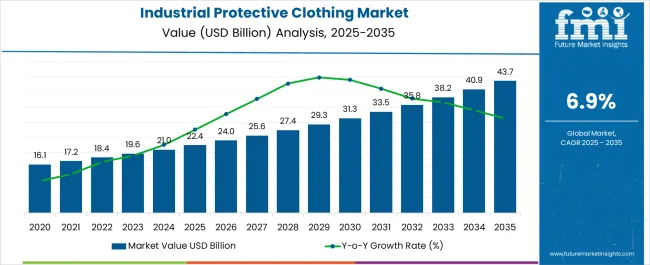

The Industrial Protective Clothing Market is estimated to be valued at USD 22.4 billion in 2025 and is projected to reach USD 43.7 billion by 2035, registering a compound annual growth rate (CAGR) of 6.9% over the forecast period.

| Metric | Value |

|---|---|

| Industrial Protective Clothing Market Estimated Value in (2025 E) | USD 22.4 billion |

| Industrial Protective Clothing Market Forecast Value in (2035 F) | USD 43.7 billion |

| Forecast CAGR (2025 to 2035) | 6.9% |

The Industrial Protective Clothing market is witnessing strong expansion, driven by the rising emphasis on workplace safety, stringent regulatory standards, and increasing awareness about occupational hazards across industries. The growing number of industrial accidents and the heightened focus on employee protection are prompting companies to invest in advanced protective clothing solutions. Materials with superior durability, resistance to extreme conditions, and compliance with safety regulations are in high demand.

Technological advancements such as lightweight fabrics, breathable designs, and smart textiles are improving user comfort without compromising protection. Globalization of industries like oil and gas, construction, mining, and manufacturing has further accelerated demand for certified protective wear. Additionally, increasing investments in infrastructure projects and the expansion of hazardous industrial environments are creating sustained market opportunities.

The shift toward sustainability, including the use of eco-friendly materials and recycling initiatives, is reshaping product development strategies As industries continue to prioritize worker safety and efficiency, the Industrial Protective Clothing market is expected to expand significantly, with innovation and compliance serving as primary growth enablers.

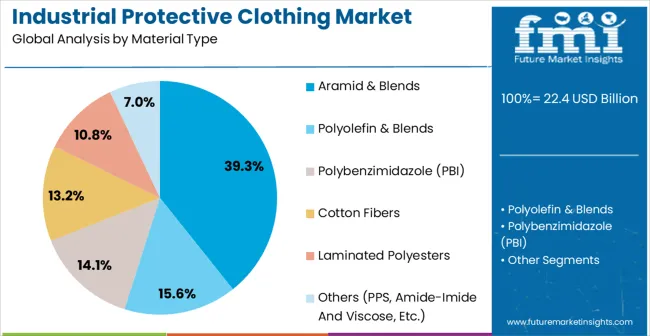

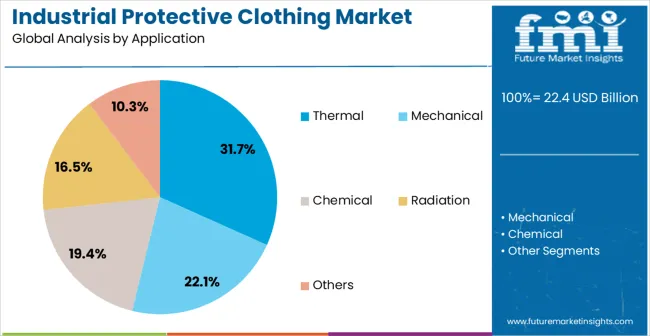

The industrial protective clothing market is segmented by material type, application, end user industry, and geographic regions. By material type, industrial protective clothing market is divided into Aramid & Blends, Polyolefin & Blends, Polybenzimidazole (PBI), Cotton Fibers, Laminated Polyesters, and Others (PPS, Amide-Imide And Viscose, Etc.). In terms of application, industrial protective clothing market is classified into Thermal, Mechanical, Chemical, Radiation, and Others. Based on end user industry, industrial protective clothing market is segmented into Oil & Gas, Construction & Manufacturing, Law Enforcement & Military, Firefighting, and Others (Mining, Chemical Industry, Etc.). Regionally, the industrial protective clothing industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The aramid and blends material type segment is projected to account for 39.3% of the Industrial Protective Clothing market revenue in 2025, positioning it as the leading material type. Growth in this segment is supported by the superior thermal resistance, durability, and mechanical strength that aramid fibers offer, making them ideal for high-risk industrial environments. The ability of aramid and its blends to withstand heat, flames, and chemical exposure has reinforced their widespread adoption in oil and gas, firefighting, and military applications.

The growing demand for lightweight yet highly protective clothing has further elevated the importance of this segment. Ongoing advancements in fabric technology have improved breathability and comfort, addressing key user concerns while ensuring compliance with safety regulations.

The high cost-effectiveness of aramid blends compared to pure fibers has also broadened accessibility for multiple industries As industries increasingly prioritize both protection and productivity, aramid and blends are expected to maintain leadership, supported by continuous material innovation and global expansion of hazardous work environments.

The thermal application segment is expected to hold 31.7% of the Industrial Protective Clothing market revenue in 2025, making it the largest application area. Its dominance is being driven by the rising need for protective clothing that can safeguard workers from extreme heat, flames, and arc flash hazards. Industries such as oil and gas, metal processing, power generation, and welding are primary adopters of thermal protective clothing, where exposure to high temperatures is a persistent risk.

Advanced multi-layered fabrics, enhanced thermal insulation, and flame-retardant finishes are being developed to ensure superior protection while maintaining wearer comfort. Increasing government regulations mandating the use of thermal protective gear across hazardous industries are fueling adoption. The emphasis on reducing workplace injuries and ensuring worker safety standards is strengthening this segment’s growth.

Continuous R&D aimed at improving durability, flexibility, and wearability is also supporting demand As industrial operations expand globally, the need for advanced thermal protective clothing is expected to remain robust, consolidating this segment’s market leadership.

The oil and gas end user industry segment is anticipated to account for 34.5% of the Industrial Protective Clothing market revenue in 2025, positioning it as the leading end user. The hazardous working conditions in exploration, drilling, refining, and transportation activities necessitate advanced protective clothing that can withstand extreme heat, chemical exposure, and fire risks. The high prevalence of accidents in oilfields and refineries has made compliance with stringent safety standards non-negotiable, driving widespread adoption of certified protective gear.

Aramid-based protective clothing, chemical-resistant coatings, and flame-retardant fabrics are particularly critical in this sector. The growing global energy demand, alongside significant investments in new oil and gas projects, is further fueling market growth.

Additionally, increasing adoption of automation and digital monitoring in oil and gas operations requires protective clothing that integrates safety with comfort, ensuring workforce efficiency As safety awareness continues to heighten and regulations become stricter, the oil and gas segment is expected to sustain its leadership, supported by continuous innovation in advanced protective clothing solutions.

The Industrial Protective Clothing are made of advanced materials that protect employee against hazardous flame and fire, electric arc flash, cuts, life threatening chemicals and other hazardous materials. The industrial Protective Clothing also helps protect emergency team members and workers across various industry vertical.

The market participants are focusing on offering complete product portfolio of industrial protective clothing as per required protection and comfort for meeting prevailing standards listed by the concerned authorities. Some of the required key features are non-flammability, thermal insulation, thermo stability, chemical resistance, permanent color, comfort, appearance and mechanical resistance.

The product innovation is one of major focus area among key market participant in the global industrial protective clothing market. The available range of inexpensive industrial protective clothing products from local players had increased competition in the highly fragmented industrial clothing marketplace resulting in reduction in the price of the products.

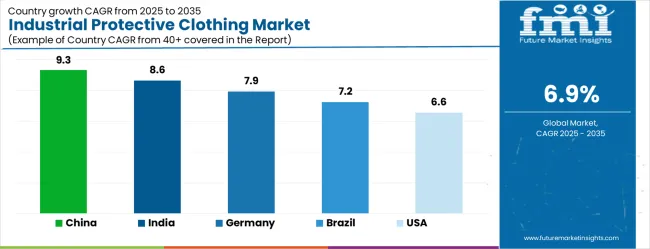

| Country | CAGR |

|---|---|

| China | 9.3% |

| India | 8.6% |

| Germany | 7.9% |

| Brazil | 7.2% |

| USA | 6.6% |

| UK | 5.9% |

| Japan | 5.2% |

The Industrial Protective Clothing Market is expected to register a CAGR of 6.9% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 9.3%, followed by India at 8.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.2%, yet still underscores a broadly positive trajectory for the global Industrial Protective Clothing Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.9%. The USA Industrial Protective Clothing Market is estimated to be valued at USD 8.1 billion in 2025 and is anticipated to reach a valuation of USD 8.1 billion by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 1.2 billion and USD 623.9 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 22.4 Billion |

| Material Type | Aramid & Blends, Polyolefin & Blends, Polybenzimidazole (PBI), Cotton Fibers, Laminated Polyesters, and Others (PPS, Amide-Imide And Viscose, Etc.) |

| Application | Thermal, Mechanical, Chemical, Radiation, and Others |

| End User Industry | Oil & Gas, Construction & Manufacturing, Law Enforcement & Military, Firefighting, and Others (Mining, Chemical Industry, Etc.) |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

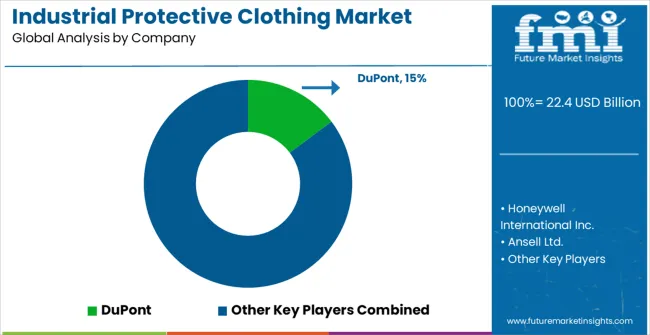

| Key Companies Profiled | DuPont, Honeywell International Inc., Ansell Ltd., Lakeland Industries, Inc., W. L. Gore & Associates, Inc., Kimberly-Clark, TEIJIN LIMITED, TenCate Protective, Workwear Outfitters, LLC, PBI Performance Products, Inc., ADA (Australian Defence Apparel), and Bennett Safetywear |

The global industrial protective clothing market is estimated to be valued at USD 22.4 billion in 2025.

The market size for the industrial protective clothing market is projected to reach USD 43.7 billion by 2035.

The industrial protective clothing market is expected to grow at a 6.9% CAGR between 2025 and 2035.

The key product types in industrial protective clothing market are aramid & blends, polyolefin & blends, polybenzimidazole (pbi), cotton fibers, laminated polyesters and others (pps, amide-imide and viscose, etc.).

In terms of application, thermal segment to command 31.7% share in the industrial protective clothing market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Protective Clothing Market - Trends, Growth & Forecast 2025 to 2035

Industrial Protective Footwear Market Insights - Growth & Forecast 2025 to 2035

Nonwoven Protective Clothing Market Size and Share Forecast Outlook 2025 to 2035

Aluminum Coated Thermal Protective Clothing Market Size and Share Forecast Outlook 2025 to 2035

Industrial Grade Electrochemical CO Sensor Market Size and Share Forecast Outlook 2025 to 2035

Industrial Bench Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Low Profile Floor Scale Market Size and Share Forecast Outlook 2025 to 2035

Industrial Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Industrial Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Safety Gloves Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA