivered effectively by foamer bottles.

The segment’s dominance is further supported by the expansion of direct-to-consumer (DTC) and e-commerce channels, where leak-proof, tamper-evident packaging is prioritized. Additionally, as natural and organic formulations gain traction, foamer bottles are favored for their ability to preserve product integrity without the need for aerosols or harsh preservatives.

The product benefits such as easy dispensing, attractive looks, ease in storing and carrying are projected in the growing popularity of foam pumps in the cosmetics & skincare, and personal care application segments. In addition, improved standards of living and the introduction of various cosmetics and personal care products are likely to drive the market for foam pumps.

Foamer bottle market is driven by cosmetic and beverage industries. Global foamer bottle market is dominated by synthetic material like HDPE and PET. The end use industries of these products are about to witness double digit growth in the foamer bottle market demand, thereby accelerating the demand for foamer bottles.

To minimize the single use containers, packaging manufacturers has come up with advance solution by introducing foamer bottle technology which has minimal impact on environment.

The technology reduces use of resin in production by 15%, instead used bobble honeycomb structure which light weight yet rigid. It protects from contamination. The bottles are biodegradable made up from either starch foam or synthetic foam.

The unique pump technology is perfect for cosmetics and more. Increase in per capita expenditure on personal grooming, strong regulatory framework and growth in beauty and cosmetic market are the key factors for the growth of the market. Foamer bottles market is driven by the increase in market of cosmetics.

USA has captured dominant share in pharmaceutical worldwide. The application of foamer bottles is cost effective and efficient. Qosmedix has added new series of foaming bottles. These are new PET bottles which are recyclable and each pump includes clear over cap to ensure secure closer.

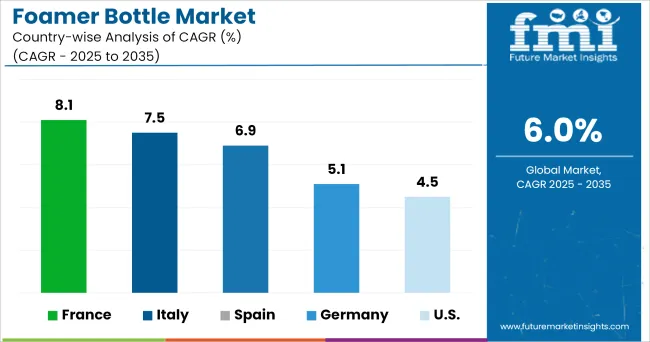

The European cosmetics and personal care market is the potential market for cosmetic products in the world, valued at €5.4 billion at retail sales price in 2024. It is estimated that the cosmetics and personal care industry brings at least €29 billion in added value to the European economy annually. €11 billion is contributed directly by the manufacture of cosmetic products.

Frapak is the key player in packaging. Since 2010, the subsidiary FlexPET has been developing PET packaging solutions, aiming not only cosmetic and personal care market but also pharmaceutical market.

Some of the leading manufacturers and suppliers of Foamer Bottle include

Alpla, the leading packaging molder received 2 awards for its innovative extrusion blow moulding. This reduces the amount of resins required to produce bottles. Technology reduces plastic consumption and weight by up to 15%.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global foamer bottle market is estimated to be valued at USD 5.7 billion in 2025.

The market size for the foamer bottle market is projected to reach USD 10.2 billion by 2035.

The foamer bottle market is expected to grow at a 6.0% CAGR between 2025 and 2035.

The key product types in foamer bottle market are blow moulding technology and extrusion moulding technology.

In terms of material, hdpe segment to command 56.0% share in the foamer bottle market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Market Share Breakdown of Foamer Bottle Manufacturers

Foamer Pump Market Size, Share & Forecast 2025 to 2035

Defoamers Market Size & Trends 2025 to 2035

Fermentation Defoamer Market Size and Share Forecast Outlook 2025 to 2035

Non-Silicone Emulsion Defoamer Market Size and Share Forecast Outlook 2025 to 2035

Anti-Foaming Agents / Defoamers Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Demand for Non-Silicone Emulsion Defoamer in UK Size and Share Forecast Outlook 2025 to 2035

Bottle Sealing Wax Market Size and Share Forecast Outlook 2025 to 2035

Bottle Filling Machines Market Size and Share Forecast Outlook 2025 to 2035

Bottle Shippers Market Size and Share Forecast Outlook 2025 to 2035

Bottled Water Packaging Market Size and Share Forecast Outlook 2025 to 2035

Bottle Sticker Labelling Machine Market Size and Share Forecast Outlook 2025 to 2035

Bottle Dividers Market Size and Share Forecast Outlook 2025 to 2035

Bottle Jack Market Size and Share Forecast Outlook 2025 to 2035

Bottles Market Analysis - Growth & Forecast 2025 to 2035

Bottle Capping Machine Market Analysis by Automation, Operating Speed, Machine Type, End-use Industry, and Region Forecast Through 2035

Market Share Distribution Among Bottle Dividers Suppliers

Bottle Carrier Market Trends – Growth & Forecast 2024-2034

Bottle Cap Market Analysis & Industry Forecast 2024-2034

Bottled Water Processing Equipment Market Trends – Growth & Industry Forecast 2025-2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA