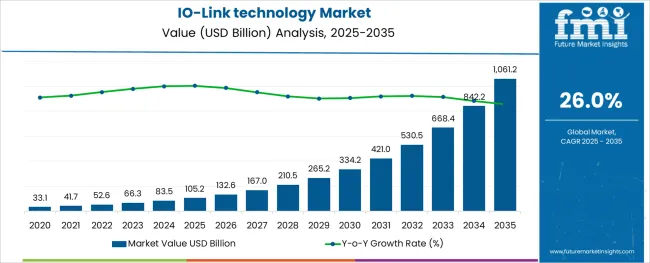

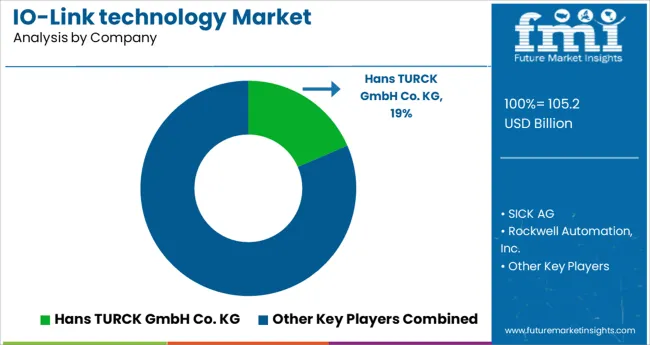

The IO-Link technology Market is estimated to be valued at USD 105.2 billion in 2025 and is projected to reach USD 1,061.2 billion by 2035, registering a compound annual growth rate (CAGR) of 26.0% over the forecast period.

The IO-Link technology market is expanding rapidly, fueled by the growing need for smart factory automation and improved machine communication. Industry sources highlight the increasing adoption of IO-Link for seamless integration of sensors and actuators in manufacturing equipment. The push towards Industry 4.0 and digital transformation in factories is driving demand for technologies that enable better data exchange and diagnostics.

This trend is particularly strong in sectors where precision and efficiency are critical, such as semiconductor and electronics manufacturing. Improvements in device interoperability and simplified installation have accelerated IO-Link adoption across various industrial processes.

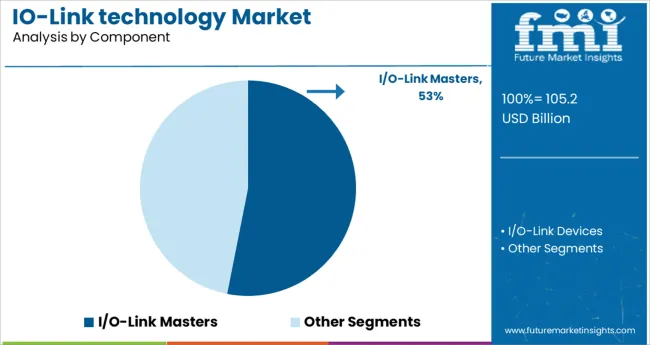

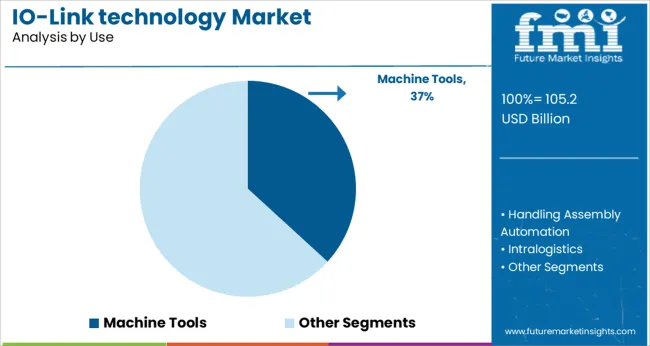

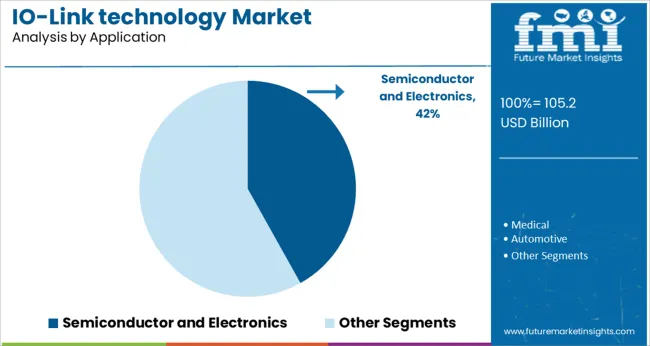

The market is expected to benefit from ongoing investments in smart machine tools and automation solutions, helping manufacturers enhance productivity and reduce downtime. Segment growth is anticipated to be led by the I/O-Link Masters component segment, machine tools as the primary use case, and semiconductor and electronics as the leading application sector.

The market is segmented by Component, Use, and Application and region. By Component, the market is divided into I/O-Link Masters and I/O-Link Devices. In terms of Use, the market is classified into Machine Tools, Handling Assembly Automation, Intralogistics, and Packaging.

Based on Application, the market is segmented into Semiconductor and Electronics, Medical, Automotive, and Other Applications. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The I/O-Link Masters segment is forecasted to hold 53.1% of the IO-Link technology market revenue in 2025, making it the dominant component category. This segment’s growth stems from the critical role that masters play in connecting field devices to control systems, enabling standardized communication protocols.

The simplicity of IO-Link masters facilitates easy integration into existing automation architectures, allowing for streamlined data transfer and improved system diagnostics. Increasing demand for plug-and-play connectivity and device parameterization has bolstered the use of I/O-Link masters in industrial environments.

As manufacturing facilities upgrade towards more connected and flexible operations, the I/O-Link Masters segment is expected to maintain its leading position.

The Machine Tools segment is projected to contribute 36.8% of the market revenue in 2025, establishing it as the key use segment for IO-Link technology. This growth is driven by the necessity to monitor and control critical machine parameters for quality assurance and operational efficiency.

IO-Link enables real-time monitoring of tool condition, spindle speed, and other vital metrics that improve manufacturing precision and reduce machine downtime. The adoption of smart sensors and actuators in machine tools has been widely accepted due to the advantages in predictive maintenance and process optimization.

With manufacturers increasingly automating machining processes, the demand for IO-Link technology in this segment is expected to remain strong.

The Semiconductor and Electronics segment is forecasted to account for 41.9% of the IO-Link technology market revenue in 2025, retaining its leadership among applications. Growth in this segment is linked to the high demand for precise and reliable automation in semiconductor fabrication and electronics assembly.

IO-Link technology supports stringent quality control requirements by facilitating detailed monitoring of process parameters and equipment status. The complexity and miniaturization in semiconductor manufacturing processes necessitate advanced communication technologies for efficient operation.

As the electronics industry continues to innovate and expand, the integration of IO-Link technology is becoming essential to maintaining competitive manufacturing processes. The segment’s prominence is expected to continue as demand for higher throughput and automation sophistication rises.

The rising adoption of IO-link technology in multiple industries, such as machine manufacturing, automotive, medical devices, packaging, semiconductor & electronics, and aerospace & defense is set to drive the market. These industries are following strict norms associated with their manufacturing operations and are aiming to lower their operational costs.

These norms are expected to propel the adoption of IoT and industrial automation technologies to enhance their business operations. These industries are also set to focus on meeting the surging demand from customers by improving the operational efficiency of machines.

The ability of this technology to reduce the downtime of machines, speed up commissioning times, and lower manufacturing costs is anticipated to augment the IO-link technology market growth.

IO-link technology is vulnerable to numerous threats, such as Denial-of-Service (DoS), Cross-site Request Forgery (CSRF), blind command injection, and reflected Cross-site Scripting (XSS) issues. Some of the other risks related to this technology include database injection, watering holes, and spear phishing.

These cyber risks can hamper Industrial Automation and Control Systems (IACS). In case of a phishing assault, a digital criminal steals confidential data from various devices by deceiving users into sharing the security key for a specific application. These factors may obstruct the demand for IO-link technology in the assessment period.

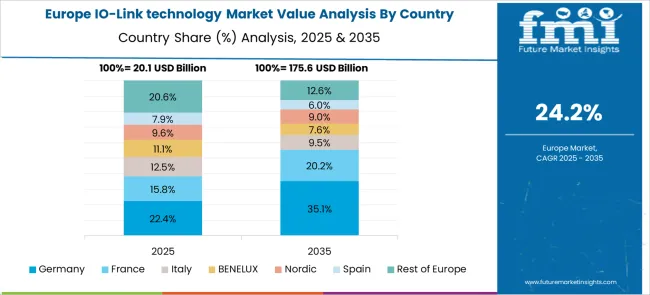

Europe is expected to remain at the forefront by procuring the largest IO-link technology market share in the upcoming years. The presence of a large number of companies in the industrial manufacturing, aerospace & defense, and automotive industries in the U.K. and Germany is set to contribute to this growth.

The surging demand for industrial automation and IoT-connected devices in the manufacturing sector, especially in France and the U.K. is another crucial factor that is projected to augur well for the regional market. Besides, the European Union is expected to take numerous initiatives to digitize the region’s industries and set up smart factories. This factor is also set to positively affect the growth in the Europe market.

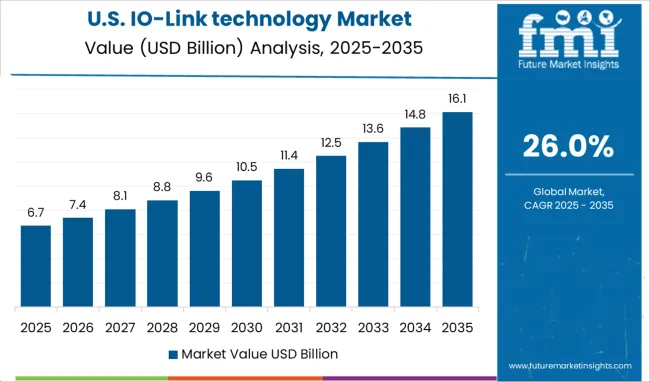

The presence of a well-established packaging sector in the U.S. and Canada is projected to bolster the North America IO-link technology market growth in the future years. The sector uses automation solutions to initiate multiple packaging processes, such as product shipment, storage, handling, and sorting.

IO-link technology also helps in optimizing the packaging process by setting up bidirectional communication between automation systems and sensors. This technology provides various features, such as rapid returns on investment, safe commissioning, reliable packaging processes, improved remote diagnosis, and easy availability of the final packaging machines.

These beneficial properties of IO-link technology are expected to propel its demand across North America.

Some of the renowned companies operating in the IO-link technology market include Hans TURCK GmbH Co. KG, SICK AG, Rockwell Automation, Inc., Banner Engineering, OMRON Corporation, Balluff GmbH, Pepperl+Fuchs, Leuze Electronic GmbH + Co. KG, ifm electronic FZC, Siemens AG, Festo AG & Co. KG, and Datalogic S.p.A. among others.

Majority of the leading companies are aiming to develop more secure, cost-effective, and technologically advanced solutions to attract a large consumer base worldwide. Meanwhile, a few other key players are engaging in mergers and acquisitions, partnerships, and joint ventures with start-up companies to co-develop novel products and expand their existing product portfolios.

| Report Attribute | Details |

|---|---|

| Growth Rate | CAGR of 26% from 2025 to 2035 |

| Base Year for Estimation | 2024 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in billion, Volume in Kilotons and CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends and Pricing Analysis |

| Segments Covered | Component, Use, Application, Region |

| Regions Covered | North America; Latin America; Western Europe; Easter Europe; APEJ; Japan; Middle East & Africa |

| Key Countries Profiled | USA, Canada, Brazil, Argentina, Germany, UK, France, Spain, Italy, Nordics, BENELUX, Australia & New Zealand, China, India, ASEAN, GCC, South Africa |

| Key Companies Profiled | Hans TURCK GmbH Co. KG; SICK AG; Rockwell Automation, Inc.; Banner Engineering; OMRON Corporation; Balluff GmbH; Pepperl+Fuchs; Leuze Electronic GmbH + Co. KG; ifm electronic FZC; Siemens AG; Festo AG & Co. KG; Datalogic S.p.A. |

| Customization | Available Upon Request |

The global io-link technology market is estimated to be valued at USD 105.2 billion in 2025.

It is projected to reach USD 1,061.2 billion by 2035.

The market is expected to grow at a 26.0% CAGR between 2025 and 2035.

The key product types are i/o-link masters and i/o-link devices.

machine tools segment is expected to dominate with a 36.8% industry share in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

4K Technology Market Size and Share Forecast Outlook 2025 to 2035

5G technology market Analysis by Technology Type, Application, Vertical, and Region – Growth, trends and forecast from 2025 to 2035

8K Technology Market

Nanotechnology Photocatalysis Surface Coating Industry Analysis in AMEA Size and Share Forecast Outlook 2025 to 2035

Nanotechnology Packaging Market Size and Share Forecast Outlook 2025 to 2035

Key Players & Market Share in GDS Technology Market

GDS Technology Market Insights - Growth & Forecast 2025 to 2035

Nanotechnology for food packaging Market

Food Technology Market Size and Share Forecast Outlook 2025 to 2035

Smart-Technology Anti-Wrinkle Peptides Market Size and Share Forecast Outlook 2025 to 2035

Laser Technology Market Size and Share Forecast Outlook 2025 to 2035

Green Technology And Sustainability Market Size and Share Forecast Outlook 2025 to 2035

Camera Technology Market Analysis – Trends & Forecast 2025 to 2035

Battery Technology Market Size and Share Forecast Outlook 2025 to 2035

Airline Technology Integration Market Size and Share Forecast Outlook 2025 to 2035

Food Biotechnology Market Size and Share Forecast Outlook 2025 to 2035

Scaffold Technology Market Size and Share Forecast Outlook 2025 to 2035

Ablation Technology Market Size, Share, and Forecast Outlook 2025 to 2035

Sapphire Technology Market Trends – Growth & Forecast 2025 to 2035

Deception Technology Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA