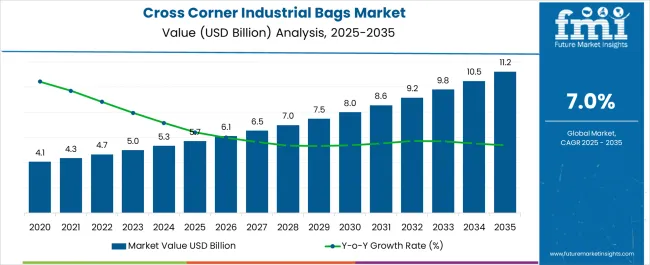

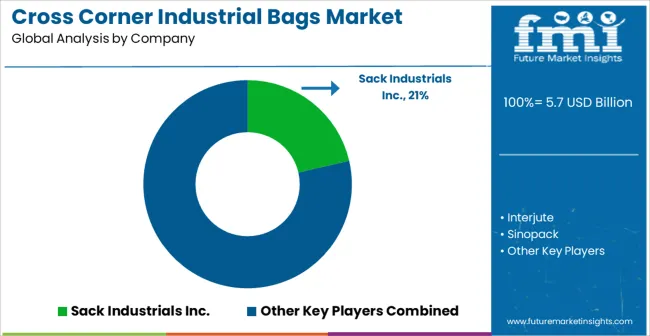

The Cross Corner Industrial Bags Market is estimated to be valued at USD 5.7 billion in 2025 and is projected to reach USD 11.2 billion by 2035, registering a compound annual growth rate (CAGR) of 7.0% over the forecast period.

| Metric | Value |

|---|---|

| Cross Corner Industrial Bags Market Estimated Value in (2025 E) | USD 5.7 billion |

| Cross Corner Industrial Bags Market Forecast Value in (2035 F) | USD 11.2 billion |

| Forecast CAGR (2025 to 2035) | 7.0% |

The Cross Corner Industrial Bags market is experiencing steady growth, supported by the increasing adoption of bulk packaging solutions across industries such as chemicals, construction, agriculture, and food processing. The demand for these bags is being driven by their superior durability, load-bearing capacity, and ease of handling compared to traditional packaging formats.

Growth is further encouraged by rising global trade activities that require safe and efficient transportation of dry bulk materials. The ability of cross corner industrial bags to maintain structural integrity during long supply chains has made them a preferred choice for manufacturers and distributors seeking reliability and cost optimization.

Additionally, the shift toward eco-friendly and recyclable materials is shaping innovations within the market, with producers focusing on sustainable raw materials and advanced coating technologies With industries placing higher emphasis on packaging efficiency, safety, and compliance with international transport standards, the market is anticipated to expand further, offering long-term opportunities for suppliers that can deliver both performance and sustainability.

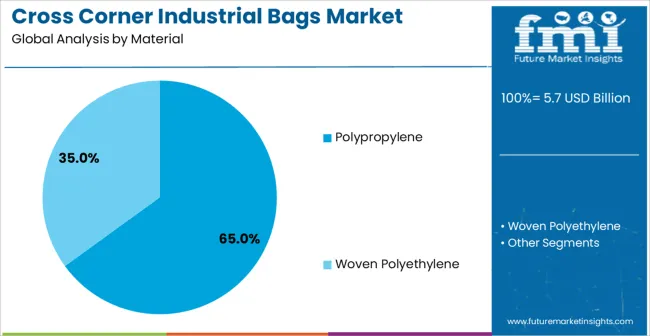

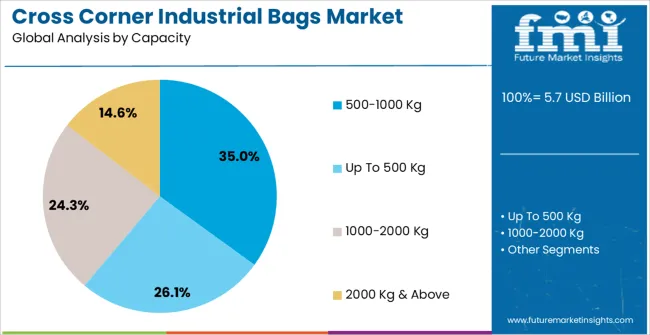

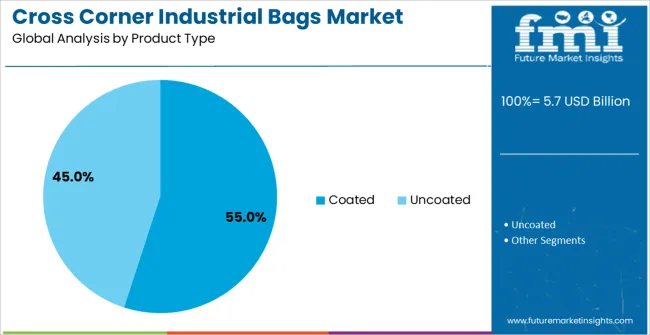

The cross corner industrial bags market is segmented by material, capacity, product type, inlet type, end use, and geographic regions. By material, cross corner industrial bags market is divided into Polypropylene and Woven Polyethylene. In terms of capacity, cross corner industrial bags market is classified into 500-1000 Kg, Up To 500 Kg, 1000-2000 Kg, and 2000 Kg & Above. Based on product type, cross corner industrial bags market is segmented into Coated and Uncoated.

By inlet type, cross corner industrial bags market is segmented into Spout Top, Open Top, Duffle Top, and Flap With Spout Top. By end use, cross corner industrial bags market is segmented into Food & Beverage, Chemicals, Agriculture, Building & Construction, and Mining Industry. Regionally, the cross corner industrial bags industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The material segment is led by polypropylene, which is projected to hold 65.00% of the Cross Corner Industrial Bags market revenue in 2025. This dominance is being attributed to the material’s combination of strength, flexibility, and resistance to environmental stress. Polypropylene bags are preferred in industries handling heavy or abrasive materials, as the fabric offers superior tear resistance while maintaining lightweight characteristics.

The growth of this segment has been supported by its cost efficiency in comparison to alternative materials, making it widely adopted across developing and developed regions. The ability of polypropylene to be recycled and reused has also encouraged its selection as industries prioritize sustainable packaging options.

Additionally, polypropylene is compatible with advanced coating and lamination processes, which enhances the bag’s resistance to moisture and improves overall product safety during long transportation cycles As global demand for bulk packaging continues to rise, polypropylene-based bags are expected to retain their leadership by balancing durability, cost, and sustainability.

In terms of capacity, bags with 500-1000 Kg load bearing are estimated to contribute 35.00% of the overall market revenue in 2025, making them a leading choice among buyers. This strong adoption is being influenced by the growing demand for mid-sized bulk packaging solutions that balance storage efficiency with ease of handling. Bags in this capacity range are particularly suitable for industries requiring optimized warehouse space, reduced handling costs, and efficient logistics management.

The segment has gained traction as these bags provide a cost-effective alternative to rigid containers while ensuring safe transportation of powders, granules, and semi-bulk materials. The standardized size and compatibility with lifting equipment have further supported their popularity in both domestic and international supply chains.

With increasing emphasis on reducing operational inefficiencies, industries are relying on packaging formats that deliver maximum payload while minimizing space utilization As a result, 500-1000 Kg capacity bags are expected to remain in high demand across multiple industrial applications.

By product type, coated bags are anticipated to command 55.00% of the Cross Corner Industrial Bags market revenue in 2025. The leading position of this segment is being attributed to the enhanced protection offered by coatings against moisture, dust, and environmental contaminants. Industries transporting sensitive or hygroscopic materials have favored coated bags due to their ability to safeguard products during extended storage and transit.

The coating also extends the shelf life of stored materials, ensuring quality is maintained throughout the supply chain. Adoption has been accelerated by increasing regulatory requirements for safe packaging and storage, particularly in sectors such as food processing, agriculture, and specialty chemicals.

The combination of durability and protection against external factors has made coated bags a trusted solution for international shipping, where exposure to varying climates is a concern As industries continue to prioritize reliability and risk reduction in packaging, coated cross corner bags are expected to sustain their leadership position with strong long-term demand.

Cross Corner Industrial Bags are used for primary as well as secondary packaging to protect the contents from contamination. Cross Corner Industrial Bags are widely used during the transportation of goods from one place to another without any damage.

Cross Corner Industrial Bags are also known as Cross Corner FIBC’s (Flexible Intermediate Bulk Container). Cross Corner Industrial Bags are equipped with cross loops for easy handling during transportation.

Cross Corner Industrial Bags are available in variety of inlets and outlets including open top, spout top, duffle top and flap with spout top whereas come outlets are flat bottom, discharge spout, and discharge spout with flap. Cross

Corner Industrial Bags are primarily used for storing and transporting powdered and granular as well as wet materials. Cross Corner Industrial Bags can be easily customized as per the customer requirement. Cross Corner Industrial Bags are available with PE coated lamination and UV resistant material.

Cross Corner Industrial Bags witnesses an increase in demand and popularity attributing to the bag’s perfect stitching and the cross corner loop design allows for easy fork lift. The U-panel construction of the cross corner industrial bags is ideal for storing variety of products and the long cross loops offer tremendous lifting capacity.

Cross Corner Industrial Bags are produced with the lifting loops sewn on adjacent corners to ensure that the loops stand upright. After the filling of the bags, the independent stand-up cross loops reduces bag handling times by forklift as the operator does not need an extra help to keep the loops upright and open.

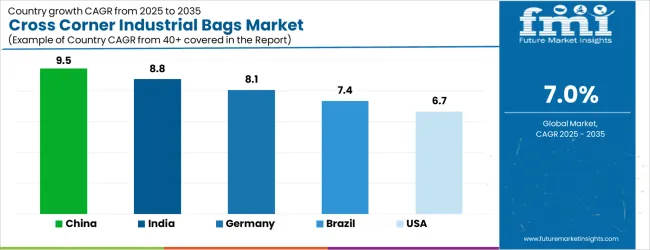

| Country | CAGR |

|---|---|

| China | 9.5% |

| India | 8.8% |

| Germany | 8.1% |

| Brazil | 7.4% |

| USA | 6.7% |

| UK | 6.0% |

| Japan | 5.3% |

The Cross Corner Industrial Bags Market is expected to register a CAGR of 7.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.5%, followed by India at 8.8%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.3%, yet still underscores a broadly positive trajectory for the global Cross Corner Industrial Bags Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 8.1%. The USA Cross Corner Industrial Bags Market is estimated to be valued at USD 2.0 billion in 2025 and is anticipated to reach a valuation of USD 2.0 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 291.2 million and USD 143.7 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 5.7 Billion |

| Material | Polypropylene and Woven Polyethylene |

| Capacity | 500-1000 Kg, Up To 500 Kg, 1000-2000 Kg, and 2000 Kg & Above |

| Product Type | Coated and Uncoated |

| Inlet Type | Spout Top, Open Top, Duffle Top, and Flap With Spout Top |

| End Use | Food & Beverage, Chemicals, Agriculture, Building & Construction, and Mining Industry |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Sack Industrials Inc., Interjute, Sinopack, Aditya Timpack Pvt Ltd., Strosack Group, Bonus Bags, Accon, Years Sentetik, Virgo Polymer India Ltd., and Vishish Bulkpack Solution |

The global cross corner industrial bags market is estimated to be valued at USD 5.7 billion in 2025.

The market size for the cross corner industrial bags market is projected to reach USD 11.2 billion by 2035.

The cross corner industrial bags market is expected to grow at a 7.0% CAGR between 2025 and 2035.

The key product types in cross corner industrial bags market are polypropylene and woven polyethylene.

In terms of capacity, 500-1000 kg segment to command 35.0% share in the cross corner industrial bags market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Plastic Bags Market from 2025 to 2035

Circular Industrial Bags Market Size and Share Forecast Outlook 2025 to 2035

Industrial Grade Electrochemical CO Sensor Market Size and Share Forecast Outlook 2025 to 2035

Industrial Bench Scale Market Size and Share Forecast Outlook 2025 to 2035

Cross-chain NFT Market Size and Share Forecast Outlook 2025 to 2035

Industrial Low Profile Floor Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Industrial Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA