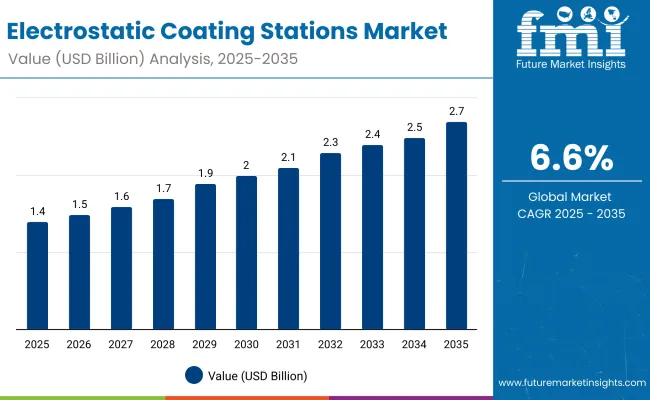

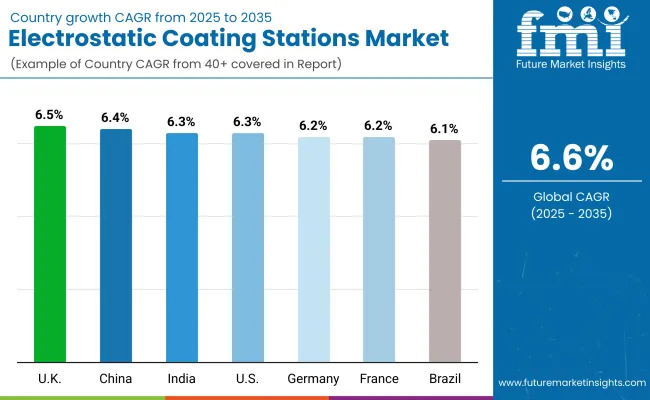

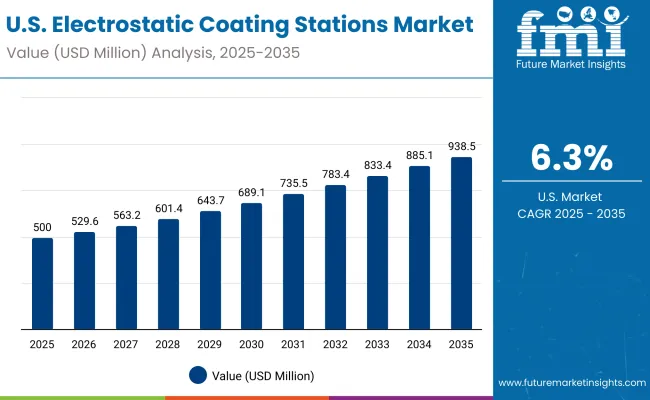

The global electrostatic coating stations market will expand from USD 1.4 billion in 2025 to USD 2.7 billion by 2035, recording a CAGR of 6.6%. Growth is supported by advanced surface finishing demand in food, beverage, and industrial packaging. Electrostatic powder coating remains the dominant technology due to its efficiency and waste reduction capabilities. Between 2025 and 2030, automation and hybrid dual-system coatings will enhance throughput and precision. Asia-Pacific’s rising manufacturing infrastructure and sustainable coating standards are expected to make the region a key revenue hub by 2035, particularly within electronics and consumer packaging sectors.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 1.4 billion |

| Forecast Value in (2035F) | USD 2.7 billion |

| Forecast CAGR (2025 to 2035) | 6.6% |

From 2020 to 2024, manufacturers accelerated transition toward efficient powder coating stations to reduce emissions and improve transfer efficiency. Automation in electrostatic coating enabled higher line speeds and uniform surface finish quality. By 2035, the market will reach USD 2.7 billion, driven by precision-engineered packaging components and eco-friendly coatings. Rapid adoption of dual-system hybrid coating machines will reshape production environments in Asia-Pacific and Europe. Increasing regulatory focus on solvent-free formulations is expected to sustain long-term innovation across both powder and liquid coating segments.

The market’s growth is fueled by technological modernization and sustainability regulations in packaging and industrial applications. Electrostatic systems enable superior finish quality, reduced waste, and compliance with VOC reduction mandates. Increasing global packaging volumes and demand for corrosion-resistant, aesthetically coated surfaces further reinforce adoption across end-use sectors.

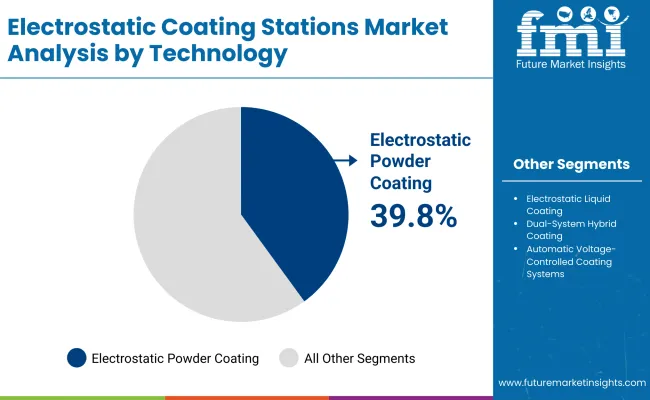

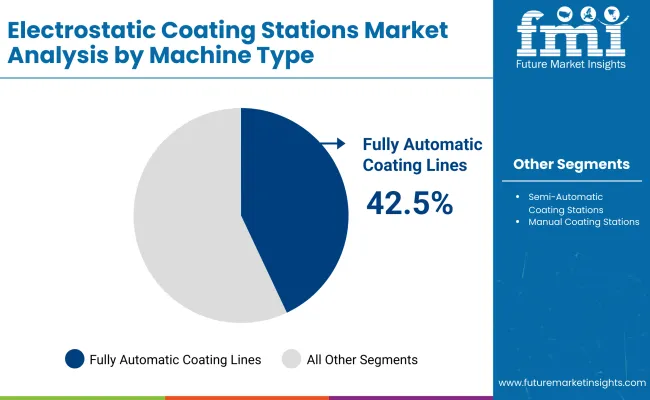

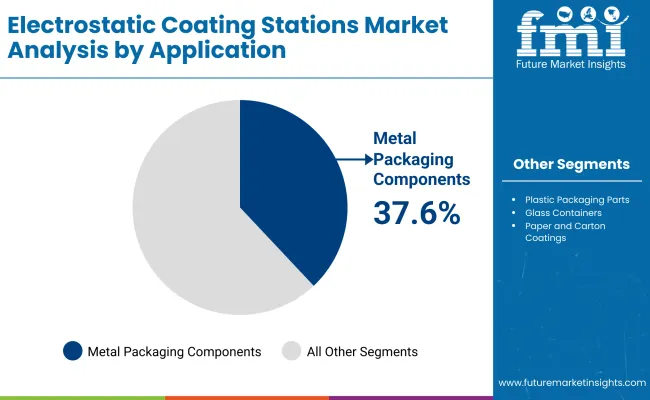

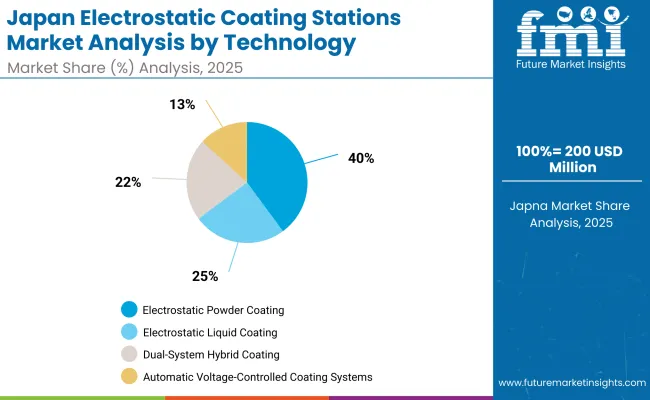

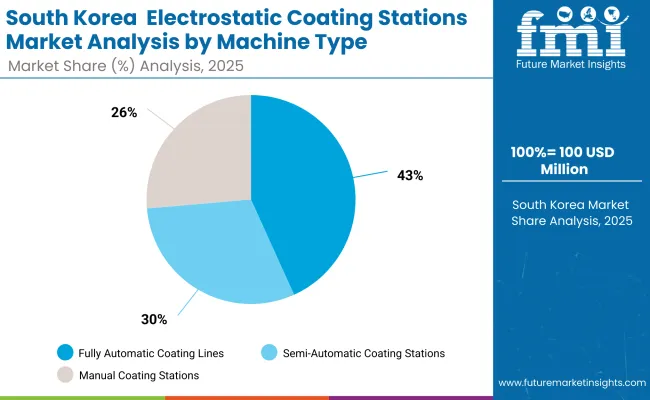

The market is segmented by technology, machine type, application, end-use industry, and region. Technology segmentation includes electrostatic powder coating, electrostatic liquid coating, dual-system hybrid coating, and automatic voltage-controlled coating systems, ensuring precision and uniform finish quality. Machine type covers fully automatic coating lines, semi-automatic coating stations, and manual coating stations, supporting varied production capacities and automation levels. Applications span metal packaging components, plastic packaging parts, glass containers, and paper and carton coatings, catering to industrial and consumer product needs. End-use industries include food and beverages, pharmaceuticals and healthcare, consumer goods, industrial packaging, and automotive and electronics, reflecting broad adoption across sectors. Regionally, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Electrostatic powder coating is projected to capture 39.8% of the market in 2025, owing to its superior finish quality, minimal waste generation, and low VOC emissions. The technology ensures uniform coverage on metal and plastic surfaces, delivering durability and corrosion resistance for packaging components. Its dry application process also supports cost and energy savings.

Growing environmental regulations and sustainability goals drive adoption across metal can, closure, and industrial packaging lines. The reduced need for solvents and improved material recovery align with green manufacturing trends. As industries pursue cleaner coating solutions, electrostatic powder coating remains the preferred technology.

Fully automatic coating lines are forecast to account for 42.5% of the market in 2025, supported by their ability to deliver consistent output and enhanced throughput. Equipped with robotics and advanced control systems, these lines ensure precise coating thickness and minimize operator dependency.

Manufacturers favor automation for its ability to reduce downtime, improve coating uniformity, and support high-speed production. Integration with smart sensors and monitoring systems enhances quality assurance and process efficiency. As packaging lines become more digitalized, fully automatic systems lead the shift toward intelligent coating operations.

Metal packaging components are expected to hold 37.6% of the market in 2025, reflecting their critical role in food and beverage can coating. Electrostatic coatings prevent corrosion, preserve product safety, and maintain visual appeal through durable finishes.

The application is expanding with the rise of lightweight metal containers and decorative coating innovations. Manufacturers emphasize hygiene and resistance to heat and chemicals during sterilization. As the metal packaging industry modernizes, this segment continues to anchor coating station demand.

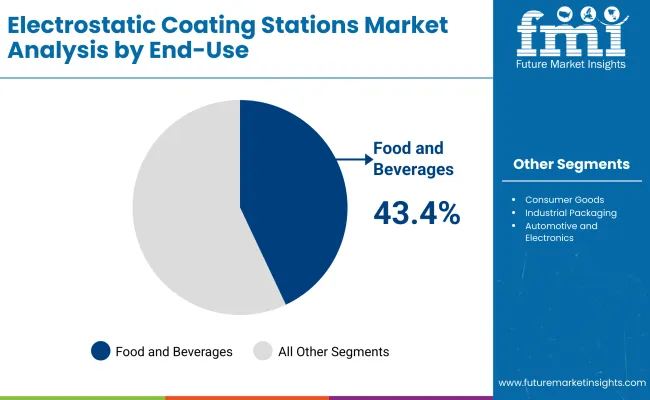

The food and beverages sector is projected to represent 43.4% of the market in 2025, driven by the need for safe, compliant, and visually appealing packaging finishes. Coating stations ensure that cans, closures, and containers meet global food-contact standards while maintaining brand aesthetics.

Adoption is reinforced by consumer preference for sustainable and high-quality packaging. Advanced coating materials improve recyclability and resistance to contamination. With ongoing innovation in decorative and protective coatings, the food and beverages segment remains the primary end-use driver.

Automation, sustainability mandates, and coating consistency improvements are key market drivers.

High setup costs and complex maintenance requirements limit adoption in small manufacturing plants.

Emerging IoT-enabled monitoring systems and robotic automation open new optimization pathways.

Powder technology advancements, hybrid coating formulations, and modular system designs define evolving standards.

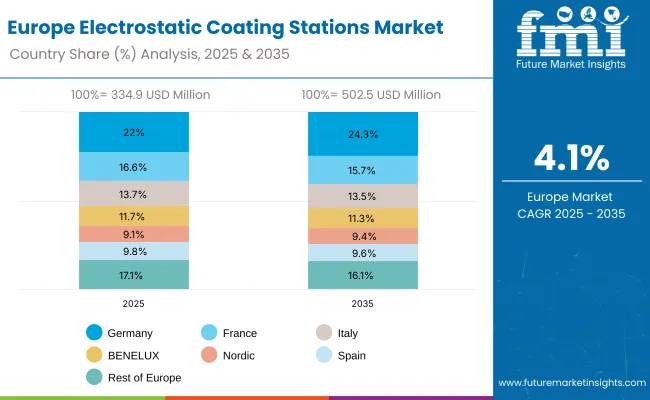

The global electrostatic coating stations market is advancing steadily as automation, digital control, and eco-friendly formulations redefine industrial coating processes. Asia-Pacific dominates global production, supported by strong manufacturing ecosystems and expanding automation capacity. North America emphasizes precision and smart control systems, while Europe advances through energy-efficient and VOC-free coating technologies. The transition toward sustainable powder coatings, improved line automation, and environmental compliance continues to shape market competitiveness worldwide.

The U.S. will grow at 6.5% CAGR, driven by rapid adoption of powder coating and automated control technologies. Packaging, automotive, and beverage industries are implementing digital electrostatic systems to enhance quality and efficiency. Sustainability goals and reduced VOC mandates are encouraging the shift toward eco-friendly coatings. Smart controls and robotics integration are improving precision and reducing operational downtime across production lines.

Germany will expand at 6.2% CAGR, maintaining its position as a technological leader in electrostatic coating equipment. Precision applications in automotive and industrial packaging are driving demand for advanced systems. High environmental standards under EU regulations are promoting adoption of clean, efficient coating technologies. Germany’s strong export network continues to support global supply of premium electrostatic coating machinery.

The U.K. will grow at 6.3% CAGR, with industries upgrading to VOC-compliant and energy-efficient coating solutions. Automation deployment is increasing across manufacturing sectors as part of modernization drives. Powder coating applications are gaining ground in food and beverage packaging for durability and eco-performance. Industrial refurbishment programs are fostering steady demand for hybrid electrostatic systems.

China will grow at 6.4% CAGR, driven by large-scale industrial expansion and domestic innovation in coating machinery. The country is scaling its production capacity for electrostatic systems used in packaging, consumer goods, and automotive applications. Local R&D is improving efficiency and cost competitiveness. Exports of advanced coating stations are rising as automation and precision standards improve.

India will grow at 6.3% CAGR, supported by rapid industrialization and the expansion of packaging manufacturing clusters. Adoption of hybrid electrostatic coating systems is growing across FMCG and automotive industries. Government-led green manufacturing policies are accelerating the transition toward sustainable coatings. Local production capacity expansion is making India an emerging hub for coating technology innovation.

Japan will grow at 6.9% CAGR, driven by advancements in hybrid automation and high-efficiency coating processes. Precision manufacturing in electronics and industrial packaging sectors is boosting adoption. Energy-optimized powder coating lines are aligning with Japan’s decarbonization goals. Continued innovation in automation and control software enhances both productivity and environmental performance.

South Korea will lead with 7.0% CAGR, emerging as a frontrunner in robotics-driven and smart coating technology. Integration of AI and sensor analytics in coating stations is improving accuracy and consistency. VOC-free formulations are aligning with the nation’s sustainability targets. Rapid export growth across Asia underscores South Korea’s strength in high-tech, eco-efficient coating systems.

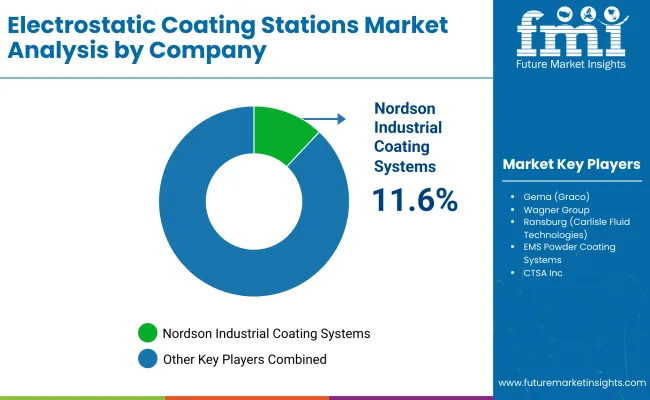

The market is moderately consolidated with Nordson, Gema, Wagner Group, Ransburg, EMS Powder Coating, CTSA Inc., Graco, Binks/DeVilbiss, SAMES Kremlin, and Double D Engineering as the key players. Companies focus on energy efficiency, predictive maintenance integration, and robotics-based automation for precision coating.

Key Developments

| Item | Value |

|---|---|

| Quantitative Units | USD 1.4 Billion |

| By Technology | Powder, Liquid, Hybrid, Voltage-Controlled Coating |

| By Machine Type | Fully Automatic, Semi-Automatic, Manual Stations |

| By Application | Metal, Plastic, Glass, Paper & Carton Packaging |

| By End-Use Industry | Food & Beverages, Healthcare, Consumer, Industrial |

| Key Companies Profiled | Nordson, Gema, Wagner Group, Ransburg, EMS Powder Coating, CTSA Inc., Graco, Binks/DeVilbiss, SAMES Kremlin, Double D Engineering |

| Additional Attributes | Market growth driven by automation, energy efficiency, and VOC-free coating innovation. |

The Electrostatic Coating Stations Market is valued at USD 1.4 billion in 2025.

The Electrostatic Coating Stations Market will reach USD 2.7 billion by 2035.

The market is expected to grow at a CAGR of 6.6%.

Electrostatic Powder Coating leads with a 39.8% share.

Fully Automatic Coating Lines dominate with a 42.5% share.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Electrostatic Discharge (ESD) Packaging Market Growth - Forecast 2025 to 2035

Electrostatic Coalescers Market Growth - Trends & Forecast 2025 to 2035

Electrostatic Precipitator Market Growth - Trends & Forecast 2025 to 2035

Wet Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Dry Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Dry Electrostatic Wipes Market Size and Share Forecast Outlook 2025 to 2035

Plate Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Power Generation Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Manufacturing Scale Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Chemicals And Petrochemicals Electrostatic Precipitator Market Size and Share Forecast Outlook 2025 to 2035

Coating Pretreatment Market Size and Share Forecast Outlook 2025 to 2035

Coating Resins Market Size and Share Forecast Outlook 2025 to 2035

Coating Auxiliaries Market Size and Share Forecast Outlook 2025 to 2035

Coatings and Application Technologies for Robotics Market Outlook – Trends & Innovations 2025-2035

Coating Additives Market Growth – Trends & Forecast 2025 to 2035

Coating Thickness Gauge Market

Coating Thickness Measurement Instruments Market

AR Coating Liquid Market Size and Share Forecast Outlook 2025 to 2035

UV Coatings Market Growth & Forecast 2025 to 2035

2K Coatings Market Growth – Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA