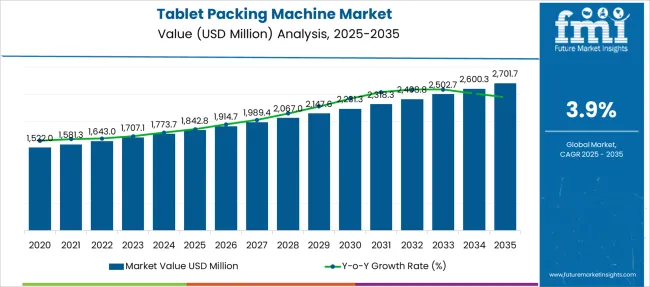

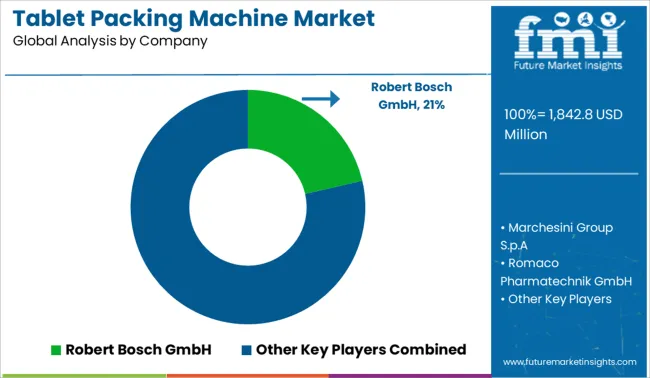

The Tablet Packing Machine Market is estimated to be valued at USD 1842.8 million in 2025 and is projected to reach USD 2701.7 million by 2035, registering a compound annual growth rate (CAGR) of 3.9% over the forecast period.

| Metric | Value |

|---|---|

| Tablet Packing Machine Market Estimated Value in (2025 E) | USD 1842.8 million |

| Tablet Packing Machine Market Forecast Value in (2035 F) | USD 2701.7 million |

| Forecast CAGR (2025 to 2035) | 3.9% |

The tablet packing machine market is expanding steadily due to increased pharmaceutical production volumes, heightened regulatory focus on packaging integrity, and the need for high-speed, contamination-free packing solutions. Rising demand for patient-centric packaging formats and improved medication adherence has encouraged the adoption of precision-oriented packaging technologies.

Automation, digital control systems, and integration with vision inspection tools have significantly enhanced efficiency and compliance across manufacturing lines. The shift toward flexible and modular machines that support multiple packaging formats is also creating new opportunities across contract manufacturing and specialty drug segments.

With a growing emphasis on safety, traceability, and operational scalability, the market is expected to continue its upward trajectory, driven by evolving industry standards and the push for faster turnaround in pharmaceutical supply chains.

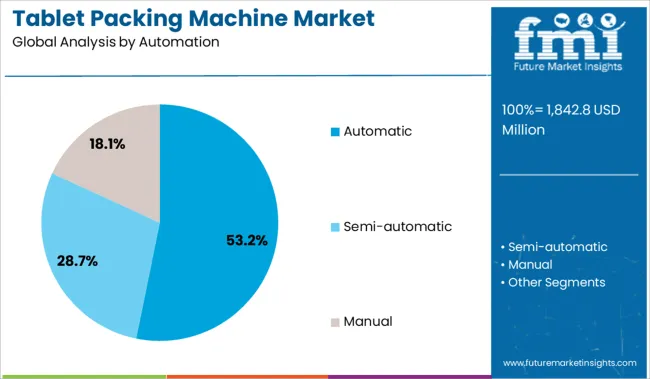

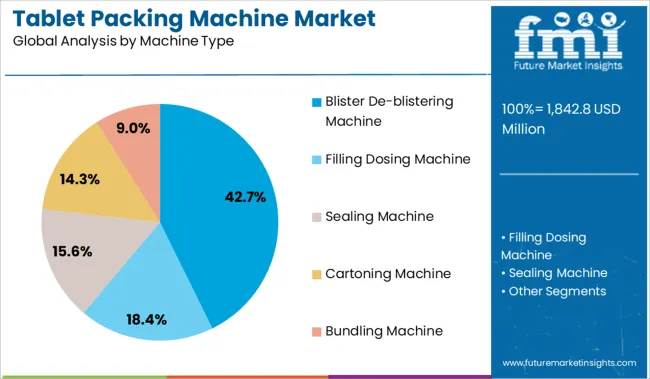

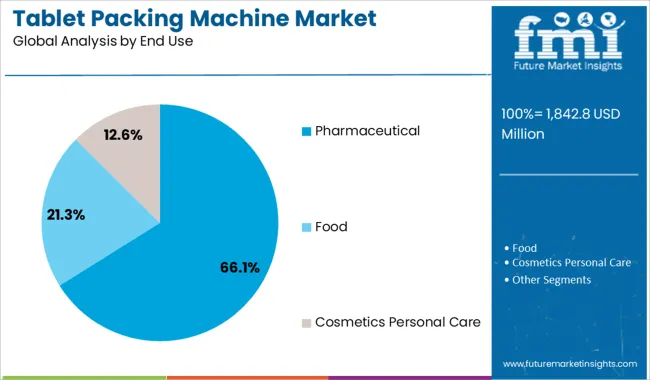

The market is segmented by Automation, Machine Type, and End Use and region. By Automation, the market is divided into Automatic, Semi-automatic, and Manual. In terms of Machine Type, the market is classified into Blister De-blistering Machine, Filling Dosing Machine, Sealing Machine, Cartoning Machine, and Bundling Machine. Based on End Use, the market is segmented into Pharmaceutical, Food, and Cosmetics Personal Care. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The automatic segment is projected to hold 53.20% of total market revenue by 2025 within the automation category, emerging as the dominant format. This preference is being led by the pharmaceutical industry's demand for uninterrupted, high-throughput packaging with minimal human intervention.

Automatic machines offer greater accuracy, reduced labor dependency, and consistent sealing integrity, all of which are critical in regulated manufacturing environments. These systems also support better integration with serialization, labeling, and inspection processes, making them ideal for compliance with evolving global packaging mandates.

With manufacturers prioritizing speed, reliability, and reduced operational costs, automatic packing machines have become the preferred solution for large-scale production lines.

The blister de-blistering machine type segment is expected to account for 42.70% of total revenue by 2025 under the machine type category, making it the leading segment. Its adoption is being driven by the increased need to recover tablets from incorrectly packed or damaged blister packs in a clean and efficient manner.

These machines are essential for quality control, minimizing product loss, and ensuring GMP compliance in pharmaceutical operations. They enable precise recovery without damaging tablets, which is especially important in high-value or sensitive drug formulations.

As batch reprocessing and repackaging requirements rise, the use of de-blistering machines continues to increase, reinforcing their position as a key equipment category in modern packaging lines.

The pharmaceutical segment is anticipated to contribute 66.10% of total market revenue by 2025 under the end use category, establishing it as the most dominant application area. This leadership is driven by the critical need for precise, contamination-free packaging that ensures drug stability and shelf life.

Regulatory frameworks across major markets have intensified the demand for robust packaging lines that can accommodate traceability, tamper-evidence, and patient safety requirements. The pharmaceutical industry’s focus on efficiency, automation, and regulatory alignment has further pushed adoption of specialized tablet packing solutions.

With continuous innovation in dosage forms and delivery mechanisms, packaging operations have become more complex, cementing the pharmaceutical segment’s dominance in the overall market landscape.

The global tablet packing machine market expanded at a CAGR of 1.9% during the historic period and reached USD 1,611.8 billion in 2024 from USD 1,429.7 million in 2020.

The tablet packing machine market moving forward towards sustainability and using safe and ecological packaging is creating potential growth chances for producers. Manufacturers are seeing rapid growth in strip packaging for tablets as it is suitable for several medicines.

Growing awareness regarding health drives people conscious about their health and taking medicine as a supplement, including tablets in everyday life drives demand for packaging machines as automotive machines are capable to pack tablets in a hassle-free way.

Packaging tablets in a way that they dont lose their actual composition during transit and it seemed to be more assembled and safe, packaging techniques adding more hygienic values, starting from filling, sealing, combining, labeling, and overwrapping every step is taken care by packaging machines. Compared to the last decade the upcoming market will choose machinery over humans and this will drive demand for packaging machines in near future.

Technology plays a vital role in every industry, in pharmaceuticals, especially in tablet packing contactless packaging is one key that makes the medicine more effective as it does not lose the content due to contactless packaging.

Using innovative technology in machines results in cutting down the cost of packaging as well as provides a fast and safe way of packing tablets and also it controls adverse external effects, to maintain the heat machines are coated with interlocked printed circuit boards so the blowers are automatic on when it is overheated. Additionally, digital temperature control is provided in every machine, and modifiable conveyor speed tablet feed are offered in tablet packing machines which enhances the working of machinery.

Technology makes work easier and if we look into the safety side of technology in machinery for the packaging of medicines it ensures the quality of tablets, this is the most crucial task and requisite of pharma packaging. Moreover, the materials have to be wisely selected so that the product curing capability is not reduced by external factors. Thus, the advancement of technology in tablet packaging machinery will boost the tablet packing machine market at the global level.

According to Health and Safety Executive, manual de-blistering packaging create many problems, during the de-blistering task, the wrists were in continuous use which makes the worker fatigue in very less time abnormally working wrist and bent positions are very difficult to perform a de-blistering task when using the manual aid.

To overcome these limitations blister and de-blistering machines are used, user-friendly machines are easy installation, it is and easy tools, their easy mechanical operations make the work faster, and no skilled operator is required to perform the task.

It is a highly efficient and labor-saving technique, efficiently with effectiveness makes the blister de-blistering machine generate unexpected demand in the tablet packing machine market.

The machinery used for manufacturing and packing the oral medicines with high-quality checks, ensuring safe transit packaging and avoiding the harm which can be done by the manual process of blistering and de-blistering the tablets. Thus, blister de-blistering machines are the most sold machine type accounting for 33.1% of total sales in 2025.

A major share of the tablet packing machine market is held by the pharmaceutical industry, though it is widely used in the food as well as the cosmetics and personal care industry, there are certain limitations for humans, doing chemical packaging manually can damage the product or one organ.

Different packaging styles are adopted in packaging tablets by machinery such as stip packaging, blister packaging, and filling sealing machines, according to the National Library of Medicine coating a tablet with different materials is an important task, and using new techniques for covering, an actual assessment of coating quality is essential for automated production.

The application of computational modeling and process can be done with machines, process analytical technology is used for coating as a perfect measurement in the drug is a crucial part of and packaging of the tablet.

Moreover, by using packaging machines the drug holds a curing capacity that can easily be done with help of machinery. Thus, by end-use, the total sales of tablet packaging machines across the pharmaceutical industry are expected to reach USD 1842.8 million in 2025.

India prompts an important role as an emerging market for the packaging industry. Indian economy is growing at a decent growth rate and also has become the 5th largest economy in the world by GDP. This proposes the Indian manufacturing market is progressing and the economy is developing and is also having a surplus labor flow, resultant to this the manufacturing process is also becoming faster including the pharmaceutical industry.

According to The Ministry of Commerce and Industry, the Indian pharmaceutical industry includes a network of 3,000 pharmaceutical companies having 10,500 manufacturing plants across India. The above-mentioned factors make India one of the fastest-growing markets offering profitable growth opportunities of USD 2701.7 million till 2035.

Germany is the major exporter of medicine around the globe. According to Germany Trade Invest, Germany is one of the most developed healthcare markets in the world and a strategic gateway to the EU single market for international companies. Geographically Germany is the leading player in the production of pharmaceuticals and investment across the healthcare industry, with a favorable environment and world-class infrastructure conditions promoting the pharmaceutical industry to grow in Germany.

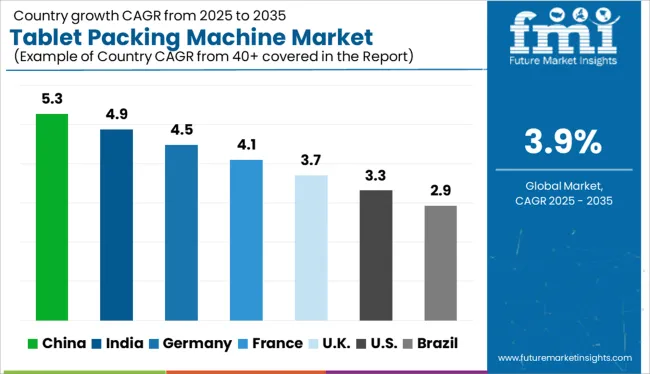

The biggest exporter of pharma drives the demand for machine packaging as machinery is used to manufacture as well as to export the products all over the globe, having the combination of the best technologies used in machinery and pharma makes Germany lead in the packaging machine market. Thus, the sales of tablet packaging machine across Germany is anticipated to grow at 4.0% between 2025 and 2035.

The major players in the global tablet packing machine market are trying to focus on expanding their production capacity by investing in their existing facilities to cater to the growing demand for the tablet packing machine market. Also, the key players are focusing on developing sustainable and innovative products to meet the demand for sustainable packaging. Some of the recent developments by the players are:

| Attribute | Details |

|---|---|

| Growth Rate | CAGR of 3.9% from 2025 to 2035 |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD Billion, Volume in Units, and CAG from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends, and Pricing Analysis |

| Segments Covered | Automation, Semi-Automatic, Manual |

| Regions Covered | North America; Latin America; Europe; East Asia; South Asia; Oceania; Middle East and Africa |

| Key Countries Covered | USA, Canada, Mexico, Brazil, Germany, United Kingdom, France, Italy, Spain, Russia, China, Japan, India, GCC countries, Australia |

| Key Companies Profiled | Robert Bosch GmbH; Marchesini Group S.p.A; Romaco Pharmatechnik GmbH; Krber Medipak Systems AG; Shiv Shakti Packaging Industries; ACG Worldwide Private Limited; Uhlmann Pac-Systeme GmbH Co. KG; Multivac Inc; OPTIMA packaging group GmbH; Jornen Machinery Co.Ltd.; Mauser Packaging Solutions; Strbel GmbH; Omnicell, Inc.; RBP Bauer GmbH; Sepha Limited |

| Customization Pricing | Available upon Request |

The global tablet packing machine market is estimated to be valued at USD 1,842.8 million in 2025.

The market size for the tablet packing machine market is projected to reach USD 2,701.7 million by 2035.

The tablet packing machine market is expected to grow at a 3.9% CAGR between 2025 and 2035.

The key product types in tablet packing machine market are automatic, semi-automatic and manual.

In terms of machine type, blister de-blistering machine segment to command 42.7% share in the tablet packing machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Key Players & Market Share in Tablet Packing Machine Industry

Tablet Hardness Testers Market Size and Share Forecast Outlook 2025 to 2035

Tablets for Oral Suspension Market Analysis Size and Share Forecast Outlook 2025 to 2035

Tablet Based E-Detailing Market Size and Share Forecast Outlook 2025 to 2035

Tablet And e-Reader Application Processor Market Size and Share Forecast Outlook 2025 to 2035

Tabletop Pizza Oven Market Size and Share Forecast Outlook 2025 to 2035

Tablet Market Analysis by Product Type, End-Use, Operating System, and Region Through 2035

Market Share Distribution Among Tablets And Capsules Packaging Companies

Tablets and Capsules Packaging Market Growth, Trends, Forecast 2025-2035

Tablet Cartons Market

Tabletop Tape Dispensers Market

Tablet Tissue Paper Market

Tablet Bottle Market

Tablet And Pellet Coating Systems Market

Tablet Press Machines Market Size and Share Forecast Outlook 2025 to 2035

Tablet Counting Machine Market Trends & Forecast 2024-2034

Tabletop CNC Milling Machines Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Soap Tablet Market Size and Share Forecast Outlook 2025 to 2035

4K Drawing Tablet with Screen Market Size and Share Forecast Outlook 2025 to 2035

Dishwasher Tablets Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA