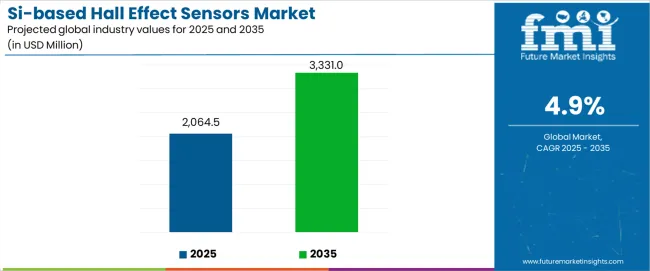

The global silicon-based Hall Effect sensors market, valued at USD 2,064.5 million in 2025 and expected to reach USD 3,331.0 million by 2035 at a CAGR of 4.9%, is shaped heavily by regulatory and standards frameworks that guide design, manufacturing, and application deployment. In the automotive sector, functional safety requirements are a major driver. ISO 26262 compliance mandates rigorous validation of electronic components used in safety-related systems such as electric power steering, braking systems, and battery management. Hall Effect sensors must meet high reliability, accuracy, and failure rate thresholds, which shape both product design and testing protocols. Emissions standards, such as those enforced by the EPA in the United States and the EU’s Euro 6/7 frameworks, also indirectly increase adoption, as Hall sensors are critical in powertrain efficiency and motor control systems designed to meet tighter regulations.

In industrial automation, regulatory frameworks emphasize equipment safety and reliability under harsh operating conditions. Standards such as IEC 61508 for functional safety of electrical/electronic systems govern sensor reliability for applications in robotics, heavy machinery, and factory automation. Compliance with CE marking requirements in Europe and OSHA workplace safety guidelines in the United States further drives demand for precision sensors that reduce operational risks.

Consumer electronics also face regulatory pressure linked to energy efficiency and electromagnetic compatibility. Directives such as the EU’s Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) push manufacturers toward eco-friendly sensor production, phasing out toxic materials and ensuring recyclability. Certification under standards such as UL (Underwriters Laboratories) in the US and CCC in China is critical for consumer product integration.

In the energy sector, where Hall Effect sensors are used in renewable energy equipment, grid monitoring, and power electronics, compliance with IEC 61000 for electromagnetic compatibility and IEEE grid interconnection standards defines the technical baseline. As renewable penetration rises, grid operators require high-precision current sensing that aligns with evolving energy efficiency regulations and carbon reduction targets. Across regions, regulatory trends point toward heightened scrutiny, tighter safety margins, and stricter environmental standards. While compliance raises production costs and technical complexity, it simultaneously creates a barrier to entry for low-quality alternatives, protecting established players.

The Si-based Hall Effect sensors market demonstrates distinct growth phases with varying market characteristics and competitive dynamics. Between 2025 and 2030, the Si-based hall effect sensors market progresses through its advanced silicon integration phase, expanding from USD 2,064.5 million to USD 2,622.4 million with steady annual increments averaging 4.9% growth. This period showcases the transition from basic magnetic detection to advanced integrated sensing systems with enhanced signal processing and temperature compensation becoming mainstream features.

The 2025 to 2030 phase adds USD 557.9 million to market value, representing 44% of total decade expansion. Market maturation factors include standardization of sensing accuracy specifications, declining silicon fabrication costs for high-performance sensors, and increasing automotive adoption of magnetic sensing, reaching 80-85% effectiveness in position detection applications. Competitive landscape evolution during this period features established manufacturers like Allegro MicroSystem and Infineon expanding their product portfolios while new entrants focus on specialized multi-axis solutions and enhanced temperature-resistant technology.

From 2030 to 2035, market dynamics shift toward advanced integration and multi-sector deployment, with growth accelerating from USD 2,622.4 million to USD 3,331.0 million, adding USD 708.6 million or 56% of total expansion. This phase transition logic centers on universal high-performance sensing systems, integration with automated manufacturing equipment, and deployment across diverse application scenarios, becoming standard rather than specialized detection formats. The competitive environment matures with focus shifting from basic sensing to comprehensive signal conditioning and compatibility with modern digital control systems.

At-a-Glance Metrics

| Metric | Value |

|---|---|

| $ Market Value (2025) | USD 2,064.5 million |

| $ Market Forecast (2035) | USD 3,331.0 million |

| # Growth Rate | 4.90% CAGR |

| Leading Sensor Type | Hall Position Sensors |

| Primary Application | Automotive and Transportation |

The Si-based hall effect sensors market demonstrates strong fundamentals with Hall Position Sensors capturing a dominant share through superior accuracy characteristics and reliable magnetic field detection capabilities. Automotive applications drive primary demand, supported by increasing vehicle electrification requirements and enhanced position sensing management solutions. Geographic expansion remains concentrated in developed markets with established automotive manufacturing infrastructure, while emerging economies show accelerating adoption rates driven by industrial automation projects and rising electronic content activity.

The si-based Hall Effect sensors market represents a compelling intersection of magnetic sensing innovation, silicon technology advancement, and position detection optimization management. With robust growth projected from USD 2,064.5 million in 2025 to USD 3,331.0 million by 2035 at a 4.90% CAGR, this market is driven by increasing automotive electrification expansion trends, industrial automation requirements, and consumer electronics demand for reliable sensing formats.

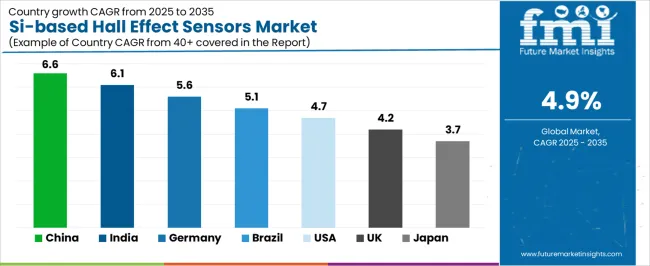

The Si-based hall effect sensors market's expansion reflects a fundamental shift in how automotive manufacturers and industrial equipment designers approach magnetic sensing infrastructure. Strong growth opportunities exist across diverse applications, from automotive systems requiring precision position sensing to industrial machinery demanding high-speed detection solutions. Geographic expansion is particularly pronounced in Asia-Pacific markets, led by China (6.6% CAGR) and India (6.1% CAGR), while established markets in North America and Europe drive innovation and specialized segment development.

The dominance of Hall Position Sensors and automotive applications underscores the importance of proven magnetic sensing technology and structural reliability in driving adoption. signal accuracy and temperature stability remain key challenges, creating opportunities for companies that can deliver consistent performance while maintaining cost efficiency.

Market expansion rests on three fundamental shifts driving adoption across automotive and industrial sectors. Vehicle electrification growth creates compelling advantages through Hall Effect sensor systems that provide comprehensive position detection with contactless operation compatibility, enabling automotive manufacturers to enhance motor control and maintain precision requirements while ensuring reliable operation and justifying investment over traditional mechanical sensing methods. Industrial automation modernization accelerates as manufacturers worldwide seek reliable sensing systems that deliver operational precision directly to production operations, enabling efficiency improvements that align with automation expectations and maximizes sensing accuracy productivity. Electronic content increases drive adoption from consumer electronics requiring compact sensing solutions that maximize detection capability while maintaining low power consumption during portable device operations.

The growth faces headwinds from silicon foundry capacity constraints that differ across semiconductor suppliers regarding production availability and technology access, potentially limiting supply consistency in high-volume automotive categories. Temperature sensitivity also persists regarding extreme operating conditions and calibration requirements that may increase complexity standards in markets with demanding automotive protocols.

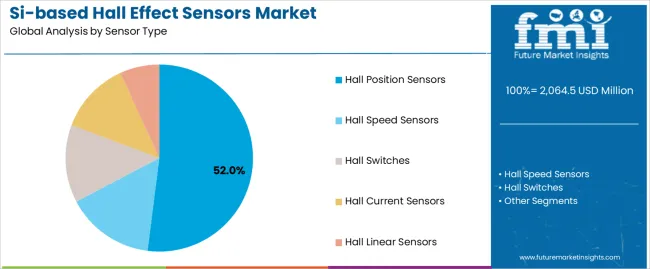

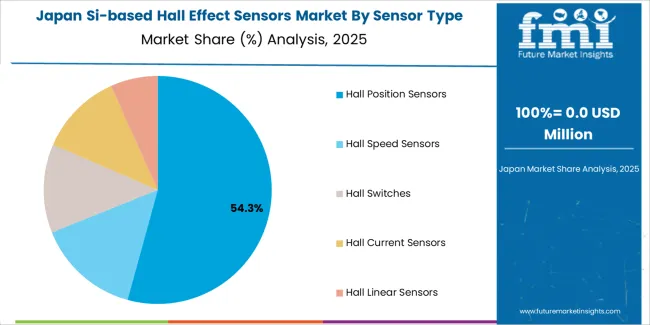

Primary Classification: The Si-based hall effect sensors market segments by sensor type into Hall Position Sensors, Hall Speed Sensors, Hall Switches, Hall Current Sensors, and Hall Linear Sensors, representing the evolution from basic magnetic switching to advanced multi-parameter sensing formats for comprehensive position and motion detection operations.

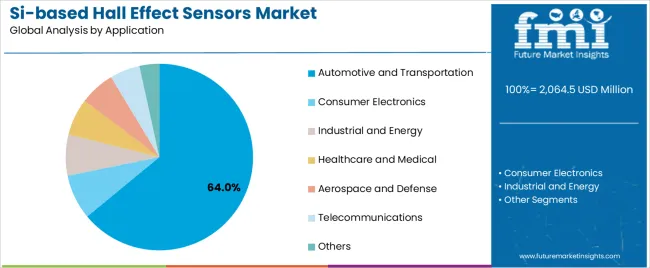

Secondary Breakdown: Application segmentation divides the Si-based hall effect sensors market into Automotive and Transportation, Consumer Electronics, Industrial and Energy, Healthcare and Medical, Aerospace and Defense, and Telecommunications sectors, reflecting distinct requirements for accuracy specifications, operating temperature ranges, and signal processing capabilities.

Regional Classification: Geographic distribution covers North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, with Asia-Pacific markets leading growth while developed markets drive innovation through advanced automotive and industrial applications.

The segmentation structure reveals technology progression from standard switching sensors toward integrated multi-axis platforms with enhanced signal processing and temperature compensation capabilities, while application diversity spans from automotive operations to industrial machinery requiring comprehensive magnetic sensing and contactless detection solutions.

Hall position sensors segment is estimated to account for 52% of the si-based Hall Effect sensors market share in 2025. The segment's leading position stems from its fundamental role as a critical component in automotive positioning applications and its extensive use across multiple industrial and consumer electronic sectors. Hall Position Sensors' dominance is attributed to their superior angular accuracy, including excellent linearity characteristics, reliable contactless operation, and balanced cost-effectiveness that make them indispensable for modern automotive and automation operations.

Market Position: Hall Position Sensors command the leading position in the si-based Hall Effect sensors market through advanced silicon fabrication technologies, including comprehensive temperature compensation, integrated signal conditioning, and reliable manufacturing performance that enable producers to deploy sensing solutions across diverse application environments.

Value Drivers: The segment benefits from automotive preference for proven magnetic sensing profiles that provide exceptional accuracy without requiring premium semiconductor costs. Efficient silicon processing enables deployment in steering systems, throttle positioning, and industrial automation applications where precision, reliability and cost efficiency represent critical selection requirements.

Competitive Advantages: Hall Position Sensors differentiate through excellent angular resolution, proven temperature stability, and compatibility with standard automotive electronics that enhance positioning capabilities while maintaining economical silicon profiles suitable for diverse magnetic sensing applications.

Key market characteristics:

Automotive AND TRANSPORTATION SEGMENT Is projected to hold 64% of the si-based Hall Effect sensors market share in 2025. The segment's market leadership is driven by the extensive use of Hall sensors in vehicle positioning systems, motor control applications, safety mechanisms, and transmission management, where magnetic sensors serve as both a detection component and precision solution. The automotive sector's consistent demand for reliable contactless sensing supports the segment's dominant position.

Market Context: Automotive applications dominate the Si-based hall effect sensors market due to widespread adoption of electronic control systems and increasing focus on vehicle electrification, position accuracy, and safety compliance that enhance driving performance while maintaining operational standards.

Appeal Factors: Automotive manufacturers prioritize contactless operation, temperature resistance, and integration with electronic control units that enable coordinated deployment across multiple vehicle subsystems. The segment benefits from substantial vehicle production growth and electrification development that emphasize reliable sensing systems for automotive applications.

Growth Drivers: Electric vehicle development programs incorporate Hall sensors as standard components for motor position sensing and battery management systems. At the same time, autonomous driving initiatives are increasing demand for precision features that comply with automotive standards and enhance vehicle safety.

Market Challenges: Semiconductor supply chain constraints and automotive qualification requirements may limit deployment flexibility in cost-sensitive automotive markets or regions with varying safety standards.

Application dynamics include:

Growth Accelerators: Vehicle electrification drives primary adoption as Hall Effect sensor systems provide exceptional position detection capabilities that enable motor control without mechanical wear, supporting efficiency improvement and automotive precision that require reliable contactless formats. Industrial automation accelerates market expansion as manufacturers seek precision sensing solutions that maintain accuracy during high-speed operations while enhancing positioning convenience through contactless operation and compatibility. Technology advancement increases worldwide, creating sustained demand for integrated sensing systems that complement electronic architectures and provide operational advantages in magnetic field detection efficiency.

Growth Inhibitors: silicon foundry capacity challenges differ across semiconductor markets regarding production availability and technology access, which may limit supply predictability and delivery planning in high-volume automotive categories with demanding qualification requirements. Automotive qualification complexity persists regarding temperature cycling and reliability testing that may increase development costs in jurisdictions with strict automotive protocols. Market fragmentation across multiple sensing specifications and package standards creates compatibility concerns between different electronic systems and existing control infrastructure.

Market Evolution Patterns: Adoption accelerates in automotive and industrial sectors where contactless benefits justify semiconductor investments, with geographic concentration in Asia-Pacific markets transitioning toward mainstream adoption in North America and Europe, driven by electrification and automation development. Technology advancement focuses on enhanced silicon integration, improved signal processing, and integration with digital communication systems that optimize sensing performance and manufacturing consistency. The Si-based Hall effect sensors market could face disruption if alternative sensing technologies or cost pressures significantly challenge traditional Hall sensor advantages in magnetic detection applications.

The si-based HALL EFFECT SENSORS market demonstrates varied regional dynamics with growth leaders including China (6.6% CAGR) and India (6.1% CAGR) driving expansion through automotive manufacturing growth and industrial automation modernization. Steady Performers encompass Germany (5.6% CAGR), Brazil (5.1% CAGR), and the USA (4.7% CAGR), benefiting from established automotive industries and advanced sensor adoption.

| Country | CAGR (2025 to 2035) |

|---|---|

| China | 6.6% |

| India | 6.1% |

| Germany | 5.6% |

| Brazil | 5.1% |

| USA | 4.7% |

| UK | 4.2% |

| Japan | 3.7% |

Regional synthesis reveals Asia-Pacific markets leading growth through automotive production expansion and industrial development, while European countries maintain steady expansion supported by automotive innovation and specialized applications. North American markets show strong growth driven by electric vehicle adoption and industrial automation upgrades.

China establishes regional leadership through rapid automotive manufacturing and comprehensive industrial automation modernization, integrating advanced Hall Effect sensor systems as standard components in electric vehicles and industrial equipment operations. The country's 6.6% CAGR through 2035 reflects automotive production growth promoting vehicle electrification and manufacturing infrastructure development that mandate the use of reliable sensing systems in motor control operations. Growth concentrates in major automotive hubs, including Shanghai, Guangzhou, and Chongqing, where manufacturing networks showcase integrated sensor systems that appeal to vehicle manufacturers seeking enhanced control efficiency and international automotive standards.

Chinese manufacturers are developing innovative Hall sensor solutions that combine local production advantages with international automotive specifications, including integrated signal processing and advanced temperature compensation capabilities.

Strategic Market Indicators:

The Indian market emphasizes automotive manufacturing applications, including rapid industrial development and comprehensive vehicle production expansion that increasingly incorporates Hall sensors for motor control and position sensing applications. The country is projected to show a 6.1% CAGR through 2035, driven by massive automotive investment activity under manufacturing initiatives and industrial demand for standardized, high-quality sensing systems. Indian automotive facilities prioritize cost-effectiveness with Hall sensors delivering operational precision through economical semiconductor usage and reliable performance capabilities.

Technology deployment channels include major automotive manufacturers, industrial equipment companies, and electronics producers that support high-volume usage for domestic and export applications.

Performance Metrics:

The German market emphasizes advanced Hall sensor features, including innovative silicon technologies and integration with comprehensive automotive platforms that manage motor control, position sensing, and safety applications through unified sensing systems. The country is projected to show a 5.6% CAGR through 2035, driven by automotive innovation under Industry 4.0 trends and manufacturer demand for premium, reliable sensing systems. German automotive companies prioritize precision with Hall sensors delivering comprehensive motor control through enhanced signal processing and operational innovation.

Technology deployment channels include major automotive manufacturers, industrial equipment companies, and semiconductor designers that support custom development for premium operations.

Performance Metrics:

In São Paulo, Belo Horizonte, and Porto Alegre, Brazilian automotive facilities and manufacturing operators are implementing advanced Hall sensor systems to enhance production capabilities and support operational efficiency that aligns with automotive protocols and manufacturing standards. The Brazilian market demonstrates sustained growth with a 5.1% CAGR through 2035, driven by automotive investment programs and industrial development that emphasize reliable sensing systems for vehicle production and manufacturing applications. Brazilian automotive facilities are prioritizing Hall sensor systems that provide exceptional accuracy while maintaining compliance with international standards and minimizing complexity, particularly important in automotive production and industrial equipment operations.

Market expansion benefits from automotive programs that mandate enhanced sensing in vehicle specifications, creating sustained demand across Brazil's automotive and industrial sectors, where precision detection and signal consistency represent critical requirements.

Strategic Market Indicators:

The USA market emphasizes advanced Hall sensor deployment, growing at 4.7% CAGR, with documented operational excellence in automotive applications and industrial automation through integration with existing electronic control systems and precision sensing infrastructure. The country leverages engineering expertise in semiconductor manufacturing and sensor design to maintain market leadership. Automotive centers, including Detroit, San Jose, and Austin, showcase advanced installations where Hall sensor systems integrate with comprehensive vehicle platforms and control systems to optimize motor performance and operational efficiency.

American automotive manufacturers prioritize sensing precision and signal reliability in product selection, creating demand for premium Hall sensor systems with advanced features, including integrated signal processing and compatibility with automotive communication protocols. The Si-based hall effect sensors market benefits from established automotive infrastructure and willingness to invest in specialized semiconductor technologies that provide superior accuracy and regulatory compliance.

Market Intelligence Brief:

The UK market demonstrates sophisticated Hall sensor deployment, growing at 4.2% CAGR, with focus on aerospace applications, advanced automotive systems, and precision industrial equipment that require enhanced sensing capabilities and regulatory compliance. British manufacturers prioritize high-performance sensing solutions that integrate with specialized control systems and maintain operational excellence under demanding environmental conditions.

Technology deployment emphasizes custom sensor solutions for aerospace, defense, and premium automotive applications where precision and reliability justify premium semiconductor investments and specialized packaging requirements.

Japan's sophisticated automotive and industrial market demonstrates meticulous Hall sensor deployment, growing at 3.7% CAGR, with documented operational excellence in vehicle manufacturing and industrial automation through integration with existing quality control systems and precision manufacturing infrastructure. The country leverages engineering expertise in semiconductor fabrication and sensor design to maintain market leadership. Manufacturing centers, including Tokyo, Osaka, and Nagoya, showcase advanced installations where Hall sensor systems integrate with comprehensive production platforms and quality systems to optimize manufacturing precision and operational efficiency.

Japanese manufacturers prioritize sensing accuracy and manufacturing consistency in product selection, creating demand for premium Hall sensor systems with advanced features, including ultra-precise calibration and integration with automated manufacturing protocols. The Si-based hall effect sensors market benefits from established manufacturing infrastructure and willingness to invest in specialized semiconductor technologies that provide superior precision and quality compliance.

Market Intelligence Brief:

The Si-based Hall Effect sensors market in Europe is projected to grow from USD 456.8 million in 2025 to USD 697.2 million by 2035, registering a CAGR of 4.3% over the forecast period. Germany is expected to maintain its leadership position with a 38.4% market share in 2025, declining slightly to 37.9% by 2035, supported by its automotive manufacturing excellence and major production centers, including Baden-Württemberg and Bavaria.

France follows with a 22.6% share in 2025, projected to reach 23.1% by 2035, driven by comprehensive automotive programs and aerospace facility initiatives. The United Kingdom holds a 16.7% share in 2025, expected to maintain 17.2% by 2035 through established automotive sectors and industrial automation adoption. Italy commands a 13.8% share, while Spain accounts for 6.9% in 2025. The Rest of Europe region is anticipated to gain momentum, expanding its collective share from 1.6% to 2.4% by 2035, driven by increasing industrial development in Eastern European countries and the implementation of advanced sensing systems in emerging automotive manufacturing programs.

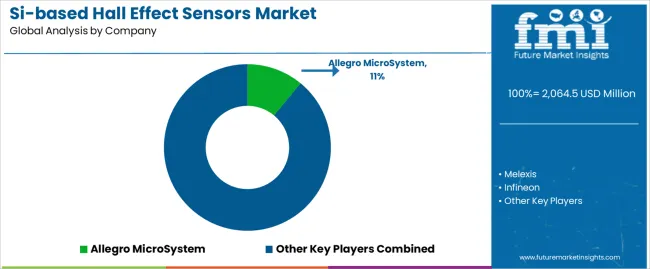

The si-based hall effect sensors market operates with moderate concentration, featuring approximately 15-22 participants, where leading companies control roughly 55-62% of the global market share through established semiconductor fabrication networks and comprehensive product development capabilities. Competition emphasizes sensing accuracy, silicon integration, and automotive qualification rather than premium feature rivalry.

Market leaders encompass Allegro MicroSystem, Melexis, and Infineon, which maintain competitive advantages through extensive semiconductor manufacturing expertise, global automotive partnerships, and comprehensive technical support capabilities that create customer loyalty and support application requirements. These companies leverage decades of silicon fabrication experience and ongoing process technology investments to develop advanced Hall sensor systems with exceptional accuracy and temperature stability features.

Specialty challengers include TDK, NXP, and ams OSRAM, which compete through specialized application innovation focus and efficient semiconductor solutions that appeal to automotive buyers seeking reliable performance formats and custom sensing flexibility. These companies differentiate through operational efficiency emphasis and specialized market focus.

Market dynamics favor participants that combine consistent sensing performance with advanced manufacturing support, including automated testing and automotive qualification capabilities. Competitive pressure intensifies as traditional semiconductor manufacturers expand into sensing systems. At the same time, specialized sensor designers challenge established players through innovative silicon architectures and cost-effective production targeting emerging automotive segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 2,064.5 million |

| Sensor Type | Hall Position Sensors, Hall Speed Sensors, Hall Switches, Hall Current Sensors, Hall Linear Sensors |

| Application | Automotive and Transportation, Consumer Electronics, Industrial and Energy, Healthcare and Medical, Aerospace and Defense, Telecommunications, Others |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, U.S., U.K., Japan, and 25+ additional countries |

| Key Companies Profiled | Allegro MicroSystem, Melexis, Infineon, TDK, NXP, ams OSRAM |

| Additional Attributes | Dollar sales by sensor type and application categories, regional adoption trends across Asia Pacific, Europe, and North America, competitive landscape with semiconductor manufacturers and sensor designers, automotive preferences for accuracy characteristics and temperature stability, integration with electronic control systems and automotive architectures, innovations in silicon fabrication technology and integrated sensing systems, and development of specialized magnetic sensing solutions with enhanced signal processing and contactless operation features |

The global si-based hall effect sensors market is estimated to be valued at USD 2,064.5 million in 2025.

The market size for the si-based hall effect sensors market is projected to reach USD 3,331.0 million by 2035.

The si-based hall effect sensors market is expected to grow at a 4.9% CAGR between 2025 and 2035.

The key product types in si-based hall effect sensors market are hall position sensors, hall speed sensors, hall switches, hall current sensors and hall linear sensors.

In terms of application, automotive and transportation segment to command 64.0% share in the si-based hall effect sensors market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Halloysite Market Size and Share Forecast Outlook 2025 to 2035

Hall-Effect Current Sensor Market Size and Share Forecast Outlook 2025 to 2035

Hall Effect Sensors Market Size and Share Forecast Outlook 2025 to 2035

Shallow Depth SURF Market Size and Share Forecast Outlook 2025 to 2035

Concert Halls And Theatres Market Size and Share Forecast Outlook 2025 to 2035

Oral Food Challenge Testing Market Analysis Size and Share Forecast Outlook 2025 to 2035

Sensors Market Analysis by Type, Technology, End User & Region - Forecast from 2025 to 2035

Biosensors Market Trends – Growth & Future Outlook 2025 to 2035

UV Sensors Market Analysis by Type, End User, and Region from 2025 to 2035

Nanosensors Market Size and Share Forecast Outlook 2025 to 2035

VOC Sensors and Monitors Market Analysis - Size, Growth, and Forecast 2025 to 2035

Rain Sensors Market Size and Share Forecast Outlook 2025 to 2035

Skin Sensors Market Size, Growth, and Forecast for 2025 to 2035

Weft Sensors Market - Size, Share, and Forecast Outlook 2025 to 2035

ADAS Sensors Market Growth - Trends & Forecast 2025 to 2035

PM2.5 Sensors for Home Appliances Market Size and Share Forecast Outlook 2025 to 2035

Image Sensors Market Growth – Trends & Forecast through 2034

Chest Sensors Market

PPG Biosensors Market – Size, Share & Growth Forecast 2025 to 2035

Motion Sensors Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA