Growing demand for advancements in traditional nutrunners to meet high speed, better accuracy, high durability and exceptional up time availability requirements has led to the introduction of handheld DC torque tools across aviation, automotive and energy industries, among others. Handheld DC torque tools work with high accuracy and provide safe fastening without the need for a reaction device, which eliminates the need for regular maintenance of the tool as no oil is required due to no reaction device.

Furthermore, handheld DC torque tools available in the market have built-in angle encoders and torque transducers having a high capacity of torques Upto 250 Nm coupled with of lower energy consumption rates. Hydraulic valve assembly, gearbox assembly, counter weights and swing bearing are some of the applications where handheld DC torque tools find major usage. The tool helps to simply carry out the fastening in continuity by avoiding the troublesome channel change operation and continuously defining the necessary fastening channels as one multi-channel system.

Inline, inline offset, pistol grip, angle nutrunners, among others, are some of the latest handheld DC torque tools which offer various features, such as one-handed operation, comfortable ergonomic grip, etc. The overall production process for handheld DC torque tools uses finest electronic machinery and control and program technology. Moreover, these tools have an ergonomic design, are of high-quality and are environment friendly

Industries, such as aerospace or aviation, automotive, energy, among others, are now shifting their focus towards automation to manufacture parts and equipment in bulk to meet the customers’ demand in a very short period of time.

Due to growing demand for products with enhanced performance, better durability and longer lifetime span, the focus of original equipment manufacturers and suppliers is shifting from conventional nutrunners to their new version, which are expected to witness substantial growth over the next decade. The introduction of handheld DC torque tools has made it possible for workers to reduce the reaction during fastening and tightening of the parts with the help of pulse technology and enhanced productivity.

The conventional nutrunners were slow and required effort and time, which often slowed down the process of production assembly and thus, the total efficiency of the plant. The cordless feature of the handheld DC torque tools allows workers to carry along the torque tools to places where the power supply is not feasible. Furthermore, high accuracy offerings to comply with industry requirements along with low power consumption are expected to drive the global handheld DC torque tools market during the forecast period.

Some of the market participants in the global handheld DC torque tools market are:

The global handheld DC torque tools market is segmented into the following regions -- North America, Latin America, Western Europe, Eastern Europe, South East Asia-Pacific, China, Japan, India and the Middle East and Africa. Western Europe is estimated to dominate the global handheld DC torque tools market owing to growing awareness about technologically advancements for smooth fastening and tightening of nuts in the aerospace and automotive industries.

North America is further expected to dominate the global handheld DC torque tools market owing to strong penetration of electric tools in automotive, construction and aerospace industries, among others. China and India are estimated to witness substantial growth during the forecast period owing to the robust growth of the automotive as well as aerospace industry in the region.

FMI will follow a modelling-based approach and triangulation methodology to estimate data covered in this report. A detailed market understanding and assessment of the nature, product type of the product segments covered in the study is followed by a demand-side analysis to estimate the sales of target product segments, which is then cross-referenced with a supply-side assessment of value generated over a pre-defined period. The statistics and data is collected at a regional level and consolidated and synthesized at a global level to estimate the overall market sizes.

Furthermore, on the regional level, penetration rate across key end-use industries is analyzed by conducting surveys and collecting responses from industry experts to understand the trend for projections over the next decade.

Some of the key data points covered in our report include:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global handheld DC torque tools market can be segmented on the basis of type, control system and end-use industry.

On the basis of type, the global handheld DC torque tools market is segmented into:

On the basis of control system, the global handheld DC torque tools market is segmented into:

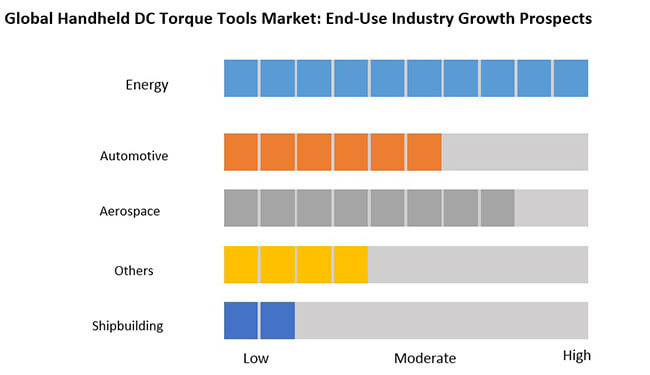

On the basis of end-use industry, the global handheld DC torque tools market is segmented into:

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Handheld Electrostatic Meter Market Size and Share Forecast Outlook 2025 to 2035

Handheld Ultrasound Scanner Market Size and Share Forecast Outlook 2025 to 2035

Handheld Tagging Gun Market Forecast and Outlook 2025 to 2035

Handheld Imaging Systems Market Size and Share Forecast Outlook 2025 to 2035

Handheld XRF Analyzers Market Size and Share Forecast Outlook 2025 to 2035

DC Traction Switchgear Market Size and Share Forecast Outlook 2025 to 2035

Handheld Police Radar Guns Market Size and Share Forecast Outlook 2025 to 2035

Handheld DNA Reader Market Size and Share Forecast Outlook 2025 to 2035

DC Electromagnetic Brakes Market Size and Share Forecast Outlook 2025 to 2035

DC and PKI Market Size and Share Forecast Outlook 2025 to 2035

Handheld Robotic Navigation Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Handheld Mesh Nebulizer Market Size and Share Forecast Outlook 2025 to 2035

DCIM Market Size and Share Forecast Outlook 2025 to 2035

DC Contactor Market Size and Share Forecast Outlook 2025 to 2035

DC Solar Cable Market Size and Share Forecast Outlook 2025 to 2035

DC Servo Motors and Drives Market Size and Share Forecast Outlook 2025 to 2035

Handheld Chemical and Metal Detector Market Size and Share Forecast Outlook 2025 to 2035

DC BEV On-Board Charger Market Size and Share Forecast Outlook 2025 to 2035

Handheld Dental X-Ray Systems Market Analysis - Size, Share, and Forecast 2025 to 2035

Torque Gauge Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA