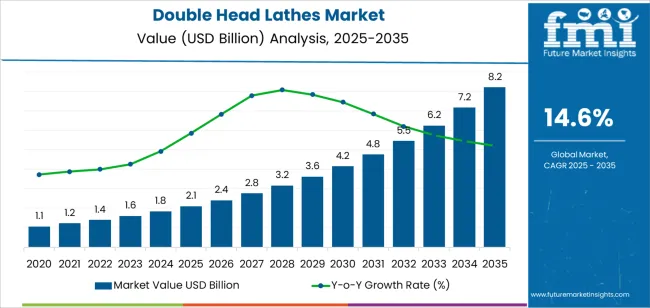

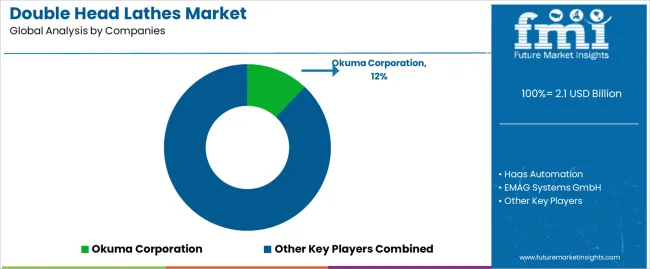

The global double head lathes market is valued at USD 2.1 billion in 2025. It is slated to reach USD 8.2 billion by 2035, recording an absolute increase of USD 6171.4 million over the forecast period. This translates into a total growth of 290.5%, with the market forecast to expand at a compound annual growth rate (CAGR) of 14.6% between 2025 and 2035. The overall market size is expected to grow by nearly 3.9X during the same period, supported by increasing demand for high-precision machining equipment across manufacturing sectors, growing adoption of double head lathes in automotive component production and aerospace manufacturing, and rising emphasis on production efficiency and multi-tasking capabilities across machinery manufacturing, shipbuilding, and industrial fabrication applications.

Between 2025 and 2030, the double head lathes market is projected to expand from USD 2.1 billion to USD 3375.4 million, resulting in a value increase of USD 1251.0 million, which represents 20.3% of the total forecast growth for the decade. This phase of development will be shaped by increasing automotive manufacturing automation and precision machining requirements, rising adoption of advanced CNC control systems in machinery production, and growing demand for multi-spindle machining solutions in shipbuilding and aerospace applications. Machine tool manufacturers and industrial equipment suppliers are expanding their double head lathe capabilities to address the growing demand for efficient and high-precision machining solutions that ensure production quality and operational throughput.

From 2030 to 2035, the market is forecast to grow from USD 3375.4 million to USD 8.2 billion, adding another USD 4920.4 million, which constitutes 79.7% of the overall ten-year expansion. This period is expected to be characterized by the expansion of Industry 4.0 integration and smart manufacturing platforms requiring connected machine tools, the development of advanced automation features and robotic loading systems, and the growth of specialized applications for complex component machining and high-volume production environments. The growing adoption of digitalization strategies and predictive maintenance capabilities will drive demand for double head lathes with enhanced connectivity features and intelligent machining capabilities.

Between 2020 and 2025, the double head lathes market experienced steady growth, driven by increasing precision machining standards and growing recognition of double head lathes as essential equipment for enhancing manufacturing productivity and component quality across automotive, aerospace, and heavy machinery manufacturing applications. The market developed as manufacturing engineers and production managers recognized the potential for double head lathe technology to reduce cycle times, improve machining accuracy, and support high-volume production objectives while meeting stringent quality requirements. Technological advancement in CNC control systems and spindle synchronization began emphasizing the importance of maintaining machining precision and operational reliability in demanding production environments.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 2.1 billion |

| Forecast Value in (2035F) | USD 8.2 billion |

| Forecast CAGR (2025 to 2035) | 14.6% |

Market expansion is being supported by the increasing global demand for high-efficiency machining solutions driven by automotive production volume requirements and manufacturing cost reduction pressures, alongside the corresponding need for advanced machine tools that can enhance productivity, enable simultaneous machining operations, and maintain precision quality across automotive component production, machinery manufacturing, shipbuilding, and aerospace fabrication applications. Manufacturing facilities and production engineers are increasingly focused on implementing double head lathe solutions that can reduce processing time, improve material utilization, and provide consistent machining accuracy in high-volume production environments.

The growing emphasis on manufacturing automation and production efficiency is driving demand for double head lathes that can support lights-out manufacturing, enable unmanned operation capabilities, and ensure comprehensive throughput optimization. Manufacturing managers' preference for machine tools that combine dual-spindle productivity with automation compatibility and operational flexibility is creating opportunities for innovative double head lathe implementations. The rising influence of Industry 4.0 connectivity and smart manufacturing integration is also contributing to increased adoption of double head lathes that can provide real-time production monitoring without compromising machining precision or equipment reliability.

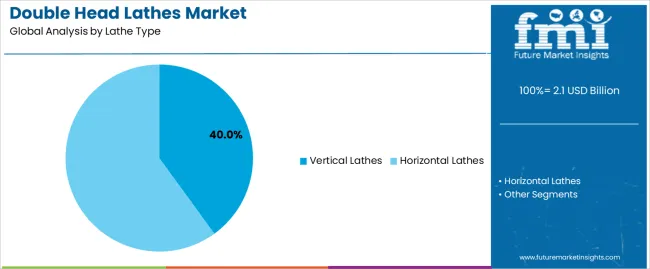

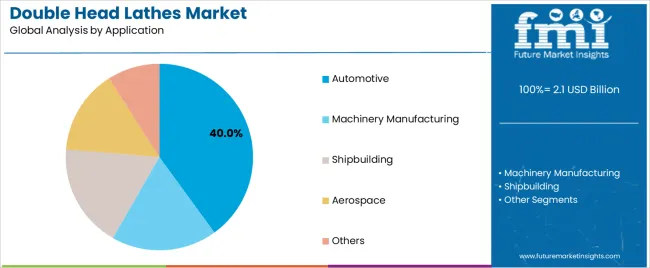

The market is segmented by lathe type, application, and region. By lathe type, the market is divided into vertical lathes and horizontal lathes. Based on application, the market is categorized into automotive, machinery manufacturing, shipbuilding, aerospace, and others. Regionally, the market is divided into East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, and Eastern Europe.

The vertical lathes segment is projected to maintain its leading position with 40% market share in the double head lathes market in 2025, reaffirming its role as the preferred lathe configuration for large component machining and heavy-duty manufacturing applications. Manufacturing facilities and machine shops increasingly utilize vertical double head lathes for their superior workpiece handling capabilities, excellent floor space efficiency, and proven effectiveness in machining large diameter components while maintaining gravitational stability. Vertical lathe technology's proven effectiveness and application versatility directly address the industry requirements for heavy component processing and large-scale manufacturing operations across diverse automotive platforms and industrial machinery production environments.

This lathe type segment forms the foundation of heavy component manufacturing operations, as it represents the configuration with the greatest contribution to large workpiece machining capabilities and established performance record across multiple industrial applications and manufacturing sectors. Manufacturing industry investments in production capacity expansion continue to strengthen adoption among automotive manufacturers and heavy equipment producers. With production requirements demanding large component capabilities and floor space optimization, vertical double head lathes align with both operational objectives and facility layout requirements, making them the central component of comprehensive manufacturing strategies.

The automotive application segment is projected to represent the largest share of double head lathe demand in 2025, underscoring its role as the primary driver for double head lathe adoption across automotive component manufacturing, powertrain production facilities, and transmission system fabrication operations. Automotive manufacturers prefer double head lathes for component machining due to their exceptional productivity characteristics, precise machining capabilities, and ability to reduce cycle times while supporting high-volume production and quality consistency. Positioned as essential equipment for modern automotive manufacturing, double head lathes offer both efficiency advantages and quality assurance benefits.

The segment is supported by continuous innovation in automotive manufacturing technology and the growing availability of specialized machine tool configurations that enable superior machining performance with enhanced automation integration and reduced production costs. Automotive manufacturers are investing in comprehensive advanced machining equipment programs to support increasingly demanding production volumes and component precision requirements. As automotive electrification accelerates and manufacturing complexity increases, the automotive application will continue to dominate the market while supporting advanced machining utilization and production optimization strategies.

The double head lathes market is advancing steadily due to increasing demand for productivity enhancement solutions driven by manufacturing cost pressures and growing adoption of multi-tasking machine tools that require specialized equipment providing enhanced efficiency characteristics and precision benefits across automotive, machinery manufacturing, shipbuilding, and aerospace applications. However, the market faces challenges, including high capital investment costs for advanced CNC equipment, competition from alternative machining technologies and turning centers, and skill requirements related to programming complexity and operational expertise. Innovation in automation integration technologies and digital connectivity features continues to influence product development and market expansion patterns.

The growing automotive manufacturing sector is driving demand for specialized machining solutions that address production requirements including reduced cycle times, enhanced component accuracy, and high-volume manufacturing capabilities for drivetrain and suspension components. Automotive production requires advanced double head lathe configurations that deliver superior machining performance across multiple operations while maintaining quality consistency and cost-effectiveness. Automotive manufacturers are increasingly recognizing the productivity advantages of double head lathe integration for component manufacturing and production efficiency, creating opportunities for innovative machine designs specifically engineered for high-volume automotive manufacturing environments.

Modern double head lathe manufacturers are incorporating Industry 4.0 connectivity and smart manufacturing technologies to enhance production monitoring, enable predictive maintenance, and support comprehensive operational intelligence objectives through integrated sensor systems and cloud-based analytics platforms. Leading companies are developing machine tools with real-time performance monitoring, implementing automated quality verification systems, and advancing control technologies that optimize machining parameters and minimize unplanned downtime. These technologies improve manufacturing effectiveness while enabling new operational capabilities, including remote diagnostics, automated process optimization, and data-driven production planning. Advanced digitalization integration also allows manufacturers to support comprehensive efficiency objectives and competitive differentiation beyond traditional machining performance attributes.

The expansion of unmanned manufacturing and lights-out production capabilities is driving demand for double head lathes with integrated automated loading systems and robotic material handling compatibility. These advanced manufacturing applications require specialized machine configurations with automation interfaces, pallet systems, and connectivity features that enable continuous unattended operation and maximize equipment utilization. Manufacturers are investing in automation-ready machine designs and robotic integration capabilities to serve emerging smart factory applications while supporting innovation in automotive manufacturing, aerospace production, and high-volume component fabrication sectors.

| Country | CAGR (2025-2035) |

|---|---|

| China | 4.3% |

| India | 4.0% |

| Germany | 3.7% |

| Brazil | 3.4% |

| USA | 3.0% |

| UK | 2.7% |

| Japan | 2.4% |

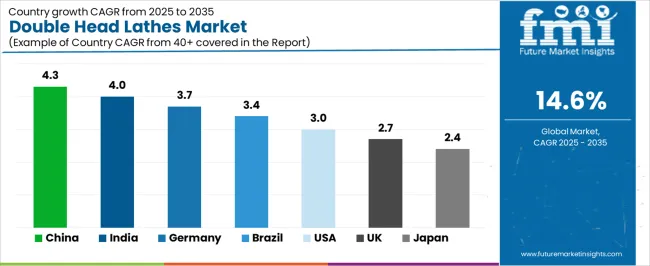

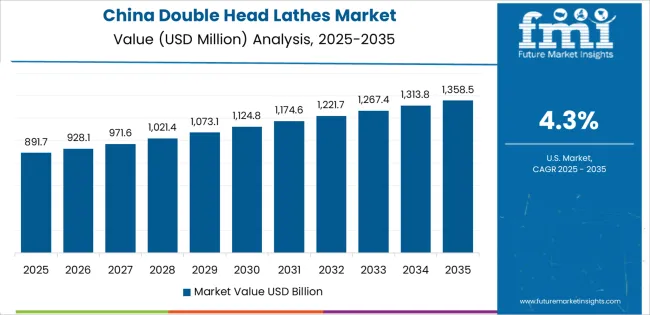

The double head lathes market is experiencing solid growth globally, with China leading at a 4.3% CAGR through 2035, driven by expanding automotive manufacturing capacity, growing machinery production infrastructure, and increasing adoption of advanced CNC machine tools across industrial manufacturing sectors. India follows at 4.0%, supported by growing automotive component manufacturing, expanding heavy machinery production, and rising investments in manufacturing modernization programs.

Germany shows growth at 3.7%, emphasizing precision engineering excellence, automotive manufacturing leadership, and advanced machine tool technology development. Brazil demonstrates 3.4% growth, supported by expanding automotive assembly operations, growing machinery manufacturing sector, and increasing industrial equipment modernization. The United States records 3.0%, focusing on aerospace manufacturing capabilities, automotive production efficiency, and advanced machining technology adoption. The United Kingdom exhibits 2.7% growth, emphasizing precision manufacturing and aerospace component production. Japan shows 2.4% growth, supported by machine tool manufacturing excellence and automotive production technology leadership.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

Revenue from double head lathes in China is projected to exhibit exceptional growth with a CAGR of 4.3% through 2035, driven by expanding automotive manufacturing capacity and rapidly growing machinery production infrastructure supported by government manufacturing upgrade initiatives and industrial modernization programs. The country's massive manufacturing scale and increasing investment in advanced machine tool technologies are creating substantial demand for double head lathe solutions. Major machine tool manufacturers and automotive suppliers are establishing comprehensive production capabilities to serve both domestic markets and export opportunities.

Revenue from double head lathes in India is expanding at a CAGR of 4.0%, supported by growing automotive component manufacturing capabilities, expanding heavy machinery production, and increasing investments in manufacturing modernization programs across industrial sectors. The country's developing manufacturing infrastructure and production capacity expansion are driving adoption of advanced machine tools throughout automotive and machinery sectors. Leading machine tool suppliers and manufacturing equipment companies are establishing distribution and service facilities to address growing domestic demand.

Revenue from double head lathes in Germany is expanding at a CAGR of 3.7%, supported by the country's emphasis on precision engineering excellence, automotive manufacturing leadership, and advanced machine tool technology development capabilities. The nation's automotive engineering sophistication and machine tool industry expertise are driving demand for high-specification double head lathe solutions. Leading machine tool manufacturers and automotive suppliers are investing extensively in advanced machining technologies and production optimization systems.

Revenue from double head lathes in Brazil is expanding at a CAGR of 3.4%, supported by expanding automotive assembly operations, growing machinery manufacturing sector, and increasing industrial equipment modernization across manufacturing industries. The nation's developing automotive production capabilities and industrial expansion are driving demand for advanced machining equipment solutions. Machine tool distributors and manufacturing equipment suppliers are investing in market development and technical support to serve growing demand.

Revenue from double head lathes in the United States is expanding at a CAGR of 3.0%, supported by the country's focus on aerospace manufacturing capabilities, automotive production efficiency enhancement, and advanced machining technology adoption. The nation's comprehensive manufacturing sector and aerospace industry leadership are driving demand for high-performance double head lathe solutions. Machine tool manufacturers and manufacturing equipment companies are investing in technology innovation and production capabilities to serve both domestic and international markets.

Revenue from double head lathes in the United Kingdom is expanding at a CAGR of 2.7%, driven by the country's precision manufacturing capabilities, aerospace component production emphasis, and operational efficiency requirements. UK's aerospace industry strength and precision engineering capabilities are driving demand for advanced double head lathe solutions. Machine tool suppliers and manufacturing technology companies are establishing comprehensive programs for advanced equipment provision.

Revenue from double head lathes in Japan is expanding at a CAGR of 2.4%, supported by the country's machine tool manufacturing excellence, automotive production technology leadership, and strong emphasis on precision and reliability in manufacturing equipment. Japan's manufacturing sophistication and technology leadership are driving demand for high-precision double head lathe products. Machine tool manufacturers and automotive companies are investing in specialized capabilities for advanced manufacturing applications.

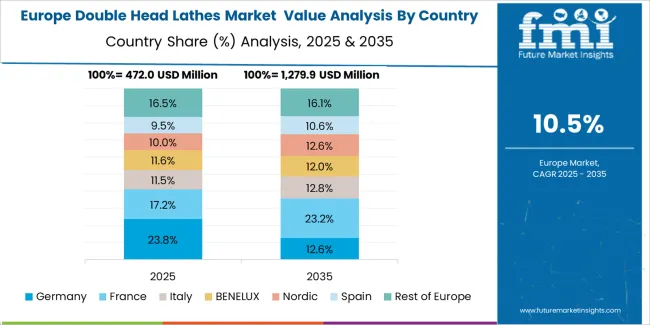

The double head lathes market in Europe is projected to grow from USD 472.1 million in 2025 to USD 1842.2 million by 2035, registering a CAGR of 14.6% over the forecast period. Germany is expected to maintain leadership with a 31.2% market share in 2025, moderating to 30.4% by 2035, supported by automotive manufacturing excellence, machine tool engineering leadership, and strong precision manufacturing capabilities.

The United Kingdom follows with 18.7% in 2025, projected at 18.3% by 2035, driven by aerospace manufacturing, precision engineering, and advanced component production. France holds 15.9% in 2025, reaching 16.2% by 2035 on the back of automotive production infrastructure and machinery manufacturing. Italy commands 13.4% in 2025, rising slightly to 13.7% by 2035, while Spain accounts for 10.1% in 2025, reaching 10.4% by 2035 aided by automotive manufacturing expansion and industrial equipment production.

The Netherlands maintains 5.6% in 2025, up to 5.8% by 2035 due to precision manufacturing operations and machinery production. The Rest of Europe region, including Nordics, Central & Eastern Europe, and other markets, is anticipated to hold 5.1% in 2025 and 5.2% by 2035, reflecting steady advancement in manufacturing capabilities and machine tool adoption.

The double head lathes market is characterized by competition among established machine tool manufacturers, CNC equipment suppliers, and specialized lathe technology companies. Companies are investing in advanced CNC control development, automation integration innovation, product configuration expansion, and application-specific feature development to deliver high-performance, reliable, and productive double head lathe solutions. Innovation in spindle synchronization systems, automated loading technologies, and smart manufacturing connectivity is central to strengthening market position and competitive advantage.

Okuma Corporation maintains strong market presence, offering comprehensive double head lathe solutions with focus on automotive manufacturing applications, advanced CNC control systems, and precision machining capabilities across industrial sectors. Haas Automation provides innovative CNC machine tool technologies with emphasis on cost-effective automation and user-friendly operation. EMAG Systems GmbH delivers specialized vertical lathe solutions focusing on automotive and industrial applications. Ningbo ZNCD Intelligent Equipment offers advanced CNC machine tools for diverse manufacturing sectors. Zhejiang Zhongzhi Jinggong Intelligent Equipment provides comprehensive machining solutions with automation integration. BOCHI Machine Tool Group emphasizes heavy-duty lathe manufacturing for industrial applications.

Additional manufacturers including Shandong Precision Group, Zhejiang Baoyu CNC Machine Tools, Anyang Anzheng Machine Tool, Taizhou Yiji Numerical Control Machine Tool, Zhejiang Zhongxing CNC Machine Tool, Nanjing Haotang Machine Tools, Dongguan SNK CNC Technology, Beijing High-Precision Technology, Chien Yih Machinery, and Anhui Lecn contribute to market diversity with specialized product offerings serving specific manufacturing requirements and regional markets.

Double head lathes represent a specialized machine tool segment within industrial manufacturing applications, projected to grow from USD 2.1 billion in 2025 to USD 8.2 billion by 2035 at a 14.6% CAGR. These precision manufacturing equipment systems—primarily vertical and horizontal configurations for industrial applications—serve as critical production tools in automotive component manufacturing, machinery production, shipbuilding operations, and aerospace fabrication where enhanced productivity, machining precision, and operational efficiency are essential. Market expansion is driven by increasing automotive production volumes, growing manufacturing automation requirements, expanding aerospace component demand, and rising emphasis on production efficiency across automotive, machinery manufacturing, and heavy industry sectors.

How Manufacturing Regulators Could Strengthen Equipment Standards and Safety Performance?

How Industry Associations Could Advance Technology Standards and Professional Development?

How Double Head Lathe Manufacturers Could Drive Innovation and Market Leadership?

How Manufacturing Facilities Could Optimize Production Performance and Equipment Utilization?

How Research Institutions Could Enable Technology Advancement?

How Investors and Financial Enablers Could Support Market Growth and Capability Enhancement?

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 2.1 billion |

| Lathe Type | Vertical Lathes, Horizontal Lathes |

| Application | Automotive, Machinery Manufacturing, Shipbuilding, Aerospace, Others |

| Regions Covered | East Asia, Europe, North America, South Asia, Latin America, Middle East & Africa, Eastern Europe |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Okuma Corporation, Haas Automation, EMAG Systems GmbH, Ningbo ZNCD Intelligent Equipment, Zhejiang Zhongzhi Jinggong Intelligent Equipment, BOCHI Machine Tool Group |

| Additional Attributes | Dollar sales by lathe type and application category, regional demand trends, competitive landscape, technological advancements in CNC control systems, automation integration development, smart manufacturing connectivity, and machining performance optimization |

The global double head lathes market is estimated to be valued at USD 2.1 billion in 2025.

The market size for the double head lathes market is projected to reach USD 8.2 billion by 2035.

The double head lathes market is expected to grow at a 14.6% CAGR between 2025 and 2035.

The key product types in double head lathes market are vertical lathes and horizontal lathes.

In terms of application, automotive segment to command 40.0% share in the double head lathes market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Double Zipper Bags Market Size and Share Forecast Outlook 2025 to 2035

Double End Truck Wrench Market Size and Share Forecast Outlook 2025 to 2035

Double Hung Windows Market Size and Share Forecast Outlook 2025 to 2035

Double Coated Film Tapes Market Size and Share Forecast Outlook 2025 to 2035

Double Stack Oven Market Size and Share Forecast Outlook 2025 to 2035

Double Decker Roll Forming Machine Market Size and Share Forecast Outlook 2025 to 2035

Double Sided Tapes Market Size, Share & Forecast 2025 to 2035

Competitive Overview of Double Decker Roll Forming Machine Market Share

Double Seam Bowl Market

High Power Double-Clad Fiber Bragg Grating Market Size and Share Forecast Outlook 2025 to 2035

Head Protection Equipment Market Forecast Outlook 2025 to 2035

Head-up Display Market Size and Share Forecast Outlook 2025 to 2035

Head Band Ophthalmoscopes Market Size and Share Forecast Outlook 2025 to 2035

Head and Neck Cancer (HNC) Therapeutics Market - Growth & Drug Developments 2025 to 2035

Headspace Gas Analyzers Market - Trends & Forecast 2025 to 2035

Head Mounted Display Market Analysis by Product, HMD, Application, and Region through 2025 to 2035

Headwear Market Analysis by Product Type, Distribution Channel, and Region through 2025 to 2035

Headless CMS Software Market - Trends & Forecast 2025 to 2035

Head and Neck Squamous Cell Carcinoma Market

VR Headsets Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA