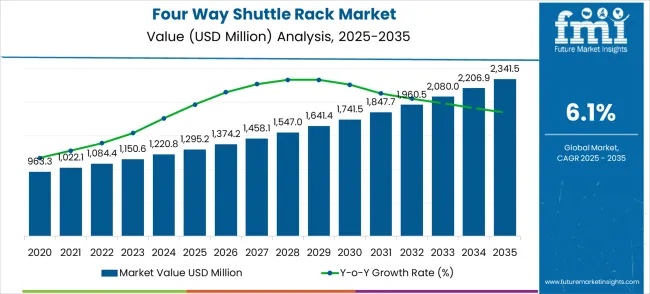

The global four way shuttle rack market is projected to reach USD 2,341.5 million by 2035, recording an absolute increase of USD 1,046.3 million over the forecast period. The market is valued at 1,295.2 million in 2025 and is set to rise at a CAGR of 6.1% during the assessment period. The market size is expected to grow by nearly 1.8 times during the same period, supported by increasing adoption of automated warehouse technologies and digital transformation initiatives across logistics and storage sectors. High initial investment costs and the complexity of integrating new shuttle rack systems with existing warehouse infrastructure may pose challenges to market expansion.

Between 2025 and 2030, the four way shuttle rack market is projected to expand from USD 1,295.2 million to USD 1,741.5 million, resulting in a value increase of USD 446.3 million, which represents 42.7% of the total forecast growth for the decade. This phase of development will be shaped by rising demand for automated storage solutions, product innovation in shuttle technologies and warehouse management systems, as well as expanding integration with IoT and AI technologies. Companies are establishing competitive positions through investment in advanced automation technologies, AI-powered warehouse optimisation capabilities, and strategic market expansion across third-party logistics, e-commerce, and automotive industries.

From 2030 to 2035, the market is forecast to grow from USD 1,741.5 million to USD 2,341.5 million, adding another USD 600.0 million, which constitutes 57.3% of the ten-year expansion. This period is expected to be characterised by the expansion of specialised shuttle systems, including advanced automation levels and cloud-based warehouse management platforms tailored for specific industrial applications, strategic collaborations between technology providers and logistics equipment manufacturers, and an enhanced focus on operational efficiency and space optimisation. The growing emphasis on supply chain automation and warehouse digitisation will drive demand for intelligent shuttle rack solutions across diverse logistics and storage applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 1,295.2 million |

| Market Forecast Value (2035) | USD 2,341.5 million |

| Forecast CAGR (2025-2035) | 6.1% |

The four way shuttle rack market grows by enabling warehouse operators to maximise storage density and operational efficiency through automated shuttle technologies and intelligent warehouse management systems. Logistics facilities face mounting pressure to reduce operational costs and improve throughput, with modern warehouses typically experiencing 40-50% space utilisation challenges, making automated shuttle systems essential for storage optimisation. The logistics sector's need for continuous operation - warehouses must maintain 24/7 efficiency to meet growing eCommerce demands - creates demand for automated technologies that can operate without manual intervention while maximising storage capacity and retrieval speed. Energy efficiency regulations and operational cost optimisation requirements drive adoption in third-party logistics and e-commerce sectors, where storage density directly impacts operational profitability and competitive positioning. Budget constraints for warehouse automation upgrades and the complexity of retrofitting legacy facilities with advanced shuttle systems may limit adoption rates among smaller logistics operators.

The four way shuttle rack market represents a transformative force in warehouse automation and logistics optimisation. With substantial growth projected from USD 1,295.2 million in 2025 to USD 2,341.5 million by 2035 at a 6.1% CAGR, this market is driven by the urgent need for storage density maximisation, operational efficiency improvements, and labour cost reduction across global supply chains.

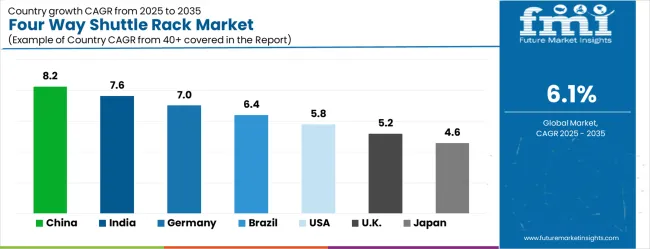

The market's robust expansion reflects the critical role automated storage systems play in modern logistics infrastructure, where space utilisation challenges affect 40-50% of warehouse operations. Strong growth momentum exists particularly in Asia-Pacific markets, with China leading at 8.2% CAGR and India at 7.6% CAGR, driven by the e-commerce boom and logistics modernisation initiatives. The dominance of fully automatic systems and third-party logistics applications underscores the industry's shift toward complete automation and outsourced logistics services.

Key market dynamics favour solutions that can deliver 40-60% storage density improvements and 35% faster order fulfilment rates. High initial investment costs and integration complexity create opportunities for companies that can simplify deployment while maintaining performance standards.

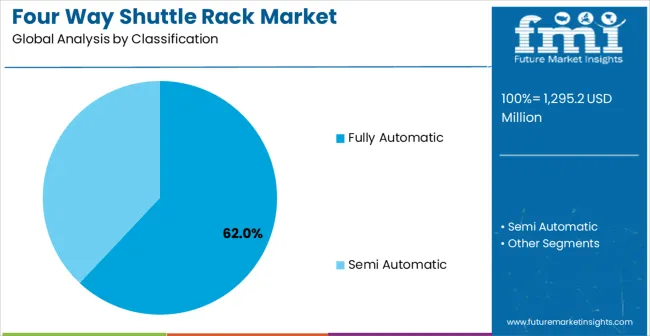

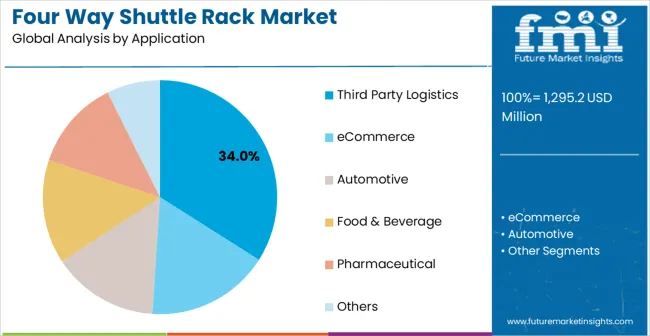

The market is segmented by Automation Level, Application, End User, and region. By Automation Level, the market is divided into Fully Automatic and semi-automatic. Based on the Application, the market is categorised into Third Party Logistics, eCommerce, Automotive, Food & Beverage, Pharmaceutical, and Others. Regionally, the market is divided into North America, Latin America, Europe, East Asia, South Asia & Pacific, and the Middle East & Africa.

Fully automatic systems are projected to account for the largest share of the four-way shuttle rack market share 62% in 2025. This dominant position is supported by the technology's ability to provide complete automated storage and retrieval operations with minimal human intervention, enabling operators to achieve maximum throughput and storage density while reducing labour costs. The segment allows for stakeholders to benefit from 24/7 operational capabilities, advanced inventory management integration, and real-time optimisation for warehouse efficiency improvement.

Key advantages include:

Third-party logistics applications are expected to represent the dominant share of the way shuttle rack applications market share 34% in 2025. This leading position reflects the critical role of automated storage systems in modern logistics operations, where efficient space utilisation and rapid order fulfilment are essential for customer satisfaction and operational profitability. The segment provides critical support for multi-client inventory management and flexible storage solutions in high-volume distribution environments where manual operations are impractical for meeting service level agreements. Growth drivers include the logistics industry's focus on reducing operational costs, improving order accuracy, and maximising warehouse throughput in facilities that must handle diverse client requirements simultaneously.

Key market dynamics include:

The market is driven by three concrete demand factors tied to operational outcomes. First, storage density optimisation capabilities increase warehouse capacity by 40-60% compared to traditional racking systems, with logistics facilities experiencing significant space utilisation improvements through automated shuttle technologies. Second, operational efficiency enhancement through automated retrieval systems enables warehouse operators to achieve 35% improvements in order fulfillment speed while maintaining accuracy standards. Third, labour cost reduction requirements and workforce optimisation create compelling adoption scenarios across logistics sectors where automated systems reduce dependency on manual operations.

Market restraints include high initial investment costs that can deter smaller warehouse operators from upgrading their storage systems, particularly in developing regions where capital allocation for automation technologies remains limited. Integration complexity poses another significant challenge, as implementing new shuttle rack systems with existing warehouse management systems requires substantial expertise and operational planning, potentially causing disruptions during installation and commissioning periods. Rapid technological advancement creates continuous pressure for system updates, demanding ongoing maintenance and upgrade investments that strain operational budgets.

Key trends indicate accelerated adoption in Asia-Pacific markets, particularly China and India, where e-commerce growth and logistics infrastructure expansion drive shuttle system deployment. Design shifts toward AI-powered warehouse optimisation, IoT-enabled monitoring, and cloud-based management platforms enable predictive capabilities that transform warehouse operations from reactive to proactive management approaches. The market thesis could face disruption if alternative storage technologies or significant changes in logistics automation reduce reliance on traditional shuttle rack systems.

| Country | CAGR (2025-2035) |

|---|---|

| China | 8.2% |

| India | 7.6% |

| Germany | 7% |

| Brazil | 6.4% |

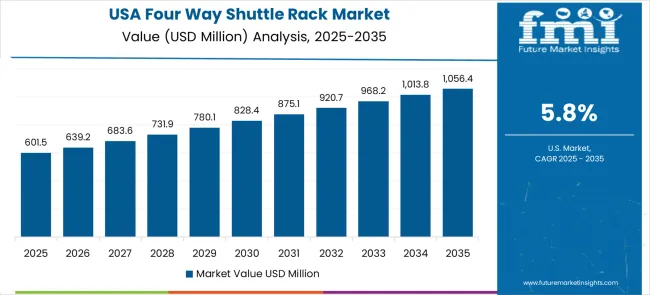

| USA | 5.8% |

| UK | 5.2% |

| Japan | 4.6% |

The four-way shuttle rack market is gathering pace worldwide, with China taking the lead thanks to rapid eCommerce expansion and logistics infrastructure modernisation mandates. Close behind, India benefits from expanding warehouse automation capacity and government initiatives promoting logistics efficiency, positioning itself as a strategic hub for growth. Germany shows steady advancement, where the integration of Industry 4.0 technologies strengthens its role in the European logistics supply chain. Brazil is sharpening its focus on warehouse optimisation efficiency and logistics infrastructure development, signalling an ambition to capture niche opportunities in South American markets. Meanwhile, the USA stands out for its advanced adoption of automation technology, and the UK and Japan continue to record consistent progress. Together, China and India anchor the global expansion story, while the rest build stability and diversity into the market's growth path.

The report covers an in-depth analysis of 40+ countries; 7 top-performing countries are highlighted below.

The four way shuttle rack market in China is projected to grow at a CAGR of 8.2% from 2025 to 2035. China’s rapid industrialization, robust e-commerce sector, and expanding manufacturing base are driving significant adoption of automated storage and retrieval solutions, including four-way shuttle racks. The country’s logistics and warehouse infrastructure is undergoing modernization to meet the growing demands of high-volume operations, particularly in automotive, electronics, and consumer goods industries. Four-way shuttle racks offer high-density storage, faster throughput, and flexibility, making them ideal for large-scale warehouses. Domestic manufacturers are increasingly investing in research and development to enhance shuttle speed, control systems, and integration with warehouse management software. Government initiatives supporting smart logistics and industrial automation further encourage the adoption of these solutions. China’s focus on reducing labor dependency, optimizing space utilization, and supporting the growing e-commerce and cold storage sectors ensures that the market will experience robust growth throughout the forecast period.

Key market factors:

The four way shuttle rack market in India is anticipated to expand at a CAGR of 7.6% from 2025 to 2035. India’s growing manufacturing sector, along with the rise of e-commerce, FMCG, and cold chain logistics, is increasing the demand for high-density storage solutions. Four-way shuttle racks are particularly advantageous in warehouses where space optimization and rapid retrieval are critical. Several large-scale distribution centers and fulfillment hubs are adopting automated systems to enhance operational efficiency and reduce labor costs. Domestic and multinational warehouse solution providers are collaborating to introduce advanced shuttle technologies, integrating them with warehouse management systems and robotics solutions. Government initiatives aimed at “Make in India” and logistics modernization, coupled with the rising adoption of automation and digitalization, are further propelling market growth. The need for faster order fulfillment, efficient inventory management, and optimized warehouse layouts ensures long-term adoption of four-way shuttle rack systems across industrial and retail segments.

The four way shuttle rack market in Germany is expected to grow at a CAGR of 7% between 2025 and 2035. Germany’s strong manufacturing base, particularly in automotive, machinery, and electronics, emphasizes high-density, flexible storage solutions for efficient supply chain operations. Four-way shuttle racks are increasingly deployed in automated warehouses to optimize space, improve inventory management, and enhance retrieval speed. The country’s focus on Industry 4.0 and smart factories accelerates the integration of shuttle rack systems with robotics, automated guided vehicles (AGVs), and warehouse management software. The growing trend of e-commerce and just-in-time production systems supports the adoption of high-density storage technologies. German warehouse operators prioritize precision, safety, and long-term operational efficiency, favoring solutions that combine automation, energy efficiency, and advanced control systems. These factors collectively position Germany as a mature yet steadily growing market for four-way shuttle racks.

Key development areas:

The four way shuttle rack market in Brazil is projected to grow at a CAGR of 6.4% from 2025 to 2035. Brazil’s expanding industrial base, along with a growing e-commerce sector, is increasing demand for high-density storage solutions in warehouses, distribution centers, and cold storage facilities. Four-way shuttle racks provide advantages in terms of space utilization, faster material handling, and improved workflow efficiency, which are particularly important in urban warehouses with limited space. The country’s industrial sectors, including automotive, food and beverage, and pharmaceuticals, are increasingly investing in automated storage solutions to optimize inventory management and reduce labor costs. Import dependency remains high, with many systems sourced from international manufacturers, but local distributors and integrators are enhancing service capabilities and maintenance support. Government initiatives for logistics modernization and infrastructure improvement are expected to further support the adoption of shuttle rack technologies throughout Brazil’s industrial landscape.

Market characteristics:

The four way shuttle rack market in the USA is expected to grow at a CAGR of 5.8% from 2025 to 2035. The country’s mature logistics, distribution, and industrial sectors are increasingly adopting high-density storage solutions to optimize warehouse operations. Four-way shuttle racks offer superior space utilization, faster order picking, and improved inventory management, making them ideal for e-commerce fulfillment centers, cold storage warehouses, and manufacturing facilities. The growing demand for automation and robotics, particularly in large-scale distribution centers operated by retail and logistics giants, is fueling adoption. USA companies also focus on integrating shuttle racks with warehouse management systems, automated guided vehicles, and IoT-enabled monitoring for real-time operational efficiency. While the market growth is comparatively moderate due to already high warehouse automation penetration, the need for scalable, flexible, and cost-efficient storage solutions ensures demand over the forecast period.

Leading market segments:

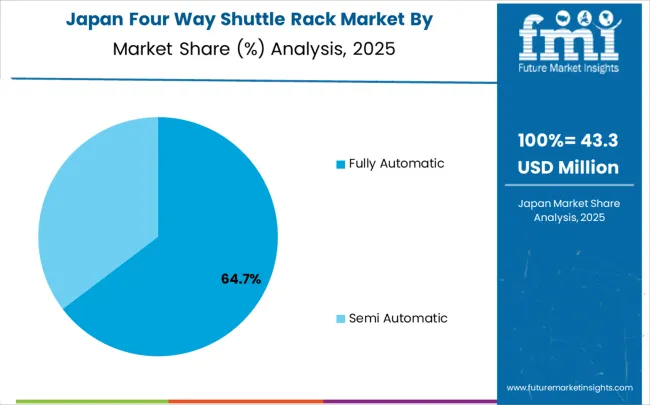

Japan's four way shuttle rack market demonstrates sophisticated implementation focused on precision logistics and operational efficiency optimisation, with documented integration of shuttle systems achieving 25% improvement in warehouse productivity across automotive and pharmaceutical distribution facilities. The country maintains steady growth momentum with a CAGR of 4.6% through 2035, driven by warehouse facilities' emphasis on operational excellence and continuous improvement methodologies that align with lean logistics principles. Major logistics centres, including Tokyo, Osaka, and Nagoya, showcase advanced deployment of automated storage platforms where shuttle systems integrate seamlessly with existing warehouse management systems and inventory control processes.

Key market characteristics:

The four-way shuttle rack market in the UK is anticipated to grow at a CAGR of 5.2% from 2025 to 2035. The UK’s logistics and warehousing sector is modernizing to meet the demands of e-commerce, retail distribution, and industrial supply chains. Four-way shuttle racks are adopted to improve space utilization, streamline inventory handling, and increase throughput in automated and semi-automated warehouses. Key industries driving adoption include pharmaceuticals, consumer goods, automotive components, and FMCG. Warehouse operators prioritize energy efficiency, safety, and integration with warehouse management systems to enhance productivity. Despite being a mature market, ongoing warehouse expansion, e-commerce growth, and modernization initiatives continue to provide opportunities for four-way shuttle rack suppliers. Government programs supporting smart logistics and industrial digitization further bolster market adoption and long-term growth.

Market development factors:

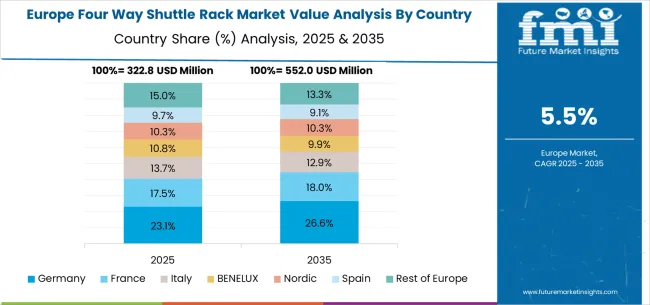

The four way shuttle rack market in Europe is projected to grow from USD 285.4 million in 2025 to USD 516.2 million by 2035, registering a CAGR of 6.1% over the forecast period. Germany is expected to maintain its leadership position with a 29.7% market share in 2025, declining slightly to 28.9% by 2035, supported by its advanced logistics infrastructure and major distribution centres, including automotive and industrial logistics hubs.

France follows with an 18.2% share in 2025, projected to reach 18.8% by 2035, driven by comprehensive warehouse modernisation programs and enhanced eCommerce logistics protocols across major distribution facilities. The United Kingdom holds a 16.4% share in 2025, expected to decrease to 15.9% by 2035 due to post-Brexit logistics operational adjustments. Italy commands a 13.8% share, while Spain accounts for 11.5% in 2025. The Rest of Europe region is anticipated to gain momentum, expanding its collective share from 10.4% to 11.7% by 2035, attributed to increasing shuttle rack adoption in Nordic countries and emerging Eastern European logistics facilities implementing automation programs.

The Japanese four way shuttle rack market demonstrates a mature and precision-focused landscape, characterised by sophisticated integration of fully automatic systems with existing warehouse management infrastructure across automotive, pharmaceutical, and precision manufacturing logistics facilities. Japan's emphasis on operational excellence and continuous improvement drives demand for high-performance shuttle solutions that support kaizen initiatives and statistical process control requirements in warehouse operations. The market benefits from strong partnerships between international technology providers like Daifuku, Jungheinrich, and domestic logistics leaders, creating comprehensive service ecosystems that prioritise system reliability and operator training. Logistics centres in Tokyo, Osaka, and Nagoya showcase advanced automated implementations where shuttle systems achieve 95% operational uptime through integrated maintenance programs, while the country's focus on space optimisation and labour efficiency supports steady adoption of fully automatic shuttle technologies across diverse warehouse sectors.

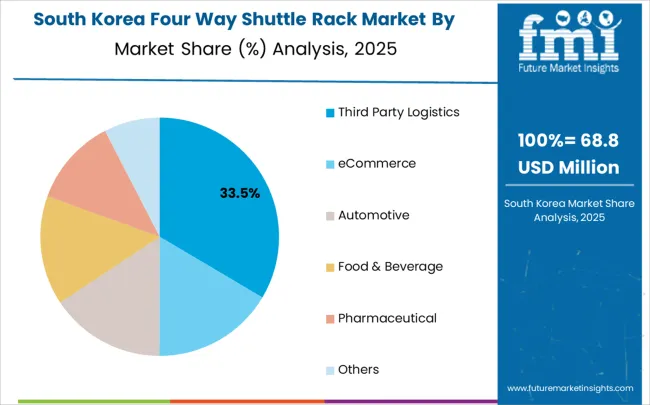

The South Korean four way shuttle rack market is characterised by strong international technology provider presence, with companies like Daifuku, SSI SCHÄFER, and Jungheinrich maintaining dominant positions through comprehensive system integration and maintenance services capabilities. The market is demonstrating a growing emphasis on localised technical support and rapid deployment capabilities, as Korean logistics operators increasingly demand customised solutions that integrate with domestic warehouse management infrastructure and operational processes. Local logistics automation companies and regional distributors are gaining market share through strategic partnerships with global providers, offering specialised services, including training programs and certification services for warehouse personnel. The competitive landscape shows increasing collaboration between multinational shuttle system manufacturers and Korean logistics specialists, creating hybrid service models that combine international technology expertise with local market knowledge and customer relationship management, particularly in the country's concentrated logistics regions around Seoul, Busan, and Incheon, where manufacturing and distribution industries drive continuous demand for advanced shuttle rack solutions.

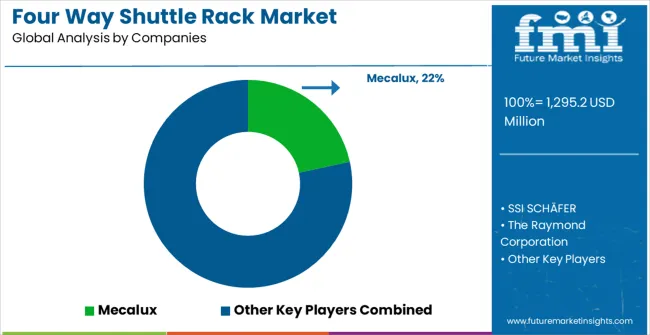

The Four Way Shuttle Rack market features approximately 20-25 meaningful players with moderate concentration, where the top three companies control roughly 35-40% of global market share through established automation platforms and extensive logistics customer relationships. Competition centres on technological differentiation, service capabilities, and integration expertise rather than price competition alone.

Market leaders include Mecalux, SSI SCHÄFER, and The Raymond Corporation, which maintain competitive advantages through comprehensive warehouse automation portfolios, global service networks, and deep expertise in logistics processes, creating high switching costs for customers. These companies leverage installed base relationships and ongoing service contracts to defend market positions while expanding into adjacent storage automation applications.

Challengers encompass Daifuku, Frazier Industrial Company, and Gold Wind Engineering, which compete through specialised shuttle solutions and strong regional presence in key logistics markets. Technology specialists, including Whittan Storage Systems, AR Racking, and WSL Giraffe Storage Solutions, focus on specific shuttle technologies or vertical applications, offering differentiated capabilities in automated storage, warehouse control integration, and logistics optimisation platforms.

Regional players and emerging technology providers create competitive pressure through cost-effective solutions and rapid deployment capabilities, particularly in high-growth markets including China and India, where local presence provides advantages in customer support and regulatory compliance. Market dynamics favour companies that combine advanced shuttle technologies with AI-powered warehouse management and comprehensive service offerings that address the complete automation system lifecycle from installation through ongoing optimisation.

| Item | Value |

|---|---|

| Quantitative Units | USD 1,295.2 million |

| Automation Level | Fully Automatic, Semi Automatic |

| Application | Third Party Logistics, eCommerce, Automotive, Food & Beverage, Pharmaceutical, Others |

| Regions Covered | North America, Latin America, Europe, East Asia, South Asia & Pacific, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, the USA, the UK, Japan, and 40+ countries |

| Key Companies Profiled | Mecalux, SSI SCHÄFER, The Raymond Corporation, Daifuku, Frazier Industrial Company, Gold Wind Engineering, Whittan Storage Systems, AR Racking, WSL Giraffe Storage Solutions, Jungheinrich |

| Additional Attributes | Dollar sales by automation level and application categories, regional adoption trends across North America, Europe, and Asia-Pacific, competitive landscape with technology providers and system integrators, warehouse facility preferences and requirements, integration with Industry 4.0 initiatives and IoT platforms, innovations in shuttle rack technology and warehouse optimisation analytics, and development of specialised storage applications with operational efficiency capabilities. |

The global four way shuttle rack market is estimated to be valued at USD 1,295.2 million in 2025.

The market size for the four way shuttle rack market is projected to reach USD 2,341.5 million by 2035.

The four way shuttle rack market is expected to grow at a 6.1% CAGR between 2025 and 2035.

The key product types in four way shuttle rack market are fully automatic and semi automatic.

In terms of application, third party logistics segment to command 34.0% share in the four way shuttle rack market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Fourth Party Logistics Market Size and Share Forecast Outlook 2025 to 2035

Four Side Flat Pouch Market Size and Share Forecast Outlook 2025 to 2035

Four Side-Sealed Pouches Market

Sway Bar Bushing Market

Airway Disease Treatment Market Size and Share Forecast Outlook 2025 to 2035

Airway Management Devices Market Growth – Demand & Industry Forecast 2025 to 2035

Airway Catheters Market Analysis - Growth & Industry Insights 2025 to 2035

Airway Clearance Devices Market Growth - Trends & Forecast 2025 to 2035

Runway Lighting Market Trends, Outlook & Forecast 2025 to 2035

Norway Aquaculture Vaccines Market Insights – Size, Demand & Growth 2025-2035

Runway Lighting System Market

Railway System Market Size and Share Forecast Outlook 2025 to 2035

Railway Air Conditioning System Market Size and Share Forecast Outlook 2025 to 2035

Railway Braking System Market Size and Share Forecast Outlook 2025 to 2035

Railway CNC Wheel Lathe Market Size and Share Forecast Outlook 2025 to 2035

Railway Flatcar Market Size and Share Forecast Outlook 2025 to 2035

Highway Maintenance Market Size and Share Forecast Outlook 2025 to 2035

Railway Roof Switches Market Size and Share Forecast Outlook 2025 to 2035

Railway Window Market Size and Share Forecast Outlook 2025 to 2035

Railway Maintenance Machinery Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA