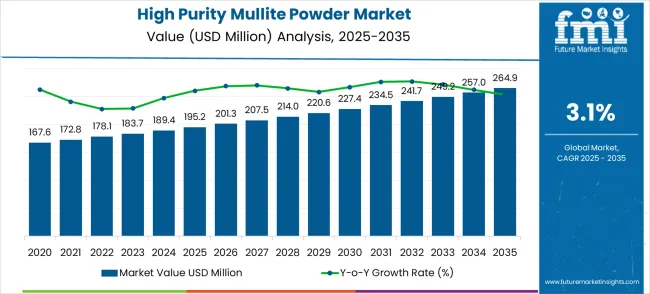

The high purity mullite powder market begins its decade journey from a USD 195.2 million foundation in 2025, setting the stage for substantial expansion ahead. The first half of the decade witnesses steady momentum building, with market value climbing from USD 172.8 million in 2026 to USD 207.5 million by 2030. This initial phase reflects growing refractory industry modernization and increasing precision requirements across high-temperature manufacturing sectors.

The latter half will witness accelerated growth dynamics, propelling the market from USD 214.0 million in 2031 to reach USD 264.9 million by 2035. Dollar additions during 2030-2035 outpace the earlier period, with annual increments averaging USD 11.5 million compared to USD 8.0 million in the first phase. This progression represents a 58.1% total value increase over the forecast decade.

Market maturation factors include expanding steel production volumes, glass industry precision demands, and ceramic manufacturing sophistication. The 4.9% compound annual growth rate positions participants to capitalize on USD 97.3 million in additional market value creation. This trajectory signals robust opportunities for technology innovators, distribution network developers, and end-user solution providers across the global industrial landscape.

Market expansion unfolds through two distinct growth periods, each with different competitive characteristics. The 2025-2030 foundation period delivers USD 39.9 million in value additions, representing 23.8% growth from the baseline. Market dynamics during this phase center on technology standardization, distribution channel establishment, and end-user adoption acceleration across the steel and glass manufacturing sectors.

The 2030-2035 acceleration period generates USD 57.4 million in incremental value, representing a 27.7% increase from the 2030 position. This phase exhibits mature market characteristics with enhanced competition, product differentiation strategies, and geographic expansion initiatives. Dollar contributions shift from foundational infrastructure development to market share optimization and technological advancement in ultra-high purity grades.

The competitive landscape evolves from early market development to established player positioning. The first period focuses on market education and reducing adoption barriers in traditional refractory applications. The second period witnesses intensified competition for premium market segments and expansion of geographical territories. Market maturation factors include standardized purity requirements, automated production integration capabilities, and cross-industry application development across steel, glass, and advanced ceramics sectors.

| Metric | Value |

|---|---|

| Market Value (2025) → | USD 195.2 million |

| Market Forecast (2035) ↑ | USD 264.9 million |

| Growth Rate ★ | 4.9% CAGR |

| Leading Classification → | 99.97% purity |

| Primary Application → | Steel |

Market expansion rests on three fundamental shifts driving industrial demand acceleration:

The growth faces headwinds from high raw material costs and complex purification requirements. Traditional lower-grade alternatives maintain cost advantages for less demanding applications. Technical complexity creates adoption barriers for smaller manufacturing environments without specialized processing capabilities.

Primary Classification: Purity Level Distribution

Secondary Breakdown: Application Categories

Geographic Segmentation: Regional Market Distribution

Market Position: Ultra-high purity mullite powders establish clear market leadership through superior thermal properties and chemical stability benefits. 99.97% purity systems eliminate impurity-related performance limitations in demanding high-temperature applications. Consistent composition capabilities enable precise thermal expansion control where standard alternatives cannot achieve required specifications.

Value Drivers: Advanced purification technology improvements enhance particle size uniformity and reduce contamination risks. Digital quality control integration provides real-time composition verification and batch consistency monitoring. Specialized processing capabilities accommodate multiple application requirements within single production configurations for operational efficiency.

Competitive Advantages: Ultra-pure systems offer enhanced thermal shock resistance compared to standard purity alternatives requiring frequent replacement cycles. Superior chemical stability increases service life through reduced degradation rates in corrosive environments. Premium pricing justification occurs through total cost of ownership advantages and performance reliability benefits.

Market Challenges: Complex purification processes increase manufacturing costs compared to standard purity grades. Quality control requirements demand sophisticated testing equipment and technical expertise, which are not available in all production facilities. Limited supplier base creates supply chain vulnerabilities for specialized applications requiring consistent availability.

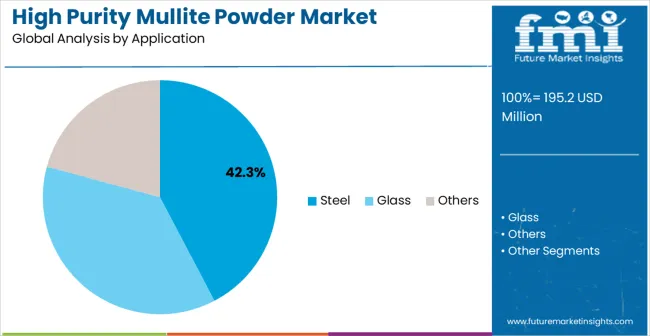

Strategic Market Importance: Steel manufacturing represents the primary demand driver for high-temperature refractory applications across global production facilities. Blast furnace operations, continuous casting processes, and heat treatment applications require precise thermal properties for operational efficiency. Quality control standards mandate consistent refractory performance for production optimization and equipment protection.

Market Dynamics Q&A:

Business Logic: Steel production facilities prioritize operational reliability and energy efficiency, making high purity mullite powders essential for meeting production targets. Cost justification occurs through reduced energy consumption and extended refractory service life. Equipment protection requirements demand consistent thermal shock resistance for operational continuity.

Forward-looking Implications: Green steel production initiatives create new application requirements for energy-efficient refractory systems. Advanced steel grades manufacturing demands enhanced thermal stability for specialized processing conditions. Global steel production growth market demand across emerging manufacturing regions with expanding industrial infrastructure.

Drivers of the High Purity Mullite Powder Market The high purity mullite powder market is primarily driven by increasing demand from industries requiring superior thermal shock resistance and high-temperature performance. Applications in advanced ceramics, aerospace, and electronics necessitate materials that maintain structural integrity under extreme conditions, making high purity mullite an attractive solution. The integration of advanced ceramics into industrial processes further emphasizes the need for precise particle size distribution and strict chemical composition control, ensuring consistent performance. Stringent environmental regulations across manufacturing sectors encourage the use of energy-efficient materials that reduce operational costs and carbon emissions. High purity mullite’s compliance with quality certification standards also makes it a preferred choice for critical applications, where documented material properties are essential for reliability and safety, creating a stable demand pipeline globally.

Restraints Affecting Market Growth Despite its advantages, the high purity mullite powder market faces several growth inhibitors. Production costs are significantly higher than standard or lower purity alternatives, discouraging adoption in cost-sensitive operations and smaller manufacturing units. The purification and synthesis processes are complex, requiring specialized equipment, technical expertise, and stringent quality control systems, which are not universally available. Limited availability of raw materials, including high-grade alumina and silica, further constrains large-scale production capacity expansion. The technical complexity involved in handling and processing high purity mullite powders necessitates skilled operators and advanced manufacturing protocols, adding to operational overheads. These challenges collectively slow market penetration, particularly in emerging regions or price-sensitive sectors, restraining market growth despite rising industrial demand.

Key Trends and Market Evolution Patterns The high purity mullite powder market is evolving rapidly, driven by technological innovations and initiatives. Nanotechnology integration allows precise control over particle size, enhancing properties for specialized applications such as high-performance electronics, refractory coatings, and thermal insulation. Automation in processing is another trend, reducing manufacturing costs, improving product uniformity, and minimizing human error. Green manufacturing initiatives are gaining traction, prompting the development of eco-friendly production methods that reduce energy consumption and waste. Furthermore, there is increasing demand for customizable mullite powders tailored to specific industrial requirements, offering operational flexibility while maintaining performance standards. These trends collectively indicate a market that is technologically advancing while responding to regulatory, environmental, and application-specific needs, ensuring growth and innovation.

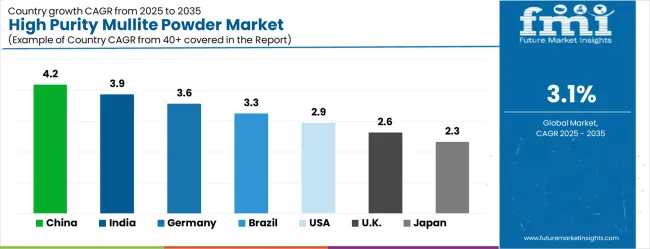

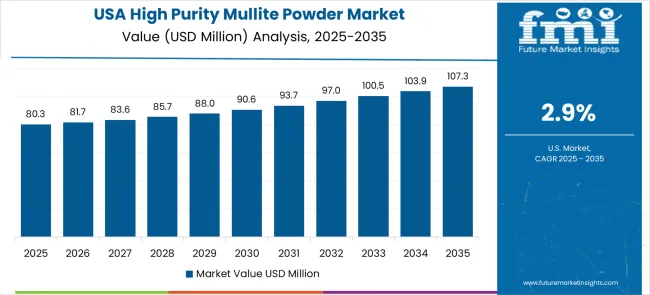

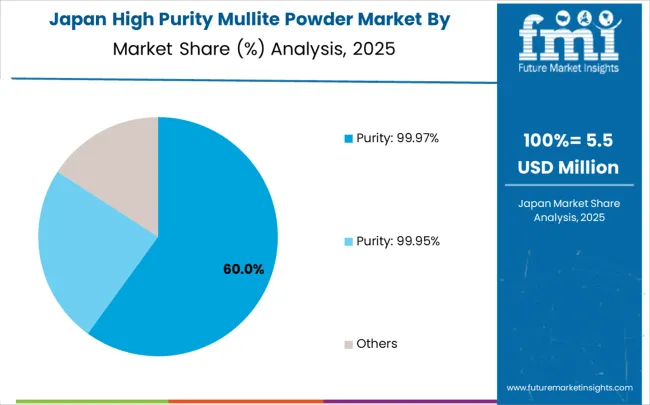

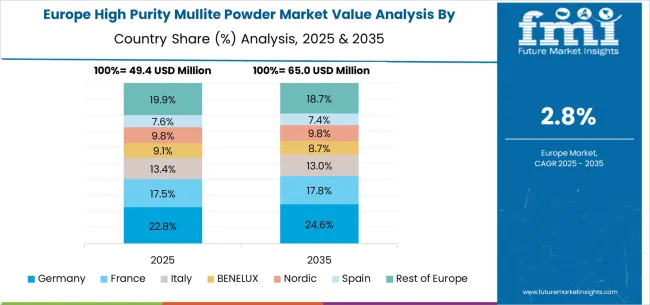

Global market dynamics reveal distinct performance tiers reflecting regional manufacturing capabilities and industrial development levels. Growth Leaders including China (4.2% CAGR) and India (3.9% CAGR), demonstrate expanding steel production ecosystems with advanced refractory adoption, while Germany (3.6% CAGR) represents European manufacturing excellence in precision applications. Steady Performers such as Brazil (3.3% CAGR) and the United States (2.9% CAGR) show consistent demand growth aligned with industrial modernization and steel sector requirements. Mature Markets including the United Kingdom (2.6% CAGR) and Japan (2.3% CAGR) display moderate growth rates reflecting established market penetration and technology advancement focus.

Regional synthesis indicates Asia Pacific dominance through steel production concentration and export manufacturing requirements. European markets emphasize quality standards and precision manufacturing applications. North American demand reflects industrial automation adoption and advanced ceramics development initiatives.

| Country | CAGR (%) |

|---|---|

| China | 4.2 |

| India | 3.9 |

| Germany | 3.6 |

| Brazil | 3.3 |

| USA | 2.9 |

| UK | 2.6 |

| Japan | 2.3 |

China establishes market leadership through steel production sector dominance across integrated mills, electric arc furnaces, and specialty steel manufacturing facilities. A 4.2% CAGR value reflects extensive production capacity and export-oriented steel manufacturing requirements driving consistent demand for high-performance refractory materials. Growth metrics demonstrate comprehensive industrial modernization supported by government infrastructure development initiatives and stringent quality improvement mandates across manufacturing sectors.

Market dynamics center on green steel production expansion creating new high-performance refractory requirements for enhanced energy efficiency and substantial emission reduction targets. State-owned enterprise modernization programs drive widespread adoption of advanced materials for operational efficiency improvement and international competitiveness. Export market demands necessitate strict international quality standard adherence through extensively documented performance specifications and certification processes.

Manufacturing concentration in major steel producing regions creates significant demand density for high-performance refractory materials and specialized applications. Industrial development policies specifically include advanced materials requirements for comprehensive technology upgrading initiatives. Foreign technology transfer partnerships bring international quality standards requiring high purity mullite applications and technical expertise development.

Strategic Market Indicators:

India demonstrates robust growth potential through rapidly expanding steel production capabilities and comprehensive government promotion of domestic manufacturing initiatives under various industrial development programs. A 3.9% CAGR reflects increasing industrial sophistication and widespread quality standard adoption across manufacturing sectors. Steel sector growth under government initiatives creates consistent demand for high-performance refractory materials across both integrated steel plants and mini steel facilities.

Automotive sector expansion drives significant secondary demand through stringent steel quality requirements for precision component manufacturing and assembly operations. Government quality certification mandates actively promoting high-performance material adoption for enhanced safety compliance and international standard adherence. Major infrastructure development projects substantially increase construction steel production volumes requiring advanced refractory applications and specialized thermal protection systems.

Market activity centers on comprehensive technology transfer agreements bringing international steel production standards and best practices to domestic manufacturing facilities. Foreign direct investment in steel operations introduces advanced refractory requirements for improved operational efficiency and competitive advantage. Skill development initiatives include extensive training programs for advanced materials application techniques and quality control procedures.

Market Intelligence Brief:

Germany maintains market leadership through exceptional engineering excellence and long-established precision manufacturing traditions across diverse industrial sectors. A 3.6% CAGR demonstrates market demand supported by an established industrial base with advanced ceramics capabilities and specialty steel production expertise. Automotive sector requirements create consistent demand for high-performance materials across precision component manufacturing and specialized tooling applications requiring superior thermal properties.

The industrial equipment manufacturing sector requires extensively certified material specifications for strict export compliance and international quality standards. The engineering services sector utilizes premium materials for advanced prototype development and comprehensive testing applications requiring precise thermal characteristics. Quality standard development significantly influences global manufacturing practices requiring advanced material adoption and technical innovation.

Advanced manufacturing research initiatives continuously develop innovative applications for high purity ceramic powders across emerging industrial sectors. Export market leadership necessitates comprehensive quality documentation supporting international sales and regulatory compliance requirements. Automotive supplier network requires consistent material performance for precision component manufacturing and assembly operations.

Performance Metrics:

Brazil represents a significant emerging market with substantial growth potential, achieving a 3.3% CAGR through comprehensive industrial development initiatives and automotive sector expansion across domestic and regional markets. The market reflects increasing manufacturing sophistication and widespread quality standard adoption driven by government policies promoting domestic production capabilities. Steel industry modernization creates consistent demand for advanced refractory materials across integrated mills and specialty steel production facilities.

Automotive manufacturing growth drives primary market demand through domestic production expansion and regional export requirements for Latin American markets. Industrial equipment manufacturing sector expansion creates substantial opportunities for precision refractory applications and high-temperature material solutions. Construction sector development significantly increases machinery production volumes requiring quality assembly tools and advanced thermal protection systems.

Market development faces challenges including economic volatility affecting industrial investment decisions and currency fluctuation impacting imported high-performance material costs. Infrastructure development projects support manufacturing sector growth requiring precision assembly capabilities and advanced material applications. Regional trade agreements facilitate improved market access for precision refractory materials and technical services.

Strategic Market Considerations:

The United States market demonstrates steady growth with a 2.9% CAGR through comprehensive manufacturing sector revitalization and strategic reshoring initiatives bringing production back to domestic facilities. The market reflects an established industrial base with significant automation adoption trends and advanced manufacturing capabilities. Automotive sector modernization creates substantial demand for advanced assembly tools and high-performance refractory materials meeting stringent quality requirements.

Aerospace industry leadership requires precision refractory applications for critical component assembly and specialized high-temperature manufacturing processes. Defense manufacturing sector maintains consistent demand for quality-certified assembly procedures and advanced material specifications. Industrial automation adoption creates connectivity requirements for refractory tool integration with sophisticated manufacturing execution systems.

Manufacturing competitiveness initiatives encourage substantial investment in efficiency-enhancing tools and advanced material technologies. Quality standard compliance requires extensively documented assembly procedures supporting comprehensive certification processes and regulatory adherence. Export market participation necessitates strict international standard adherence and quality documentation requirements.

Market Dynamics:

The United Kingdom demonstrates market stability through comprehensive industrial modernization and strategic advanced manufacturing initiatives across key sectors. A 2.6% CAGR market value reflects an established manufacturing base with strong emphasis on quality standards and precision engineering applications. Aerospace sector strength creates substantial demand for precision refractory applications in critical assembly operations and high-temperature manufacturing processes.

Automotive production sector requires precision assembly tools for component manufacturing and final assembly operations meeting stringent quality and safety standards. Industrial equipment manufacturing maintains strict quality standards requirements for export markets and international competitiveness. Advanced manufacturing research initiatives continuously develop innovative applications for precision refractory tools and high-performance materials.

Brexit-related trade considerations create significant opportunities for domestic manufacturing growth requiring precision assembly capabilities and advanced material solutions. Government industrial strategy initiatives actively support advanced manufacturing technology adoption and innovation development. Post-Brexit manufacturing policies emphasize domestic capability development and advanced material technology investment.

Current Market Observations:

Japan maintains technological leadership through exceptional precision manufacturing excellence and comprehensive quality standard development across diverse industrial sectors. A 2.3% CAGR market value reflects a mature market with established precision refractory tool adoption across industries and advanced manufacturing capabilities. Automotive sector leadership creates consistent demand for advanced assembly technologies and high-performance refractory materials meeting strict quality requirements.

Industrial robot manufacturing sector requires precision assembly tools for component production and comprehensive testing applications ensuring reliable performance. Electronics industry utilizes specialized refractory applications for miniature component assembly and precision manufacturing processes. Quality management system development significantly influences global manufacturing practices and technology adoption standards.

Manufacturing technology exports include precision refractory tool requirements for international production facilities and technology transfer programs. Research and development initiatives continuously advance refractory measurement and application technologies. Supplier network development creates substantial opportunities for precision refractory tool integration and advanced material applications.

Market Status Indicators:

The high purity mullite powder market in Europe is projected to grow steadily, supported by strong industrial demand for refractory materials. The market value in Europe is estimated at USD 53.6 million in 2025, with Germany leading the region with a 35.8% share, driven by its robust steel production and advanced ceramics manufacturing sectors. The United Kingdom follows with a 17.5% market share, benefiting from industrial modernization and stringent quality standards in aerospace and automotive manufacturing. France holds 15.1% of the market, supported by expansions in glass production and precision manufacturing investments. Italy and Spain collectively represent 22.6% of European demand, spurred by infrastructure development and growing adoption of high-performance refractory materials. The Rest of Europe, including Nordic, BENELUX, and Eastern European countries, accounts for 9.0% of the market, backed by specialized manufacturing and growing industrial applications. This diverse regional distribution highlights Europe's significance as a key market for high purity mullite powders, driven by evolving industrial needs and stringent quality requirements across multiple sectors.

Market structure reflects moderate concentration with established global players maintaining significant market positions while regional competitors serve specialized segments. Competition style emphasizes technological differentiation, purity level advancement, and geographic market coverage expansion. Industry dynamics favor companies combining production innovation with comprehensive technical service offerings.

Tier 1 - Global Market Leaders: KCM Corporation and Baikowski dominate through comprehensive product portfolios, global distribution networks, and advanced purification capabilities. Competitive advantages include research and development resources, established customer relationships, and manufacturing scale economies. Market positions reflect quality reputation and technical expertise across diverse industrial applications.

Tier 2 - Specialized Technology Providers: Companies like Washington Mills and Tethon 3D focus on specific application segments or advanced ceramic markets through specialized product offerings. Competitive advantages include application expertise, technical service capabilities, and innovation focus. Market positioning emphasizes technical specialization and customer relationship development.

Tier 3 - Regional and Niche Competitors: Companies including Ruier, Equipment Engineers, and Bayville Chemical Supply serve local markets and specialized applications. Competitive advantages include cost competitiveness, regional service capabilities, and customization flexibility. Market participation focuses on price-sensitive segments and specialized application requirements.

Competitive dynamics between tiers involve purity level advancement competition, technical service capability development, and geographic expansion initiatives. Tier 1 companies compete through innovation and global reach while Tier 2 and 3 companies emphasize specialization and customer service differentiation.

The high purity mullite powder market is central to advanced manufacturing excellence, steel production efficiency, glass industry precision, and high-temperature industrial applications. With increasing demands for energy efficiency, environmental compliance, and superior thermal properties, the sector faces pressure to balance production costs, material purity levels, and manufacturing practices. Coordinated action from governments, industry bodies, OEMs/technology players, suppliers, and investors is essential to transition toward environmentally, technologically advanced, and globally competitive high purity mullite powder systems.

| Item | Value |

|---|---|

| Quantitative Units | USD 195.2 million |

| Purity Level | 99.97%, 99.95%, Others |

| Application | Steel, Glass, Advanced Ceramics, Others |

| Regions Covered | North America, Latin America, Europe, East Asia, South Asia & Pacific, Middle East & Africa |

| Countries Covered | United States, Canada, Mexico, Germany, United Kingdom, France, Italy, Spain, Nordic, BENELUX, China, Japan, South Korea, India, ASEAN, Australia, New Zealand, Brazil, Chile, Kingdom of Saudi Arabia, GCC Countries, Turkey, South Africa |

| Key Companies Profiled | KCM Corporation, Baikowski, Tethon 3D, Washington Mills, Ruier, Equipment Engineers, Bayville Chemical Supply Company, Kyoritsu Ceramic Materials, Saint-Gobain Ceramic Materials, Almatis GmbH, Imerys Ceramics, RHI Magnesita |

| Additional Attributes | Dollar sales by purity categories, regional demand trends across Asia Pacific, Europe, and North America, competitive landscape with player descriptions, adoption patterns across steel and glass industries, integration with advanced ceramics manufacturing, innovations in purification technology and particle size control, and development of specialized applications with enhanced thermal properties |

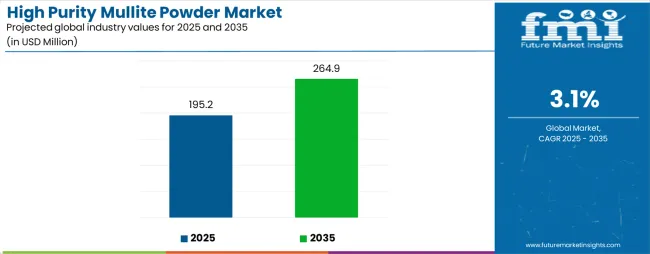

The global high purity mullite powder market is estimated to be valued at USD 195.2 million in 2025.

The market size for the high purity mullite powder market is projected to reach USD 264.9 million by 2035.

The high purity mullite powder market is expected to grow at a 3.1% CAGR between 2025 and 2035.

The key product types in high purity mullite powder market are purity: 99.97%, purity: 99.95% and others.

In terms of application, steel segment to command 42.3% share in the high purity mullite powder market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

High Purity Carbonyl Iron Powder (CIP) Market Size and Share Forecast Outlook 2025 to 2035

High Purity Nano Aluminum Oxide Powder Market Size and Share Forecast Outlook 2025 to 2035

High Purity Gas Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

High Purity Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

High Purity Process Systems for Semiconductor Market Size and Share Forecast Outlook 2025 to 2035

High Purity Chemical Filters Market Size and Share Forecast Outlook 2025 to 2035

High Purity Magnesium Citrate Market Size and Share Forecast Outlook 2025 to 2035

High Purity Tungsten Hexachloride Market Size and Share Forecast Outlook 2025 to 2035

High-purity Fluoropolymer Valves Market Size and Share Forecast Outlook 2025 to 2035

High Purity PFA Resins Market Size and Share Forecast Outlook 2025 to 2035

High Purity Lignin Market Size and Share Forecast Outlook 2025 to 2035

High Purity Boehmite Market Size and Share Forecast Outlook 2025 to 2035

High Purity Solvents Market Growth - Trends & Forecast 2025 to 2035

Understanding Market Share Trends in the High Purity Calcium Industry

High Purity Lead Market

High Purity Gases Market

High Protein Powders Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Ultra High Purity (UHP) Valve Market Size and Share Forecast Outlook 2025 to 2035

Ultra-high purity hydrofluoric acid Market

Photovoltaic Grade High Purity Crystalline Silicon Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA