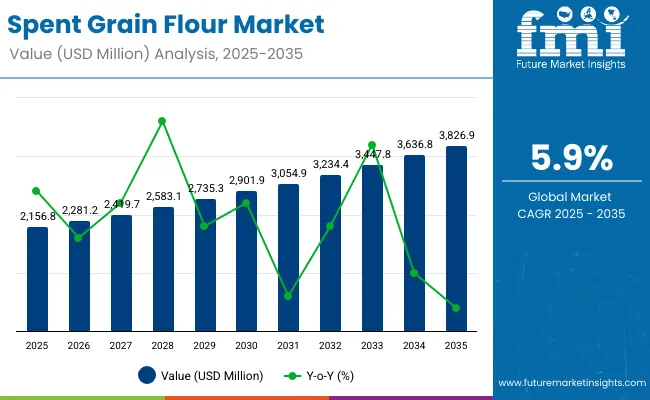

The global spent grain flour market is projected to reach USD 3,826.9 million by 2035, recording an absolute increase of USD 1,670.1 million over the forecast period. The market is valued at USD 2,156.8 million in 2025 and is set to rise at a CAGR of 5.9% during the assessment period. The overall market size is expected to grow by nearly 1.8 times during the same period, supported by increasing demand for upcycled food ingredients and protein-enriched formulations worldwide, driving demand for dried processing methods and increasing investments in bakery applications and functional ingredient sectors globally. Limited processing infrastructure in developing markets and supply chain complexity may pose obstacles to market expansion.

Spent grain flour represents a value-added byproduct derived from brewery operations, specifically the solid residue remaining after wort extraction during beer production processes. The flour maintains high protein content ranging from 18-25%, alongside significant dietary fiber levels and essential amino acids that position it as a premium functional ingredient across diverse food applications. Modern processing techniques transform wet spent grains into shelf-stable flour through controlled drying, milling, and standardization procedures that preserve nutritional integrity while extending storage capabilities.

Spent Grain Flour Market Key Takeaways

| Metric | Value |

|---|---|

| Market Value (2025) | USD 2,156.8 million |

| Market Forecast Value (2035) | USD 3,826.9 million |

| Forecast CAGR (2025-2035) | 5.9% |

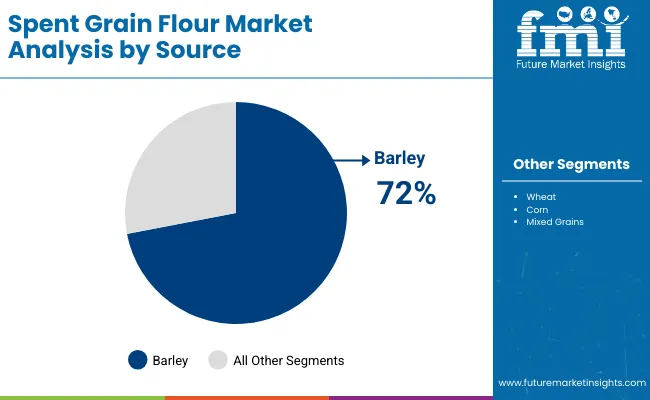

Primary source materials include barley spent grains, which dominate production volumes due to widespread brewing industry utilization of malted barley in beer manufacturing. Secondary sources encompass wheat-based brewing operations, corn-derived materials from adjunct brewing processes, and mixed grain combinations from specialty brewing applications. Each source material contributes distinct nutritional profiles and functional characteristics that influence end-product performance across applications.

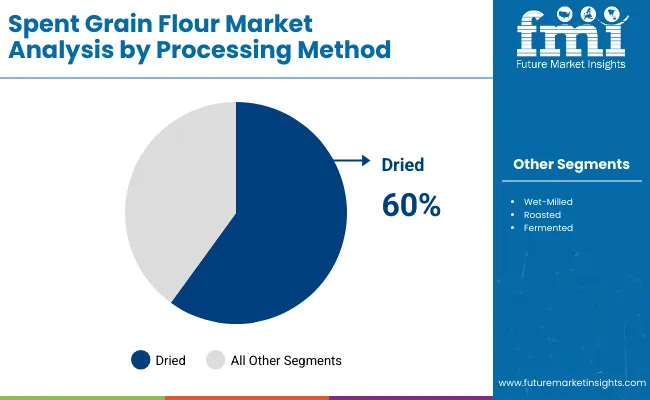

Processing methodologies encompass four principal approaches tailored to specific application requirements and quality specifications. Dried processing represents the most common technique, utilizing controlled dehydration systems to reduce moisture content below 10% while maintaining protein functionality and fiber structure. Wet-milled approaches preserve higher moisture levels for immediate processing applications requiring enhanced binding properties and texture modification capabilities.

Roasted processing methods apply thermal treatment to develop flavor profiles and improve shelf stability while creating distinctive sensory characteristics preferred in specialty bakery applications. Fermented processing utilizes controlled bacterial cultures to enhance protein digestibility, develop probiotic properties, and create unique flavor compounds that differentiate products in health-focused market segments.

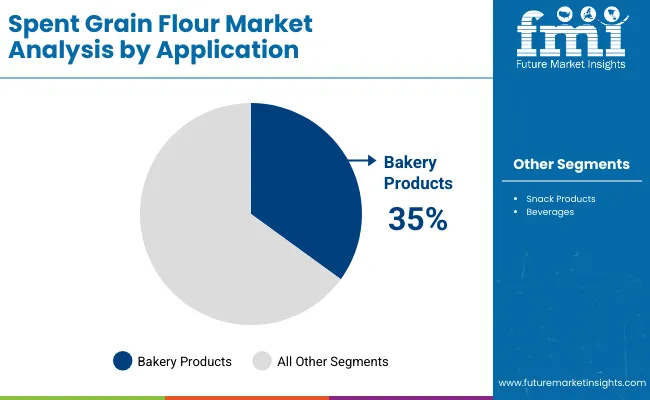

Bakery applications represent the largest consumption category, leveraging spent grain flour's protein content and fiber density to enhance nutritional profiles in bread, cookies, muffins, and crackers. The ingredient's water retention properties improve texture and extend freshness in baked goods while contributing sustainable ingredient credentials that appeal to environmentally conscious consumers. Protein-enriched bread formulations typically incorporate 10-15% spent grain flour replacement levels without compromising sensory acceptability.

Between 2025 and 2030, the spent grain flour market is projected to expand from USD 2,156.8 million to USD 2,901.9 million, resulting in a value increase of USD 745.1 million, which represents 44.6% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for upcycled food ingredients and protein-enriched formulations, product innovation in processing technologies and functional applications, as well as expanding integration with bakery manufacturing and snack production applications. Companies are establishing competitive positions through investment in processing capabilities, advanced drying technologies, and strategic market expansion across food manufacturing, pet food, and nutraceutical applications.

From 2030 to 2035, the market is forecast to grow from USD 2,901.9 million to USD 3,826.9 million, adding another USD 925.0 million, which constitutes 55.4% of the overall ten-year expansion. This period is expected to be characterized by the expansion of specialized applications, including advanced functional ingredient formulations and protein-enriched products tailored for specific nutritional requirements, strategic collaborations between spent grain flour producers and food companies, and an enhanced focus on processing standardization and automated production protocols. The growing emphasis on circular economy principles and upcycled ingredient applications will drive demand for comprehensive spent grain flour solutions across diverse food processing applications.

The spent grain flour market grows by enabling food manufacturers and bakery companies to optimize production processes while accessing specialized protein-enriched ingredients without substantial in-house processing infrastructure investment. Manufacturing companies and food operators face mounting pressure to develop advanced nutritional formulations and functional food products while managing complex ingredient sourcing requirements, with high-quality spent grain flour typically providing 40-60% protein enhancement compared to conventional flour alternatives, making advanced dried processing methods essential for competitive market positioning. The food industry's need for upcycled ingredients and application-specific nutritional capabilities creates demand for comprehensive spent grain flour solutions that can provide superior protein content, maintain consistent processing standards, and ensure reliable operation without compromising product quality or operational effectiveness.

Government initiatives promoting circular economy principles and food waste reduction drive adoption in food manufacturing, bakery production, and snack applications, where ingredient quality has a direct impact on product performance and long-term market effectiveness. Complex supply coordination constraints during large-scale production projects and the expertise requirements for processing integration may limit accessibility among smaller manufacturing companies and developing regions with limited technical infrastructure for advanced food processing systems.

The market is segmented by source, processing method, application, sales channel, product claim, end use, and region. By source, the market is divided into barley, wheat, corn, and mixed grains. Based on processing method, the market is categorized into dried, wet-milled, roasted, and fermented. By application, the market includes bakery products (bread, cookies, muffins, crackers), snack products (chips, extruded snacks), beverages (smoothie powders, malted drinks), animal feed, pet food, nutraceuticals, and functional ingredients. By sales channel, the market is divided into B2B (food & beverage manufacturers, pet food producers, foodservice) and B2C (online retail, health food stores, specialty grocery stores). Based on product claim, the market is categorized into high fiber, protein-enriched, and upcycled ingredient. By end use, the market includes human consumption, animal nutrition, and industrial applications. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

The barley segment represents the dominant force in the spent grain flour market, capturing approximately 72.0% of total market share in 2025. This established source category encompasses solutions featuring advanced nutritional characteristics and specialized processing applications, including high-performance protein profiles and enhanced fiber content that enable superior food processing benefits and nutritional outcomes across all manufacturing applications. The barley segment's market leadership stems from its proven availability through widespread brewing operations, with solutions capable of addressing diverse food processing requirements while maintaining consistent quality standards and processing effectiveness across all production environments.

The wheat segment maintains an 10.0% market share, serving specialized applications that require specific protein profiles with particular functional characteristics for targeted food formulations. The corn segment accounts for 8.0% market share, while mixed grains capture 10.0%, offering diverse nutritional profiles for specialized food processing applications and specific health formulations.

Key source advantages driving the barley segment include:

Dried processing applications dominate the spent grain flour market with approximately 60.0% market share in 2025, reflecting the critical role of moisture control in supporting extended shelf life requirements and storage stability worldwide. The dried segment's market leadership is reinforced by processing efficiency trends, ingredient handling requirements, and rising needs for shelf-stable capabilities in food manufacturing across developed and emerging markets.

The wet-milled segment represents 15.0% market share through specialized requirements for immediate processing applications, enhanced binding properties, and texture modification capabilities. This segment benefits from growing fresh application integration demand that requires specific processing requirements, quality standards, and performance optimization protocols in food processing markets.

The roasted segment accounts for 15.0% market share, serving flavor development applications, specialty bakery products, and enhanced sensory characteristics across various consumer sectors. The fermented segment captures 10.0% market share through probiotic enhancement, protein digestibility improvement, and specialized health applications.

Key market dynamics supporting processing method growth include:

Bakery products applications dominate the spent grain flour market with approximately 35.0% market share in 2025, reflecting the critical role of protein-enriched ingredients in supporting nutritional enhancement requirements and product differentiation worldwide. The bakery segment's market leadership is reinforced by increasing health-conscious consumption trends, protein fortification requirements, and rising needs for fiber enhancement capabilities in bread, cookies, muffins, and crackers across developed and emerging markets.

The snack products segment represents the second-largest application category, capturing 18.0% market share through specialized requirements for protein fortification, binding properties, and flavor enhancement applications. This segment benefits from growing snack market integration demand that requires specific nutritional requirements, processing standards, and performance optimization protocols in chip and extruded snack manufacturing.

The beverages segment accounts for 12.0% market share, serving smoothie powders and malted drink applications. Animal feed captures 15.0% market share, while pet food represents 8.0%. The nutraceuticals segment holds 5.0% market share, and functional ingredients account for 7.0% through fiber boosters and specialized health applications.

Key market dynamics supporting application growth include:

The market is driven by three concrete demand factors tied to food processing and nutritional outcomes. First, circular economy principles and food waste reduction initiatives create increasing demand for upcycled ingredient systems, with environmental benefit awareness growing in major food manufacturing markets worldwide, requiring comprehensive processing infrastructure. Second, government initiatives promoting protein fortification and functional food development drive increased adoption of spent grain flour compounds, with many countries implementing nutritional enhancement programs and regulatory frameworks for upcycled ingredient advancement by 2030. Third, technological advancements in drying processes and ingredient standardization enable more efficient and effective production methods that improve product quality while reducing processing costs and operational complexity.

Market restraints include complex supply coordination requirements and processing costs for spent grain flour platforms that can challenge market participants in developing compliant manufacturing capabilities, particularly in regions where regulatory pathways for upcycled ingredients remain evolving and uncertain. Technical complexity of drying systems and standardization requirements pose another challenge, as spent grain flour demands sophisticated processing methods and quality controls, potentially affecting production costs and operational efficiency. Supply chain constraints from limited brewery capacity coordination across different regions create additional operational challenges for manufacturers, demanding ongoing investment in supply relationships and quality assurance programs.

Key trends indicate accelerated adoption in Asia-Pacific markets, particularly India and China, where food processing expansion and protein awareness drive comprehensive spent grain flour adoption. Technology integration trends toward specialized drying systems with enhanced processing characteristics, advanced application development, and integrated quality solutions enable effective manufacturing approaches that optimize production efficiency and minimize processing risks. The market thesis could face disruption if advances in alternative protein sources or changes in brewing industry practices reduce reliance on traditional spent grain flour applications.

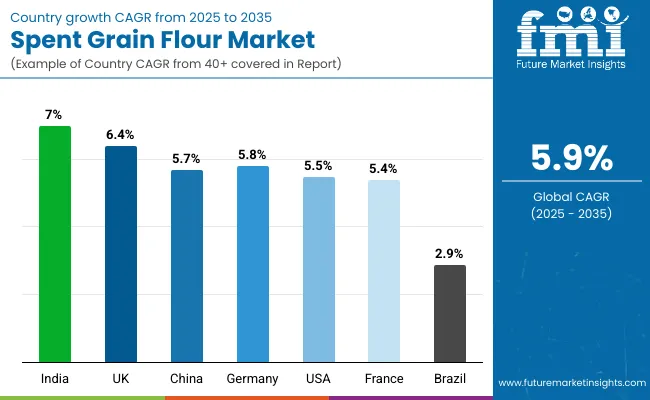

| Country | CAGR (%) |

|---|---|

| India | 7.0% |

| UK | 6.4% |

| Germany | 5.8% |

| China | 5. 7% |

| USA | 5.5% |

| France | 5.4% |

| Brazil | 2.9% |

The global spent grain flour market is expanding steadily, with India leading at a 7.0% CAGR through 2035, driven by food processing growth, protein awareness expansion, and developing manufacturing platforms. UK follows at 6.4%, supported by circular economy initiatives, food innovation programs, and manufacturing development. Germany record 5.8%, reflecting established food processing landscapes with growing integration in protein-enriched applications. USA advances at 5.5%, anchored by upcycled ingredient demand and brewing industry partnerships. France grows at 5.4%, leveraging food innovation capabilities. Brazil posts 2.9%, focusing on agricultural processing applications.

India demonstrates the strongest growth potential in the spent grain flour market with a CAGR of 7.0% through 2035. The country's leadership position stems from food processing industry expansion, protein awareness campaigns, and comprehensive food safety regulations driving the adoption of upcycled ingredient solutions. Growth is concentrated in major food processing centers, including Mumbai, Delhi, Bangalore, and Chennai, where food manufacturers and bakery companies are implementing spent grain flour systems for enhanced nutritional capabilities and product differentiation. Distribution channels through ingredient suppliers and food processing networks expand deployment across manufacturing projects and product development initiatives. The country's Ministry of Food Processing Industries provides policy support for upcycled ingredient modernization, including comprehensive processing capability development.

India's market demonstrates distinctive application patterns, with bakery products commanding 40.0% application share, reflecting the country's large bread and biscuit manufacturing sector. Snack products account for 20.0% market share, while animal feed captures 25.0%, indicating strong integration with livestock and poultry sectors. The remaining applications, including beverages and functional ingredients, represent 15.0% market share, showing diversified utilization across food processing categories.

Key market factors:

In major food processing and innovation centers including London, Manchester, Birmingham, and Bristol, the adoption of comprehensive spent grain flour solutions is accelerating across production projects and food industry development initiatives, driven by circular economy policies and government innovation programs. The market demonstrates strong growth momentum with a CAGR of 6.4% through 2035, linked to comprehensive food industry modernization and increasing focus on upcycled ingredient solutions. British companies are implementing advanced spent grain flour systems and processing platforms to enhance product performance while meeting growing demand in expanding bakery and snack manufacturing sectors. The country's food innovation initiatives create continued demand for spent grain flour compounds, while increasing emphasis on environmental responsibility drives adoption of advanced processing systems.

Key development areas:

Germany's market expansion is driven by diverse food manufacturing demand, including bakery production development in major cities and comprehensive snack processing projects across multiple regions. The country demonstrates strong growth potential with a CAGR of 5.8% through 2035, supported by industrial food processing programs and industry-level quality development initiatives. German companies face implementation challenges related to processing complexity and supply coordination requirements, requiring strategic development approaches and support from specialized spent grain flour partners. Growing protein fortification demands and advanced food processing requirements create compelling business cases for spent grain flour adoption, particularly in bakery areas where protein-enriched ingredients have a direct impact on product quality and market positioning.

Market characteristics:

The China market leads in large-scale food processing integration based on manufacturing capacity expansion and ingredient cost optimization for enhanced production performance. The country shows strong potential with a CAGR of 5.7% through 2035, driven by the modernization of existing food processing infrastructure and the expansion of advanced manufacturing facilities in major industrial areas, including Beijing, Shanghai, Guangdong, and Shandong. Chinese companies are adopting intelligent spent grain flour systems for quality improvement and cost optimization, particularly in regions with advanced food processing requirements and applications demanding comprehensive technology upgrades. Technology deployment channels through established food industry institutions and manufacturing operators expand coverage across production facilities and export-focused applications.

Leading market segments:

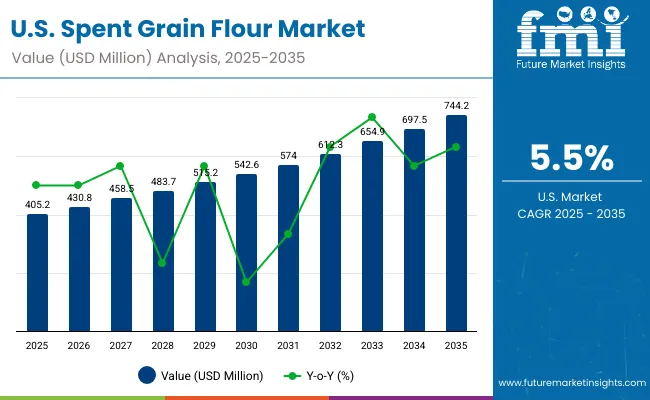

USA's spent grain flour market demonstrates advanced implementation focused on product innovation and nutritional enhancement optimization, with documented integration of specialized ingredient systems, achieving improvement in protein content across bakery and snack facilities. The country maintains steady growth momentum with a CAGR of 5.5% through 2035, driven by food processing facilities' emphasis on innovation excellence and market differentiation methodologies that align with American food standards applied to spent grain operations. Major food processing areas, including California, Texas, Illinois, and New York, showcase advanced deployment of spent grain flour platforms where ingredient systems integrate seamlessly with existing food processing infrastructure and comprehensive quality management programs.

Key market characteristics:

France's spent grain flour market demonstrates established and quality-focused landscape, characterized by growing integration of upcycled ingredient technology with existing food processing infrastructure across manufacturing projects, bakery networks, and innovation initiatives. France's emphasis on food excellence and culinary innovation drives demand for advanced spent grain flour solutions that support comprehensive food industry initiatives and quality requirements in production operations. The market benefits from partnerships between international spent grain providers and domestic food industry leaders, creating service ecosystems that prioritize ingredient quality and culinary excellence programs. Food processing centers in major regions showcase developing spent grain flour implementations where ingredient systems achieve quality improvements through integrated production programs.

Key market characteristics:

Brazil's spent grain flour market demonstrates agricultural processing integration, characterized by livestock feed applications and rural development programs across agricultural regions and food processing facilities. The country's emphasis on agricultural efficiency and feed optimization drives demand for spent grain flour solutions that support comprehensive livestock nutrition initiatives and agricultural requirements in farming operations. The market benefits from partnerships between international spent grain providers and domestic agricultural leaders, creating supply ecosystems that prioritize feed quality and agricultural productivity programs. Agricultural centers in major regions showcase developing spent grain flour implementations where ingredient systems achieve nutrition improvements through integrated feeding programs.

Brazil demonstrates distinctive application focus, with animal feed commanding 60.0% application share, reflecting the country's large livestock and poultry sectors. Pet food applications account for 15.0% market share, while human consumption applications, including bakery and snack products, represent 25.0%, showing agricultural sector prioritization over food processing applications.

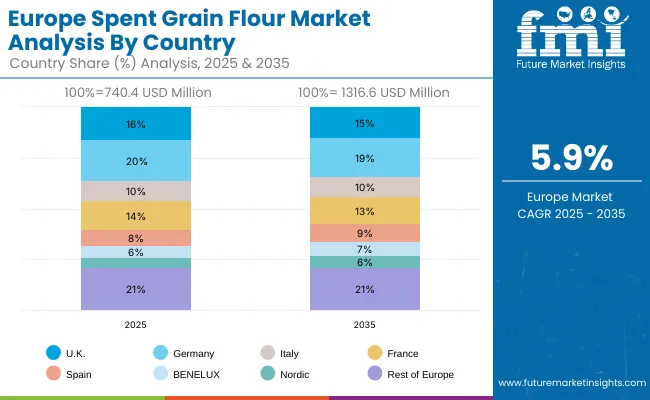

The spent grain flour market in Europe is projected to grow from USD 740.4 million in 2025 to USD 1,316.6 million by 2035, registering a CAGR of 5.9% over the forecast period. Germany is expected to maintain its leadership position with a 20.0% market share in 2025, projected to reach 19.0% by 2035, supported by its extensive food processing infrastructure, advanced manufacturing facilities, and comprehensive brewing industry networks serving major European markets.

United Kingdom follows with a 16.0% share in 2025, projected to reach 15.0% by 2035, driven by comprehensive circular economy programs in major food processing regions implementing advanced spent grain flour systems. France holds a 14.0% share in 2025, expected to maintain 13.0% by 2035 through the ongoing development of food processing facilities and manufacturing networks. Italy commands a 10.0% share, maintaining 10.0% by 2035, while Spain accounts for 8.0% in 2025, expected to reach 9.0% by 2035. BENELUX region holds 6.0% share, projected to reach 7.0%, while Nordic countries account for 5.0%, expected to expand to 6.0% by 2035. The Rest of Europe region is anticipated to maintain 21.0% share by 2035, attributed to increasing spent grain flour adoption in Eastern European food processing facilities implementing production programs.

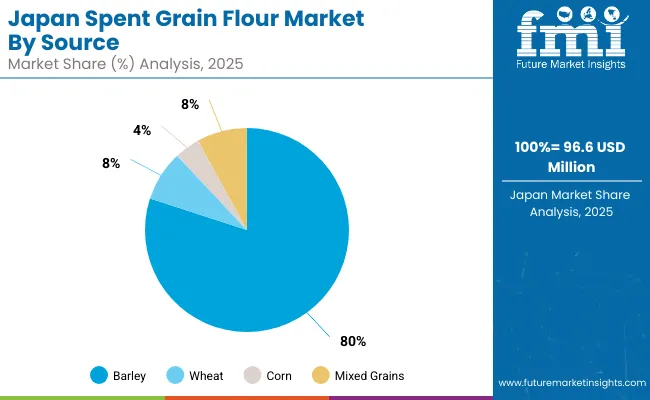

The Japanese spent grain flour market demonstrates a mature and quality-focused landscape, characterized by advanced integration of ingredient technology with existing food processing infrastructure across manufacturing facilities, processing networks, and quality initiatives. Japan's emphasis on quality excellence and precision food processing drives demand for high-reliability spent grain flour solutions that support comprehensive food industry initiatives and regulatory requirements in manufacturing operations. The market demonstrates specialized source utilization patterns, with barley commanding 80.0% source share, reflecting the country's preference for traditional brewing-derived ingredients. Wheat-based alternatives account for 8.0% market share, corn represents 4.0%, while mixed grains capture 8.0%, showing traditional ingredient preferences and established supply relationships.

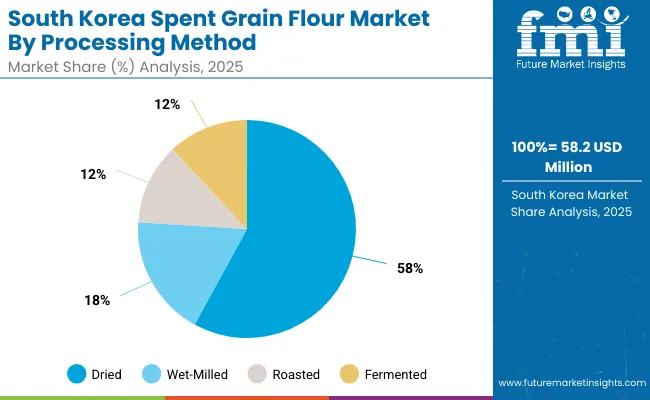

The South Korean spent grain flour market is characterized by strong processing technology integration, with companies maintaining competitive positions through comprehensive system integration and technical services capabilities for food processing and manufacturing applications. The market demonstrates distinctive processing method patterns, with dried processing commanding 58.0% method share, reflecting the country's emphasis on shelf-stable ingredient solutions. Wet-milled processing accounts for 18.0% market share, while roasted and fermented methods each represent 12.0%, indicating balanced utilization across processing technologies. The competitive landscape shows increasing collaboration between international spent grain companies and Korean food processing specialists, creating integrated service models that combine international ingredient expertise with local market knowledge and food industry relationship management.

The spent grain flour market moderate concentration, through established ingredient portfolios and extensive food industry relationships. Competition centers on processing capability, product quality, and supply consistency rather than price competition alone.

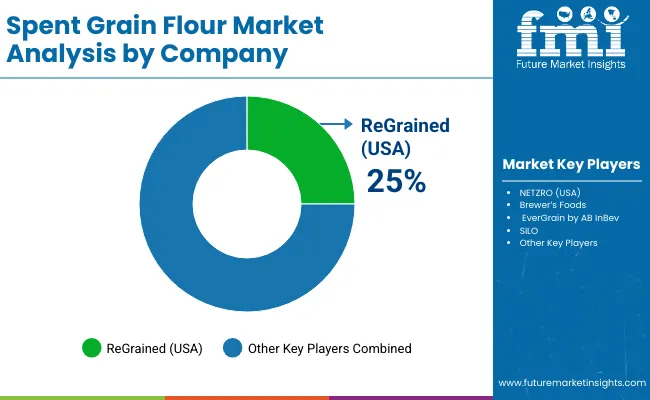

Market leaders include ReGrained, NETZRO, and Brewer's Foods, which maintain competitive advantages through comprehensive spent grain flour portfolios, advanced processing capabilities, and deep expertise in the food processing and upcycling sectors, creating high switching costs for customers. These companies leverage established brewery relationships and ongoing development partnerships to defend market positions while expanding into adjacent functional ingredient and protein enhancement applications.

Challengers encompass EverGrain by AB InBev and SILO, which compete through specialized processing technologies and strong brewery integration in key food processing markets. Regional specialists focus on specific spent grain flour applications or vertical markets, offering differentiated capabilities in bakery systems, snack applications, and application-specific processing.

Emerging spent grain flour companies create competitive pressure through innovative processing approaches and rapid development capabilities, particularly in high-growth markets including India and China, where local presence provides advantages in cost optimization and regulatory compliance. Market dynamics favor companies that combine advanced processing technologies with comprehensive food industry services that address the complete ingredient lifecycle from brewery sourcing through ongoing quality assurance and technical support.

Spent grain flour solutions represent a critical upcycled ingredient that enables food companies, bakery firms, and snack manufacturers to enhance nutritional quality and product differentiation without substantial ongoing ingredient investment, typically providing 40-60% protein enhancement compared to conventional flour alternatives while ensuring unprecedented functionality and processing compliance. With the market projected to grow from USD 2,156.8 million in 2025 to USD 3,826.9 million by 2035 at a 5.9% CAGR, these solutions offer compelling advantages - superior protein content, enhanced functionality, and processing capabilities - making them essential for bakery applications (35.0% market share), snack products (18.0% share), and diverse food processing applications seeking reliable upcycled ingredient solutions. Scaling market penetration and processing capabilities requires coordinated action across food policy, manufacturing standards, spent grain flour providers, food companies, and brewing industry institutions.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 2,156.8 Million |

| Source | Barley, Wheat, Corn, Mixed Grains |

| Processing Method | Dried, Wet-Milled, Roasted, Fermented |

| Application | Bakery Products, Snack Products, Beverages, Animal Feed, Pet Food, Nutraceuticals, Functional Ingredients |

| Sales Channel | B2B (Food & Beverage Manufacturers, Pet Food Producers, Foodservice) and B2C (Online Retail, Health Food Stores, Specialty Grocery Stores) |

| Product Claim | High Fiber, Protein-Enriched, Upcycled Ingredient, Sustainable |

| End Use | Human Consumption, Animal Nutrition, Industrial (e.g., composting, bio-composite fillers) |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | India, UK, Germany, China, USA, France, Brazil, and 40+ countries |

| Key Companies Profiled | ReGrained, NETZRO, Brewer's Foods, EverGrain by AB InBev, SILO |

| Additional Attributes | Dollar sales by source and processing method categories, regional adoption trends across Europe, South Asia & Pacific, and North America, competitive landscape with spent grain flour providers and food companies, processing facility requirements and specifications, integration with bakery initiatives and food processing platforms, innovations in processing technology and manufacturing systems. |

The spent grain flour market is valued at USD 2,156.8 million in 2025, reflecting strong early-stage adoption of upcycled ingredient systems across food processing and bakery applications.

By 2035, the market is expected to reach USD 3,826.9 million as demand for high-protein and high-fiber upcycled ingredients expands across global food manufacturing.

The market is projected to grow at a CAGR of 5.9% between 2025 and 2035 due to rising protein fortification requirements and wider availability of dried processing technologies.

Barley is the dominant source, accounting for approximately 72% of all spent grain flour production because of its central role in global brewing operations.

Dried processing leads with around 60% share, as it provides the shelf stability and standardized quality required by large-scale food manufacturers.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Dried Spent Grain Market Trends – Growth & Industry Forecast 2025 to 2035

Ancient and Specialty Grain Flour Market

Grain Hardness Meter Market Size and Share Forecast Outlook 2025 to 2035

Grain Cooling Spear Market Size and Share Forecast Outlook 2025 to 2035

Grain Roller Market Size and Share Forecast Outlook 2025 to 2035

Grain Mill Grinder Market Size and Share Forecast Outlook 2025 to 2035

Grain Alcohol Market Size and Share Forecast Outlook 2025 to 2035

Flour Mixes Market Growth – Specialty Baking & Industry Trends 2025 to 2035

Flour Substitutes Market Analysis by Baked Goods, Noodles, Pastry, Fried Food, Pasta, Bread, Crackers Applications Through 2035

Grain-Free Pet Food Market Trends - Growth & Industry Forecast 2024 to 2034

Flour Conditioner Market

Flour Improvers Market

Grain And Seed Cleaning Equipment Market

Migraine Treatment Market Insights by Drug Class, Route of Administration, Distribution Channel, Treatment, and Region through 2035

Migraine Nasal Spray Market Outlook – Trends, Growth & Forecast 2025 to 2035

Corn Flour Market Size and Share Forecast Outlook 2025 to 2035

Bean Flour Market Size and Share Forecast Outlook 2025 to 2035

Feed Grain Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Market Share Breakdown of Bean Flour Manufacturers

Multigrain Premix Market Trends – Healthy Baking & Industry Expansion 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA