The 4-Loop Flexible Intermediate Bulk Container (FIBC) market is growing at a high rate owing to rising demand for bulk material handling solutions from industries like agriculture, chemicals, construction, and food processing. High-strength materials, UV-resistant coatings, and anti-static features are being integrated by manufacturers to achieve industry requirements and ensure longer life.

Businesses are also placing emphasis on tailored solutions, production automation, and eco-friendly materials to have a competitive advantage. The trend is moving towards recyclable, food-grade, and heavy-duty 4-loop FIBCs that meet global safety standards. The industry is also observing the implementation of IoT-based smart bulk bags to enhance traceability and logistics efficiency optimization.

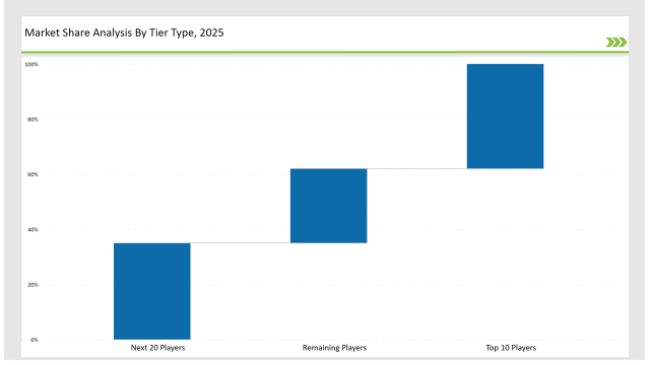

Tier1 players like Greif, Berry Global, and Conitex Sonoco share a combined 38% market share by drawing on their combined knowledge in high-performance industrial packaging and wide international distribution chains.

Tier 2 players such as LC Packaging, Global-Pak, and Rishi FIBC take up 35% of the market share, catering to affordable, eco-friendly, and personalized bulk bag packaging for various industries from food and pharmaceuticals to hazmat handling.

Tier 3 includes regional and niche players who have expertise in localized manufacturing, high-end bag designs, and industry-specific compliance solutions, which together command 27% of the market share. They are leading innovation in biodegradable FIBC materials, UV-resistant coatings, and AI-based quality.

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Greif, Berry Global, Conitex Sonoco) | 18% |

| Rest of Top 5 (LC Packaging, Global-Pak) | 12% |

| Next 5 of Top 10 (Rishi FIBC, BAG Corp, Bulk Lift, Langston Companies, Intertape Polymer) | 8% |

The 4-Loop FIBC industry serves diverse sectors where bulk material handling, durability, and compliance are critical. Companies are incorporating UV resistance, anti-static coatings, and high-strength materials to meet regulatory requirements and ensure safe transport of goods.

Manufacturers are refining 4-Loop FIBC solutions with features such as bulk handling efficiency, UV protection, tamper-proof sealing, and IoT-enabled monitoring. Companies are also integrating automated production techniques to enhance customization, durability, and compliance.

The 4-Loop FIBC industry is evolving as companies adopt AI-driven quality control, biodegradable materials, and automated bulk bag manufacturing. They enhance security by implementing tamper-proof designs, forensic-level testing, and cloud-based supply chain tracking. Manufacturers prioritize UV-resistant coatings to extend product lifespan and minimize material degradation. Firms develop fire-retardant bulk bags to ensure safety in hazardous material handling. Companies integrate RFID and NFC technology for real-time inventory monitoring. They enhance sustainability by producing reusable FIBC solutions with eco-friendly polymers. Businesses optimize logistics by designing foldable FIBCs for efficient storage and transport.

Year-on-Year Leaders

Technology suppliers should focus on automation, AI-driven monitoring, and sustainable materials to support the 4-Loop FIBC market's evolution. Strategic partnerships with industries such as agriculture, mining, and pharmaceuticals will accelerate adoption.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Greif, Berry Global, Conitex Sonoco |

| Tier 2 | LC Packaging, Global-Pak, Rishi FIBC |

| Tier 3 | BAG Corp, Bulk Lift, Langston Companies, Intertape Polymer |

Leading manufacturers are advancing 4-Loop FIBC technology with smart tracking, sustainable materials, and high-performance industrial applications. They are also investing in real-time tracking analytics, encrypted RFID tags, and reinforced FIBC structures for improved safety and efficiency.

| Manufacturer | Latest Developments |

|---|---|

| Greif | Launched biodegradable bulk bags in March 2024. |

| Berry Global | Developed 100% recyclable FIBCs in April 2024. |

| Conitex Sonoco | Expanded anti-static and tamper-proof packaging in May 2024. |

| LC Packaging | Released customized UN-certified chemical FIBCs in June 2024. |

| Global-Pak | Strengthened ventilated bulk bag designs in July 2024. |

| Langston Companies | Expanded industrial bulk bag production with sustainable materials in August 2024. |

| Bulk Lift | Developed tamper-proof and heavy-duty FIBCs for hazardous materials in September 2024. |

The 4-Loop FIBC industry is evolving as manufacturers focus on sustainability, automation, and enhanced safety measures. Leading vendors are adopting IoT-enabled tracking, AI-powered quality control, and advanced material science to improve durability and compliance. Here’s how the top players are shaping the industry:

The 4-Loop FIBC industry will continue adopting AI-powered quality control, blockchain-based tracking, and recyclable materials. Companies will enhance supply chain transparency by embedding real-time tracking chips in bulk bags. They will strengthen bag durability with nano-coatings that resist extreme temperatures. Manufacturers will improve product handling by designing collapsible FIBCs that reduce storage space. Firms will integrate self-repairing materials to extend bag lifespan. Businesses will automate quality inspections with machine learning algorithms to minimize defects.

Leading players include Greif, Berry Global, Conitex Sonoco, LC Packaging, and Global-Pak.

The top 3 players collectively hold 18% of the global market.

The market shows medium concentration, with the top players holding 38% of the industry share.

Key innovation drivers include AI-powered quality control, UV-resistant coatings, IoT-based tracking, and sustainable FIBC materials.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

4-Loop FIBC Market Growth - Size, Demand & Forecast 2025 to 2035

FIBC Market Size and Share Forecast Outlook 2025 to 2035

FIBC Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Market Share Distribution Among FIBC (Flexible Intermediate Bulk Container) Manufacturers

2 Loop FIBC Bags Market Size and Share Forecast Outlook 2025 to 2035

Breaking Down Market Share in 2 Loop FIBC Bags

Ventilated FIBC Market Size, Share & Forecast 2025 to 2035

Sales Analysis of Tourism Industry in the Middle East Size and Share Forecast Outlook 2025 to 2035

Semen Analysis Systems Market Size and Share Forecast Outlook 2025 to 2035

Stone Analysis Software Market – Trends & Forecast 2025 to 2035

Water Analysis Instrumentation Market Analysis – Size, Share, and Forecast 2025 to 2035

Spend Analysis Software Market

North America Shipping Supplies Market Trends – Innovations & Growth 2024-2034

Failure Analysis Test Equipment Market Size and Share Forecast Outlook 2025 to 2035

Failure Analysis Equipment Market Insights – Forecast 2025 to 2035

Adoption Analysis of SCADA in Oil and Gas Industry Forecast and Outlook 2025 to 2035

Industry Analysis of Syringe and Needle in GCC Size and Share Forecast Outlook 2025 to 2035

Industry Analysis Non-commercial Acrylic Paint in the United States Size and Share Forecast Outlook 2025 to 2035

Industry Analysis of Medical Device Packaging in Southeast Asia Size and Share Forecast Outlook 2025 to 2035

Industry Analysis of Paper Bag in North America Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA