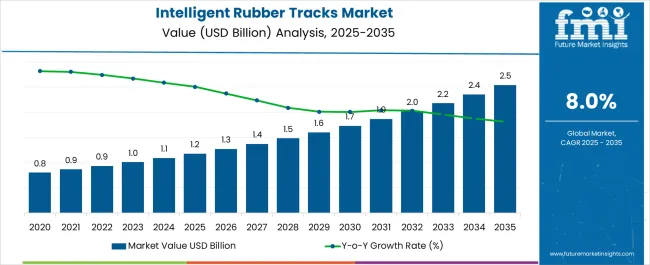

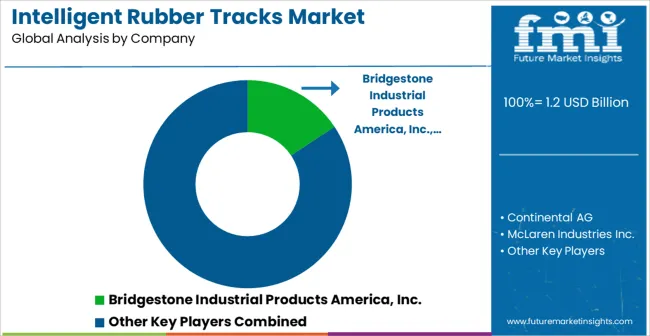

The Intelligent Rubber Tracks Market is estimated to be valued at USD 1.2 billion in 2025 and is projected to reach USD 2.5 billion by 2035, registering a compound annual growth rate (CAGR) of 8.0% over the forecast period.

| Metric | Value |

|---|---|

| Intelligent Rubber Tracks Market Estimated Value in (2025 E) | USD 1.2 billion |

| Intelligent Rubber Tracks Market Forecast Value in (2035 F) | USD 2.5 billion |

| Forecast CAGR (2025 to 2035) | 8.0% |

The Intelligent Rubber Tracks market is witnessing strong growth, driven by the rising adoption of advanced tracked mobility solutions in agriculture, construction, and industrial sectors. Demand is being supported by the need for enhanced operational efficiency, improved terrain adaptability, and reduced ground pressure in heavy machinery applications. Advancements in intelligent track design, sensor integration, and automated monitoring are enabling real-time performance optimization and predictive maintenance, which extend the operational lifespan of machinery.

The integration of durable rubber compounds with precision-engineered track systems is improving traction, load distribution, and safety across diverse working conditions. Growing mechanization in agriculture, coupled with increasing infrastructure development and modernization of industrial equipment, is further propelling market expansion.

The market is also benefiting from the focus on minimizing soil compaction, reducing fuel consumption, and improving machine reliability As organizations seek high-performance, adaptable, and low-maintenance mobility solutions, the Intelligent Rubber Tracks market is expected to sustain long-term growth, with innovation in track technologies and smart systems shaping future adoption.

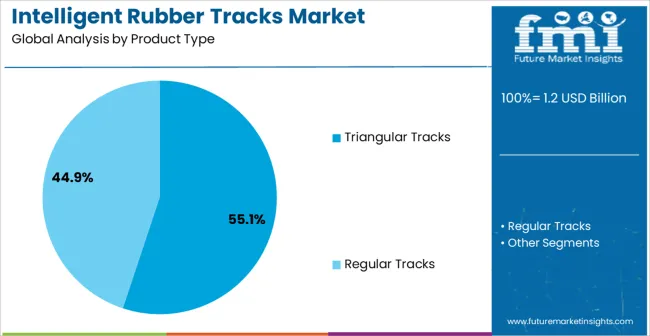

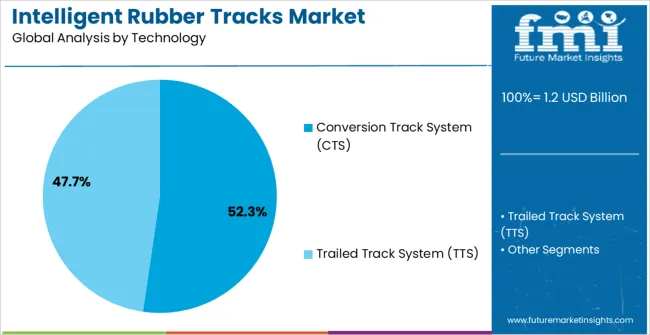

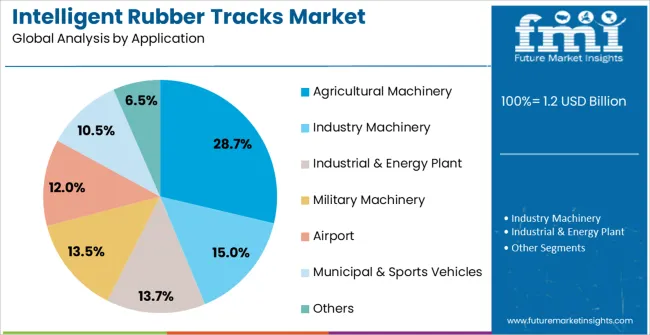

The intelligent rubber tracks market is segmented by product type, technology, application, and geographic regions. By product type, intelligent rubber tracks market is divided into Triangular Tracks and Regular Tracks. In terms of technology, intelligent rubber tracks market is classified into Conversion Track System (CTS) and Trailed Track System (TTS). Based on application, intelligent rubber tracks market is segmented into Agricultural Machinery, Industry Machinery, Industrial & Energy Plant, Military Machinery, Airport, Municipal & Sports Vehicles, and Others. Regionally, the intelligent rubber tracks industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The triangular tracks product type segment is projected to hold 55.1% of the market revenue in 2025, establishing it as the leading segment. Its dominance is being driven by the design’s superior load distribution, ground grip, and durability, which enhance the operational performance of tracked vehicles. Triangular tracks enable improved traction on uneven terrains, reduce slippage, and minimize soil compaction in agricultural and construction environments.

The ability to integrate with advanced sensor systems and automated monitoring technologies further strengthens their adoption by equipment manufacturers. Proven reliability, lower maintenance requirements, and extended service life contribute to preference among end users.

Continuous innovations in rubber compounds, track geometry, and reinforcement structures have further enhanced performance and adaptability across various applications As machinery operators increasingly prioritize efficiency, safety, and sustainability, triangular tracks are expected to maintain their market leadership, supported by their compatibility with intelligent track systems and high-performance applications.

The conversion track system (CTS) technology segment is anticipated to account for 52.3% of the market revenue in 2025, making it the leading technology segment. Growth is being driven by the ability of CTS to convert wheeled machinery into tracked vehicles, improving mobility, traction, and operational versatility. This technology reduces ground pressure, prevents soil compaction, and allows equipment to perform efficiently on diverse terrains, including soft and uneven surfaces.

Integration with sensors and intelligent control systems enables real-time monitoring of track tension, wear, and load distribution, enhancing predictive maintenance and reducing downtime. The modular and adaptable nature of CTS allows for retrofitting on existing machinery, offering cost advantages and operational flexibility.

Rising demand in agricultural, construction, and industrial sectors, coupled with increased focus on machine efficiency and productivity, further supports growth As mechanization and infrastructure development continue, CTS technology is expected to remain a primary driver of Intelligent Rubber Tracks adoption worldwide.

The agricultural machinery application segment is projected to hold 28.7% of the market revenue in 2025, establishing it as the leading application area. Growth in this segment is being fueled by the increasing adoption of intelligent tracked machinery to enhance operational efficiency, reduce soil compaction, and improve productivity. Intelligent rubber tracks provide superior traction and stability for tractors, harvesters, and other farming equipment, allowing operations on soft, uneven, or wet terrains without damaging the soil.

Integration with smart monitoring systems enables operators to track performance, predict maintenance needs, and optimize field operations. Rising investments in precision agriculture, mechanization, and large-scale farming operations are driving demand for these solutions.

Environmental and regulatory emphasis on soil preservation and sustainable farming practices further reinforces adoption As the agricultural sector increasingly relies on high-performance, durable, and intelligent mobility solutions, this application segment is expected to maintain its leadership, supported by continuous innovations in track design, materials, and smart system integration.

Increasing adoption of intelligent transportation systems and roaring demand for lightweight, low noise, less vibrating, high tractive materials are embellishing the global intelligent rubber tracks market during the forecast period. Rubber track is a type of circular tape made of rubber and fiber or metal composite materials mounted over the wheels of vehicles to assist the wheel’s movement in a condition where wheels are not helpful.

It is expected that rubber tracks may be substantial replacement of tires in heavy machineries used in the construction, mining, agriculture and military sectors. The intelligent rubber tracks provide better traction, with high stability, small ground pressure, low vibration, low noise floatation and durability without damaging the road at high speed.

Additionally, the braking distance is greatly reduced at slippery surfaces, such as ice, mud, snow and hard surface. It is expected that the top speed of the vehicle may increase by 8-10 km/h when the acceleration is increased by 15-25%, but this phenomenon totally depends on the type of vehicle and soil. Intelligent rubber track is mainly used in dozers, pavers and excavators.

Over the past few years, the intelligent rubber tracks are used in dozers, pavers, excavators, industrial ATVs/UTVs, robots, toys, shipping and space programs as well as tractors, harvester and forest machinery. The manufacturers are focusing towards advance technologies, for instance, Mattracks 400M1A1 rubber track for commercial vehicles weighing up to 40,000 pounds that require off-road mobility.

Furthermore, steel or rubber tracks are gaining remarkable traction in the market owing to their superior distinguishing traction on slippery conditions and hills. Moreover, it can work on hard ground surfaces and gravel without affecting the tread life of the rubber.

However, military machineries such as tanks, armored personnel carriers, military robots, IFV and recon are shifting towards rubber tracks as they offer higher mobility by reducing the weight, vibrations and increase the speed of the vehicle. On the other hand, regular tracks are mainly used in vehicles where conventional wheels cannot be used, for instance, in heavy construction, mining and military machineries. Triangular tracks are used primarily in small vehicles, such as cars, trucks, ATV and UTV as well in robots and rovers too.

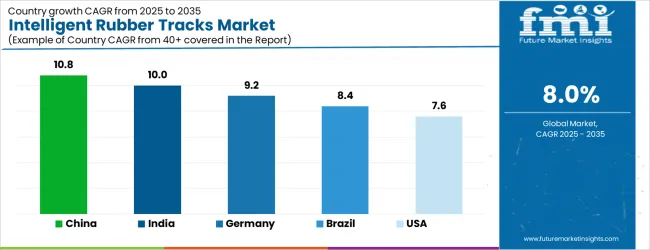

| Country | CAGR |

|---|---|

| China | 10.8% |

| India | 10.0% |

| Germany | 9.2% |

| Brazil | 8.4% |

| USA | 7.6% |

| UK | 6.8% |

| Japan | 6.0% |

The Intelligent Rubber Tracks Market is expected to register a CAGR of 8.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 10.8%, followed by India at 10.0%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 6.0%, yet still underscores a broadly positive trajectory for the global Intelligent Rubber Tracks Market.

In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 9.2%. The USA Intelligent Rubber Tracks Market is estimated to be valued at USD 429.1 million in 2025 and is anticipated to reach a valuation of USD 429.1 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 57.7 million and USD 37.0 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.2 Billion |

| Product Type | Triangular Tracks and Regular Tracks |

| Technology | Conversion Track System (CTS) and Trailed Track System (TTS) |

| Application | Agricultural Machinery, Industry Machinery, Industrial & Energy Plant, Military Machinery, Airport, Municipal & Sports Vehicles, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Bridgestone Industrial Products America, Inc., Continental AG, McLaren Industries Inc., Artic Investments S.A., Tempo International Inc., GRUPPO MINITOP srl, Chermack Machine Inc., GTW group, Jiangxi Jinlilong Rubber Track Co., Ltd., and Suntrac Industrial Co., Ltd. |

The global intelligent rubber tracks market is estimated to be valued at USD 1.2 billion in 2025.

The market size for the intelligent rubber tracks market is projected to reach USD 2.5 billion by 2035.

The intelligent rubber tracks market is expected to grow at a 8.0% CAGR between 2025 and 2035.

The key product types in intelligent rubber tracks market are triangular tracks and regular tracks.

In terms of technology, conversion track system (cts) segment to command 52.3% share in the intelligent rubber tracks market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Intelligent Touch Screen Cash Register Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Road Test Instruments Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Driving Technology Solution Market Size and Share Forecast Outlook 2025 to 2035

Rubber Molding Market Forecast Outlook 2025 to 2035

Intelligent Completion Market Size and Share Market Forecast and Outlook 2025 to 2035

Rubber Track for Defense and Security Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Cervical Massager Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Garment Hanging Conveyor System Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Rotary Kiln Monitoring Systems Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Multifunctional Laser Bird Repeller Market Size and Share Forecast Outlook 2025 to 2035

Rubber Frame Monitors Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Platform Management Interface (IPMI) Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Lighting Control Market Size and Share Forecast Outlook 2025 to 2035

Rubber Coating Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Enterprise Data Capture Software Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Rubber Anti-Tack Agents Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Vending Machine Market Insights – Demand, Size & Industry Trends 2025–2035

Intelligent Transportation System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Rubber to Metal Bonded Articles Market Analysis Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA