The intermediate bulk container (IBC) market is being driven by increasing demand for safe, cost-efficient, and reusable bulk packaging solutions across industries such as chemicals, pharmaceuticals, food & beverages, and agriculture. Growing emphasis on supply chain efficiency, sustainability, and the transport of hazardous and non-hazardous liquids and solids is fueling market adoption. The market is also being supported by stricter regulations surrounding material safety and global trade logistics.

IBC manufacturers are focusing on enhancing durability, reusability, and compatibility with automation systems. Innovations in composite and plastic IBCs, along with smart tracking technologies, are being introduced to improve container life cycles, reduce contamination risks, and enable real-time supply chain visibility. The demand for foldable and stackable IBCs is also increasing as businesses seek to optimize warehouse space and lower return logistics costs.

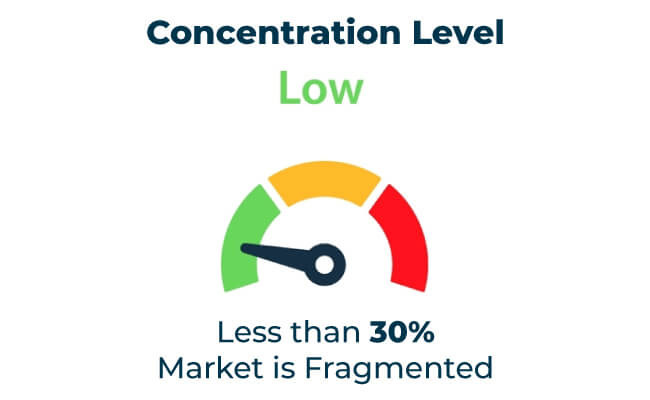

The market is moderately consolidated, with Tier 1 companies such as Greif, SCHÜTZ GmbH & Co. KGaA, and Mauser Packaging Solutions accounting for approximately 40–55% of the global market share. These players are being recognized for their global footprint, closed-loop reconditioning systems, and investments in sustainable packaging innovations. Tier 2 companies—including Time Technoplast, Hoover CS, and Snyder Industries—are being relied upon for regional supply capabilities, customer-specific design adaptations, and agile production models. Tier 3 manufacturers, often operating on a regional or local level, are contributing to the market by offering price-competitive solutions and catering to short-run or specialized application needs.

Strategic partnerships with chemical manufacturers, logistics providers, and food processors are being pursued to ensure alignment with industry-specific performance, hygiene, and compliance standards. Reconditioned IBCs are being increasingly adopted to meet sustainability targets and reduce carbon footprints.

With a balanced contribution across all tiers and growing demand from global and regional supply chains, the IBC market is being positioned as a scalable, safe, and environmentally responsible bulk packaging solution.

Global Market Share & Industry Share (%)

| Category | Market Share (%) |

|---|---|

| Top 3 Players (Mauser Packaging, Greif, Schütz) | 14% |

| Rest of Top 5 Players (Time Technoplast, Thielmann) | 08% |

| Next 5 of Top 10 Players | 07% |

Type of Player & Industry Share (%)

| Type of Player | Market Share (%) |

|---|---|

| Top 10 Players | 29% |

| Next 20 Players | 48% |

| Remaining Players | 23% |

Year-on-Year Leaders

The IBC market will grow through advancements in material science, digital integration, and automation. Companies prioritizing sustainability and leveraging smart technologies will lead the market. Automation and AI will optimize production, improve safety, and reduce costs.

| Tier | Key Companies |

|---|---|

| Tier 1 | Mauser Packaging, Greif, Schütz |

| Tier 2 | Time Technoplast, Thielmann |

| Tier 3 | Snyder Industries, Hoover CS, Schoeller Allibert |

The intermediate bulk container market is poised for significant growth, driven by sustainability trends, technological advancements, and increasing industrial demand. Companies investing in reusable designs, smart technologies, and durable materials will secure a competitive edge in this dynamic market.

Key Definitions

Abbreviations

Research Methodology

This report relies on primary research, secondary data analysis, and market modeling. Industry experts and key stakeholders validated insights.

Market Definition

The intermediate bulk container market includes innovative and sustainable storage and transportation solutions for chemicals, food and beverage, pharmaceuticals, and logistics, addressing efficiency and environmental goals.

Demand for reusable, durable, and cost-effective containers drives market growth.

the market is projected to reach USD 46 billion, growing at a compound annual growth rate (CAGR) of 5.5%.

Mauser Packaging, Greif, and Schütz lead the market with innovative and sustainable solutions.

High initial costs, regulatory complexity, and limited awareness pose challenges.

Opportunities include smart tracking technologies, industrial growth, and sustainability initiatives.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Japan Intermediate Bulk Container Market Insights – Growth & Forecast 2023-2033

Korea Intermediate Bulk Container Market Growth – Trends & Forecast 2023-2033

Western Europe Intermediate Bulk Container Market Growth – Trends & Forecast 2023-2033

Intermediate Bulk Container (IBC) Market Forecast and Outlook 2025 to 2035

LNG Intermediate Fluid Vaporizer (IFV) Market Size and Share Forecast Outlook 2025 to 2035

Hot Melt Intermediate Joint Market Size and Share Forecast Outlook 2025 to 2035

Polyamide Intermediate Chemicals Market Size and Share Forecast Outlook 2025 to 2035

Automotive Intermediate Shaft Market Growth - Demand, Trends & Forecast 2025 to 2035

Cyclic Crude Intermediate And Gum Market Size and Share Forecast Outlook 2025 to 2035

Preformulation intermediates Market Size and Share Forecast Outlook 2025 to 2035

Pharmaceutical Intermediates Market Analysis - Size, Share & Forecast 2025 to 2035

Market Share Distribution Among FIBC (Flexible Intermediate Bulk Container) Manufacturers

UK Pharmaceutical Intermediate Market Report – Trends, Demand & Outlook 2025-2035

China Pharmaceutical Intermediate Market Insights – Trends, Demand & Growth 2025-2035

India Pharmaceutical Intermediate Market Analysis – Demand, Growth & Forecast 2025-2035

Germany Pharmaceutical Intermediate Market Outlook – Size, Share & Innovations 2025-2035

United States Pharmaceutical Intermediate Market Trends – Size, Demand & Forecast 2025-2035

Bulk Bag Market Forecast and Outlook 2025 to 2035

Bulk Terminal Market Forecast and Outlook 2025 to 2035

Bulk Molding Compounds Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA