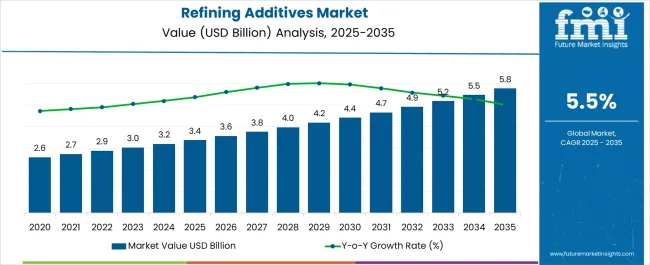

The Refining Additives Market is estimated to be valued at USD 3.4 billion in 2025 and is projected to reach USD 5.8 billion by 2035, registering a compound annual growth rate (CAGR) of 5.5% over the forecast period.

| Metric | Value |

|---|---|

| Refining Additives Market Estimated Value in (2025 E) | USD 3.4 billion |

| Refining Additives Market Forecast Value in (2035 F) | USD 5.8 billion |

| Forecast CAGR (2025 to 2035) | 5.5% |

The Refining Additives market is experiencing robust growth, driven by increasing global demand for high-quality fuels and lubricants that meet stringent performance and environmental standards. Growth is being supported by the adoption of advanced additive technologies that enhance fuel stability, improve oxidation resistance, and reduce engine deposits and emissions. Rising energy consumption across transportation, industrial, and power sectors has increased the need for refined petroleum products, creating higher demand for additives that optimize refining efficiency.

Regulatory pressure to reduce sulfur content, improve combustion efficiency, and meet international fuel standards is accelerating adoption. Additive manufacturers are investing in research and development to improve performance characteristics, enhance compatibility with diverse feedstocks, and develop multifunctional solutions.

The integration of advanced stabilizers, detergents, and corrosion inhibitors is improving operational reliability and extending the service life of fuels and lubricants As refiners seek cost-effective and sustainable solutions, the Refining Additives market is expected to maintain steady growth, driven by ongoing technological innovation and increased focus on fuel quality, efficiency, and regulatory compliance.

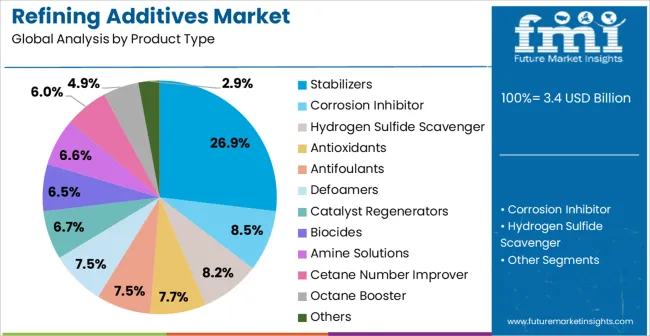

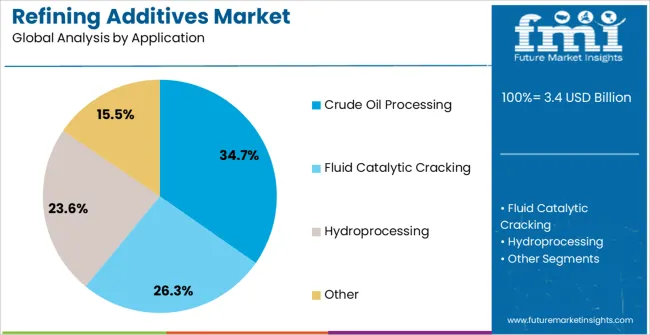

The refining additives market is segmented by product type, application, and geographic regions. By product type, refining additives market is divided into Stabilizers, Corrosion Inhibitor, Hydrogen Sulfide Scavenger, Antioxidants, Antifoulants, Defoamers, Catalyst Regenerators, Biocides, Amine Solutions, Cetane Number Improver, Octane Booster, and Others. In terms of application, refining additives market is classified into Crude Oil Processing, Fluid Catalytic Cracking, Hydroprocessing, and Other. Regionally, the refining additives industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The stabilizers product type segment is projected to hold 26.9% of the Refining Additives market revenue in 2025, establishing it as the leading product type. Growth in this segment is being driven by the critical role of stabilizers in enhancing fuel oxidation resistance, reducing sludge formation, and improving storage stability of refined petroleum products. These additives help maintain product quality during transportation and storage, which is essential for meeting regulatory standards and customer expectations.

Stabilizers also enhance the performance of other additive components, ensuring consistent functionality across various fuels and lubricants. Ongoing research in formulation optimization and compatibility with different crude oil grades has strengthened the segment’s reliability and adoption.

The cost-efficiency achieved by reducing maintenance needs and extending fuel service life further reinforces the preference for stabilizers among refiners and industrial users As the demand for high-performance and environmentally compliant fuels continues to rise globally, the stabilizers product type is expected to retain its leading position, supported by continuous technological enhancements and regulatory-driven adoption.

The crude oil processing application segment is anticipated to account for 34.7% of the market revenue in 2025, making it the leading application area. Its growth is being driven by the increasing need to optimize refinery operations and enhance the quality of intermediate and finished petroleum products. Additives used in crude oil processing improve thermal stability, prevent corrosion, and enhance the efficiency of catalytic processes, which reduces operational costs and ensures consistent product quality.

Rising global crude oil production, coupled with stringent fuel quality and emission standards, has further accelerated adoption in refinery operations. Integration of additives allows refiners to process diverse crude oil types with improved yield and reduced downtime.

Technological advancements in additive formulations have enabled enhanced performance in challenging refinery conditions, including high temperatures and variable feedstock compositions As refiners prioritize operational efficiency, regulatory compliance, and product quality, the crude oil processing segment is expected to remain a primary driver of market growth, supported by ongoing innovation in additive chemistry and process optimization.

Refinery additives (RA) are the compounds or chemicals that are used to improve and boost the performance in different refinery processes and the end-product fuels. The fuel performance is increased to meet and achieve the fuel specifications regulated by the government bodies and authorities.

These refinery additives are generally added during the refinery process and also can be used to enhance and modify the performance of specific end-product specifications, such as motor spirit and diesel. The refinery additive products are used in numerous refinery processes such as reformer system, distillation, filling plant process, process cracker, desulfurization, coker, catalytic reforming, vacuum distillation and many more.

These refinery additive products are only used by oil and gas downstream industry. There are numerous types of refining additives, such as antioxidants, stabilizers, antifoulants, defoamers, octane booster, catalyst regenerators, cold flow properties, biocides, cetane number improver, and amine solution, among others. Furthermore, more products comprise lubricity improvers and metal deactivators.

Refining additives products are used in several end-use petroleum products, such as diesel, gasoline, asphalt, and aviation fuel, among others. With the help of refinery additives the major downstream players are increasing their refinery throughputs and productivity. These type of refining additives are formulated through different processing techniques and formulated in such way to fulfill the different end-use demand.

In the construction industry, people are concerned about the health issues related to bitumen application. Recently, one of the company developed the H2S scavenger to address these types of industry challenges.

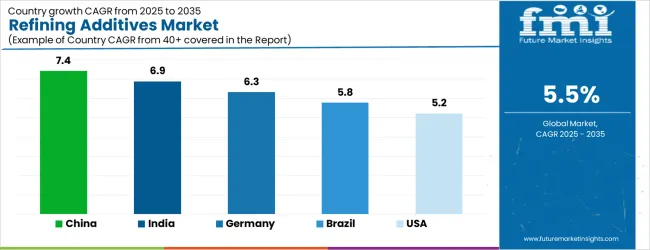

| Country | CAGR |

|---|---|

| China | 7.4% |

| India | 6.9% |

| Germany | 6.3% |

| Brazil | 5.8% |

| USA | 5.2% |

| UK | 4.7% |

| Japan | 4.1% |

The Refining Additives Market is expected to register a CAGR of 5.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.4%, followed by India at 6.9%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 4.1%, yet still underscores a broadly positive trajectory for the global Refining Additives Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.3%. The USA Refining Additives Market is estimated to be valued at USD 1.2 billion in 2025 and is anticipated to reach a valuation of USD 1.2 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 158.5 million and USD 118.0 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 3.4 Billion |

| Product Type | Stabilizers, Corrosion Inhibitor, Hydrogen Sulfide Scavenger, Antioxidants, Antifoulants, Defoamers, Catalyst Regenerators, Biocides, Amine Solutions, Cetane Number Improver, Octane Booster, and Others |

| Application | Crude Oil Processing, Fluid Catalytic Cracking, Hydroprocessing, and Other |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

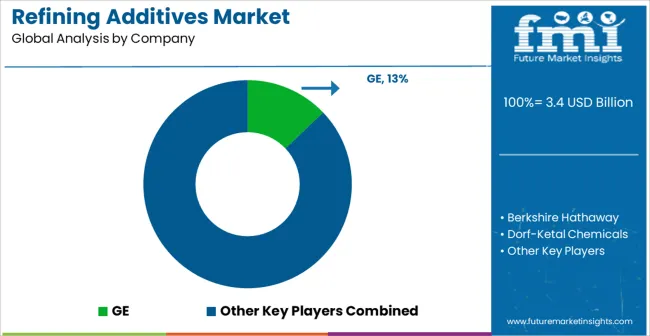

| Key Companies Profiled | GE, Berkshire Hathaway, Dorf-Ketal Chemicals, Clariant, Exxon Mobil, Amspec, Evonik Industries, Albemarle, BASF, Johnson Matthey, Ecolab, Chevron, and Infineum International |

The global refining additives market is estimated to be valued at USD 3.4 billion in 2025.

The market size for the refining additives market is projected to reach USD 5.8 billion by 2035.

The refining additives market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in refining additives market are stabilizers, corrosion inhibitor, hydrogen sulfide scavenger, antioxidants, antifoulants, defoamers, catalyst regenerators, biocides, amine solutions, cetane number improver, octane booster and others.

In terms of application, crude oil processing segment to command 34.7% share in the refining additives market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Additives for Metalworking Fluids Market Size and Share Forecast Outlook 2025 to 2035

Additives for Floor Coatings Market

Oil Refining Market Size and Share Forecast Outlook 2025 to 2035

Ink Additives Market Growth – Trends & Forecast 2025 to 2035

Seed Additives Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Fuel Additives Market Segmentation based on Type, Application, and Region: Forecast for 2025 and 2035

Anode Refining Furnace Market Size and Share Forecast Outlook 2025 to 2035

Amine Additives in Paints and Coatings Market

Alumina Refining Market Size and Share Forecast Outlook 2025 to 2035

Coating Additives Market Growth – Trends & Forecast 2025 to 2035

Understanding Market Share Trends in Brewing Additives

Ceramic Additives Market

Foundry Additives Market

Silicone Additives Market Size and Share Forecast Outlook 2025 to 2035

Butyrate Additives Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Pet Food Additives Market - Size, Share, and Forecast Outlook 2025 to 2035

Petroleum Refining Hydrogen Generation Market Size and Share Forecast Outlook 2025 to 2035

Aqua Feed Additives Market Analysis by Species Type, Ingredient and Other Additives Types Through 2035

Lubricant Additives Market Growth - Trends & Forecast 2025 to 2035

Packaging Additives Market Growth and Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA