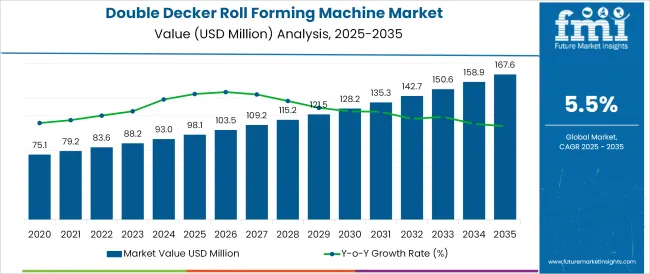

The Double Decker Roll Forming Machine Market is estimated to be valued at USD 98.1 million in 2025 and is projected to reach USD 167.6 million by 2035, registering a compound annual growth rate (CAGR) of 5.5% over the forecast period.

The double decker roll forming machine market is gaining momentum as manufacturers seek compact, high-output machinery capable of forming multiple profiles from a single line. This growth is being influenced by increasing demand for space-optimized production systems, especially in industries with high customization and volume requirements.

The integration of digital control systems and servo motors in these machines has improved precision and reduced changeover times, allowing for continuous operation and faster throughput. Additionally, stricter quality standards and demand for consistent dimensional accuracy in formed components are driving investment in advanced roll forming solutions.

The ability of double decker machines to switch between top and bottom roll sets without mechanical disassembly is creating operational flexibility that aligns with lean manufacturing practices. Looking forward, the market is expected to benefit from infrastructure expansion, electrification of transport, and increased modular construction activity across developing and developed regions.

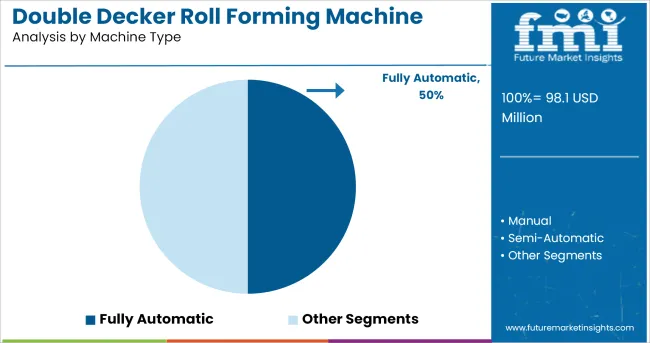

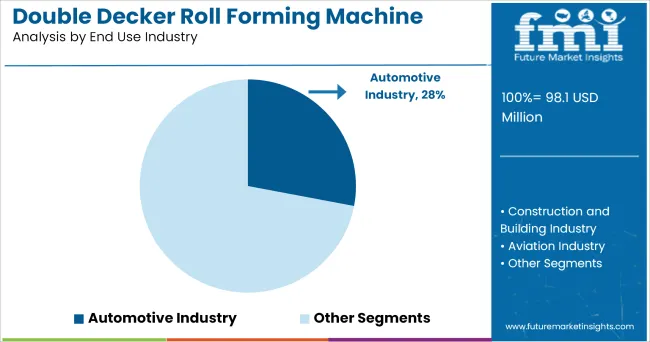

The market is segmented by Machine Type and End Use Industry and region. By Machine Type, the market is divided into Fully Automatic, Manual, and Semi-Automatic. In terms of End Use Industry, the market is classified into Automotive Industry, Construction and Building Industry, Aviation Industry, Storage Industry, Oil and Gas Industry, and Logistics.

Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Fully automatic machines are expected to hold 50.0% of the total revenue share in the double decker roll forming machine market in 2025, making it the leading segment. This dominance is being driven by the ability of fully automatic systems to streamline production, minimize operator intervention, and enhance safety. Automated systems integrate programmable logic controls (PLC), touch-screen interfaces, and sensor-based feedback loops to enable real-time adjustments and minimize defects.

The reduction in downtime and improved repeatability has made fully automatic configurations a preferred choice for mass production in high-specification environments. Their compatibility with Industry 4.0 frameworks and ease of integration into smart manufacturing ecosystems further contribute to their growing adoption.

As companies focus on boosting productivity while maintaining high tolerances and reducing labor dependency, fully automatic machines are increasingly viewed as a critical investment for long-term operational efficiency.

The automotive industry is projected to account for 28.0% of the revenue share in the double decker roll forming machine market in 2025. This leading position is attributed to the sector’s high-volume requirements for precision-formed metal components used in body panels, chassis frames, and structural reinforcements.

Roll forming technology enables production of lightweight, complex profiles with superior mechanical properties, aligning with the automotive industry's shift toward lightweighting and fuel efficiency. The ability to form dual profiles on a single line without changing tooling setups offers automotive suppliers faster turnaround and cost savings.

Compliance with stringent quality and dimensional accuracy standards has further driven the industry to adopt advanced forming technologies. As electric vehicle (EV) production accelerates and modular vehicle architectures become standard, demand for high-speed, flexible, and space-saving forming solutions like double decker roll forming machines is expected to increase significantly.

The double decker roll forming machine is designed to produce trapezoidal, corrugated roofing sheets and cladding sheets. This double decker roll forming machine is easy to operate with high efficiency reduces energy consumption.

The double decker roll forming machine can make two design sheets at a time. The machine has an additional set of rollers and cutting blades for different roofing designs. The two-set roller uses a single machine base, hydraulic station, motor, cut frame, and PLC controller; therefore, it is an economical and low-cost machine with less investment and minimum maintenance cost.

The machine is sturdy, environment-friendly, and suitable for extreme environmental conditions, and it can produce flexible roofing designs as per the customer's requirement. Therefore the double decker roller forming machine gained tremendous popularity due to the extensive use of corrugated metal sheets.

The double decker rolling machine provides high-quality products and increases the business's profitability by reducing the labour cost and manufacturing time. The machine can produce wall panels and steel roofs widely used to construct the factory sheds, warehouses, vehicle parking, garage, exhibition centres, compound wall, and temporary office sheds used during long-duration projects.

These wall and steel roof panels are easy to install, less installation period, easily transferable to another location, lightweight and durable. With the growing demand for fast and easy construction, the corrugated roof and cladding sheet are gaining importance. Therefore, the double decker roll forming machine could augment significant growth.

The corrugated sheets are long-lasting, and the repetitive folds on the sheets create higher durability and increase strength. The corrugated sheets and roof panels are used in various railway stations, metro stations, stadiums, and vehicle parking sheds. The roll forming applications are helpful in almost all metal-based industries.

The automobile industry is used for car door frames, set rails, heat exchanger radiator tubes, trims, and bumper reinforcement. In the construction and building industry, used for roofing and decking, doors and windows applications. It is also used in the oil and gas industry for deep-sea oil extraction and transportation of pipes. Therefore, the double decker roll forming machine has a tremendous growth opportunity.

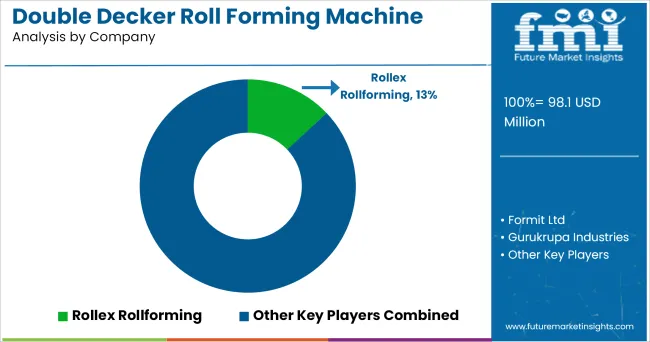

Key players such as

Key Asian players such as

are actively involved in double decker roll forming machine market for different applications.

The manufacturers involved in manufacturing double decker roll forming machine adopt various strategies such as innovation and product launch to serve the increasing demand for the double decker roll forming machine market.

India has excessive demand for double decker roll forming machines due to rapidly increasing the building and construction industry. The rapid urbanization and industrialization created a massive demand for corrugated and roof panel sheets.

The double decker roll forming machines have multiple benefits: a low cost, increase productivity, and reduce labour cost; hence, the manufacturer prefers the machine. As India has a massive demand for automobiles, building, and construction, the double decker roll forming machine anticipates substantial growth.

The global double decker roll forming machine market is estimated to be valued at USD 98.1 million in 2025.

The market size for the double decker roll forming machine market is projected to reach USD 167.6 million by 2035.

The double decker roll forming machine market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in double decker roll forming machine market are fully automatic, manual and semi-automatic.

In terms of end use industry, automotive industry segment to command 28.0% share in the double decker roll forming machine market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Competitive Overview of Double Decker Roll Forming Machine Market Share

Industry Share & Competitive Positioning in Roll Forming Machines

Roll Forming Machine Market by Type from 2024 to 2034

Glass Rolling Forming Machine Market Size and Share Forecast Outlook 2025 to 2035

Rolling Mill Machine Market Size and Share Forecast Outlook 2025 to 2035

Roll Handling Machine Market Size and Share Forecast Outlook 2025 to 2035

Roll Slitting Machine Market

Leaf Rolling Machine Market Size and Share Forecast Outlook 2025 to 2035

Wire Rolling Machine Market Share, Trends & Forecast 2024-2034

Glass Forming Machine Market Analysis - Size, Growth, and Forecast 2025 to 2035

Thermoforming Machines Market Trends - Demand & Forecast 2025 to 2035

Cereal Rolling Machine Market – Growth & Market Trends 2025-2035

Double Linkage Bending Machine Market Size and Share Forecast Outlook 2025 to 2035

Machine Automation Controller Market Growth – Trends & Forecast 2025 to 2035

Power Ring Rolling Machine Market Size and Share Forecast Outlook 2025 to 2035

PLC Controlled Packing Machine Market Trends – Forecast 2024-2034

Roll-to-Roll Type UV Imprinting Machines Market

Automatic Powder Forming Machine Market Forecast and Outlook 2025 to 2035

Semi-Auto Egg Tart Forming Machine Market

Automatic Thermoforming Vacuum Machine Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA