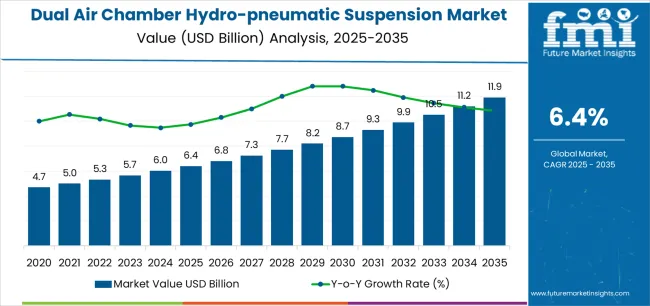

The dual air chamber hydro-pneumatic suspension market enters a decade of measured expansion that will transform vehicle performance and operational capabilities across passenger, commercial, and special vehicle sectors. The market's trajectory from USD 6,407.1 million in 2025 to USD 11,914.6 million by 2035 represents controlled growth, reflecting the accelerated adoption of advanced suspension technology and vehicle optimization across automotive applications, industrial vehicles, and specialized transport solutions worldwide.

The first half of the decade (2025-2030) will witness the market climbing from USD 6,407.1 million to approximately USD 8,211.6 million, adding USD 1,804.5 million in value, which constitutes 44% of the total forecast growth period. This phase will be characterized by the continued adoption of passenger vehicle applications over commercial vehicles, driven by increasing performance demands and the growing need for comfort optimization in automotive systems, passenger transportation, and vehicle efficiency applications globally. Enhanced suspension capabilities and automated control systems will become standard expectations rather than premium options.

The latter half (2030-2035) will witness continued growth from USD 8,211.6 million to USD 11,914.6 million, representing an addition of USD 3,703.0 million or 56% of the decade's expansion. This period will be defined by mass market penetration of intelligent suspension systems, integration with comprehensive vehicle management platforms, and seamless compatibility with existing automotive infrastructure. The market trajectory signals fundamental shifts in how automotive manufacturers approach suspension technology and vehicle performance, with participants positioned to benefit from growing demand across multiple application segments and load capacity categories.

Dual air chamber hydro-pneumatic suspension systems utilize pressurized nitrogen and hydraulic fluid to provide variable spring rates and damping characteristics across diverse operating conditions. The dual chamber configuration enables independent control of primary suspension functions and secondary stability features through electronically controlled valves and pressure regulation systems. Working pressures typically range from 50 to 300 bar with response times under 20 milliseconds, offering superior adaptability compared to conventional steel spring systems.

Passenger vehicle applications drive primary market demand through requirements for comfort optimization, road handling improvement, and adaptive suspension control in luxury sedans, SUVs, and high-performance vehicles. Active suspension management systems adjust damping characteristics in real-time based on road surface conditions, vehicle loading, and driving dynamics. Load leveling capabilities maintain consistent vehicle height regardless of passenger or cargo variations, enhancing aerodynamic efficiency and handling predictability.

Commercial vehicle applications encompass heavy-duty trucks, buses, and delivery vehicles requiring consistent load distribution and driver comfort across varying payload conditions. Agricultural and construction machinery utilize robust dual chamber systems for operator comfort during extended operation periods while maintaining equipment stability across uneven terrain. Special vehicle applications include military vehicles, emergency response equipment, and specialized transport systems requiring exceptional stability and load management capabilities.

| Period | Primary Revenue Buckets | Share | Notes |

|---|---|---|---|

| Today | Light Load applications | 60% | Passenger-focused, comfort-driven |

| Heavy Load applications | 40% | Commercial and industrial focus | |

| Passenger Vehicles | 48% | Primary automotive market | |

| Commercial Vehicles | 35% | Transportation and logistics | |

| Special Vehicles | 17% | Military and specialized applications | |

| Future (3-5 yrs) | Enhanced Light Load systems | 58-65% | Technology integration, performance gains |

| Advanced Heavy Load solutions | 35-42% | Capacity optimization, efficiency expansion | |

| Integrated Passenger systems | 45-52% | Comfort enhancement, feature integration | |

| Optimized Commercial platforms | 32-38% | Fleet efficiency, operational improvement | |

| Specialized Vehicle solutions | 15-20% | Application diversification, capability growth | |

| Digital control platforms | 5-8% | IoT integration, system optimization |

At-a-Glance Metrics

| Metric | Value |

|---|---|

| Market Value (2025) | USD 6,407.1 million |

| Market Forecast (2035) | USD 11,914.6 million |

| Growth Rate | 6.4% CAGR |

| Leading Type | Light Load Segment |

| Primary Application | Passenger Vehicles |

The market demonstrates strong fundamentals with light load applications capturing a dominant share through reliable comfort capabilities and performance optimization. Light load applications drive primary demand, supported by increasing passenger vehicle requirements and operational efficiency development. Geographic expansion remains concentrated in developed markets with established automotive infrastructure, while emerging economies show accelerating adoption rates driven by vehicle modernization initiatives and rising comfort accessibility standards.

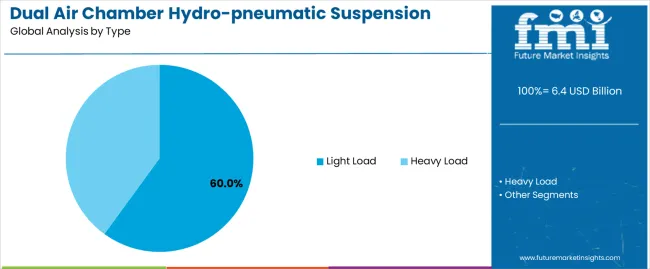

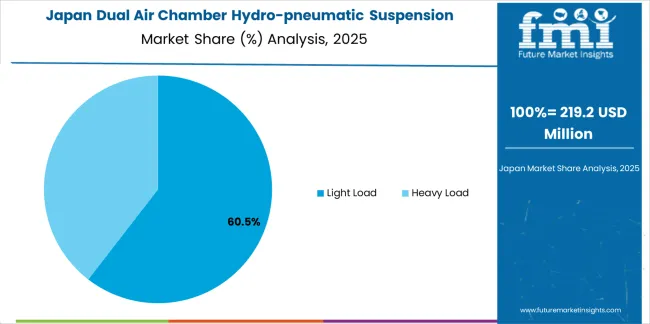

Primary Classification: The market segments by type into light load (60%) and heavy load (40%) systems, representing the evolution from basic suspension methods to specialized dual chamber solutions for comprehensive vehicle comfort and load management optimization.

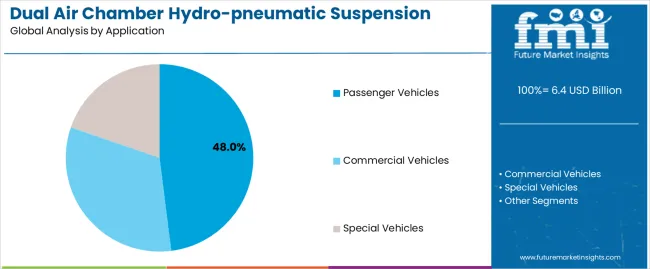

Secondary Classification: Application segmentation divides the market into passenger vehicles (48%), commercial vehicles (35%), and special vehicles (17%) systems, reflecting distinct requirements for comfort efficiency, load capacity, and specialized performance standards.

The segmentation structure reveals technology progression from standard suspension methods toward specialized dual chamber applications with enhanced performance consistency and control capabilities, while application diversity spans from passenger comfort to commercial load management requiring precise suspension solutions.

Market Position: Light load applications command the leading position in the dual air chamber hydro-pneumatic suspension market with 60% market share through advanced comfort features, including superior ride characteristics, operational efficiency, and performance optimization that enable vehicles to achieve optimal comfort across diverse passenger and light commercial applications.

Value Drivers: The segment benefits from manufacturer preference for comfort-focused suspension systems that provide consistent performance characteristics, reduced complexity, and operational efficiency optimization without requiring significant infrastructure modifications. Advanced design features enable automated comfort control systems, load monitoring, and integration with existing vehicle electronics, where operational performance and comfort compliance represent critical manufacturer requirements.

Competitive Advantages: Light load applications differentiate through proven operational reliability, consistent comfort characteristics, and integration with automated vehicle management systems that enhance ride effectiveness while maintaining optimal performance standards for diverse passenger and light commercial applications.

Key market characteristics:

Heavy load applications maintain a 40% market position in the dual air chamber hydro-pneumatic suspension market due to their enhanced load management properties and commercial application characteristics. These systems appeal to operations requiring specialized performance with premium positioning for heavy commercial and industrial applications. Market growth is driven by commercial vehicle segment expansion, emphasizing robust suspension solutions and operational efficiency through optimized load designs.

Market Context: Passenger vehicle applications demonstrate market leadership in the dual air chamber hydro-pneumatic suspension market with 48% share due to widespread adoption of comfort-focused suspension systems and increasing focus on operational performance, ride quality, and applications that maximize passenger comfort while maintaining handling standards.

Appeal Factors: Automotive manufacturers prioritize comfort consistency, operational efficiency, and integration with existing vehicle infrastructure that enables coordinated suspension operations across multiple vehicle platforms. The segment benefits from substantial automotive investment and modernization programs that emphasize the acquisition of comfort-based systems for performance optimization and ride quality applications.

Growth Drivers: Automotive facility expansion programs incorporate dual chamber suspension as standard equipment for comfort operations, while passenger vehicle growth increases demand for consistent comfort capabilities that comply with performance standards and minimize operational complexity.

Application dynamics include:

Commercial vehicle applications capture 35% market share through comprehensive load requirements in transportation vehicles, delivery operations, and heavy-duty applications. These operations demand reliable suspension systems capable of handling variable loads while providing effective load management and operational performance capabilities.

Special vehicle applications account for 17% market share, including military vehicles, emergency equipment, and specialized transport applications requiring specialized suspension solutions for operational optimization and load management capabilities.

| Category | Factor | Impact | Why It Matters |

|---|---|---|---|

| Driver | Automotive comfort demand & performance requirements (ride quality, handling standards) | ★★★★★ | Large-scale automotive markets require efficient, reliable suspension solutions with consistent performance and comfort compliance across vehicle applications. |

| Driver | Commercial vehicle growth & load optimization (transport efficiency, fleet management) | ★★★★★ | Drives demand for specialized load solutions and high-capacity suspension capabilities; suppliers providing commercial-grade systems gain competitive advantage. |

| Driver | Technology advancement & control integration (electronic systems, adaptive control) | ★★★★☆ | Vehicle applications need advanced suspension solutions; demand for intelligent systems expanding addressable market segments. |

| Restraint | System cost complexity & installation requirements (technical complexity, maintenance needs) | ★★★★☆ | Small manufacturers face cost pressure; increases price sensitivity and affects system availability in budget-sensitive markets. |

| Restraint | Conventional suspension competition & alternative systems (steel springs, conventional dampers) | ★★★☆☆ | Cost-focused applications face challenges with system selection and performance requirements, limiting adoption in price-sensitive segments. |

| Trend | Electric vehicle integration & system compatibility (battery weight, performance optimization) | ★★★★★ | Growing demand for specialized vehicle solutions; electric integration becomes core value proposition in automotive segments. |

| Trend | Asian market expansion & regional automotive growth | ★★★★☆ | Regional vehicle development drives demand for local suspension solutions; regional manufacturing capabilities drive competition toward localization. |

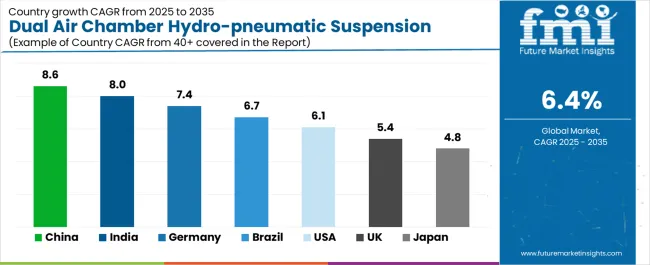

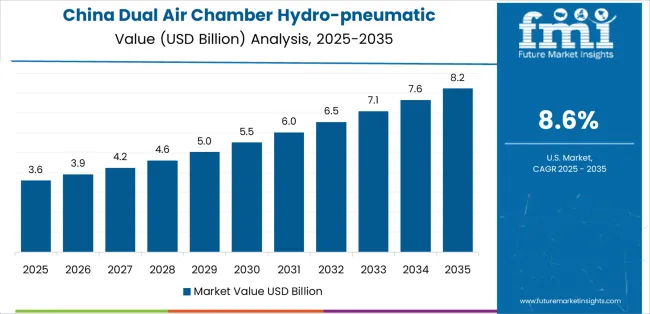

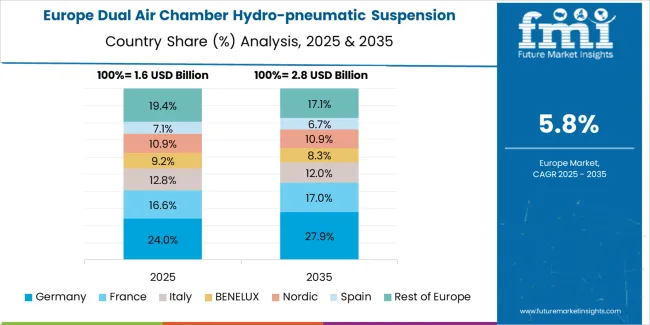

The dual air chamber hydro-pneumatic suspension market demonstrates varied regional dynamics with growth leaders including China (8.6% growth rate) and India (8.0% growth rate) driving expansion through automotive initiatives and vehicle capacity development. Steady Performers encompass Germany (7.4% growth rate), Brazil (6.7% growth rate), and USA (6.1% growth rate), benefiting from established automotive industries and advanced technology adoption. Mature Markets feature UK (5.4% growth rate) and Japan (4.8% growth rate), where suspension technology advancement and quality requirements support consistent growth patterns.

Regional synthesis reveals East Asian and South Asian markets leading adoption through automotive expansion and manufacturing development, while Western countries maintain steady expansion supported by technology advancement and regulatory requirements. Emerging markets show strong growth driven by vehicle applications and manufacturing modernization trends.

| Region/Country | 2025-2035 Growth | How to win | What to watch out |

|---|---|---|---|

| China | 8.6% | Lead with high-volume manufacturing systems | Environmental regulations; technology complexity |

| India | 8.0% | Focus on cost-effective automotive solutions | Infrastructure challenges; manufacturing availability |

| Germany | 7.4% | Premium quality positioning | Over-specification; regulatory compliance |

| Brazil | 6.7% | Provide regional manufacturing solutions | Economic volatility; infrastructure requirements |

| USA | 6.1% | Offer technology-compliant applications | Safety regulations; manufacturing requirements |

| UK | 5.4% | Comprehensive automotive services | Market maturity; technology costs |

| Japan | 4.8% | Premium efficiency positioning | Technology precision; market maturity |

China establishes fastest market growth through aggressive automotive programs and comprehensive manufacturing capacity development, integrating advanced dual chamber suspension as standard components in passenger vehicles and commercial vehicle installations. The country's 8.6% growth rate reflects government initiatives promoting automotive modernization and manufacturing development capabilities that mandate the use of advanced suspension systems in vehicle facilities. Growth concentrates in major automotive centers, including Shanghai, Guangzhou, and Chongqing, where automotive technology development showcases integrated suspension systems that appeal to manufacturers seeking advanced comfort optimization capabilities and operational vehicle applications.

Chinese manufacturers are developing high-volume suspension solutions that combine domestic manufacturing advantages with advanced operational features, including automated production systems and enhanced reliability capabilities. Distribution channels through automotive suppliers and commercial vehicle manufacturers expand market access, while government support for automotive development supports adoption across diverse manufacturer segments.

Strategic Market Indicators:

In Maharashtra, Tamil Nadu, and Karnataka states, automotive facilities and commercial operations are implementing advanced dual chamber suspension as standard equipment for vehicle optimization and operational comfort enhancement, driven by increasing government automotive investment and manufacturing modernization programs that emphasize the importance of suspension capabilities. The market holds an 8.0% growth rate, supported by government automotive initiatives and manufacturing development programs that promote advanced suspension systems for vehicle facilities.

Indian manufacturers are adopting suspension systems that provide consistent operational performance and comfort compliance features, appealing in automotive regions where vehicle efficiency and comfort standards represent critical operational requirements. Market expansion benefits from growing automotive processing capabilities and manufacturing integration agreements that enable domestic production of advanced suspension systems for vehicle applications.

Technology adoption follows patterns established in automotive equipment, where efficiency and performance drive manufacturing decisions and operational deployment. Indian manufacturers leverage cost advantages and comprehensive automotive expertise, including supply programs and technical support that create customer relationships and operational advantages. The market benefits from established automotive standards and regional requirements that support suspension system use while supporting technology advancement and operational optimization.

Germany's advanced automotive technology market demonstrates sophisticated dual chamber suspension integration with documented operational effectiveness in premium vehicle applications and modern automotive installations through integration with existing quality systems and manufacturing infrastructure. The country maintains a 7.4% growth rate, leveraging traditional automotive expertise and precision systems integration in suspension technology. Automotive centers, including Bavaria, Baden-Württemberg, and North Rhine-Westphalia, showcase premium installations where suspension systems integrate with traditional quality platforms and modern vehicle management systems to optimize automotive operations and maintain vehicle quality profiles.

German manufacturers prioritize suspension precision and quality consistency in dual chamber development, creating demand for premium systems with advanced features, including quality monitoring and automated suspension systems. The market benefits from established quality infrastructure and commitment to automotive standards that provide long-term operational benefits and compliance with traditional quality manufacturing methods.

Distribution channels through premium automotive suppliers and commercial vehicle manufacturers expand market access, while regulatory support for quality development supports adoption across diverse manufacturer segments. Technology development emphasizes precision engineering and performance optimization that appeals to German automotive manufacturers seeking proven quality capabilities and operational efficiency applications.

Brazil establishes regional manufacturing leadership through comprehensive automotive programs and established manufacturing infrastructure, integrating dual chamber suspension across vehicle facilities and commercial applications. The country's 6.7% growth rate reflects growing automotive industry relationships and established technology adoption that supports widespread use of suspension systems in vehicle facilities and manufacturing-oriented operations. Growth concentrates in major automotive centers, including São Paulo, Minas Gerais, and Rio Grande do Sul, where automotive technology showcases mature manufacturing deployment that appeals to manufacturers seeking proven manufacturing capabilities and operational efficiency applications.

Brazilian manufacturers leverage established distribution networks and comprehensive automotive capabilities, including manufacturing programs and technical support that create customer relationships and operational advantages. The market benefits from established automotive standards and regional requirements that support suspension system use while supporting technology advancement and operational optimization.

Manufacturing capabilities enable domestic production of suspension components while maintaining competitive pricing compared to imported alternatives. Regional automotive development programs incorporate suspension technology as standard manufacturing equipment, while export opportunities support market growth and technological advancement across Latin American automotive markets.

USA establishes technology-compliant market development through comprehensive automotive programs and established technology infrastructure, integrating dual chamber suspension across vehicle facilities and automotive applications. The country's 6.1% growth rate reflects mature automotive industry relationships and established technology adoption that supports widespread use of suspension systems in vehicle facilities and technology-compliant operations. Growth concentrates in major automotive centers, including Michigan, Ohio, and Tennessee, where automotive technology showcases mature technology deployment that appeals to manufacturers seeking proven technology capabilities and operational efficiency applications.

American manufacturers leverage established distribution networks and comprehensive technology capabilities, including compliance programs and technical support that create customer relationships and operational advantages. The market benefits from mature technology standards and automotive requirements that support suspension system use while supporting technology advancement and operational optimization.

Automotive facility expansion programs incorporate suspension technology as standard equipment for vehicle operations, while regulatory requirements support technology adoption across diverse manufacturer segments. Technology development follows established automotive patterns where performance and reliability drive procurement decisions and operational deployment strategies.

UK establishes comprehensive automotive development through advanced automotive programs and established technology infrastructure, integrating dual chamber suspension systems across vehicle facilities and automotive applications. The country's 5.4% growth rate reflects growing automotive industry relationships and established technology adoption that supports widespread use of suspension systems in vehicle facilities and comprehensive-oriented operations. Growth concentrates in major automotive centers, including West Midlands, North West England, and South East England, where automotive technology showcases mature technology deployment that appeals to manufacturers seeking proven comprehensive capabilities and operational efficiency applications.

British manufacturers leverage established service networks and comprehensive support capabilities, including maintenance programs and technical support that create customer relationships and operational advantages. The market benefits from established automotive standards and technology requirements that support suspension system use while supporting technology advancement and operational optimization.

Technology adoption emphasizes performance optimization and system integration that appeals to British automotive manufacturers seeking proven service capabilities and operational efficiency applications. Regional automotive development programs incorporate suspension technology as standard manufacturing equipment, while technology requirements support adoption across diverse manufacturer segments.

Japan's advanced automotive technology market demonstrates sophisticated dual chamber suspension integration with documented operational effectiveness in premium vehicle applications and modern automotive installations through integration with existing efficiency systems and manufacturing infrastructure. The country maintains a 4.8% growth rate, leveraging traditional efficiency expertise and precision systems integration in suspension technology. Automotive centers, including Tokyo, Aichi, and Kanagawa, showcase premium installations where suspension systems integrate with traditional efficiency platforms and modern vehicle management systems to optimize automotive operations and maintain vehicle efficiency profiles.

Japanese manufacturers prioritize suspension precision and efficiency consistency in dual chamber development, creating demand for premium systems with advanced features, including efficiency monitoring and automated suspension systems. The market benefits from established efficiency infrastructure and commitment to automotive standards that provide long-term operational benefits and compliance with traditional quality manufacturing methods.

Distribution channels through premium automotive suppliers and commercial vehicle manufacturers expand market access, while regulatory support for efficiency development supports adoption across diverse manufacturer segments. Technology development emphasizes precision engineering and efficiency optimization that appeals to Japanese automotive manufacturers seeking proven efficiency capabilities and operational performance applications.

The European dual air chamber hydro-pneumatic suspension market is projected to represent a significant portion of global consumption, with strong regional distribution across major economies. Germany is expected to maintain its leadership position with USD 2,247.0 million in 2025, accounting for substantial European market share, supported by its advanced automotive infrastructure and major manufacturing centers.

United Kingdom follows with USD 348.9 million, representing significant European market share in 2025, driven by comprehensive automotive programs and suspension technology development initiatives. France holds USD 201.0 million through specialized vehicle applications and automotive compliance requirements. Italy commands substantial market share, while Spain accounts for significant consumption in 2025. The rest of Europe region maintains substantial market presence, attributed to increasing suspension system adoption in Nordic countries and emerging automotive facilities implementing vehicle modernization programs.

| Stakeholder | What they actually control | Typical strengths | Typical blind spots |

|---|---|---|---|

| Global platforms | Manufacturing networks, broad suspension portfolios, automotive facilities | Proven reliability, multi-region support, comprehensive service | Technology refresh cycles; customer lock-in dependency |

| Technology innovators | R&D capabilities; advanced suspension systems; digital interfaces | Latest technology first; attractive ROI on specialized applications | Service density outside core regions; customization complexity |

| Regional specialists | Local manufacturing, fast delivery, nearby technical support | "Close to site" support; pragmatic pricing; local regulations | Technology gaps; talent retention in engineering |

| Application-focused ecosystems | Industry expertise, technical support, specialized solutions | Lowest application variation; comprehensive industry support | Scaling costs if overpromised; technology obsolescence |

| Service specialists | Maintenance programs, system supply, technical training | Win service-intensive applications; flexible support | Scalability limitations; narrow market focus |

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 6,407.1 million |

| Type | Light Load, Heavy Load |

| Application | Passenger Vehicles, Commercial Vehicles, Special Vehicles |

| Regions Covered | East Asia, Western Europe, South Asia Pacific, North America, Latin America, Middle East & Africa |

| Countries Covered | China, Germany, United States, Japan, India, Brazil, United Kingdom, and 25+ additional countries |

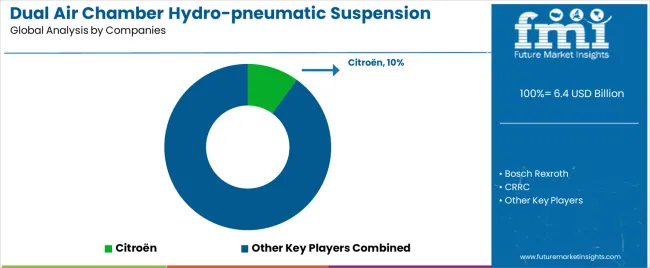

| Key Companies Profiled | Citroën, Bosch Rexroth, CRRC, HYDAC, Wantong Hydraulic, HYPSUS, Horstman, ARGO-HYTOS, HUAYON, Hendrickson |

| Additional Attributes | Dollar sales by type and application categories, regional adoption trends across East Asia, Western Europe, and South Asia Pacific, competitive landscape with suspension suppliers and service providers, manufacturer preferences for performance consistency and operational reliability, integration with vehicle platforms and automotive monitoring systems, innovations in suspension technology and system enhancement, and development of advanced dual chamber solutions with enhanced performance and vehicle optimization capabilities. |

The global dual air chamber hydro-pneumatic suspension market is estimated to be valued at USD 6.4 billion in 2025.

The market size for the dual air chamber hydro-pneumatic suspension market is projected to reach USD 11.9 billion by 2035.

The dual air chamber hydro-pneumatic suspension market is expected to grow at a 6.4% CAGR between 2025 and 2035.

The key product types in dual air chamber hydro-pneumatic suspension market are light load and heavy load.

In terms of application, passenger vehicles segment to command 48.0% share in the dual air chamber hydro-pneumatic suspension market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

DualMode Automated Tow Tractor Market Size and Share Forecast Outlook 2025 to 2035

Dual Clutch Transmission Market Size and Share Forecast Outlook 2025 to 2035

Dual Frequency Ultrasonic Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Dual-Cure Luting Cements Market Size and Share Forecast Outlook 2025 to 2035

Dual Screen Laptops Market Size and Share Forecast Outlook 2025 to 2035

Dual Ovenable Trays and Containers Market Size and Share Forecast Outlook 2025 to 2035

Dual Relay Board Market Size and Share Forecast Outlook 2025 to 2035

Dual Voltage Comparator Market Size and Share Forecast Outlook 2025 to 2035

Dual and Multi-Energy Computed Tomography (CT) Market Size and Share Forecast Outlook 2025 to 2035

Dual-Phase Cleanser Market Size and Share Forecast Outlook 2025 to 2035

The Dual Balloon Angioplasty Catheter Market is segmented by Peripheral, and Coronal from 2025 to 2035

Dual Biomarker Assays Market Analysis - Size, Share, & Forecast Outlook 2025 to 2035

Dual Flap Dispensing Closure Market Size & Trends 2025 to 2035

Dual Ovenable Lidding Films Market by Material, Seal Type, Application & Region - Forecast 2025 to 2035

Dual Axis Solar Tracker Market Growth - Trends & Forecast 2025 to 2035

Market Share Breakdown of Dual Ovenable Lidding Films Manufacturers

Dual Containment Pipe Market Growth – Trends & Forecast 2024-2034

Dual-Ovenable Cook Trays Market

Dual Chamber Dispensing Bottles Market Size and Share Forecast Outlook 2025 to 2035

Dual-Chamber Pumps Market Analysis - Size, Share, and Forecast Outlook (2025 to 2035)

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA