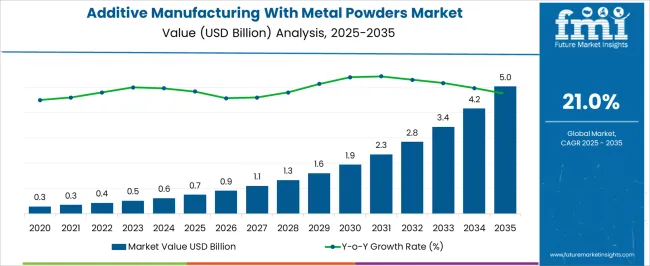

The additive manufacturing with metal powders market is valued at USD 0.7 billion in 2025 and is set to reach USD 5.0 billion by 2035, growing at a robust CAGR of 21.0%. In the early growth phase, from 2021 to 2025, the market expands from USD 0.3 billion to 0.7 billion, with intermediate milestones at USD 0.3 billion, 0.4 billion, and 0.5 billion. This period is characterized by limited adoption, driven primarily by niche applications in industries like aerospace, automotive, and healthcare, where additive manufacturing is used for prototyping and small-batch production. However, high material costs and limited availability of metal powders restrict mass-market adoption.

The inflection point occurs between 2026 and 2030, where the market accelerates significantly, growing from USD 0.7 billion to 2.3 billion. Technological advancements in material quality, printing speeds, and cost reduction make metal additive manufacturing more viable for large-scale production. The market experiences exponential growth from 2031 to 2035, reaching USD 5.0 billion. This late growth phase is marked by widespread industrial adoption as manufacturing processes become more efficient, making metal powder-based 3D printing a mainstream technology. The decline in production costs and increased production capacity further fuel rapid adoption across sectors that demand complex geometries and lightweight components.

| Metric | Value |

|---|---|

| Additive Manufacturing With Metal Powders Market Estimated Value in (2025 E) | USD 0.7 billion |

| Additive Manufacturing With Metal Powders Market Forecast Value in (2035 F) | USD 5.0 billion |

| Forecast CAGR (2025 to 2035) | 21.0% |

The additive manufacturing with metal powders market is influenced by five key parent markets that collectively define its growth, demand, and technological advancements across various industries. The additive manufacturing and 3D printing market contributes the largest share, about 30-35%, as metal powders are crucial in additive manufacturing processes such as selective laser sintering (SLS) and direct metal laser sintering (DMLS), enabling the production of complex, high-performance components for industries like aerospace, automotive, and healthcare. The metal powder production market adds approximately 20-24%, as the demand for high-quality metal powders, including titanium, aluminum, and stainless steel, increases to support the growing use of metal 3D printing across various sectors.

The aerospace and defense market contributes around 15-18%, with additive manufacturing offering lightweight, durable parts for aircraft and defense equipment, reducing material waste and improving design flexibility. The automotive market accounts for roughly 12-15%, as manufacturers use metal 3D printing for producing custom parts, tooling, and prototypes, enabling rapid prototyping and reducing lead times in vehicle production. The medical devices and healthcare market represents about 8-10%, as additive manufacturing with metal powders is used to create customized implants, prosthetics, and surgical instruments that match individual patient needs, offering higher precision and reduced recovery times.

The additive manufacturing with metal powders market is advancing rapidly, driven by the increasing demand for lightweight, high-strength components across industries such as aerospace, automotive, and healthcare. Industry publications and corporate announcements have underscored the shift toward metal-based 3D printing as manufacturers seek greater design flexibility, reduced material waste, and shorter production cycles.

Technological advancements in laser and electron beam systems have improved precision, throughput, and surface finish quality, broadening the scope of end-use applications. Strategic investments by aerospace and defense companies in additive manufacturing facilities have accelerated adoption, particularly for producing complex geometries and critical components that are difficult to fabricate using traditional methods.

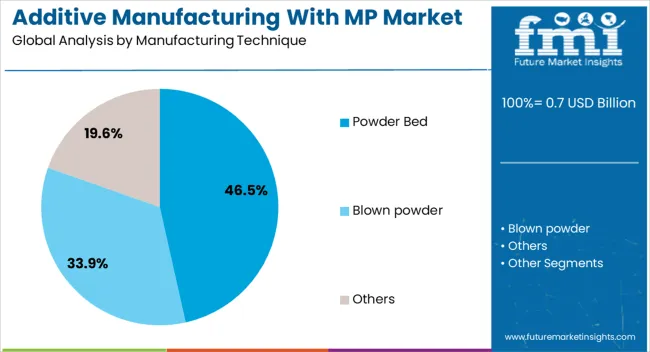

Furthermore, developments in powder metallurgy and improved material availability have enhanced performance consistency and reduced costs. Government-backed innovation programs and industrial partnerships are also supporting the integration of additive manufacturing into mainstream production lines. The market’s growth trajectory is expected to be led by powder bed manufacturing techniques, alloy materials, and aerospace applications, reflecting their established performance credentials and strong return on investment.

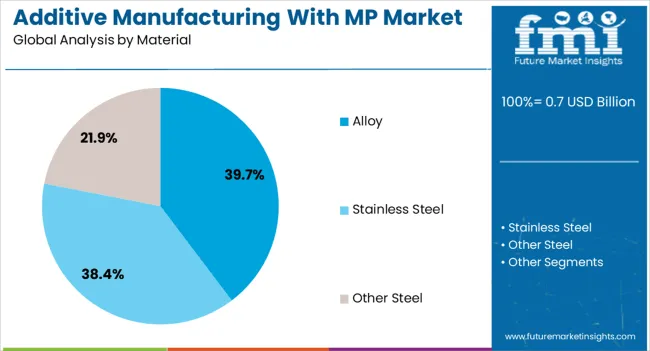

The additive manufacturing with metal powders market is segmented by manufacturing technique, material, application, and geographic regions. By manufacturing technique, additive manufacturing with metal powders market is divided into Powder Bed, Blown powder, and Others. In terms of material, additive manufacturing with metal powders market is classified into Alloy, Stainless Steel, Other Steel, Precious Metal, Tungsten, Silicon carbide, Aluminium oxide powder, Zirconium, Zirconium dioxide, Molybdenum, Magnesium, Aluminium nitride, and Tungsten carbide.

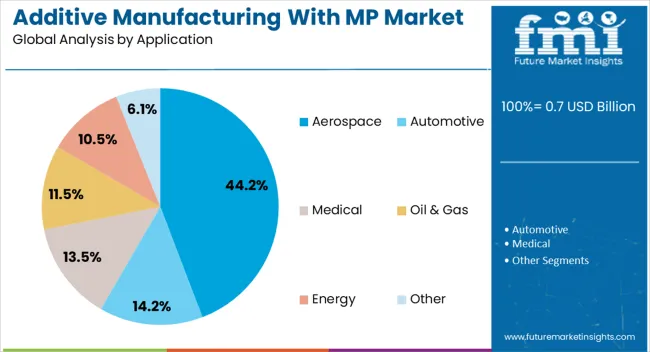

Based on application, additive manufacturing with metal powders market is segmented into Aerospace, Automotive, Medical, Oil & Gas, Energy, and Other. Regionally, the additive manufacturing with metal powders industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The powder bed segment is projected to account for 46.5% of the additive manufacturing with metal powders market revenue in 2025, maintaining its position as the leading manufacturing technique. Its dominance has been built on the ability to produce highly detailed and structurally sound components with excellent dimensional accuracy.

Laser powder bed fusion (LPBF) and electron beam melting (EBM) technologies, which form the core of this segment, have been widely adopted in industries requiring precision-engineered parts. The controlled layer-by-layer process enables efficient material usage and minimal post-processing, which reduces waste and improves cost-effectiveness for small- to medium-scale production runs.

Industry reports have highlighted the segment’s capacity to work with a wide range of metals and alloys, providing flexibility for diverse applications. As machine reliability improves and build sizes increase, the powder bed technique is expected to retain its leadership in producing high-performance, complex metal components.

The alloy segment is projected to capture 39.7% of the additive manufacturing with metal powders market revenue in 2025, leading due to its versatility and enhanced performance characteristics. Alloys such as titanium, nickel, and aluminum-based blends have been favored for their strength-to-weight ratios, corrosion resistance, and suitability for high-stress environments.

Industry data has shown that alloys outperform pure metals in applications where durability and performance under extreme conditions are critical, particularly in aerospace, defense, and energy sectors. Additive manufacturing with alloys enables the creation of tailored compositions for specific functional requirements, further enhancing their appeal.

Continuous advancements in alloy powder production methods have improved particle size uniformity and flowability, resulting in consistent build quality. With increasing emphasis on performance optimization and material efficiency, the alloy segment is expected to sustain its market-leading role.

The aerospace segment is projected to hold 44.2% of the additive manufacturing with metal powders market revenue in 2025, remaining the dominant application area. Growth in this segment has been fueled by the aerospace industry’s need for lightweight, high-strength components that can withstand extreme operating conditions.

Additive manufacturing enables the production of complex geometries, such as lattice structures, which reduce weight without compromising strength or safety. Aerospace companies have integrated metal 3D printing into both prototyping and end-use part production, reducing lead times and enabling on-demand manufacturing for critical components.

Certification advancements and quality assurance processes have further increased the sector’s confidence in additive manufacturing technologies. Additionally, the use of high-performance alloys in aerospace parts has complemented the advantages of additive manufacturing, ensuring compliance with stringent regulatory and safety standards. As sustainability initiatives drive further weight reduction and fuel efficiency goals, the aerospace segment is expected to continue as the leading application in this market.

The additive manufacturing with metal powders market is growing due to increased adoption in aerospace, automotive, and other industries requiring high-performance parts. Technological advancements in metal powder development and AM technologies are enhancing accuracy and material properties. However, high material costs and slow production speeds remain challenges.

Opportunities lie in customized, low-volume production and integration with Industry 4.0, improving efficiency and scalability. With advancements in automation, post-processing, and machine learning, manufacturers can reduce costs, enhance production speeds, and create more complex components, positioning additive manufacturing with metal powders for continued growth across various sectors.

The additive manufacturing (AM) with metal powders market is expanding rapidly, driven by its increasing adoption in the aerospace and automotive industries. These sectors require parts with complex geometries and high-performance characteristics, making metal powder-based AM technologies ideal. Metal powder-based additive manufacturing enables the production of lightweight, durable, and intricate components that cannot be easily achieved with traditional manufacturing methods. For aerospace, companies like Boeing and Airbus are using metal 3D printing to produce jet engine parts and structural components. In the automotive sector, manufacturers such as BMW and Ford are utilizing additive manufacturing for prototyping, tooling, and low-volume production of critical parts, thereby enhancing design flexibility and reducing production costs.

New metal powders, including titanium, stainless steel, aluminum, and cobalt chrome, are being developed to offer improved mechanical properties, corrosion resistance, and heat resistance for high-performance applications. Advances in powder bed fusion (PBF), directed energy deposition (DED), and binder jetting technologies are making it possible to produce parts with higher accuracy and surface finish quality. Additionally, improvements in post-processing techniques, such as heat treatment and surface finishing, are enhancing the final product quality. These advancements are enabling manufacturers to create more complex, cost-effective, and functional components that cater to industries requiring high-strength materials and tight tolerances, such as healthcare, defense, and industrial equipment manufacturing.

Additive manufacturing with metal powders offers significant opportunities in the production of customized and low-volume parts, especially in industries like healthcare, defense, and tooling. The ability to create highly personalized parts, such as custom implants in healthcare or precision components for military equipment, is a major driver for the adoption of metal powder-based AM technologies. Furthermore, metal 3D printing is well-suited for low-volume production runs, eliminating the need for costly and time-consuming tooling that is typically required in traditional manufacturing methods. Companies are leveraging additive manufacturing to reduce inventory, shorten lead times, and meet the specific needs of their customers. This flexibility, combined with cost savings in the production process, presents a significant growth opportunity for the market, particularly for small batches of specialized parts.

The additive manufacturing with metal powders market is also benefiting from the integration of automation and Industry 4.0 technologies. As manufacturers strive for greater efficiency and precision, the integration of artificial intelligence (AI), machine learning, and real-time monitoring systems is transforming additive manufacturing processes. These technologies allow for better control over the printing process, improving accuracy and reducing errors. Additionally, the automation of post-processing tasks, such as part cleaning and finishing, is reducing labor costs and enhancing production efficiency. The connection of AM systems with larger production networks, enabled by the Industrial Internet of Things (IIoT), is facilitating smarter production systems and greater scalability, allowing for on-demand manufacturing and faster time-to-market.

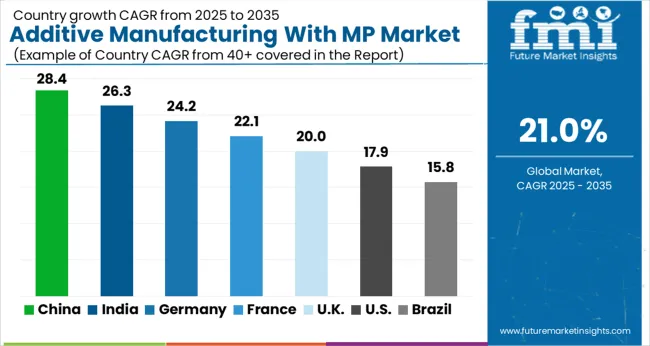

| Country | CAGR |

|---|---|

| China | 28.4% |

| India | 26.3% |

| Germany | 24.2% |

| France | 22.1% |

| UK | 20.0% |

| USA | 17.9% |

| Brazil | 15.8% |

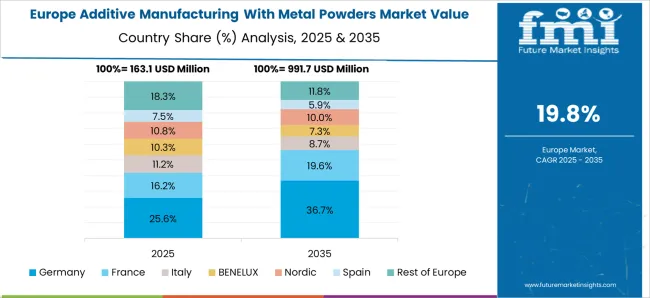

The global additive manufacturing with metal powders market is projected to grow at a CAGR of 21% from 2025 to 2035, with China leading the market at 28.4%, followed by India at 26.3%. France, the UK, and the USA are also seeing significant growth, with CAGRs ranging from 22.1% to 17.9%. The market is driven by the increasing demand for customized, high-performance, and lightweight metal components across industries such as aerospace, automotive, and healthcare. Key drivers include advancements in 3D printing technologies, government support for manufacturing innovation, and the growing need for more efficient production processes. The analysis includes over 40+ countries, with the leading markets detailed below.

The additive manufacturing with metal powders market in China is projected to grow at a CAGR of 28.4% from 2025 to 2035, making it one of the fastest-growing markets globally. The country's strong industrial base, large-scale manufacturing capabilities, and ongoing technological advancements in 3D printing are driving the demand for metal powders in additive manufacturing. The growth is further fueled by the expanding aerospace, automotive, and healthcare sectors, where additive manufacturing is increasingly used to create complex metal parts with high precision. China’s robust research and development (R&D) initiatives and significant investments in advanced manufacturing technologies, particularly in metal 3D printing, are key drivers of market growth. Additionally, the growing demand for customized and lightweight components in industries like aerospace and automotive is expected to further boost the adoption of additive manufacturing using metal powders.

The additive manufacturing with metal powders market in India is expected to grow at a CAGR of 26.3% from 2025 to 2035. India’s market growth is being fueled by the increasing adoption of additive manufacturing in industries such as aerospace, automotive, and healthcare. As industrial sectors in India continue to evolve, the need for precise and customized metal components is rising. The expansion of R&D activities and the government’s push for advanced manufacturing technologies further support the growth of the market. The increased availability of metal powder materials and 3D printing equipment at competitive prices is facilitating market penetration. The country’s strong focus on the digital manufacturing sector, along with growing investments in automation, will continue to drive the adoption of additive manufacturing solutions.

The additive manufacturing with metal powders market is in France projected to grow at a CAGR of 22.1% from 2025 to 2035. The demand for additive manufacturing in France is driven by its strong aerospace, automotive, and defense industries, which are increasingly adopting 3D printing technologies for producing metal parts. France's significant focus on advanced manufacturing technologies, supported by both government and private sector investments, is driving the adoption of metal powders in additive manufacturing. The growing trend of manufacturing customized and lightweight metal parts, particularly in aerospace and automotive industries, is expected to contribute to market growth. Additionally, France’s strong R&D efforts and the expansion of its digital manufacturing capabilities are expected to create new growth opportunities for additive manufacturing with metal powders.

The UK additive manufacturing with metal powders market is expected to grow at a CAGR of 20.0% from 2025 to 2035. The market’s growth is driven by the increasing adoption of additive manufacturing in various industries, particularly aerospace, automotive, and healthcare. The UK is making significant strides in integrating 3D printing into its industrial base, particularly for the production of metal components in sectors that demand high precision. Government incentives and collaborations between industries and research institutions are accelerating the development of new metal powder technologies. As the demand for highly customized, lightweight components rises, the use of additive manufacturing in the UK is expected to grow rapidly, with industries continuing to embrace metal powders for more efficient production processes.

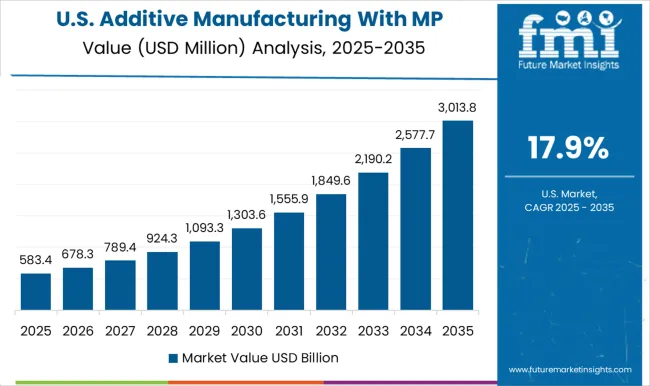

The USA additive manufacturing with metal powders market is projected to grow at a CAGR of 17.9% from 2025 to 2035. As one of the leading markets for advanced manufacturing technologies, the USA is witnessing growing adoption of 3D printing in various industries, including aerospace, automotive, healthcare, and defense. The demand for metal powders in additive manufacturing is driven by the need for high-performance, customized, and lightweight metal components. Additionally, the USA is home to several key players in the additive manufacturing sector, which are continuously innovating to develop new and improved metal powders for 3D printing. Government and private sector investments in R&D are further boosting market growth, as industries continue to adopt more efficient and cost-effective manufacturing techniques.

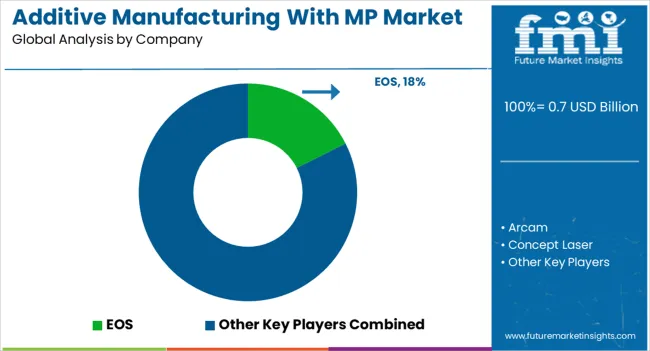

Competition in the additive manufacturing with metal powders market is driven by innovation in materials, print speed, and the ability to meet the complex demands of industries such as aerospace, automotive, and healthcare. EOS leads the market by offering cutting-edge solutions for metal additive manufacturing, specializing in high-precision systems that deliver exceptional build quality and material performance. Their product brochures emphasize the wide range of metal powders compatible with their machines, highlighting the flexibility, reliability, and precision of their additive manufacturing systems for industries requiring high-performance materials. Arcam, a subsidiary of GE Additive, competes by providing electron beam melting (EBM) technology that allows for the production of dense and complex metal parts. Their brochures emphasize the precision and efficiency of their systems, especially for the aerospace and medical sectors. Arcam focuses on delivering high-quality parts with superior mechanical properties, emphasizing the ability to print high-performance metal alloys.

Concept Laser, also a part of GE Additive, stands out with its laser powder bed fusion technology, offering machines capable of producing high-strength metal parts. Their brochures showcase a variety of metal powders for diverse applications, ranging from automotive components to highly complex medical devices. Concept Laser emphasizes its systems' versatility and speed, enabling manufacturers to rapidly prototype and produce production-quality parts. 3D Systems offers a comprehensive portfolio of additive manufacturing solutions, with a focus on flexibility, material choice, and customization. Their product brochures highlight their high-speed metal 3D printing systems, which cater to industries looking for advanced prototyping and direct manufacturing solutions.

| Item | Value |

|---|---|

| Quantitative Units | USD 0.7 Billion |

| Manufacturing Technique | Powder Bed, Blown powder, and Others |

| Material | Alloy, Stainless Steel, Other Steel, Precious Metal, Tungsten, Silicon carbide, Aluminium oxide powder, Zirconium, Zirconium dioxide, Molybdenum, Magnesium, Aluminium nitride, and Tungsten carbide |

| Application | Aerospace, Automotive, Medical, Oil & Gas, Energy, and Other |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | EOS, Arcam, Concept Laser, 3D systems, Trumpf, Renishaw, Optomec, Matsuura Machinery, and ExOne |

| Additional Attributes | Dollar sales by product type (laser melting, electron beam melting, binder jetting), application (aerospace, automotive, medical devices, industrial manufacturing), and material type (titanium, stainless steel, aluminum, cobalt-chrome). The market is driven by the growing adoption of additive manufacturing for producing complex, lightweight, and customized metal parts, along with advancements in metal powder technologies and process optimization. Regional trends indicate strong growth in North America, Europe, and Asia-Pacific, with industries increasingly turning to metal additive manufacturing to improve production efficiency, reduce waste, and enable more sustainable manufacturing processes. |

The global additive manufacturing with metal powders market is estimated to be valued at USD 0.7 billion in 2025.

The market size for the additive manufacturing with metal powders market is projected to reach USD 5.0 billion by 2035.

The additive manufacturing with metal powders market is expected to grow at a 21.0% CAGR between 2025 and 2035.

The key product types in additive manufacturing with metal powders market are powder bed, _direct metal laser sintering (dmls), _selective laser melting (slm), _electron beam melting (ebm), blown powder, _direct metal deposition (dmd), _laser engineering net shapes (lens) and others.

In terms of material, alloy segment to command 39.7% share in the additive manufacturing with metal powders market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Additives for Floor Coatings Market

Additives for Metalworking Fluids Market Size and Share Forecast Outlook 2025 to 2035

Additive Manufacturing and Material Market Trends - Growth & Forecast 2025 to 2035

Ink Additives Market Growth – Trends & Forecast 2025 to 2035

Feed Additive Nosiheptide Premix Market Size and Share Forecast Outlook 2025 to 2035

Seed Additives Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Fuel Additives Market Segmentation based on Type, Application, and Region: Forecast for 2025 and 2035

Global Food Additive Market Size, Growth, and Forecast for 2025 to 2035

Glass Additive Market Forecast and Outlook 2025 to 2035

Paint Additives Market Growth 2024-2034

Amine Additives in Paints and Coatings Market

Silage Additive Market Size and Share Forecast Outlook 2025 to 2035

Hybrid Additive Manufacturing Machines Market Size and Share Forecast Outlook 2025 to 2035

Plastic Additive Market Size and Share Forecast Outlook 2025 to 2035

Coating Additives Market Growth – Trends & Forecast 2025 to 2035

Understanding Market Share Trends in Brewing Additives

Ceramic Additives Market

Foundry Additives Market

Refining Additives Market Size and Share Forecast Outlook 2025 to 2035

Silicone Additives Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA