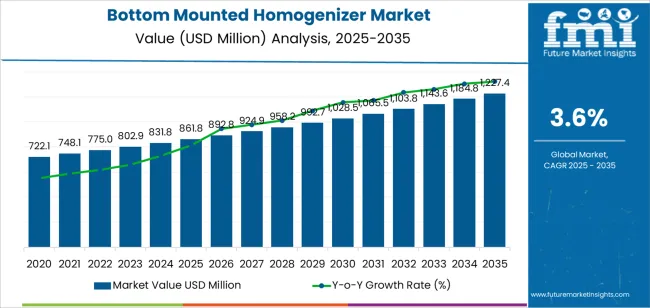

The bottom mounted homogenizer market is valued at USD 861.8 million in 2025 and is projected to reach USD 1,227.4 million by 2035 at a CAGR of 3.6%, creating an absolute dollar opportunity of USD 365.6 million across the assessment timeline. Demand expands as processing facilities prioritise compact, energy efficient and low maintenance homogenization units that support uniform emulsification and dispersion across food, pharmaceutical, cosmetic and chemical applications.

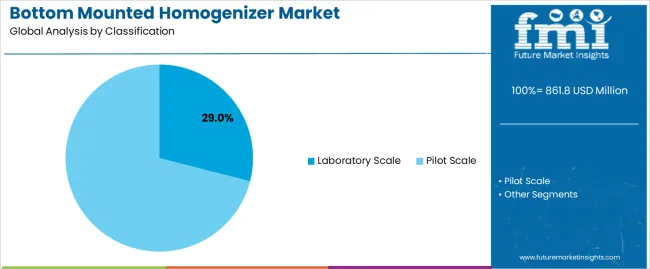

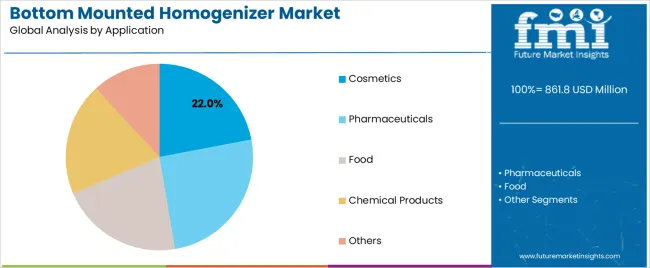

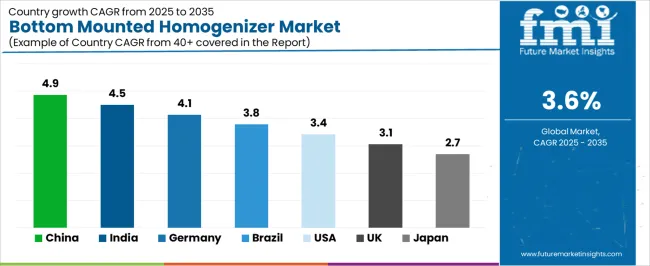

Laboratory scale systems lead with a 29.0% share in 2025 due to strong utilisation in formulation development, viscosity evaluation and small batch testing, while cosmetics represent the dominant application segment with a 22.0% share driven by rising production of creams, gels, emulsions and serums requiring consistent texture and particle size control. From 2025 to 2030, growth progresses at a GVI of 1.08, supported by improved rotor stator geometries, advanced sealing systems and variable speed platforms that strengthen process accuracy. Between 2030 and 2035, a GVI of 0.92 reflects moderated expansion as equipment standardisation increases across global processing hubs. Asia Pacific, Europe and North America anchor long-term adoption, with China advancing at 4.9%, India at 4.5% and Germany at 4.1% through 2035.

Asia Pacific remains the primary growth center, driven by expansion in large-scale processing plants and increased investment in production automation. Europe and North America continue to see steady replacement demand from advanced pharmaceutical and cosmetic industries. Through 2035, the integration of real-time process monitoring, digital control solutions, and advanced material engineering is expected to reinforce long-term growth and operational efficiency across the bottom mounted homogenizer market.

Between 2025 and 2030, the Bottom Mounted Homogenizer Market is projected to grow from USD 861.8 million to USD 1,028.5 million, yielding a growth volatility index (GVI) of 1.08, which reflects a moderate acceleration phase. Growth during this period will be driven by increasing demand for high-shear mixing systems across industries such as pharmaceuticals, food processing, cosmetics, and chemicals. The rising emphasis on efficient emulsification and particle size reduction, coupled with advancements in stainless steel fabrication and automation, is enhancing homogenizer performance. Manufacturers are integrating variable-speed drives, precision control systems, and maintenance-friendly designs to improve processing consistency and operational reliability across production facilities.

From 2030 to 2035, the market is expected to rise from USD 1,028.5 million to USD 1,227.4 million, resulting in a GVI of 0.92, indicating a mild deceleration as market adoption stabilizes. This slowdown will reflect the maturity of key end-use sectors and widespread standardization of mixing technology. However, steady replacement demand, energy-efficient system upgrades, and integration with automated process control solutions will sustain market activity. Growth will also be supported by the increasing focus on sustainable production practices and hygienic design compliance within the food and pharmaceutical industries.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 861.8 million |

| Market Forecast Value (2035) | USD 1,227.4 million |

| Forecast CAGR (2025–2035) | 3.6% |

The bottom mounted homogenizer market is growing as industries seek efficient mixing technologies that deliver consistent product texture, stability, and dispersion quality. Installed at the base of mixing vessels, these homogenizers create high-shear zones that ensure uniform blending of immiscible liquids, powders, and emulsions. Their configuration minimizes air incorporation, enhances energy transfer, and facilitates easy integration into closed processing systems. Food, pharmaceutical, cosmetic, and chemical manufacturers increasingly adopt bottom-mounted units to improve batch consistency, reduce processing time, and optimize cleaning efficiency through clean-in-place compatibility. The shift toward automated production lines and stringent quality standards continues to reinforce steady global demand.

Technological developments in rotor-stator design, seal durability, and variable speed control enhance performance flexibility across a wide viscosity range. Manufacturers prioritize stainless-steel construction, precision balancing, and modular components to support high hygiene and maintenance reliability. Expanding applications in dairy, lotion, and liquid suspension manufacturing drive adoption among both large-scale and mid-size processors. Asia-Pacific and Europe represent key growth regions due to rising investment in food processing and pharmaceutical formulation facilities. Although high initial costs and customization requirements limit smaller operations, advancements in compact design and energy efficiency continue to broaden accessibility, ensuring sustained market growth for bottom-mounted homogenizers worldwide.

The bottom mounted homogenizer market is segmented by classification, application, and region. By classification, the market is divided into laboratory scale and pilot scale units. Based on application, it is categorized into cosmetics, pharmaceuticals, food, chemical products, and others. Regionally, the market is segmented into North America, Europe, East Asia, South Asia, Latin America, and the Middle East & Africa. These divisions reflect scale-based operational capacity, industrial usage diversity, and regional adoption trends within processing and formulation industries.

The laboratory scale segment accounts for approximately 29.0% of the global bottom mounted homogenizer market in 2025, representing the leading classification category. This dominance is supported by the increasing demand for small-scale, high-precision mixing and emulsification equipment used in product development and formulation testing. Laboratory homogenizers provide controlled shear rates and adjustable speed settings suitable for experiments requiring consistent particle size distribution and dispersion uniformity.

These systems are essential in research laboratories and quality control departments across cosmetics, pharmaceuticals, and food manufacturing sectors. Manufacturers are focusing on enhancing performance through improved impeller design, reduced vibration levels, and optimized energy efficiency. The laboratory scale segment benefits from continuous innovation in sample handling and clean-in-place configurations that ensure operational convenience and reproducibility. Its adoption is particularly strong in Europe and East Asia, where R&D activity in specialty chemicals and life sciences continues to expand. The laboratory scale category remains the primary choice for product formulation, process validation, and pilot testing applications, establishing its continued leadership in the bottom mounted homogenizer market.

The cosmetics segment represents about 22.0% of the total bottom mounted homogenizer market in 2025, making it the largest application category. Its leading position is attributed to the increasing use of homogenization technology in producing creams, emulsions, gels, and serums requiring stable and uniform texture. Bottom mounted homogenizers ensure efficient mixing and dispersion of immiscible ingredients, reducing batch times while improving product consistency and aesthetic quality.

Demand in the cosmetics sector is supported by global expansion in skincare and personal care manufacturing, particularly in East Asia and Europe, where contract formulation facilities and private-label production are growing. These homogenizers are valued for their ability to handle a wide viscosity range and provide uniform particle reduction at low operational noise levels. Manufacturers focus on material compatibility, energy efficiency, and hygienic design to meet cosmetic industry quality and safety standards. The segment’s steady growth also reflects increasing emphasis on innovation in natural and bio-based formulations that require precise emulsification. The cosmetics application continues to drive overall market demand, underscoring the essential role of homogenization technology in high-quality, scalable, and reproducible product manufacturing.

The bottom-mounted homogenizer market is expanding as industries seek efficient mixing and homogenization solutions mounted at the base of vessels, especially for high-solid slurries, emulsions and dispersion of immiscible phases. Demand is driven across food and beverages, pharmaceuticals, cosmetics and chemicals where bottom entry units reduce impeller-induced vortexes and enhance fluid turnover. Nevertheless, the market faces constraints such as high capital cost, integration complexity in existing plant systems and maintenance challenges in high-viscosity environments. Providers are responding with modular bottom-mounted units, improved rotor/stator designs and enhanced service packages to support adoption.

Growth is driven by need for high-shear mixing in applications where surface-mounted mixers are ineffective such as heavy slurries, suspensions with high solids content and tanks requiring minimal turbulence. Bottom-mounted mixers allow better flow patterns, reduced shear-zone segregation and easier access for cleaning and maintenance. Manufacturers targeting process engineers emphasise features such as large clearances, high-speed rotor/stator configurations and bottom-drive mountings to support efficient mixing, reduced downtime and consistent product quality. These factors strengthen equipment justification in demanding processing environments.

Adoption of bottom-mounted homogenizers is tempered by several challenges: high upfront investment, special installation requirements such as vessel bottom reinforcement and shaft sealing, and cleaning concerns in hygienic applications. Existing plants may face retrofit difficulties or require downtime to convert to bottom-mounted units, making upgrades less attractive. Moreover, in some lighter-duty mixing tasks standard top-entry mixers suffice at lower cost, reducing the incremental benefit of bottom-mounted systems. These factors slow uptake in smaller operations or cost-conscious segments.

The market is trending toward more modular and plug-and-play bottom-mounted units that simplify installation and maintenance. Technological enhancements such as advanced rotor/stator geometries, high-speed capabilities, and materials resistant to corrosion and wear are becoming prevalent. Additionally, demand is growing in emerging regions where process industries are expanding and hygiene standards are rising. Suppliers are offering digital monitoring interfaces, service-package options and global support to appeal to a wider customer base seeking reliable performance and lifecycle support.

| Country | CAGR (%) |

|---|---|

| China | 4.9% |

| India | 4.5% |

| Germany | 4.1% |

| Brazil | 3.8% |

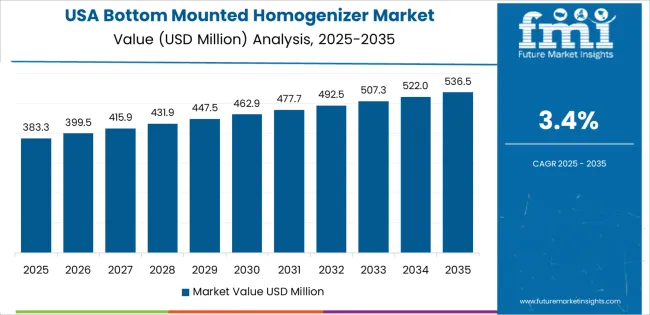

| USA | 3.4% |

| UK | 3.1% |

| Japan | 2.7% |

The bottom mounted homogenizer market is expanding steadily across major economies, with China leading at a 4.9% CAGR through 2035, driven by strong industrial processing growth, advancements in food and pharmaceutical manufacturing, and increasing automation in liquid blending systems. India follows at 4.5%, supported by rising production in dairy, cosmetics, and biotech sectors along with greater adoption of efficient mixing technologies. Germany records 4.1%, leveraging precision engineering and innovation in high-shear homogenization solutions. Brazil grows at 3.8%, reflecting modernization in food processing and chemical industries. The USA, at 3.4%, remains a stable market focused on process optimization and sustainability, while the UK (3.1%) and Japan (2.7%) emphasize compact design, energy efficiency, and precision in fluid processing for high-quality end applications.

China is recording stable advancement in the bottom mounted homogenizer market, projected to grow at a CAGR of 4.9% through 2035. Rising demand from food, beverage, and pharmaceutical industries is driving adoption of high-capacity mixing systems. Domestic manufacturers are improving rotor-stator design and automation to enhance efficiency and energy use. Expanding production facilities and continuous investment in process modernization continue to support market expansion across multiple industrial sectors.

India is witnessing consistent growth in the bottom mounted homogenizer market, increasing at a CAGR of 4.5% through 2035. Expanding dairy, cosmetics, and chemical processing industries are contributing to higher equipment demand. Local producers are developing stainless steel systems optimized for low maintenance and energy efficiency. Government manufacturing initiatives and private sector investment in processing infrastructure are further promoting adoption across medium and large-scale facilities.

Across Germany, the bottom mounted homogenizer market is advancing at a CAGR of 4.1%, supported by engineering precision, automation, and innovation in fluid mixing technologies. Manufacturers emphasize high-shear efficiency, temperature stability, and hygiene standards for food and biopharmaceutical applications. Integration of digital control systems enables accurate process monitoring. Compliance with EU manufacturing and safety standards ensures long-term product credibility and supports steady export performance across global industrial markets.

Brazil is recording gradual progress in the bottom mounted homogenizer market, forecast to grow at a CAGR of 3.8% through 2035. Expansion in food processing, beverage manufacturing, and pharmaceutical production is stimulating adoption. Local firms are forming partnerships with international equipment suppliers to improve technological capacity. Increasing investment in automation and plant efficiency supports demand for durable homogenization systems across industrial operations.

In the United States, the bottom mounted homogenizer market is growing at a CAGR of 3.4% through 2035. Strong demand from biotechnology, personal care, and chemical industries is driving steady system installation. Manufacturers are incorporating smart sensors, variable-speed drives, and clean-in-place compatibility for enhanced process control. Focus on energy efficiency and product quality optimization continues to influence equipment design. Ongoing modernization in food and pharmaceutical sectors maintains a stable market outlook.

Across the United Kingdom, the bottom mounted homogenizer market is expanding at a CAGR of 3.1% through 2035. Demand from food, cosmetics, and biopharmaceutical production facilities supports steady product utilization. Manufacturers are focusing on compact designs and low-noise operation to meet urban manufacturing requirements. Ongoing digitalization of production lines encourages integration of automated homogenization systems. Regulatory alignment with European hygiene and safety standards ensures consistent system reliability.

Japan is showing stable growth in the bottom mounted homogenizer market, projected to expand at a CAGR of 2.7% through 2035. Domestic producers emphasize process optimization, precision manufacturing, and long-term equipment durability. Advanced rotor-stator configurations support uniform dispersion in pharmaceutical and food applications. Continuous improvements in automation, energy control, and reliability reinforce product demand across specialized industries. Technological refinement and product miniaturization sustain competitiveness in compact production environments.

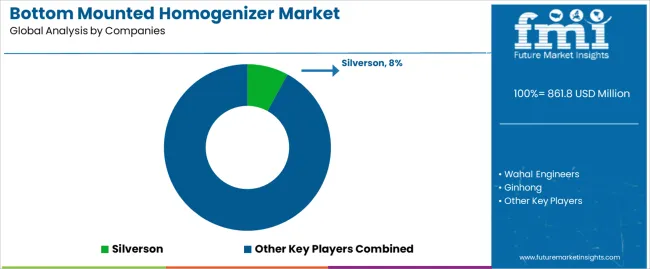

The global bottom mounted homogenizer market shows moderate concentration, driven by process equipment manufacturers specializing in liquid mixing, emulsification, and dispersion systems. Silverson leads the market with an estimated 8% share, supported by its precision-engineered homogenizers designed for consistent shear performance and scalability across pharmaceutical, food, and cosmetic applications. Wahal Engineers and Ginhong maintain strong positions through a diverse portfolio of bottom-entry and inline homogenizers tailored for batch and continuous production setups.

Fluid Process Solutions and Mecworks Innovations enhance market competitiveness by providing customized process equipment designed for viscosity control and efficient particle size reduction. PT. LOB Machinery Jaya and PerMix contribute to regional production capacity, offering cost-effective systems suited for small to mid-scale industrial processing.

Euromixers, Yekeey, and SeFluid expand market accessibility through modular homogenizer designs emphasizing energy efficiency and ease of maintenance. Competition in this segment is shaped by rotor–stator design precision, motor efficiency, and adaptability to varying process viscosities. Strategic differentiation depends on shear rate optimization, CIP (clean-in-place) capability, and system durability under continuous operation. As demand for high-quality emulsions, dispersions, and suspensions increases across biopharmaceutical and food sectors, manufacturers are investing in automation, digital monitoring, and hygienic design standards. Long-term competitiveness will rely on customization flexibility, mechanical reliability, and adherence to global manufacturing regulations ensuring consistent mixing quality and process reproducibility.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD million |

| Type (Classification) | Laboratory Scale, Pilot Scale |

| Application | Cosmetics, Pharmaceuticals, Food, Chemical Products, Others |

| Regions Covered | North America, Europe, East Asia, South Asia, Latin America, Middle East & Africa, Eastern Europe |

| Countries Covered | China, India, USA, Germany, Brazil, UK, Japan, and 40+ countries |

| Key Companies Profiled | Silverson, Wahal Engineers, Ginhong, Fluid Process Solutions, Mecworks Innovations, PT. LOB Machinery Jaya, PerMix, Euromixers, Yekeey, SeFluid |

| Additional Attributes | Market breakdown by classification and application segments; regional analysis across industrial mixing and processing sectors; competitive focus on rotor–stator technology, CIP compatibility, and energy-efficient system designs. |

The global bottom mounted homogenizer market is estimated to be valued at USD 861.8 million in 2025.

The market size for the bottom mounted homogenizer market is projected to reach USD 1,227.4 million by 2035.

The bottom mounted homogenizer market is expected to grow at a 3.6% CAGR between 2025 and 2035.

The key product types in bottom mounted homogenizer market are laboratory scale and pilot scale.

In terms of application, cosmetics segment to command 22.0% share in the bottom mounted homogenizer market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Bottom Stacking Cone Market Size and Share Forecast Outlook 2025 to 2035

Top Bottom Packaging Box Market from 2024 to 2034

Flat Bottom Pouch Market Size and Share Forecast Outlook 2025 to 2035

Flat Bottom Bags Market Size and Share Forecast Outlook 2025 to 2035

Leading Providers & Market Share in Flat Bottom Pouch Manufacturing

Bicycle Bottom Bracket Market Size and Share Forecast Outlook 2025 to 2035

Crash Lock Bottom Cartons Market

Kraft Block Bottom Pouch Market Growth – Size, Trends & Forecast 2024-2034

Pad Mounted Distribution Transformer Market Size and Share Forecast Outlook 2025 to 2035

Pad Mounted Switchgear Market Growth – Trends & Forecast 2024-2034

Wall Mounted Manifolds Market Size and Share Forecast Outlook 2025 to 2035

Wall Mounted Paper Napkin Dispensers Market Growth - Demand & Forecast 2025 to 2035

Head Mounted Display Market Analysis by Product, HMD, Application, and Region through 2025 to 2035

Truck Mounted Cranes Market Size and Share Forecast Outlook 2025 to 2035

Panel Mounted Disconnect Switch Market Size and Share Forecast Outlook 2025 to 2035

Truck Mounted Knuckle Boom Cranes Market – Growth & Demand 2025 to 2035

Tower Mounted Amplifier Market by Type, by Technology, by End User & Region Forecast till 2035

Analyzing Tower Mounted Amplifier Market Share & Industry Leaders

Track Mounted Gangway Market

Truck Mounted Concrete Mixer Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA