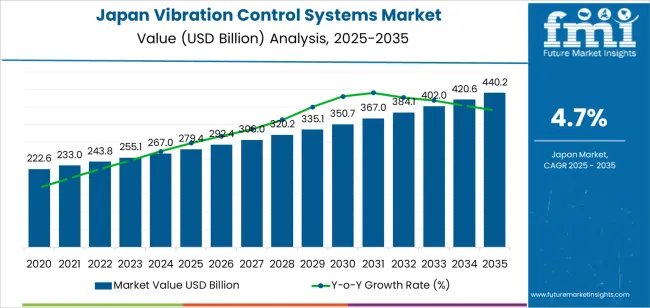

The demand for vibration control systems in Japan is expected to grow from USD 279.4 million in 2025 to USD 440.2 million by 2035, reflecting a compound annual growth rate (CAGR) of 4.7%. Vibration control systems are widely used in industries such as automotive, construction, aerospace, and manufacturing to minimize the impact of vibrations on equipment, machinery, and structures. As Japan’s industrial and infrastructure sectors continue to expand, the demand for effective vibration control solutions will increase. These systems play a critical role in enhancing the longevity, performance, and safety of equipment and structures by mitigating the harmful effects of excessive vibrations.

Key drivers for this growth include the increasing need for high-precision machinery, advancements in construction technologies, and the expanding adoption of automation in manufacturing processes. The rising emphasis on noise and vibration reduction in urban planning and construction projects will further boost the demand for vibration control systems. Japan’s focus on maintaining and upgrading its infrastructure, including the development of transportation systems, industrial facilities, and residential buildings, will continue to create demand for advanced vibration mitigation technologies.

Between 2025 and 2030, the demand for vibration control systems in Japan is expected to grow steadily, increasing from USD 279.4 million to USD 292.4 million. This moderate growth will be driven by the expansion of key industries such as automotive, construction, and manufacturing. Innovations in vibration control technologies, along with the rise of more sophisticated machinery and infrastructure, will contribute to this demand. As industries continue to prioritize efficiency, precision, and machinery longevity, the adoption of advanced vibration control systems will become more widespread, ensuring optimal performance and safety in various applications.

From 2030 to 2035, the growth in demand is expected to accelerate, with the industry expanding from USD 292.4 million to USD 440.2 million. This sharp increase can be attributed to continued infrastructure development, increasing industrial automation, and the growing need for precision in high-tech engineering applications. The construction sector, in particular, will see a significant rise in demand as urbanization and infrastructure projects continue to expand. The automotive and aerospace industries will increasingly rely on vibration control systems to enhance the performance of more sophisticated machinery. As Japan’s industrial landscape evolves and the need for high-performance machinery grows, vibration control systems will play an essential role in ensuring the stability and reliability of equipment.

| Metric | Value |

|---|---|

| Demand for Vibration Control Systems in Japan Value (2025) | USD 279.4 billion |

| Demand for Vibration Control Systems in Japan Forecast Value (2035) | USD 440.2 billion |

| Demand for Vibration Control Systems in Japan Forecast CAGR (2025 to 2035) | 4.7% |

The demand for vibration control systems in Japan is increasing due to their critical role in enhancing the performance and longevity of machinery and structures across various industries. Vibration control systems are used in applications ranging from automotive and manufacturing to construction and electronics, where they help reduce noise, prevent damage, and ensure smooth operation of equipment. As Japan continues to lead in technology and manufacturing innovation, the need for advanced vibration control solutions is growing.

A key driver of this demand is the growing focus on reducing noise pollution and enhancing operational efficiency. In sectors such as automotive and electronics, vibration control systems are essential for improving product quality and ensuring the reliability of machines and devices. As Japan’s industrial sector continues to invest in automation and advanced manufacturing processes, vibration control systems are becoming increasingly vital for maintaining high performance and minimizing wear and tear on machinery.

Japan's strong focus on infrastructure development and seismic resilience is contributing to the growth of vibration control systems in the construction sector. As Japan faces frequent seismic activity, vibration control technologies are increasingly being integrated into building designs to minimize the impact of earthquakes and improve the safety and stability of structures. With advancements in material science and technology, the demand for vibration control systems is expected to continue growing steadily through 2035, driven by both technological innovation and the need for enhanced safety and efficiency across industries.

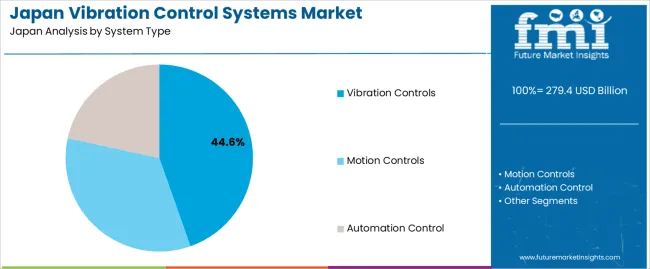

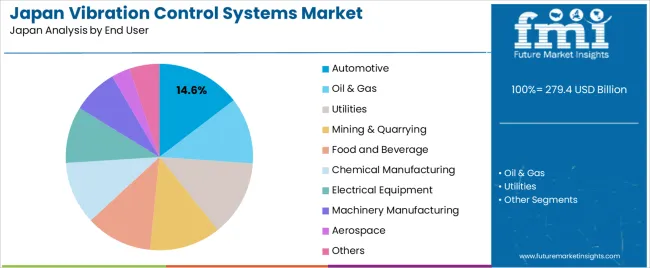

Demand for vibration control systems in Japan is segmented by system type, end user, and sales type. By system type, demand is divided into vibration controls, motion controls, and automation control. The demand is also segmented by end user, including automotive, oil & gas, utilities, mining & quarrying, food and beverage, chemical manufacturing, electrical equipment, machinery manufacturing, aerospace, and others. In terms of sales type, demand is divided into OEM (original equipment manufacturer) and aftermarket. Regionally, demand is divided into Kanto, Kinki, Chubu, Kyushu & Okinawa, Tohoku, and the Rest of Japan.

Vibration control systems account for 45% of the demand for vibration control systems in Japan. These systems are designed to minimize the harmful effects of vibrations in various industrial applications, ensuring smoother operations and improved equipment longevity. Vibration control systems are widely used in machinery, automotive, aerospace, and other industries where vibration can impact the performance and safety of machinery or vehicles. They help reduce maintenance costs by protecting sensitive equipment from wear and tear caused by excessive vibrations. As industries continue to focus on improving efficiency, safety, and operational reliability, the demand for vibration control systems has increased. The versatility of vibration control systems, coupled with their ability to enhance the performance and durability of equipment, ensures their dominance in the industry, particularly in sectors like automotive, aerospace, and machinery manufacturing.

The automotive industry accounts for 14.6% of the demand for vibration control systems in Japan. Automotive manufacturers use vibration control systems to ensure the smooth operation of vehicles, reduce noise, and enhance comfort for passengers. These systems are critical in minimizing the vibrations caused by engines, suspension systems, and other mechanical components. With the rising demand for high-performance vehicles, the need for effective vibration control systems has grown. Automotive companies are increasingly focusing on producing vehicles with improved driving comfort, noise reduction, and better fuel efficiency, which requires advanced vibration control technologies. As electric vehicles (EVs) and hybrid vehicles gain traction, the automotive sector’s demand for vibration control systems is expected to increase, driven by the need for quiet, energy-efficient, and high-performance vehicles. This makes automotive the leading end-user sector for vibration control systems in Japan.

Key drivers include the expansion of advanced manufacturing locally and for export requiring precise vibration isolation in semiconductor fabs, automotive production lines and smart‑factory setups. Japan’s infrastructure aging and seismic risk spur demand for building‑ and equipment‑level vibration mitigation solutions. Technological upgrade cycles in rail, aerospace and industrial plants also boost demand. Restraints include high upfront cost of active or high‑precision isolation systems, long product life‑cycles in many Japanese industries which slow replacement demand, and competition from simpler passive solutions which may suffice in less‑critical settings.

In Japan demand for vibration‑control systems are growing because manufacturers of electronics, automotive and precision equipment need robust vibration mitigation to ensure high yield, accuracy and reliability. Infrastructure and industrial plants also face increased regulatory and safety demands especially given Japan’s seismic activity so vibration control becomes an integral requirement in design and retrofit. Smart‑factory implementations and the move towards micro‑vibration‑sensitive production (e.g., semiconductors) further raise the need. These factors combine to drive higher investment in vibration‑control systems across multiple sectors.

Technological innovations are enhancing the appeal of vibration‑control systems in Japan by introducing active isolation, smart materials and integrated sensor/monitoring platforms. Examples include pneumatic active vibration isolators for low‑frequency control (for cleanrooms), tuned‑mass dampers for buildings and bridges, and IoT‑enabled vibration sensors feeding predictive maintenance systems. Lightweight composites and advanced elastomer isolators improve performance and reduce footprint. These developments enable applications in more demanding environments and help manufacturers justify higher investment in vibration‑control systems.

Despite rising interest, adoption of high‑end vibration‑control systems in Japan faces several obstacles. One is cost, the capital and integration expense of active or smart isolation systems can be prohibitive for smaller facilities. Another is complexity: integrating vibration‑control systems into existing equipment or infrastructure may require redesign, downtime and specialist skills. Also, many industries operate with long‑equipment lifecycles, reducing the frequency of retrofit opportunities. Finally, in less critical applications simpler passive solutions may capture the majority share, limiting the uptake of more advanced vibration‑control systems.

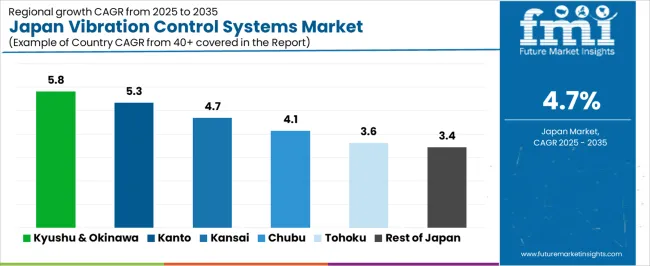

| Region | CAGR (%) |

|---|---|

| Kyushu & Okinawa | 5.8 |

| Kanto | 5.3 |

| Kinki | 4.7 |

| Chubu | 4.1 |

| Tohoku | 3.6 |

| Rest of Japan | 3.4 |

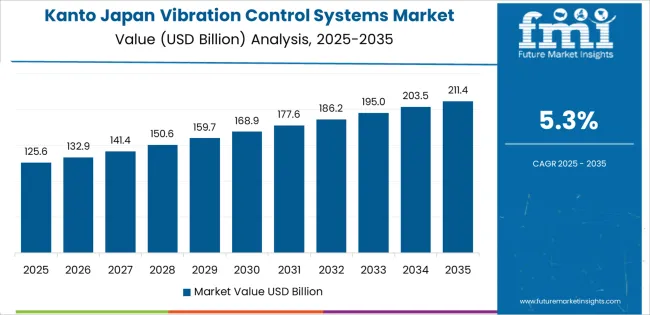

Demand for vibration control systems in Japan is increasing across all regions, with Kyushu & Okinawa leading at a 5.8% CAGR. Kanto follows with a 5.3% CAGR, driven by its industrial and commercial centers, particularly Tokyo and Yokohama. The Kinki region shows a 4.7% CAGR, fueled by its automotive, machinery, and electronics industries. Chubu experiences a 4.1% CAGR, with demand driven by its strong automotive manufacturing presence, particularly in Nagoya. Tohoku is seeing a 3.6% CAGR, supported by its manufacturing and infrastructure projects. The Rest of Japan has the lowest growth at 3.4%, with steady demand driven by regional industries and infrastructure development.

Kyushu & Okinawa are experiencing the highest demand for vibration control systems in Japan, with a 5.8% CAGR. This growth is largely driven by the region’s thriving manufacturing and infrastructure sectors. Kyushu, in particular, has a strong industrial base, with significant investments in automotive, electronics, and energy industries. These sectors require high-performance vibration control systems to improve equipment efficiency, safety, and reduce wear and tear. The region is also home to key manufacturing plants and production facilities, which utilize vibration control systems to minimize downtime and increase productivity. As these industries continue to expand and modernize, the demand for vibration control systems in Kyushu & Okinawa will remain strong. The ongoing focus on improving industrial processes and ensuring smoother operations in manufacturing environments further supports the demand for these systems.

Kanto is experiencing steady demand for vibration control systems in Japan, with a 5.3% CAGR. The region, which includes major industrial and commercial centers like Tokyo and Yokohama, has a well-established manufacturing sector that drives the demand for these systems. The growing number of high-tech industries, including electronics, robotics, and automotive manufacturing, rely heavily on vibration control systems to ensure precision and reduce mechanical failures. As Japan’s industries shift towards automation and high-tech production methods, the need for reliable vibration control systems has increased. Kanto’s dense urban development and focus on infrastructure projects, such as high-speed rail and construction, further contribute to this demand. The region’s emphasis on improving operational efficiency and enhancing industrial performance will continue to drive the adoption of vibration control technologies, making Kanto a key industry for these systems in Japan.

Kinki is seeing moderate demand for vibration control systems in Japan, with a 4.7% CAGR. The region is a key hub for Japan’s automotive, machinery, and electronics industries, all of which require vibration control to maintain product quality and operational efficiency. Cities like Osaka and Kyoto are central to Japan’s manufacturing base, and the growing demand for vibration isolation in industrial machinery, construction equipment, and transportation systems supports the region’s need for these technologies. As the automotive and electronics industries increasingly focus on minimizing vibration to improve product precision and performance, the adoption of vibration control systems is becoming essential. Kinki’s infrastructure projects, including the expansion of transportation networks and urban development, are driving demand for these systems to ensure operational stability and safety. With continued industrial growth and technological advancements, Kinki remains an important region for vibration control system demand.

Chubu is experiencing steady demand for vibration control systems in Japan, with a 4.1% CAGR. The region is home to significant automotive manufacturing centers like Nagoya, where companies such as Toyota are major drivers of demand for vibration control technologies. The automotive sector in Chubu requires vibration control systems to ensure smooth operation, enhance product quality, and reduce noise in vehicles. Chubu’s growing focus on infrastructure development and energy projects, including renewable energy installations, further contributes to the need for these systems. Vibration control plays a crucial role in the design and construction of machinery, electronics, and industrial equipment in Chubu. As the region continues to see investments in new technologies, including automation and robotics, the demand for vibration control systems is expected to remain strong. With steady industrial growth, Chubu is well-positioned to continue adopting advanced vibration control solutions in various sectors

Tohoku is experiencing moderate demand for vibration control systems in Japan, with a 3.6% CAGR. The region’s industrial base, particularly in manufacturing and infrastructure projects, drives the demand for vibration control technologies. Tohoku’s automotive and machinery sectors require vibration control systems to enhance product quality and maintain smooth operational efficiency. The region’s focus on infrastructure development, including large-scale construction projects, has led to an increased need for vibration control to protect structures and machinery from unwanted vibrations. As Tohoku continues to rebuild and modernize following past natural disasters, there is a strong emphasis on utilizing advanced technologies, such as vibration control systems, to enhance safety and operational performance. With growing industrial activity and continued investment in infrastructure, the demand for vibration control systems in Tohoku is expected to see moderate growth in the coming years.

The Rest of Japan is experiencing the lowest demand for vibration control systems in Japan, with a 3.4% CAGR. While not as industrially dense as regions like Kanto or Kyushu, the Rest of Japan continues to see steady demand for vibration control systems in sectors such as agriculture, manufacturing, and transportation. Smaller manufacturing plants and regional industries that rely on machinery and construction equipment are key contributors to this demand. As regional infrastructure projects, including transportation and building construction, continue to grow, there is an increasing need for vibration control systems to ensure safety and operational efficiency. The Rest of Japan’s adoption of these systems is driven by the continued need to improve machinery performance, reduce downtime, and ensure the safety of buildings and infrastructure. Despite the slower growth rate, the demand for vibration control systems in the Rest of Japan is expected to remain steady.

In Japan, demand for vibration control systems is driven by a wide range of industries including automotive manufacturing, precision industrial machinery, aerospace, and civil infrastructure where vibration presents risks to performance, durability and safety. These systems comprising isolators, mounts, dampers and active control solutions help reduce unwanted motion and structural resonance in highly engineered applications. With Japan’s reputation for high‑precision manufacturing and critical infrastructure, the uptake of advanced vibration control hardware is strong.

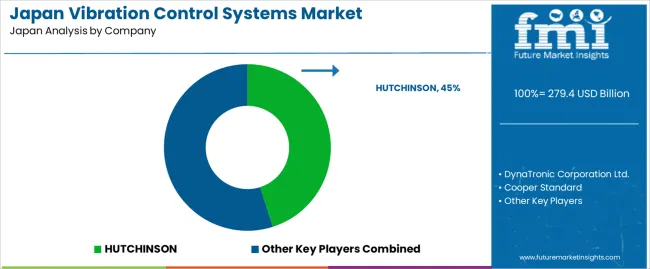

Major suppliers competing in the Japanese vibration control systems segment include Hutchinson (45.1% share), Dynatron Corporation Ltd., Cooper Standard, GERB and Technical Manufacturing Corporation. These companies differentiate through their technological capabilities in high‑performance isolators, materials tailored for harsh environments, global logistic networks and close collaboration with leading OEMs. Hutchinson’s leadership reflects its scale, deep specialization in vibration‑multipliers and strong integration with automotive and industrial customers in Japan.

Competitive dynamics in this segment are shaped by several factors. First, innovation in material technologies (such as advanced rubbers, composites, and active control elements) and precision engineering remains a key differentiator. Second, Japan’s high standards for product reliability, as well as the need to support stringent vibration and noise regulations in vehicles, infrastructure and equipment, create a barrier for lesser‑equipped entrants.

Third, small‑to‑mid‑sized vendors may struggle with high up‑front tooling and certification costs and the dominance of incumbents with established supply‑chains and service offerings. Suppliers that combine technical leadership, trusted OEM partnerships and efficient local service are best positioned to grow in Japan’s vibration control systems landscape.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD billion |

| System Type | Vibration Controls, Motion Controls, Automation Control |

| End User | Automotive, Oil & Gas, Utilities, Mining & Quarrying, Food and Beverage, Chemical Manufacturing, Electrical Equipment, Machinery Manufacturing, Aerospace, Others |

| Sales Type | OEM, Aftermarket |

| Region | Kyushu & Okinawa, Kanto, Kinki, Chubu, Tohoku, Rest of Japan |

| Countries Covered | Japan |

| Key Companies Profiled | HUTCHINSON, DynaTronic Corporation Ltd., Cooper Standard, GERB, Technical Manufacturing Corporation |

| Additional Attributes | Dollar sales by system type, end user, and sales type; regional CAGR and adoption trends; demand trends in vibration control systems; growth in automotive, oil & gas, utilities, and manufacturing sectors; technology adoption for vibration and motion control solutions; vendor offerings including OEM and aftermarket services; regulatory influences and industry standards |

The demand for vibration control systems in japan is estimated to be valued at USD 279.4 billion in 2025.

The market size for the vibration control systems in japan is projected to reach USD 440.2 billion by 2035.

The demand for vibration control systems in japan is expected to grow at a 4.7% CAGR between 2025 and 2035.

The key product types in vibration control systems in japan are vibration controls, motion controls and automation control.

In terms of end user, automotive segment is expected to command 14.6% share in the vibration control systems in japan in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Vibration Control Systems Market Growth - Trends & Forecast 2025 to 2035

Demand for Vibration Control Systems in USA Size and Share Forecast Outlook 2025 to 2035

Door Controller Systems Market

Tower Vibration Control System Market Size and Share Forecast Outlook 2025 to 2035

Version Control Systems Market Size and Share Forecast Outlook 2025 to 2035

Driveline Control Systems and Devices Market Size and Share Forecast Outlook 2025 to 2035

Japan Sleep Apnea Diagnostic Systems Market Report – Size, Demand & Outlook 2025-2035

Aspiration Control Systems Market Size and Share Forecast Outlook 2025 to 2035

Valve Remote Control Systems Market Analysis by Type, Application and Region - Forecast for 2025 to 2035

Train Control and Management Systems Market Size and Share Forecast Outlook 2025 to 2035

EV Telematics Control Systems Market Size and Share Forecast Outlook 2025 to 2035

Competitive Overview of Air Pollution Control Systems Providers

Air Pollution Control Systems Market – Applications & Growth Forecast 2025-2035

Combustion Controls, Equipment & Systems Market – Forecast 2025 to 2035

Electronic Control Unit in Automotive Systems Market Size and Share Forecast Outlook 2025 to 2035

Automotive Touch Screen Control Systems Market Growth - Trends & Forecast 2025 to 2035

Demand for Palletizing Systems in Japan Size and Share Forecast Outlook 2025 to 2035

Demand for Self-checkout Systems in Japan Size and Share Forecast Outlook 2025 to 2035

Card-Based Electronic Access Control Systems Market Growth - Forecast 2025 to 2035

Demand for Patient-Controlled Analgesia Pumps in Japan Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA