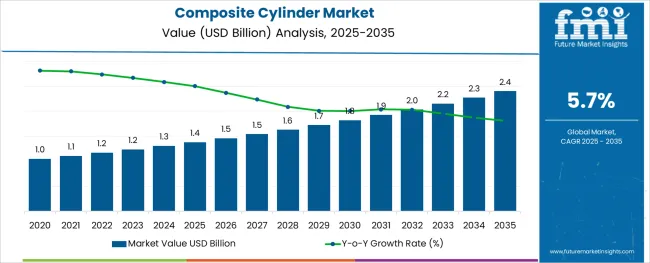

The Composite Cylinder Market is estimated to be valued at USD 1.4 billion in 2025 and is projected to reach USD 2.4 billion by 2035, registering a compound annual growth rate (CAGR) of 5.7% over the forecast period.

The composite cylinder market is witnessing significant growth due to the increasing global emphasis on safety, durability, and energy efficiency in gas storage and transportation. Composite cylinders are gaining traction as they offer a superior alternative to traditional steel cylinders, particularly in environments where weight, corrosion, and transparency are critical considerations.

Advancements in fiber-reinforced materials and polymer science are enabling manufacturers to offer high-strength, impact-resistant cylinders with longer lifespans and improved gas containment. Government initiatives to promote clean fuel adoption, particularly LPG and CNG, are further supporting the use of composite cylinders in residential, commercial, and transport sectors.

Additionally, the recyclability of composite materials aligns with evolving sustainability mandates, driving their adoption in both developed and emerging economies. As energy distribution networks modernize and safety regulations tighten, the market is expected to see strong demand across various end-use industries including household, hospitality, and fleet fueling operations.

The market is segmented by Material Type, Product Type, and End Use and region. By Material Type, the market is divided into High-density polyethylene (HDPE), Metal, Steel, Aluminum, Carbon Fibers, and Glass Fibers. In terms of Product Type, the market is classified into Type III, Type II, and Type IV. Based on End Use, the market is segmented into Household Purpose, Hotels & Restaurants, Ballooning, Gas Cutting, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

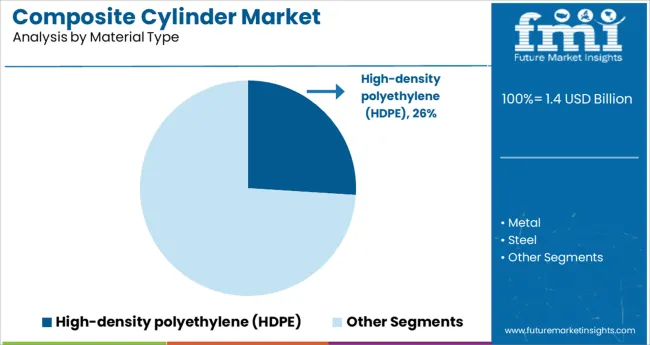

High-density polyethylene (HDPE) is expected to account for 26.0% of the total market revenue in 2025, establishing it as a key material segment in the composite cylinder industry. This leadership is driven by HDPE’s high strength-to-weight ratio, corrosion resistance, and compatibility with gas storage applications. Its performance under varied climatic conditions and resistance to UV degradation make it ideal for both indoor and outdoor environments.

HDPE is increasingly being integrated into multi-layer composite designs that enhance pressure resistance while maintaining structural flexibility. Furthermore, its recyclability and compliance with environmental regulations support its role in sustainable manufacturing.

As manufacturers prioritize lightweighting and safety, HDPE continues to serve as a foundational component in next-generation composite cylinders, particularly in domestic and light commercial sectors.

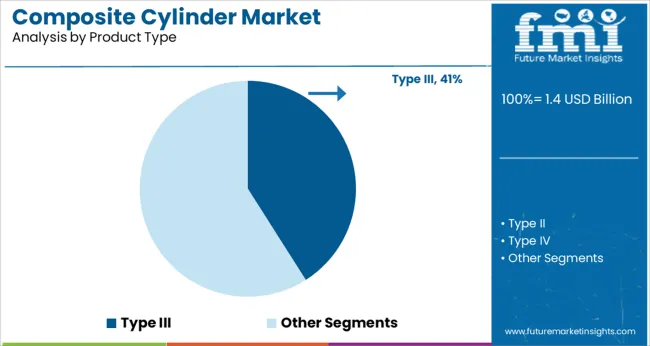

Type III composite cylinders are projected to hold 41.0% of the total market share in 2025, emerging as the leading product category. Their dominance is attributed to the use of a metal liner reinforced with full composite wrapping, offering a favorable balance between weight reduction and structural integrity.

These cylinders provide enhanced safety and gas retention properties, making them highly suitable for both stationary and mobile gas distribution applications. Type III cylinders also offer cost efficiency over their lifecycle, due to reduced maintenance needs and extended service life.

Technological advancements in filament winding and resin systems have improved manufacturing consistency, while innovations in leak detection and pressure monitoring have expanded their use in critical applications. As demand grows for cleaner fuels and safer storage solutions, Type III cylinders are increasingly being adopted in residential, industrial, and automotive sectors.

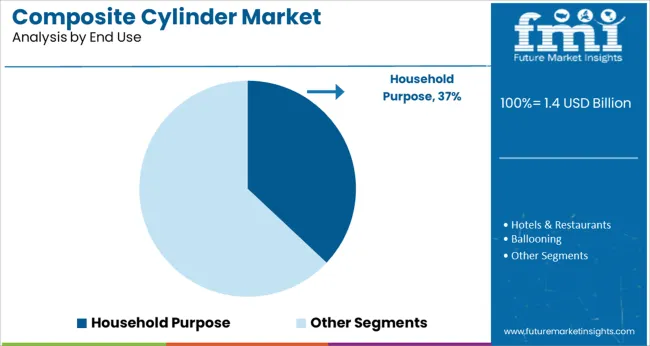

he household segment is expected to contribute 37.0% of total market revenue in 2025, making it the dominant end-use application for composite cylinders. Growth in this segment is being fueled by the replacement of traditional steel cylinders with lighter, transparent, and safer alternatives in domestic LPG distribution.

Households are increasingly favoring composite cylinders due to their ease of handling, non-corrosive nature, and visual gas-level monitoring capabilities. The push for safer cooking solutions in developing nations, supported by government subsidies and clean fuel campaigns, is further enhancing demand.

Additionally, urbanization and growing residential construction are expanding the user base for household LPG systems. With enhanced portability and child-safe features, composite cylinders have become the preferred choice for home use, driving their widespread acceptance in both rural and urban settings.

Composite cylinder has emerged are as a superb alternative for traditional metal cylinders. Composite cylinder being made of plastic material are extremely light and easy to handle in comparison with metal cylinders. The partial or full use of plastic in the manufacturing of Composite cylinder helps cooking gas suppliers and end users to leverage the physical properties of plastic & glass fiber material.

Composite cylinder has high resistance against corrosion and UV light hence qualifying it as a perfect solution for gas storage. The composite cylinder is also technologically advanced over traditional cylinders due to their explosion-proof technology. The truculent body of the Composite cylinder allows end users to keep a check on the level of gas inside the vessel while using and buying without the help of any measuring instrument.

For regular functioning, every business or operation relies heavily on energy obtained from fossil fuels and increased usage of composite cylinders for fulfilling the energy needs are driving the growth in composite cylinders market. Preference of end users for composite cylinders due to its ease of handling and partial visibility is driving the demand in composite cylinder market.

Composite cylinders being explosion proof is another important factor supporting the growth is composite cylinders market. Apart from light weight and partial visibility composite cylinders are manufactured using recyclable materials which reduce its manufacturing and maintenance cost and thus benefitting the overall value chain by reducing cost operations for businesses and other entities.

Composite cylinders are also available with colorful outer casing and barcode application which can help suppliers in handling and tracking cylinders more efficiently. Some additional features available with composite cylinders such integrated chips for providing information regarding the life of the composite cylinder.

However, some end users may speculate the safety regarding the use of plastic for packaging of gas as the consumers are habitual for using steel cylinders which can limit the pace of growth in composite cylinder market. Introduction of gas pipe line has eliminated the need for cylinders hence hampering composite cylinder market significantly.

Over the forecast period despite all the speculations the use of composite cylinders is poised to increase in many end-use industries due to the need for gas from a portable source is pushing the consumption of composite cylinders across the globe.

Regionally global composite cylinder market is segmented into:

APEJ region is expected to lead the composite cylinder market over the forecast period owing to the large base of manufacturing industry. North America is expected to follow APEJ region in composite cylinder market as the region has high per capita consumption of goods.

Western Europe and Eastern Europe being the mature region are expected to grow moderately over the forecast period in composite cylinder market. MEA and Latin America are expected to exhibit sluggish growth in the composite cylinder market. Japan is expected to contribute significant value share in composite cylinder market.

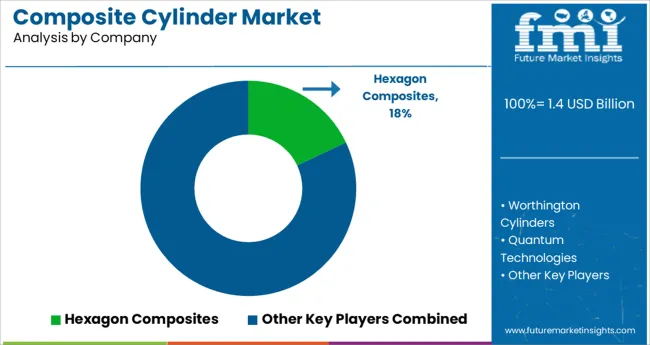

Some major players of the composite cylinder market are Quantum Technologies, Worthington Cylinders, Hexagon Composites, LiteSafe Cylinder, Santek Equipments Pvt Ltd, Luxfer Gas Cylinders, Beijing Tianhai Industry Co., Aburi Composites, ALAMAN Gas Cylinders Manufacturing LLC, Time Technoplast, Faber Industries S.p.A., Shijiazhuang Yunhong Trade Co., Ltd. and Shanghai Qiaoyu Industrial Co., Ltd.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, types, technology and applications.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global composite cylinder market is estimated to be valued at USD 1.4 billion in 2025.

It is projected to reach USD 2.4 billion by 2035.

The market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types are high-density polyethylene (hdpe), metal, steel, aluminum, carbon fibers and glass fibers.

type iii segment is expected to dominate with a 41.0% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Key Players & Market Share in Composite Cylinder Production

Composite Resin Market Size and Share Forecast Outlook 2025 to 2035

Composite Pin Insulator Market Size and Share Forecast Outlook 2025 to 2035

Composite Roller Market Size and Share Forecast Outlook 2025 to 2035

Composite Insulator Market Size and Share Forecast Outlook 2025 to 2035

Composite Paper Cans Market Size and Share Forecast Outlook 2025 to 2035

Composite Drums Market Size and Share Forecast Outlook 2025 to 2035

Composite Textile Production Equipment Market Size and Share Forecast Outlook 2025 to 2035

Composite Cans Market Size and Share Forecast Outlook 2025 to 2035

Composite Film Market Size and Share Forecast Outlook 2025 to 2035

Composite Cardboard Tube Packaging Market Size and Share Forecast Outlook 2025 to 2035

Composite Tooling Market Outlook- Share, Growth and Forecast 2025 to 2035

Composite Cardboard Tubes Market from 2025 to 2035

Composite IBCs System Market from 2025 to 2035

Market Share Breakdown of Composite Paper Cans Manufacturers

Breaking Down Market Share in Composite Cardboard Tube Packaging

Analyzing Composite Insulator Market Share & Industry Trends

Composite Door & Window Market Growth – Trends & Forecast 2024-2034

Composite AI Market Insights – Growth & Forecast 2024-2034

Biocomposite Market Growth – Trends & Forecast 2024-2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA