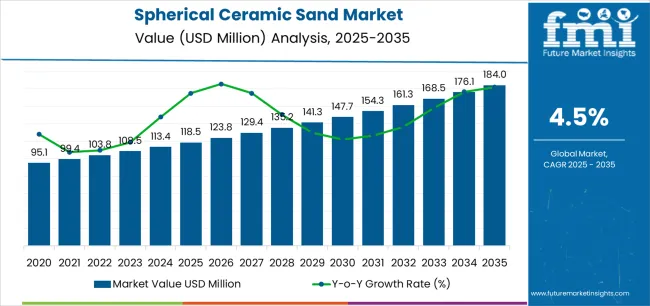

The global spherical ceramic sand market is valued at USD 118.5 million in 2025. It is slated to reach USD 184 million by 2035, recording an absolute increase of USD 65.6 million over the forecast period. This translates into a total growth of 55.3%, with the market forecast to expand at a compound annual growth rate (CAGR) of 4.5% between 2025 and 2035. The overall market size is expected to grow by nearly 1.55X during the same period, supported by increasing demand for high-performance foundry materials, growing adoption of spherical ceramic sand in precision casting and advanced manufacturing processes, and rising emphasis on superior surface finish and dimensional accuracy across diverse metal casting, sand blasting, and refractory applications.

Between 2025 and 2030, the spherical ceramic sand market is projected to expand from USD 118.5 million to USD 141.4 million, resulting in a value increase of USD 22.9 million, which represents 34.9% of the total forecast growth for the decade. This phase of development will be shaped by increasing automotive and aerospace casting complexity driving premium foundry sand requirements, rising adoption of advanced molding technologies and precision casting processes, and growing demand for reusable and environmentally friendly foundry materials reducing waste and improving casting economics. Metal casting foundries and manufacturing facilities are expanding their spherical ceramic sand capabilities to address the growing demand for high-quality and cost-effective molding materials that ensure casting precision and operational efficiency.

From 2030 to 2035, the market is forecast to grow from USD 141.4 million to USD 184 million, adding another USD 42.7 million, which constitutes 65.1% of the overall ten-year expansion. This period is expected to be characterized by the expansion of lightweight materials casting including aluminum and magnesium for electric vehicles, the development of specialized ceramic sand grades for additive manufacturing and 3D printing integration, and the growth of specialized applications for investment casting, precision components, and high-temperature metal forming. The growing adoption of circular economy principles and sand reclamation technologies will drive demand for spherical ceramic sand with enhanced durability and multiple-use capabilities.

Between 2020 and 2025, the spherical ceramic sand market experienced steady growth, driven by increasing quality standards in metal casting and growing recognition of spherical ceramic sand as premium foundry materials offering superior thermal properties and casting surface quality in diverse automotive casting, industrial manufacturing, and precision component production applications. The market developed as foundry operators and casting engineers recognized the potential for spherical ceramic sand technology to improve casting quality, reduce defects, and support operational optimization while meeting demanding dimensional tolerances. Technological advancement in ceramic sand production and spheroidization processes began emphasizing the critical importance of maintaining particle uniformity and thermal stability in challenging casting environments.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 118.5 million |

| Forecast Value in (2035F) | USD 184 million |

| Forecast CAGR (2025 to 2035) | 4.5% |

Market expansion is being supported by the increasing global demand for high-quality foundry materials driven by automotive lightweighting trends, aerospace component complexity, and precision casting requirements, alongside the corresponding need for advanced molding sands that can deliver superior surface finish, enable dimensional accuracy, and maintain thermal stability across various metal casting, sand blasting, and refractory applications. Modern foundry operators and manufacturing engineers are increasingly focused on implementing spherical ceramic sand solutions that can improve casting quality, reduce finishing costs, and provide consistent performance in demanding production environments.

The growing emphasis on sustainable manufacturing and operational efficiency is driving demand for spherical ceramic sand that can support sand reclamation, enable multiple-use cycles, and ensure comprehensive cost-effectiveness. Foundry operators' preference for molding materials that combine casting quality excellence with environmental responsibility and economic viability is creating opportunities for innovative spherical ceramic sand implementations. The rising influence of electric vehicle production and lightweight materials casting is also contributing to increased adoption of spherical ceramic sand that can provide superior thermal properties without compromising casting integrity or dimensional control.

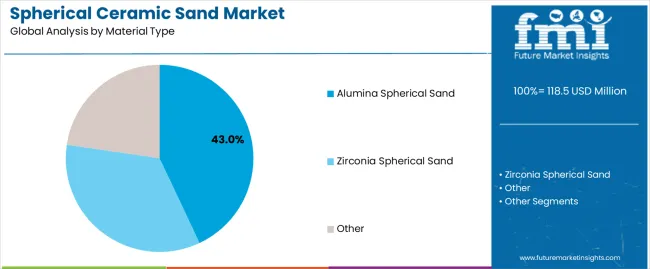

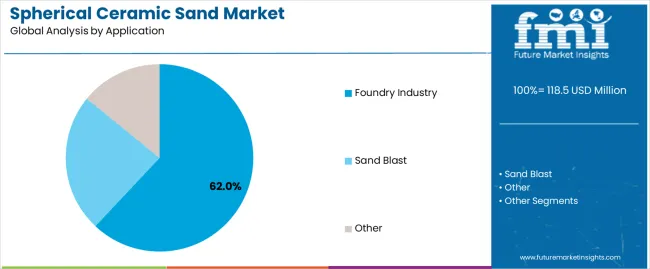

The market is segmented by material type, application, and region. By material type, the market is divided into alumina spherical sand, zirconia spherical sand, and other. Based on application, the market is categorized into foundry industry, sand blast, and other. Regionally, the market is divided into East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, and Eastern Europe.

The alumina spherical sand segment is projected to maintain its leading position in the spherical ceramic sand market in 2025, reaffirming its role as the preferred material type for foundry applications and precision casting operations. Metal casting foundries increasingly utilize alumina spherical sand for its optimal balance of thermal properties, proven mechanical strength, and established effectiveness in producing high-quality castings while maintaining cost-competitiveness and availability. Alumina spherical sand technology's proven effectiveness and industry acceptance directly address operational requirements for reliable casting performance and economical molding material solutions across diverse foundry applications and metal types.

This material type segment forms the foundation of spherical ceramic sand applications, as it represents the material with the greatest industry adoption and established performance record across multiple casting processes and component specifications. Foundry industry investments in quality improvement continue to strengthen alumina spherical sand adoption among automotive foundries and precision casting operations. With operational pressures requiring quality castings and cost-effective materials, alumina spherical sand aligns with both technical objectives and economic requirements, making it the central component of comprehensive foundry material strategies.

The foundry industry application segment is projected to represent the 62% market share of spherical ceramic sand demand in 2025, underscoring its critical role as the primary driver for spherical ceramic sand adoption across metal casting operations, investment casting processes, precision component production, and automotive foundries. Foundry operators prefer spherical ceramic sand for molding applications due to superior casting surface finish, excellent dimensional accuracy, and ability to produce complex geometries while supporting reduced finishing requirements and improved yield. Positioned as premium foundry materials for quality-critical applications, spherical ceramic sand offers both performance advantages and economic benefits through reduced downstream processing.

The segment is supported by continuous advancement in casting technologies and the growing complexity of automotive and aerospace components requiring precision molding materials with enhanced thermal properties and dimensional stability. Additionally, foundry operators are investing in premium molding materials to support increasingly stringent quality requirements and demand for defect-free castings. As casting complexity increases and quality standards tighten, the foundry industry application will continue to dominate the market while supporting advanced casting capabilities and quality assurance strategies.

The spherical ceramic sand market is advancing steadily due to increasing demand for high-quality foundry materials driven by automotive casting complexity, aerospace precision requirements, and manufacturing quality standards necessitating specialized molding sands providing enhanced performance characteristics and casting benefits across diverse metal casting, precision manufacturing, and surface finishing applications. However, the market faces challenges, including higher material costs compared to conventional silica sands, limited production capacity and specialized manufacturing requirements, and competition from alternative molding materials and casting technologies. Innovation in production efficiency and material performance optimization continues to influence product development and market expansion patterns.

The growing automotive industry transition toward electric vehicles combined with lightweighting imperatives is driving increased aluminum and magnesium casting requirements demanding premium foundry materials with superior thermal properties and dimensional control. Electric vehicle production emphasizes lightweight structural components, battery housings, and electric motor casings requiring precision casting with excellent surface finish and dimensional accuracy. Foundry operators are increasingly recognizing the competitive advantages of spherical ceramic sand for aluminum casting applications achieving thin-wall castings, complex geometries, and superior surface quality, creating opportunities for specialized alumina-based ceramic sands specifically optimized for non-ferrous metal casting and high-pressure die casting integration.

Modern foundry operators are incorporating sand reclamation technologies, closed-loop material management, and circular economy principles to enhance environmental performance, reduce material consumption, and support comprehensive sustainability objectives through optimized sand usage and waste minimization. Leading foundries are developing mechanical and thermal reclamation systems, implementing quality control for reclaimed materials, and advancing processing technologies that extend spherical ceramic sand service life through multiple casting cycles. These practices improve economic viability while enabling environmental benefits, including reduced landfill waste, decreased virgin material consumption, and minimized environmental impact. Advanced sustainability integration also allows foundries to support comprehensive environmental compliance objectives and operational cost reduction beyond traditional single-use material approaches.

The expansion of additive manufacturing integration with traditional casting, precision investment casting growth, and specialized industrial applications is driving demand for customized spherical ceramic sand grades with tailored particle size distributions, enhanced thermal properties, and application-specific characteristics. These specialized applications require engineered ceramic sands with precise specifications exceeding standard foundry material requirements, creating premium market segments with differentiated value propositions and technical support requirements. Manufacturers are investing in product development capabilities and application engineering to serve demanding specialty applications while supporting innovation in advanced manufacturing processes and precision component production.

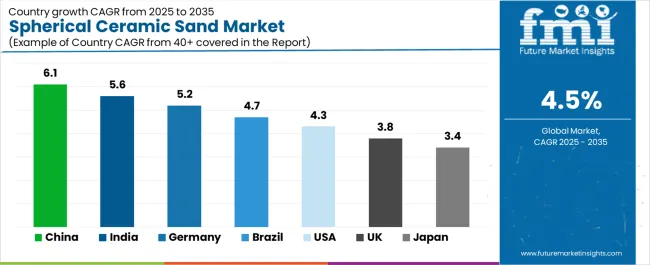

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| Brazil | 4.7% |

| United States | 4.3% |

| United Kingdom | 3.8% |

| Japan | 3.4% |

The spherical ceramic sand market is experiencing solid growth globally, with China leading at a 6.1% CAGR through 2035, driven by massive automotive production, expanding foundry capacity, and growing adoption of premium casting materials supporting manufacturing quality improvement. India follows at 5.6%, supported by expanding automotive manufacturing, growing foundry sector, and increasing quality consciousness among metal casting operations. Germany shows growth at 5.2%, emphasizing precision casting, automotive excellence, and premium foundry materials. Brazil demonstrates 4.7% growth, supported by automotive sector, industrial casting, and manufacturing development. The United States records 4.3%, focusing on aerospace casting, automotive lightweighting, and precision component manufacturing. The United Kingdom exhibits 3.8% growth, emphasizing aerospace applications and precision casting. Japan shows 3.4% growth, focusing on quality casting materials and advanced manufacturing applications.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

Revenue from spherical ceramic sand in China is projected to exhibit exceptional growth with a CAGR of 6.1% through 2035, driven by massive automotive production volumes including growing electric vehicle manufacturing and expanding metal casting capacity supported by government initiatives promoting manufacturing quality and environmental compliance. The country's comprehensive foundry industry and increasing investment in premium casting materials are creating substantial demand for spherical ceramic sand solutions. Major foundry operators and material suppliers are establishing production and distribution capabilities to serve both domestic markets and export opportunities.

Revenue from spherical ceramic sand in India is expanding at a CAGR of 5.6%, supported by expanding automotive manufacturing including electric vehicle adoption, growing foundry sector serving domestic and export markets, and increasing adoption of quality casting materials addressing dimensional accuracy requirements. The country's comprehensive manufacturing development and quality consciousness are driving sophisticated foundry material market growth throughout industrial regions. Foundry material suppliers and automotive manufacturers are establishing supply chains to address growing premium sand requirements.

Revenue from spherical ceramic sand in Germany is expanding at a CAGR of 5.2%, supported by the country's precision casting capabilities, automotive engineering excellence, and emphasis on quality foundry materials ensuring dimensional accuracy and surface finish. The nation's technological sophistication and quality standards are driving premium spherical ceramic sand capabilities throughout precision manufacturing. Leading foundries and automotive suppliers are investing extensively in advanced casting materials and quality assurance.

Revenue from spherical ceramic sand in Brazil is expanding at a CAGR of 4.7%, driven by automotive sector production, industrial casting operations, and growing adoption of quality foundry materials supporting manufacturing improvement. Brazil's automotive industry and foundry sector are supporting investment in premium casting materials. Foundry operators and material suppliers are establishing capabilities for advanced foundry material applications.

Revenue from spherical ceramic sand in the United States is expanding at a CAGR of 4.3%, supported by the country's aerospace casting leadership, automotive lightweighting trends, and precision component manufacturing requiring premium foundry materials. The nation's advanced manufacturing capabilities and quality requirements are driving demand for specialized casting materials. Aerospace foundries and automotive suppliers are investing in premium molding materials for critical applications.

Revenue from spherical ceramic sand in the United Kingdom is growing at a CAGR of 3.8%, driven by the country's aerospace industry presence, precision casting capabilities, and emphasis on quality foundry materials for critical applications. The United Kingdom's aerospace expertise and precision manufacturing are supporting investment in premium casting materials. Aerospace foundries and precision casting operations are establishing comprehensive material specifications.

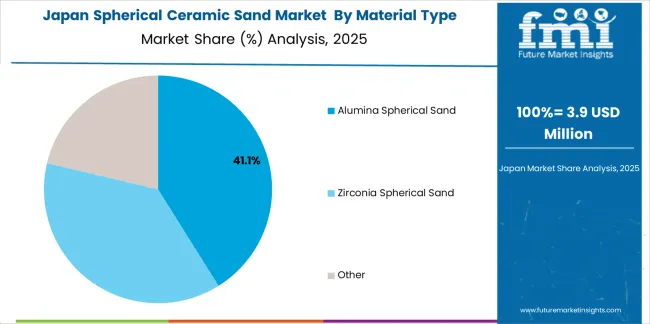

Revenue from spherical ceramic sand in Japan is expanding at a CAGR of 3.4%, supported by the country's emphasis on quality casting materials, advanced manufacturing capabilities, and precision component production requiring superior foundry materials. Japan's technological sophistication and quality standards are driving demand for premium spherical ceramic sand products. Foundry operators and manufacturing companies are investing in high-quality casting materials for demanding applications.

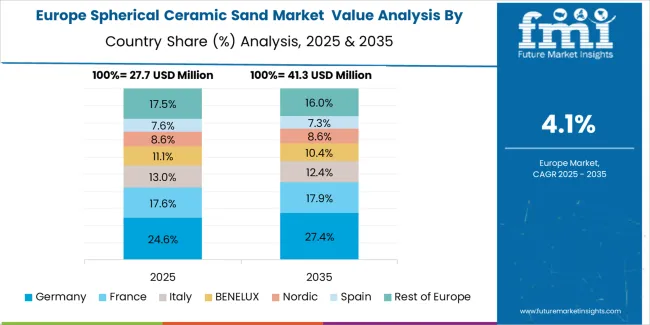

The spherical ceramic sand market in Europe is projected to grow from USD 30.6 million in 2025 to USD 46.3 million by 2035, registering a CAGR of 4.2% over the forecast period. Germany is expected to maintain leadership with a 28.4% market share in 2025, moderating to 28.1% by 2035, supported by precision casting excellence, automotive industry strength, and quality foundry materials adoption.

France follows with 17.6% in 2025, projected at 17.8% by 2035, driven by automotive manufacturing, aerospace casting, and precision component production. The United Kingdom holds 15.8% in 2025, declining slightly to 15.5% by 2035 due to market maturity. Italy commands 13.2% in 2025, reaching 13.4% by 2035, while Spain accounts for 10.4% in 2025, rising to 10.6% by 2035 aided by automotive sector and foundry development. The Netherlands maintains 6.8% in 2025, up to 7.0% by 2035 due to industrial casting and precision manufacturing. The Rest of Europe region, including Nordics, Central & Eastern Europe, and other markets, is anticipated to hold 7.8% in 2025 and 7.6% by 2035, reflecting steady development in foundry applications and quality casting materials.

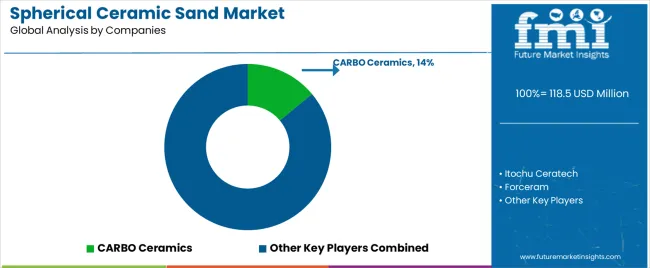

The spherical ceramic sand market is characterized by competition among specialized ceramic material manufacturers, foundry supply companies, and industrial minerals producers. Companies are investing in production capacity expansion, particle uniformity optimization, application-specific grade development, and technical support capabilities to deliver high-performance, reliable, and cost-effective spherical ceramic sand solutions. Innovation in spheroidization technologies, thermal property enhancement, and sustainable production methods is central to strengthening market position and competitive advantage.

CARBO Ceramics leads the market with 14% share, offering comprehensive ceramic proppant and spherical sand solutions with focus on industrial applications and material performance. Itochu Ceratech provides specialized ceramic materials including spherical sands with emphasis on Japanese market and quality standards. Forceram delivers ceramic sand products for foundry and industrial applications. Covia offers industrial minerals including specialized foundry materials. Chesapeake Specialty Products provides foundry materials and technical support. Kupper Corporation focuses on ceramic sand production and foundry applications. Refractory Engineers offers specialized refractory and foundry materials. Hunan Jiashun specializes in Chinese market ceramic sand production. Hua New Materials provides ceramic materials for diverse applications. Hebei Chida Manufacture delivers foundry materials and ceramic products. Zhengzhou HAIXU offers abrasive and foundry materials. Jinnaiyuan (Henan) Industrial Technology provides ceramic sand and industrial materials.

Spherical ceramic sand represents a specialized foundry materials segment within metal casting and precision manufacturing applications, projected to grow from USD 118.5 million in 2025 to USD 184 million by 2035 at a 4.5% CAGR. These high-performance molding materials-primarily alumina and zirconia-based spherical particles-serve as premium foundry sands in metal casting operations, precision investment casting, sand blasting, and refractory applications where superior surface finish, dimensional accuracy, and thermal stability are essential. Market expansion is driven by automotive lightweighting trends, aerospace precision requirements, electric vehicle casting demands, and rising emphasis on quality casting materials across diverse foundry and manufacturing segments.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 118.5 million |

| Material Type | Alumina Spherical Sand, Zirconia Spherical Sand, Other |

| Application | Foundry Industry, Sand Blast, Other |

| Regions Covered | East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, Eastern Europe |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | CARBO Ceramics, Itochu Ceratech, Forceram, Covia, Chesapeake Specialty Products |

| Additional Attributes | Dollar sales by material type and application categories, regional demand trends, competitive landscape, technological advancements in spheroidization processes, reclamation technology development, application optimization, and sustainability innovation |

The global spherical ceramic sand market is estimated to be valued at USD 118.5 million in 2025.

The market size for the spherical ceramic sand market is projected to reach USD 184.0 million by 2035.

The spherical ceramic sand market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in spherical ceramic sand market are alumina spherical sand, zirconia spherical sand and other.

In terms of application, foundry industry segment to command 62.0% share in the spherical ceramic sand market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Aspherical Lens Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Textile Market Size and Share Forecast Outlook 2025 to 2035

Ceramic and Porcelain Tableware Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Matrix Composites Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Frit Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Substrates Market Size and Share Forecast Outlook 2025 to 2035

Ceramic 3D Printing Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Injection Molding Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Tableware Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Paper Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Balls Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Tester Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Membranes Market Analysis - Size, Share and Forecast Outlook 2025 to 2035

Ceramic Barbeque Grill Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Ceramic Tiles Market Growth & Trends 2025 to 2035

Ceramic Sanitary Ware Market Trends & Forecast 2025 to 2035

Ceramic Transducers Market Growth - Trends & Forecast 2025 to 2035

Leading Providers & Market Share in Ceramic Barbeque Grill Industry

Ceramic Ink Market

Ceramic Coating Market Growth – Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA