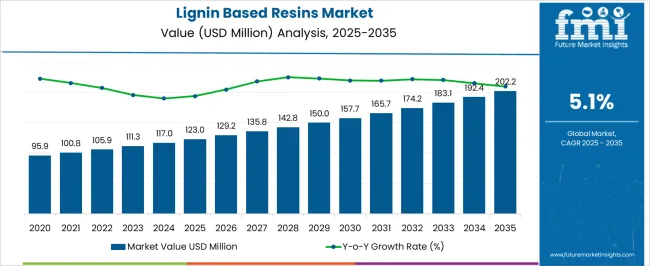

The lignin based resins market is projected to see notable growth, increasing from USD 123 million in 2025 to USD 202.2 million by 2035, with a CAGR of 5.1%. This growth is attributed to the rising demand for eco-friendly and high-performance resins, particularly in the automotive, construction, and packaging industries. Lignin-based resins are gaining traction due to their cost-effectiveness and superior mechanical properties compared to conventional resins. The shift toward more sustainable, bio-based products has driven a growing interest in lignin as a key component, offering enhanced product performance in a variety of applications.

Year-over-year, the market is expected to show consistent expansion, from USD 127 million in 2026 to USD 202.2 million by 2035. The increasing adoption of these resins across industries focused on reducing reliance on petroleum-based materials is a key factor behind this growth. As companies continue to invest in environmentally conscious alternatives, the demand for lignin-based resins is expected to rise, contributing to steady market gains. The market's evolution will be further propelled by advancements in production processes and the widening application base of these resins, especially in composites, adhesives, and coatings.

| Metric | Value |

|---|---|

| Lignin Based Resins Market Estimated Value in (2025 E) | USD 123.0 million |

| Lignin Based Resins Market Forecast Value in (2035 F) | USD 202.2 million |

| Forecast CAGR (2025 to 2035) | 5.1% |

The lignin based resins market holds a growing share within several key parent markets. In the broader resin market, it represents approximately 2-3%, driven by the increasing adoption of lignin-based resins as sustainable alternatives to petroleum-based resins. Within the bioplastics market, the lignin-based resins segment accounts for about 4-5%, as these resins are valued for their renewable nature and reduced environmental impact, fitting within the rising demand for bio-based materials.

In the chemical manufacturing market, lignin-based resins hold around 1-2%, as they are used in the production of various specialty chemicals and formulations. In the automotive materials market, these resins contribute around 3-4%, owing to their application in lightweight and environmentally friendly automotive components, which align with the industry's move towards sustainable manufacturing practices.

In the construction materials market, the share of lignin-based resins is around 2-3%, as they are increasingly used in adhesives, coatings, and composites, offering strong bonding properties and eco-friendly alternatives for construction applications. This growing presence across these markets highlights the expanding use of lignin-based resins driven by sustainability trends and the need for renewable materials in industrial applications.

The market is experiencing strong growth as industries increasingly prioritize sustainable and bio-based materials over conventional petrochemical alternatives. Lignin, as a renewable byproduct of the pulp and paper industry, offers significant potential for developing resins with reduced environmental impact while maintaining performance characteristics required in various applications. Regulatory initiatives promoting the use of eco-friendly raw materials, along with rising awareness of carbon footprint reduction, are contributing to market expansion.

Technological advancements in lignin extraction, purification, and functionalization have improved its compatibility and reactivity in resin formulations, further enhancing adoption. Growing investment from chemical manufacturers and material science innovators is enabling the development of high-performance lignin-based resin systems tailored to meet stringent industrial standards.

With demand rising in adhesives, coatings, and composite materials, the market is set to benefit from both policy-driven and market-driven factors. The trend toward circular economy practices and the need for cost-efficient sustainable solutions will continue to shape the future outlook of the lignin-based resins industry.

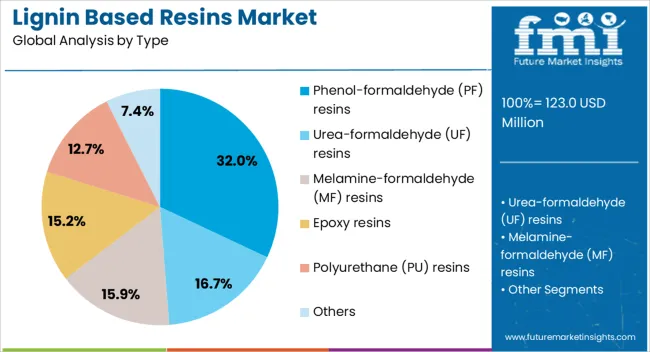

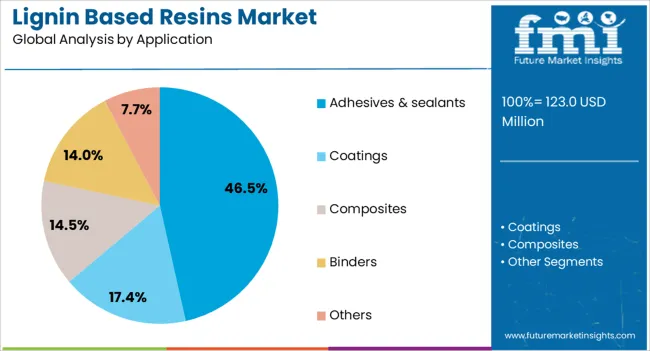

The lignin based resins market is segmented by type, application, and geographic regions. By type, lignin based resins market is divided into Phenol-formaldehyde (PF) resins, Urea-formaldehyde (UF) resins, Melamine-formaldehyde (MF) resins, Epoxy resins, Polyurethane (PU) resins, and Others. In terms of application, lignin based resins market is classified into Adhesives & sealants, Coatings, Composites, Binders, and Others. Regionally, the lignin based resins industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The phenol formaldehyde (PF) resins type segment is projected to account for 32% of the lignin-based resins market revenue share in 2025, making it the leading type segment. The dominance of this segment has been attributed to the ability of lignin to partially replace phenol in PF resin formulations without compromising strength, thermal stability, or durability.

This substitution not only reduces reliance on petroleum-derived phenol but also lowers production costs, which has encouraged wider adoption across multiple industrial sectors. PF resins derived from lignin exhibit enhanced bonding properties and resistance to moisture, making them suitable for demanding applications such as wood panels, laminates, and molded products.

Ongoing research and development activities have focused on improving lignin reactivity, allowing for higher substitution rates and better process efficiency. The alignment of these technical improvements with sustainability objectives has positioned lignin-based PF resins as a viable and competitive alternative, strengthening their market leadership in the overall type segment.

The adhesives and sealants application segment is anticipated to hold 46.50% of the Lignin Based Resins market revenue share in 2025, securing its position as the leading application segment. The high share has been driven by the growing demand for sustainable bonding solutions in industries such as construction, packaging, automotive, and furniture manufacturing. Lignin-based resins offer strong adhesive performance, good heat resistance, and improved environmental compatibility compared to synthetic alternatives.

Their ability to be tailored for specific bonding requirements through software-assisted formulation and chemical modification processes has further enhanced their utility. The shift toward low-emission and formaldehyde-free adhesives in response to stringent environmental regulations has significantly boosted adoption.

Additionally, the cost advantages associated with replacing a portion of petroleum-based binders with lignin have appealed to manufacturers aiming to improve both sustainability and profitability. As industries increasingly transition toward green materials, lignin-based adhesives and sealants are expected to maintain their strong position and continue driving growth in the application segment.

The lignin-based resins market is witnessing growth due to rising demand for renewable, eco-friendly alternatives to conventional resins. Opportunities in various applications, including packaging, automotive, and adhesives, are driving this growth, as industries seek sustainable and high-performance materials. Key trends, such as the shift toward bio-based products and lightweight composites, are further fueling the market’s expansion. However, challenges related to cost and production scalability must be addressed for lignin-based resins to become a mainstream alternative. Despite these challenges, the market for lignin-based resins is poised for significant growth.

The demand for lignin-based resins is increasing as industries seek eco-friendly alternatives to conventional synthetic resins. Lignin, a natural polymer found in wood and agricultural by-products, offers a sustainable solution for industries such as automotive, construction, and packaging. The growing focus on reducing environmental impact and the shift toward renewable materials are driving the adoption of lignin-based resins. As companies face increasing pressure to reduce their carbon footprint, lignin-based resins present a viable solution that aligns with both environmental goals and performance requirements.

Opportunities in the lignin-based resins market are expanding as new applications emerge across various industries. The potential for lignin-based resins in the production of adhesives, coatings, and composites is gaining traction, especially as industries move towards more sustainable and high-performance materials. Manufacturers are exploring the use of lignin-based resins in biodegradable packaging and automotive parts, areas where their strength, durability, and low environmental impact can offer significant advantages. As the demand for green alternatives continues to grow, lignin-based resins are positioned to expand their reach in multiple sectors.

A key trend shaping the lignin-based resins market is the increasing adoption of bio-based materials in manufacturing. Consumers and regulatory bodies are pushing for more renewable and low-impact solutions, prompting industries to explore alternatives to petrochemical-based products. Lignin-based resins, being derived from renewable sources like wood and agricultural waste, align with this shift. The trend of lightweighting in automotive and aerospace sectors is also driving the demand for lignin-based composites, as these resins offer high strength-to-weight ratios and improve fuel efficiency without sacrificing performance.

Despite the growing demand, several challenges hinder the widespread adoption of lignin-based resins. The extraction and refinement of lignin from natural sources can be complex and expensive, limiting cost-competitiveness with traditional synthetic resins. Moreover, ensuring consistent quality and performance in lignin-based resins can be difficult, particularly when scaling production. There are also concerns about the potential variability in lignin sources, which may affect the uniformity and reliability of the resin products. Overcoming these production challenges will be critical to driving mass adoption of lignin-based resins in mainstream markets.

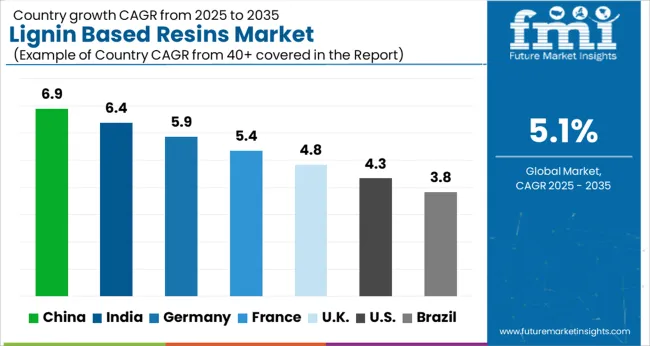

| Country | CAGR |

|---|---|

| China | 6.9% |

| India | 6.4% |

| Germany | 5.9% |

| France | 5.4% |

| UK | 4.8% |

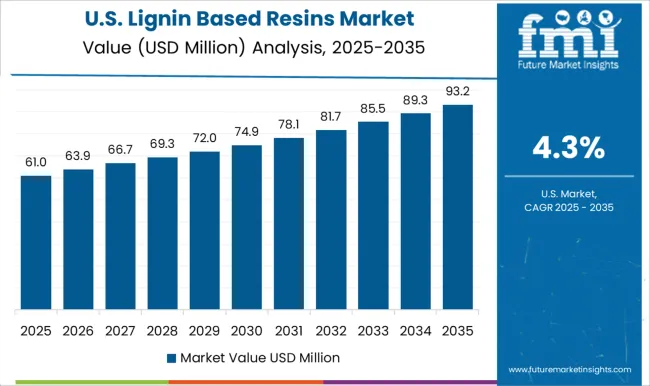

| USA | 4.3% |

| Brazil | 3.8% |

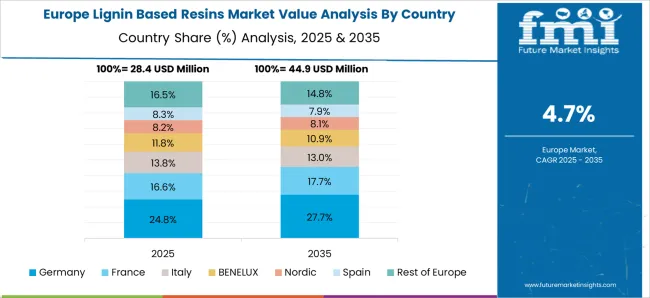

The global lignin-based resins market is projected to grow at a 5.1% CAGR from 2025 to 2035. China leads with a growth rate of 6.9%, followed by India at 6.4%, and France at 5.4%. The United Kingdom records a growth rate of 4.8%, while the United States shows the slowest growth at 4.3%. This growth is driven by increasing demand for sustainable and eco-friendly resins in various applications, including adhesives, coatings, and composites.

Emerging markets, such as China and India, are experiencing higher growth rates due to industrialization, the adoption of sustainable materials, and a growing push for green solutions. In contrast, mature markets like the USA and the UK are seeing steady growth, driven by increasing environmental regulations and the demand for renewable resources in manufacturing. This report includes insights on 40+ countries; the top markets are shown here for reference.

The lignin-based resins market in China is projected to grow at a CAGR of 6.9%. China’s rapid industrialization and focus on sustainable development are key factors driving the market growth. The country’s increasing demand for eco-friendly materials, particularly in the construction, automotive, and packaging sectors, is accelerating the adoption of lignin-based resins. China’s efforts to replace petrochemical-based products with renewable resources, such as lignin, align with global sustainability goals and government initiatives promoting green chemistry. Additionally, the growing automotive and construction sectors continue to fuel demand for lignin-based resins in adhesives, coatings, and composites.

The lignin-based resins market in India is expected to grow at a CAGR of 6.4%. India’s growing industrial base, combined with increasing awareness of sustainability and environmental issues, is fostering demand for lignin-based resins. The government’s focus on promoting renewable resources and green technologies is encouraging manufacturers to adopt eco-friendly resins in various applications, including coatings, adhesives, and construction materials. Additionally, the rising demand for lightweight and durable materials in the automotive and packaging sectors further supports the market’s growth. India’s expanding infrastructure and industrialization continue to create new opportunities for lignin-based resins.

The lignin-based resins market in France is projected to grow at a CAGR of 5.4%. France’s emphasis on sustainability and environmental protection continues to drive the demand for lignin-based resins, particularly in industries like automotive, packaging, and construction. The increasing adoption of green materials in response to stricter environmental regulations is also supporting market growth. Additionally, France’s commitment to reducing its carbon footprint and reliance on petrochemical-based products is accelerating the shift toward renewable resources like lignin. The growing trend of incorporating sustainable materials into consumer goods and industrial applications further fuels the market’s expansion.

The lignin-based resins market in the United Kingdom is expected to grow at a CAGR of 4.8%. The UK’s growing emphasis on reducing carbon emissions and promoting sustainable manufacturing practices continues to drive the demand for eco-friendly resins. The increasing adoption of renewable resources, such as lignin, in adhesives, coatings, and composites is accelerating market growth. Additionally, the UK’s strong regulatory framework promoting the use of sustainable materials in various industries, including automotive, construction, and packaging, supports the continued expansion of the lignin-based resins market. The growing preference for green chemistry and renewable resources among manufacturers also contributes to the market’s growth.

The lignin-based resins market in the United States is projected to grow at a CAGR of 4.3%. The USA market is driven by increasing environmental regulations and a growing preference for renewable and eco-friendly materials in industrial applications. The automotive, construction, and packaging sectors are major drivers of demand for lignin-based resins, as companies look for sustainable alternatives to traditional petrochemical-based products. Additionally, the USA government’s push for more sustainable manufacturing practices and the rising consumer demand for green products continue to support the growth of the lignin-based resins market. Despite slower growth compared to emerging markets, the ongoing focus on sustainability ensures steady market expansion in the USA

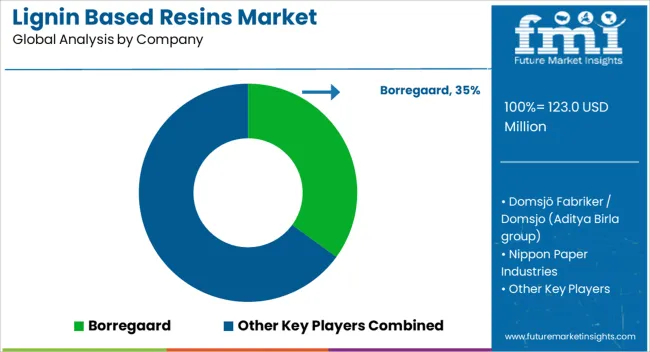

The lignin-based resins market is experiencing substantial growth, driven by major players such as Borregaard, Domsjö Fabriker (Aditya Birla Group), Nippon Paper Industries, Ingevity, Rayonier Advanced Materials, Stora Enso, UPM Biochemicals, and West Fraser. Borregaard, a leader in lignin-based products, focuses on sustainable alternatives for various applications, including resins, with a strong emphasis on eco-friendly solutions. Domsjö Fabriker, part of the Aditya Birla Group, has made significant strides in the market by producing high-quality lignin-based resins derived from renewable biomass, enhancing its position as a key player in sustainable chemicals. Nippon Paper Industries is also a significant contributor to the market, producing lignin-based resins used in diverse industrial applications such as coatings and adhesives.

The company continues to expand its portfolio with a focus on sustainability and renewable resources. Ingevity has established itself as an important player in the production of lignin-based resins, particularly for use in coatings, adhesives, and other high-performance applications. Rayonier Advanced Materials has capitalized on its expertise in wood-based chemicals, producing lignin-based resins that cater to a growing demand for sustainable materials. Stora Enso and UPM Biochemicals, both leaders in the forest industry, are expanding their product portfolios to include lignin-based resins for various industrial uses, with a strong commitment to green chemistry and circular economy principles.

| Item | Value |

|---|---|

| Quantitative Units | USD 123.0 Million |

| Type | Phenol-formaldehyde (PF) resins, Urea-formaldehyde (UF) resins, Melamine-formaldehyde (MF) resins, Epoxy resins, Polyurethane (PU) resins, and Others |

| Application | Adhesives & sealants, Coatings, Composites, Binders, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Borregaard, Domsjö Fabriker / Domsjo (Aditya Birla group), Nippon Paper Industries, Ingevity, Rayonier Advanced Materials, Stora Enso, UPM Biochemicals, West Fraser, and Others |

| Additional Attributes | Dollar sales by product type (phenolic resins, epoxy resins, polyurethane resins), dollar sales by form (liquid, solid, powder), trends in bio-based and sustainable materials, use in adhesives, coatings, and composites, growth in demand for eco-friendly alternatives in construction and automotive industries, and regional patterns of lignin-based resin adoption in manufacturing sectors. |

The global lignin based resins market is estimated to be valued at USD 123.0 million in 2025.

The market size for the lignin based resins market is projected to reach USD 202.2 million by 2035.

The lignin based resins market is expected to grow at a 5.1% CAGR between 2025 and 2035.

The key product types in lignin based resins market are phenol-formaldehyde (pf) resins, urea-formaldehyde (uf) resins, melamine-formaldehyde (mf) resins, epoxy resins, polyurethane (pu) resins and others.

In terms of application, adhesives & sealants segment to command 46.5% share in the lignin based resins market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Lignin Waste Market Size and Share Forecast Outlook 2025 to 2035

High Purity Lignin Market Size and Share Forecast Outlook 2025 to 2035

Si-based Hall Effect Sensors Market Size and Share Forecast Outlook 2025 to 2035

AI-based 3D reconstruction Tools Market Size and Share Forecast Outlook 2025 to 2035

AI based Triage Tools Market Size and Share Forecast Outlook 2025 to 2035

Ph Based Lip Balm Market Size and Share Forecast Outlook 2025 to 2035

AI-Based Driving Systems (L2 to L5) Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Biobased And Synthetic Polyamides Market Size and Share Forecast Outlook 2025 to 2035

AI-based Research Services Market Analysis Size and Share Forecast Outlook 2025 to 2035

AI-based Atrial Fibrillation AFib Detection Market Size and Share Forecast Outlook 2025 to 2035

Biobased Polypropylene PP Size Market Size and Share Forecast Outlook 2025 to 2035

AI-based Surgical Robots Market Size and Share Forecast Outlook 2025 to 2035

Biobased Degreaser Market Size and Share Forecast Outlook 2025 to 2035

pH Based Lipstick Market Size and Share Forecast Outlook 2025 to 2035

Biobased Biodegradable Plastic Market Growth - Trends & Forecast 2025 to 2035

Biobased Propylene Glycol Market Growth - Trends & Forecast 2025 to 2035

AI-based Clinical Trials Solution Provider Market Trends – Growth & Forecast 2024-2034

Biobased Transformer Oil Market

CO2-based Polycarbonate Polyol Market Size and Share Forecast Outlook 2025 to 2035

Bio Based Paraxylene Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA